5441336665

HALDOR TOPSDE U

5/20

Latest developments in ammonia production technology

The HTER-p is heated by the exit gas from the secondary reformer, and thereby the waste heat normally used for HP steam production can be used for the reforming process down to typically 750-850°C, depending upon actual requirements. Operating conditions in the HTER-p are adjusted independently of the primary reformer in order to get the optimum performance of the overall reforming unit. Typically up to around 20% of the natural gas feed can in this way by-pass the primary reformer.

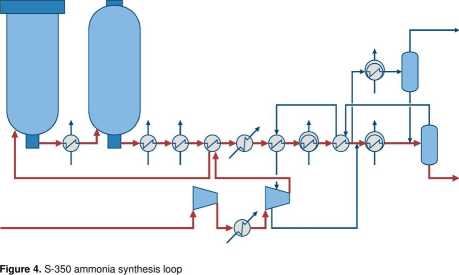

3.3 S- 350 ammonia synthesis loop

In the ammonia synthesis section, the 3-bed radial flow converter - the S-300 - has been developed and commercialised as an improved version of the work horse - the S-200. A highly efficient combination of the S-300 converter and the one-bed S-50 converter - the S-350 synthesis loop - has been developed, which is applicable for new plants as well as for revamp jobs.

Figurę 4 above describes a typical Topsoe ammonia synthesis loop.

RESEARCH | TECHNOLOGY | CATALYSTS

Wyszukiwarka

Podobne podstrony:

HALDOR TOPSDE U 9/20 Latest developments in ammonia production technology 4.1.3 IFFCO, Kalol energy

HALDOR TOPSDE U 2/20 Latest developments in ammonia production technology 2 Latest developments in a

HALDOR TOPSDE U 3/20 Latest developments in ammonia production technology 3 New developments Two mai

HALDOR TOPSDE [T 4/20 Latest developments in ammonia production technology installed as shown in Fig

HALDOR TORSOE U 8/20 Latest developments in ammonia production technology The S-50 converter consist

HALDOR TOPSDE U 10/20 Latest developments in ammonia production technology The RCF, Trombay V revamp

HALDOR TOPSDE U 11/20 Latest developments in ammonia production technology Figurę 7. HTER internat b

HALDOR TORSOE U 1 / 20 Latest developments in ammonia production technology by Svend Erik Nielsen Ha

HALDOR TORSOE U 7/20 Latest developments in ammonia production technology Figurę 5. Layout of synthe

HALDOR TOPSDE U 12/20 Latest developments in ammonia production technology During the test-run, it w

HALDOR TOPSDE [T 13/20 Latest developments in ammonia production technology Figurę 10. NH3 plant ref

HALDOR TOPSDE U 15/20 Latest developments in ammonia production technology Figurę 11. Layout of ammo

HALDOR TOPSDE U 16/20 Latest developments in ammonia production technology Figurę 12. Corwentional s

HALDOR TOPSDE [T 17/20 Latest developments in ammonia production technology 7.2 ATR Scheme - 5000

HALDOR TOPSDE U 18/20 Latest developments in ammonia production technology 7.3 Autothermal reformer

HALDOR TOPSOE CE 19/20 Latest developments in ammonia production technology importance. For further

HALDOR TOPSDE U Latest developments in ammonia production technology

2013 SYSTEMS SUPPORTING PRODUCTION ENGEINEERING field, what is revealed by a change in their posturę

Theoretical and practical skills of a wide rangę of technologies in food production - technolog

więcej podobnych podstron