5441336663

HALDOR TOPSDE U

3/20

Latest developments in ammonia production technology

3 New developments

Two main areas have significant impact on the performance and cost of an ammonia plant - the reforming section and the ammonia synthesis section. The following items will be covered in this paper:

- High flux primary reformer with prereformer

- HTER-p (Haldor Topsoe Exchange Reformer)

- S-300 and S-50 converters

In particular the design and performance of the side-fired primary reformer has been significantly improved. This has been possible due to the availability of better tubę materials with higher strength. Better tubę materials permit a reduction in tubę wali thickness, thus reducing the level of thermal stress in the tubę wali, which again will give potentials for increased lifetime of the tubes. Very high heat flux can be accepted in a modern type reformer, and with a prereformer in front of the reformer the acceptable heat flux can be increased even further.

S-removal Prereformer High flux reformer

Hydrocarbon feed

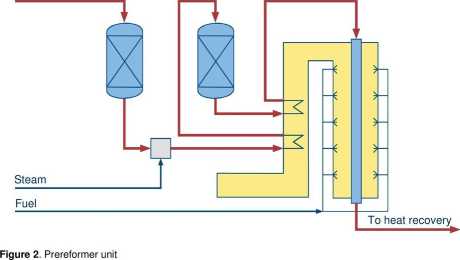

3.1 Prereforming

Adiabatic prereforming can be used for steam reforming of feedstocks ranging from natural gas to heavy naphtha. In the prereformer all higher hydrocarbons are converted into a mixture of carbon oxides, hydrogen and methane. When a prereformer is

RESEARCH | TECHNOLOGY | CATALYSTS

Wyszukiwarka

Podobne podstrony:

HALDOR TOPSDE U 9/20 Latest developments in ammonia production technology 4.1.3 IFFCO, Kalol energy

HALDOR TOPSDE U 2/20 Latest developments in ammonia production technology 2 Latest developments in a

HALDOR TOPSDE [T 4/20 Latest developments in ammonia production technology installed as shown in Fig

HALDOR TOPSDE U 5/20 Latest developments in ammonia production technology The HTER-p is heated by th

HALDOR TOPSDE U 10/20 Latest developments in ammonia production technology The RCF, Trombay V revamp

HALDOR TOPSDE U 11/20 Latest developments in ammonia production technology Figurę 7. HTER internat b

HALDOR TOPSDE U 12/20 Latest developments in ammonia production technology During the test-run, it w

HALDOR TOPSDE [T 13/20 Latest developments in ammonia production technology Figurę 10. NH3 plant ref

HALDOR TOPSDE U 15/20 Latest developments in ammonia production technology Figurę 11. Layout of ammo

HALDOR TOPSDE U 16/20 Latest developments in ammonia production technology Figurę 12. Corwentional s

HALDOR TOPSDE [T 17/20 Latest developments in ammonia production technology 7.2 ATR Scheme - 5000

HALDOR TOPSDE U 18/20 Latest developments in ammonia production technology 7.3 Autothermal reformer

HALDOR TOPSDE U Latest developments in ammonia production technology

HALDOR TORSOE U 1 / 20 Latest developments in ammonia production technology by Svend Erik Nielsen Ha

HALDOR TOPSOE CE 19/20 Latest developments in ammonia production technology importance. For further

HALDOR TORSOE U 7/20 Latest developments in ammonia production technology Figurę 5. Layout of synthe

HALDOR TORSOE U 8/20 Latest developments in ammonia production technology The S-50 converter consist

Theoretical and practical skills of a wide rangę of technologies in food production - technolog

f2 20 Microsoft Developer Studio [break] - QSEND 000 File Edit View insert Debug J

więcej podobnych podstron