5441336667

HALDOR TORSOE U

7/20

Latest developments in ammonia production technology

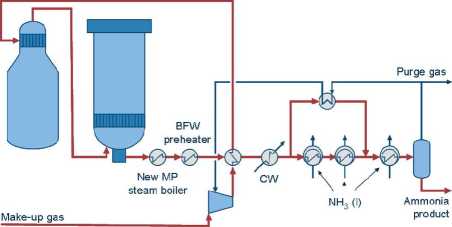

Figurę 5. Layout of synthesis loop in M.W. Kellogg-designed plant with S-50 converter

Phase II

- Installation of a S-50 radial flow corwerter with internal electric start-up heater and lower heat exchanger, and MP waste heat boiler in the loop in series with the existing converter

- Drying of make-up gas and synthesis loop re-piping

- Replacement of HP and LP rotors in synthesis gas compressor with kick-back cooler for synthesis gas compressor recycle stage

- Installation of a new boiler feed water coil in the waste heat section of the primary reformer

- Modification of ID fan turbinę

4.1.2 S-50 converter - Kalol plant

The original ammonia synthesis loop contains an existing ammonia converter unit with built-in feed/effluent exchanger. After the revamp, the exit gas from the existing converter is sent direct to the new S-50 converter at a temperaturę of approx. 325°C. After the S-50 converter a new MP steam boiler is installed. See Figurę 5.

As the inlet temperaturę to the S-50 converter is lower than the required inlet temperaturę to the catalyst bed, an S-50 converter with a lower heat exchanger is applied.

RESEARCH | TECHNOLOGY | CATALYSTS

Wyszukiwarka

Podobne podstrony:

HALDOR TORSOE U 1 / 20 Latest developments in ammonia production technology by Svend Erik Nielsen Ha

HALDOR TORSOE U 8/20 Latest developments in ammonia production technology The S-50 converter consist

HALDOR TOPSDE U 9/20 Latest developments in ammonia production technology 4.1.3 IFFCO, Kalol energy

HALDOR TOPSDE U 11/20 Latest developments in ammonia production technology Figurę 7. HTER internat b

HALDOR TOPSDE [T 13/20 Latest developments in ammonia production technology Figurę 10. NH3 plant ref

HALDOR TOPSDE U 15/20 Latest developments in ammonia production technology Figurę 11. Layout of ammo

HALDOR TOPSDE U 16/20 Latest developments in ammonia production technology Figurę 12. Corwentional s

HALDOR TOPSDE U 2/20 Latest developments in ammonia production technology 2 Latest developments in a

HALDOR TOPSDE U 3/20 Latest developments in ammonia production technology 3 New developments Two mai

HALDOR TOPSDE [T 4/20 Latest developments in ammonia production technology installed as shown in Fig

HALDOR TOPSDE U 5/20 Latest developments in ammonia production technology The HTER-p is heated by th

HALDOR TOPSDE U 10/20 Latest developments in ammonia production technology The RCF, Trombay V revamp

HALDOR TOPSDE U 12/20 Latest developments in ammonia production technology During the test-run, it w

HALDOR TOPSDE [T 17/20 Latest developments in ammonia production technology 7.2 ATR Scheme - 5000

HALDOR TOPSDE U 18/20 Latest developments in ammonia production technology 7.3 Autothermal reformer

HALDOR TOPSOE CE 19/20 Latest developments in ammonia production technology importance. For further

HALDOR TOPSDE U Latest developments in ammonia production technology

Theoretical and practical skills of a wide rangę of technologies in food production - technolog

więcej podobnych podstron