5441336664

HALDOR TOPSDE [T

4/20

Latest developments in ammonia production technology

installed as shown in Figurę 2, the primary reformer has to reform methane only, and at the same time at sulphur free conditions, because the prereforming catalyst will pick up any sulphur components in the feed quantitatively. The sulphur free operation is one of the reasons for allowing a much higher heat flux in the reformer.

The prereformed feed can be reheated to 650 °C before entering the primary reformer. This will result in reduced firing in the primary reformer, and thereby a reduced fuel consumption. When the hot flue gas is used to reheat the reformer feed, the amount of heat available for HP steam production is reduced. This will overall result in a reduced HP steam production in the ammonia plant.

In generał, the reformer size can be reduced up to 25% in a natural gas based plant by incorporating a prereformer.

3.2 HTER-p

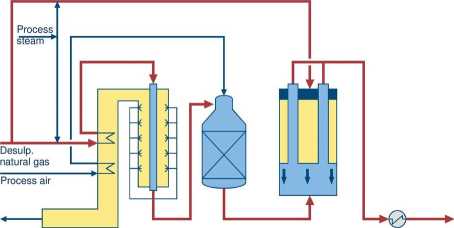

Tubular reformer Secondary reformer HTER-p

Figurę 3. HTER-p

Another feature that can be used to reduce the size of the primary reformer, and at the same time reduce the HP steam production, is the HTER-p (Haldor Topsoe Exchange Reformer). Please see Figurę 3. This is a new feature, initially developed for use in synthesis gas plants. In ammonia plants this unit is operated in parallel with the primary reformer, and that is why the name is HTER-p.

RESEARCH | TECHNOLOGY | CATALYSTS

Wyszukiwarka

Podobne podstrony:

HALDOR TOPSDE U 9/20 Latest developments in ammonia production technology 4.1.3 IFFCO, Kalol energy

HALDOR TOPSDE U 2/20 Latest developments in ammonia production technology 2 Latest developments in a

HALDOR TOPSDE U 3/20 Latest developments in ammonia production technology 3 New developments Two mai

HALDOR TOPSDE U 5/20 Latest developments in ammonia production technology The HTER-p is heated by th

HALDOR TORSOE U 1 / 20 Latest developments in ammonia production technology by Svend Erik Nielsen Ha

HALDOR TORSOE U 7/20 Latest developments in ammonia production technology Figurę 5. Layout of synthe

HALDOR TORSOE U 8/20 Latest developments in ammonia production technology The S-50 converter consist

HALDOR TOPSDE U 10/20 Latest developments in ammonia production technology The RCF, Trombay V revamp

HALDOR TOPSDE U 11/20 Latest developments in ammonia production technology Figurę 7. HTER internat b

HALDOR TOPSDE U 12/20 Latest developments in ammonia production technology During the test-run, it w

HALDOR TOPSDE [T 13/20 Latest developments in ammonia production technology Figurę 10. NH3 plant ref

HALDOR TOPSDE U 15/20 Latest developments in ammonia production technology Figurę 11. Layout of ammo

HALDOR TOPSDE U 16/20 Latest developments in ammonia production technology Figurę 12. Corwentional s

HALDOR TOPSDE [T 17/20 Latest developments in ammonia production technology 7.2 ATR Scheme - 5000

HALDOR TOPSDE U 18/20 Latest developments in ammonia production technology 7.3 Autothermal reformer

HALDOR TOPSOE CE 19/20 Latest developments in ammonia production technology importance. For further

HALDOR TOPSDE U Latest developments in ammonia production technology

00268 ?a148167663d78e6679e602ee961c3b 270 Montgomery experiments are often used in the design and/o

więcej podobnych podstron