Research Paper

Energy intensity and energy ratio in producing

willow chips as feedstock for an integrated

biorefinery

Mariusz J. Stolarski

, Michał Krzy

_zaniak

, Jo´zef Tworkowski

Stefan Szczukowski

, Janusz Gołaszewski

University of Warmia and Mazury in Olsztyn, Faculty of Environmental Management and Agriculture, Department

of Plant Breeding and Seed Production, Plac Ło´dzki 3/420, 10-724 Olsztyn, Poland

a r t i c l e i n f o

Article history:

Received 20 November 2013

Received in revised form

5 March 2014

Accepted 28 April 2014

Published online

Keywords:

Willow

Energy inputs

Diesel consumption

Energy intensity

Energy ratio

This study examined the production of willow at a commercial plantation with an area of

10.5 ha, situated in north-eastern Poland. Its aim was to evaluate the energy intensity and

energy ratio of the production of chips of new willow cultivars as feedstock for an inte-

grated biorefinery. This study emphasises the key importance of the selection of a willow

cultivar for the production of willow chips and the transport distance to a biorefinery for

the energy intensity of the production process and the energy ratio of the supplied

biomass. The lowest energy intensity for willow chip production was achieved for the

plantation of the highest-yielding cultivar (UWM 006). When the yield exceeded 86 t ha

1

of

fresh biomass, the energy intensity was 0.35 GJ t

1

of fresh matter (f.m.). The energy ratio

for the product at the farm gate varied depending on the cultivar and ranged from 23.9 to

10.2, for UWM 006 and UWM 155 cultivars, respectively. The distance of biomass transport

to a biorefinery significantly affected the energy ratio. When chips were transported for

25 km, the energy intensity for the production of 1 t of chips increased by 3

e7% compared

to its value at the farm gate. The energy intensity for the longest of the analysed transport

distances increased by 23

e53%. The energy ratio for each cultivar decreased significantly

by 3

e35% with increasing transport distance. The values of energy intensity and energy

ratio for UWM 006 and UWM 043 were better than those achieved in other studies.

ª 2014 IAgrE. Published by Elsevier Ltd. All rights reserved.

1.

Introduction

Bio-based industry and renewable energy are one of the new

research and development directions supported in Europe by

the European Commission and by other countries around the

world (

Bridge 2020, 2014; European Commission, 2012

). Until

recently, biomass was perceived as feedstock mainly for heat

and power production, while its use for other purposes was

regarded as a niche activity. A huge part of the energy and

* Corresponding author. Tel.:

þ48 895234838; fax: þ48 895234880.

E-mail addresses:

(M.J. Stolarski),

(M. Krzy

_zaniak),

(J. Tworkowski),

(S. Szczukowski),

(J. Gołaszewski).

1

Tel./fax:

þ48 895234880.

Available online at

ScienceDirect

journal homepa ge: www .e lsev ie r.com/locate/issn/153 75110

b i o s y s t e m s e n g i n e e r i n g 1 2 3 ( 2 0 1 4 ) 1 9 e2 8

http://dx.doi.org/10.1016/j.biosystemseng.2014.04.011

1537-5110/

ª 2014 IAgrE. Published by Elsevier Ltd. All rights reserved.

chemical industry base their production on fossil feedstock

(non-renewable). The continuous increase in consumption of

fossil feedstocks has led to their depletion and to price in-

creases. Moreover, their mining and consumption is accom-

panied by the emission of greenhouse gases and, in

consequence, an escalation of the greenhouse effect (

). As a result, the status of biomass may

change from the “fuel of the poor” to a component of many

biorefinery industry products.

Willow biomass is used in the production of heat, power

and biofuels (

Carroll & Finnan, 2013, 2012; Stolarski,

Krzyzaniak, et al., 2013; Stolarski, Szczukowski, Tworkowski,

& Klasa, 2013; Wang, Dunn, & Wang, 2012

). However, ulti-

mately, willow biomass can be one of the potential lignocel-

lulose feedstocks for integrated multi-product biorefineries.

The EuroBioRef project will develop a new highly-integrated

and diversified concept, including multiple feedstocks

(including

lignocellulosic

biomass),

multiple

processes

(chemical, biochemical, thermochemical) and multiple prod-

ucts (aviation fuels and chemicals). A flexible approach will

widen bio-refinery implementation to the full geographical

range of Europe and will offer opportunities to export bio-

refinery technology packages to more local markets and

feedstock hotspots. The ambitious objectives of the Euro-

BioRef project seek a decrease in energy consumption by 30%

for a final product and at least 10% lower raw material con-

sumption (

). Willow, as a lignocellulose

biomass, is proposed as the feedstock in two value chains: VC

3

e alcohols to fuels and VC 5 e syngas-based products.

Perennial energy crops, including willow, should be char-

acterised by high productivity and the biomass produced from

them should have high calorific value. This would produce

considerable amounts of energy and would result in a high

energy ratio of biomass production. Only if this is achieved

will further stages of biomass conversion to secondary energy

carriers and bioproducts be justified as an environmentally-

friendly and sustainable solution. Short-rotation willow

output achieved in experiments conducted in Poland has

reached 30 t dry matter (d.m.) ha

1

year

1

. The average yield

has usually ranged from 10 to 12 t d.m. ha

1

year

1

Szczukowski, Tworkowski, Wroblewska, & Krzyzaniak, 2011;

Tworkowski, Szczukowski, & Stolarski, 2006

). On the other

hand, the willow yield on large (70

e300 ha) commercial

plantations was usually much lower than that in experiments

and typically amounted to 4

e10 t d.m. ha

1

year

1

. Such a low

yield was achieved on commercial plantations because of

difficulties with the right choice and preparation of the field,

errors in setting up plantations, ineffective weed control,

wrong fertilisation and using clones with low efficiency

(

s, Szczukowski, & Stolarski, 2010

). Therefore,

it is very important from a practical point of view that the yield

obtained in experiments should be verified in professional

commercial production. Further development of this type of

production requires an analysis of the relationship between

the effectiveness of different cultivars and clones of willow on

commercial plantations and environmental and agrotechnical

procedures. An evaluation of the energy intensity (the ratio of

the total energy use per t of fresh matter yield) and energy

ratio (the energy value of yield divided by the total energy

input) in willow chip production for industrial or energy

feedstock is also necessary.

Similar studies on energy yield and energy ratio of biomass

production can be found in scientific literature. For instance,

Boehmel, Lewandowski, and Claupein (2008)

compare energy

yield and primary net energy yield (the difference between the

primary energy yield and the energy consumption) of peren-

nial (SRC willow, miscanthus) and annual (maize, rape) plants.

Vande Walle, Van Camp, Van de Casteele, Verheyen, and

Lemeur (2007)

studied the utilisation potential of birch,

maple, poplar and willow as feedstock for the production of

renewable power in Flanders (Belgium). On the other hand,

modelled the energy and carbon budgets of

wood fuel coppice systems, to study the energy and carbon

budgets of biofuel production systems. The above-mentioned

studies, as well as those recently conducted in Italy with

poplar cultivated in a 6-year harvest cycle (

), prove the high energy ratio of

both the cultivation and acquisition of perennial plants.

The advantage of the present study was the possibility of

using varieties offering the lowest willow chip production

energy intensity. This further reduced this indicator for the

final product in the biorefinery. Therefore, the aim of this

study was to evaluate the energy intensity and energy ratio of

the production of chips of seven new willow cultivars har-

vested in a three-year rotation as feedstock for an integrated

biorefinery, depending on the transport distance.

2.

Materials

This study was conducted on a commercial willow plantation

with an area of 10.5 ha, set up in mid-April 2010 at the Didactic

and Research Station in Łe˛

_zany, owned by the University of

Warmia and Mazury in Olsztyn. It is located in the north-east

of Poland, on land of the village of Samławki (53

59

0

N, 21

05

0

E). The area on which the plantation was situated is undu-

lating and very diverse in elevation. Low quality soil (mainly

on soil created from slightly loamy sand and light loamy sand)

that was of limited use for typical annual crops was selected

for the plantation. Generally, the land in the elevated areas

had a groundwater level far below 1.50 m so the soil was

permanently dry. By selecting a relatively poor soil site it was

possible to evaluate the willow yield potential in areas of little

use for food or feed crops. Three cultivars and four clones of

willow were planted on the plantation; for this study they

were regarded as cultivars and all had been bred at the

Department of Plant Breeding and Seed Production of the

University of Warmia and Mazury in Olsztyn. Start, Tur,

Turbo, UWM 006, UWM 043 were of the species Salix viminalis,

UWM 035 was of the species Salix pentandra and UWM 155 was

of the species Salix dasyclados.

Willows were planted at a density of 18

10

3

ha

1

. Willow

cuttings were planted in strips, with two rows in a strip spaced

every 0.75 m, with 1.5 m of space separating the next 2 rows in

a strip with 0.75 m space between them, etc., with plants in a

row spaced every 0.5 m.

Triticale was sown as the previous crop. The following

procedures were carried out in order to prepare the site:

spraying with glyphosate to eliminate weeds (Roundup

b i o s y s t e m s e n g i n e e r i n g 1 2 3 ( 2 0 1 4 ) 1 9 e2 8

20

4 l ha

1

), disking (

2), winter ploughing, fertilisation with PRP

Sol (300 kg ha

1

), harrowing (

2), mechanical planting of

willow cuttings with a step planter, spraying with a soil her-

bicide (Guardian CompleteMix 664 SE 3.5 l ha

1

), mechanical

weeding (

2), spraying with a herbicide against mono-

cotyledon weeds (Targa Super 2.5 l ha

1

).

According to our 20-year experience, which involved willow

cultivation as an energy crop, and to the principles of the Euro-

bioref project, no top dressing was applied in the first year of the

willow vegetation. However, before the beginning of the second

year of vegetation, i.e. in spring 2011, mineral fertilisation was

performed at: N 90 kg ha

1

; P

2

O

5

30 kg ha

1

, K

2

O 60 kg ha

1

.

Phosphorus was applied as triple superphosphate and potas-

sium as potassium salt. Nitrogen was applied in two doses as

ammonium nitrate. The first dose of 50 kg ha

1

was applied

immediately before the start of the plant growth, and the

remaining dose (40 kg ha

1

) was applied at the end of May 2011.

In the second year of vegetation, the plantation was sprayed with

a herbicide against monocotyledons (Targa Super 2.5 l ha

1

).

After the third year of growth, in December 2012, three-

year-old willows were harvested with a Claas Jaguar 830

harvester. Chips were collected from the harvester with three

units, each one consisting of New Holland TM 130 tractors and

T 169/2 transport trailers. Subsequently, the trailers with

chips produced from different cultivars were weighed and the

fresh biomass yield in t ha

1

was determined. Further ana-

lyses took into account the transport of chips to a biorefinery

over one of four distances; 25, 50, 100 and 200 km. Professional

containers with a capacity of 80 m

3

of chips each were used for

biomass transport, which totalled about 25 t of fresh chips per

run.

3.

Methods

The energy intensity and energy ratio of the production of

chips from the willow cultivars under study was analysed

based on the fresh biomass yield obtained in the first three-

year harvest cycle. The total input was divided into three

stages. The first one involved setting up a plantation and its

liquidation and the second one involved its operation. The

third stage was transport to a biorefinery. The input for

setting up and running a plantation in the first year of

growth and for its future liquidation is presented here in

whole and was allocated across each of the 21 years of its

operations.

The analysis of materials and energy, incurred for setting

up the plantation and the production of willow chips,

covered separate streams of energy: direct energy carriers

(diesel fuel); utilisation of fixed assets (tractors, machines,

equipment); consumption of materials (mineral fertilisers,

agrochemicals, willow cuttings) and human labour. The total

energy input for the willow cultivation, production and

transport of chips to a biorefinery was calculated based on

the indexes shown in

. The types of equipment used

in field operations and the maximum power of the tractors

and those used in different procedures are shown in

The total power of the Claas Jaguar harvester was 236.0 kW

and the power used was 212.4 kW. The field transport of

willow chips used a tractor with a maximum power of

95.6 kW and the power used was 47.8 kW. The technical and

operational parameters adopted for analyses were based on

the data contained in the paper by

in the catalogue of agricultural machines (

) and in materials published by manufacturers of trac-

tors and machines.

The yield energy value was calculated as the product of

fresh biomass yield and its lower heating value.

Y

ev

¼ Y

b

$Q

r

i

(1)

where Y

ev

is the biomass yield energy value (GJ ha

1

), Y

b

is the

biomass yield (t f.m. ha

1

), and Q

r

i

is the biomass lower heating

value (GJ t

1

).

Accumulated energy gain at the farm gate is the difference

between the yield energy value and the total input for its

production at the farm gate:

E

g

¼ Y

ev

I

fg

(2)

where E

g

is the accumulated energy gain at the farm gate

(GJ ha

1

), Y

ev

is the biomass yield energy value (GJ ha

1

), and I

fg

e total energy input at the farm gate (GJ ha

1

).

Energy intensity is the energy consumption per tonne of

fresh chips, which is the ratio of total energy input to the yield:

EI

¼ E

i

=Y

b

(3)

where EI is the energy intensity (GJ t

1

f.m.), E

i

is the energy

input (GJ ha

1

) and Y

b

e biomass yield (t f.m. ha

1

).

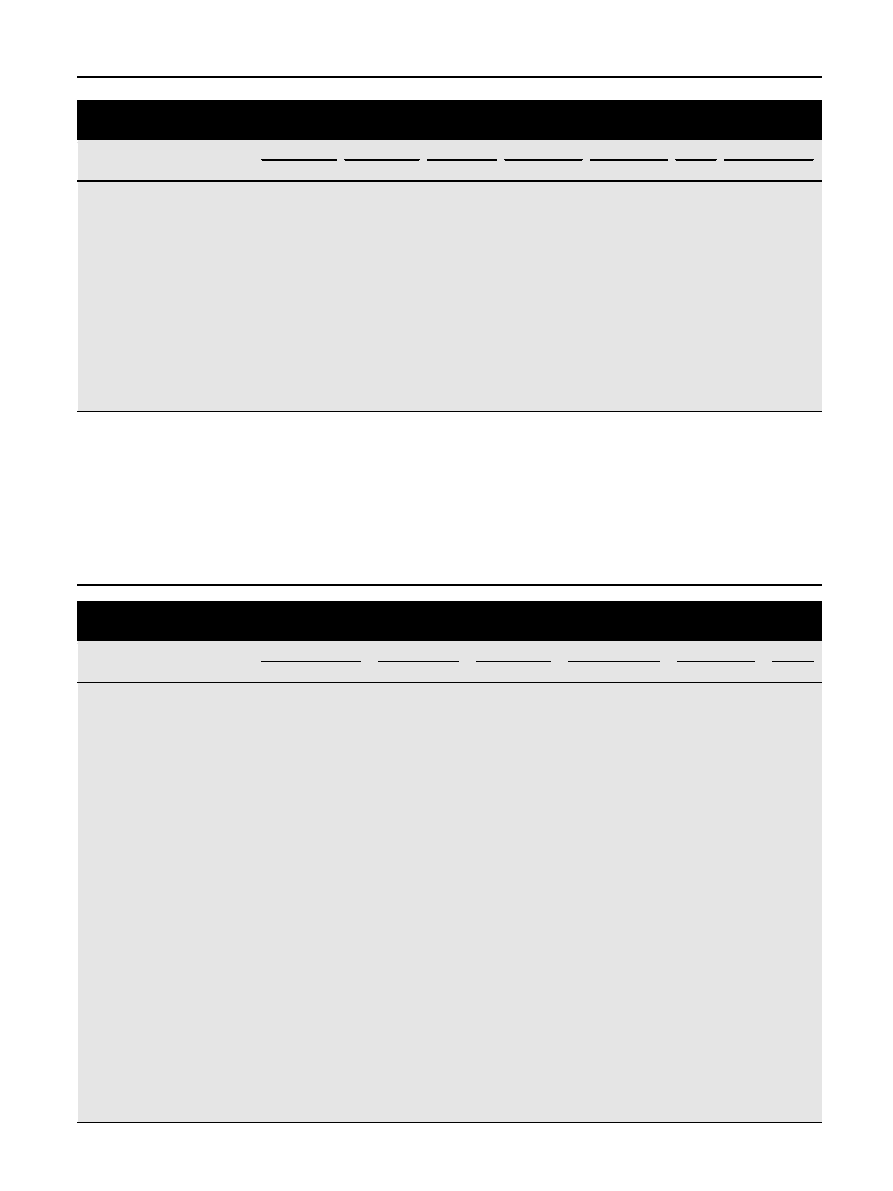

Table 1

e Energy conversion coefficients used to calculate the energy intensity of willow production.

Item

Unit

Energy conversion

coefficient (MJ)

Source

Fuel oil

1 kg

43.1

Nitrogen fertilisers

1 kg N

48.99

Phosphorus fertilisers

1 kg P

2

O

3

15.23

Potassium fertilisers

1 kg K

2

O

9.68

Other fertilisers, e.g. PRP sol

1 kg of fertiliser

15.23

Pesticides

1 kg of active substance

268.4

Cuttings

1 kg or 1 cutting

3.04 or 0.057

This research

Tractors, vehicles, self-propelled machines

1 kg

125

Szeptycki and Wo´jcicki (2003)

Agricultural machines and equipment

1 kg

110

Szeptycki and Wo´jcicki (2003)

Human labour

1 h

60

Szeptycki and Wo´jcicki (2003)

Transport of biomass

1 t d.m. km

1

0.94

b i o s y s t e m s e n g i n e e r i n g 1 2 3 ( 2 0 1 4 ) 1 9 e2 8

21

Diesel fuel consumption per tonne of fresh or dry willow

chips is the ratio of the diesel fuel consumption and the wil-

low yield:

D

¼ F

c

=Y

b

(4)

where D is the diesel fuel consumption (kg t

1

f.m. or d.m.), F

c

is the fuel consumption (kg ha

1

) and Y

b

is the biomass yield

(t f.m. or d.m ha

1

).

The energy ratio of willow chips production is the ratio of

the yield energy value (energy output) and the accumulated

material and energy input for its production:

ER

¼ E

o

=E

i

(5)

where ER is the energy ratio, E

o

is the energy output, and E

i

e

energy input.

4.

Results and discussion

4.1.

Accumulated material and energy inputs

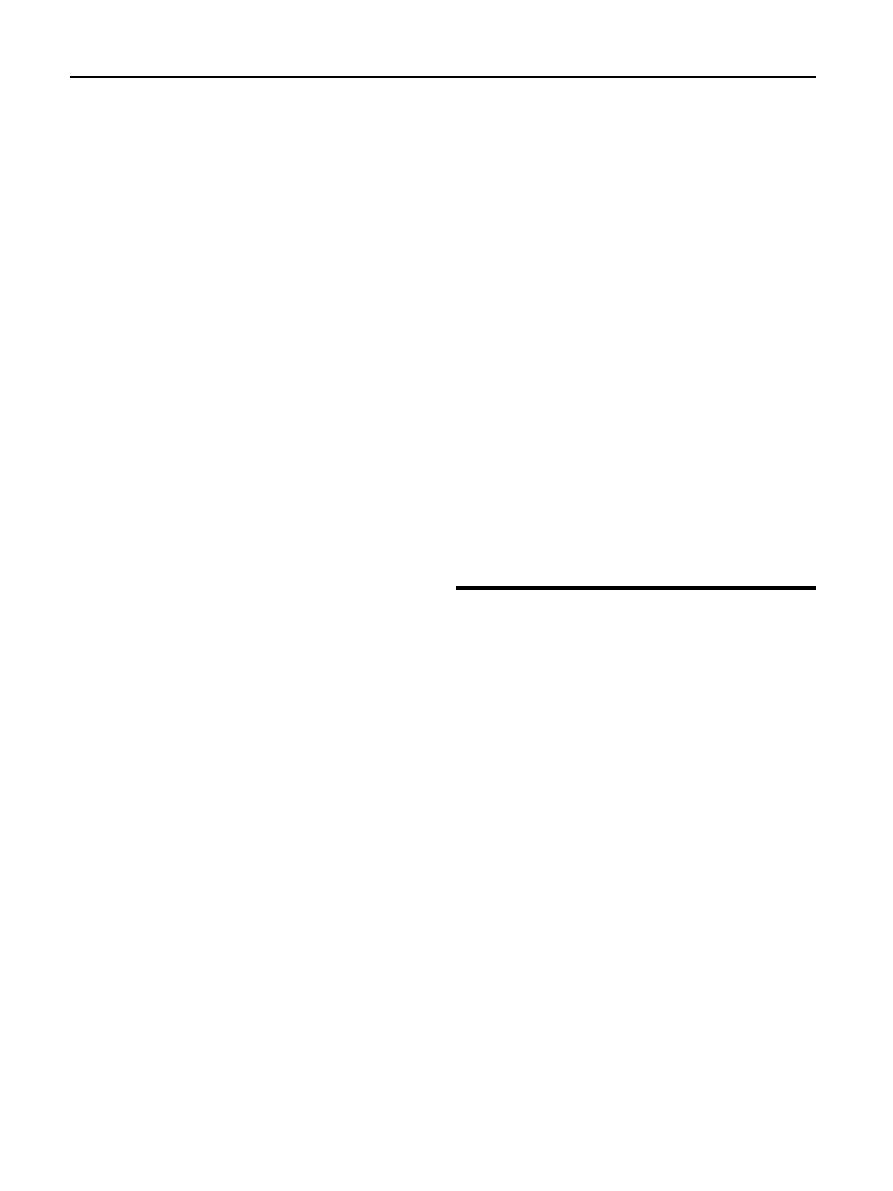

The accumulated material and energy inputs for setting up

and running 1 ha of a plantation of willow coppice during the

first year of growth and its liquidation after its exploitation

was completed, amounted to 20.37 GJ ha

1

(

). Con-

verted to one year of plantation exploitation (assuming that

the plantation will be used for 21 years), it amounts to

0.97 GJ ha

1

. The input structure was dominated by the

plantation liquidation (36.3%). This was followed by fertilisa-

tion and planting of willow cuttings. On the other hand, the

energy stream was dominated by direct energy carriers, i.e.

diesel fuel (45.9%), followed by materials (32.6%). The energy

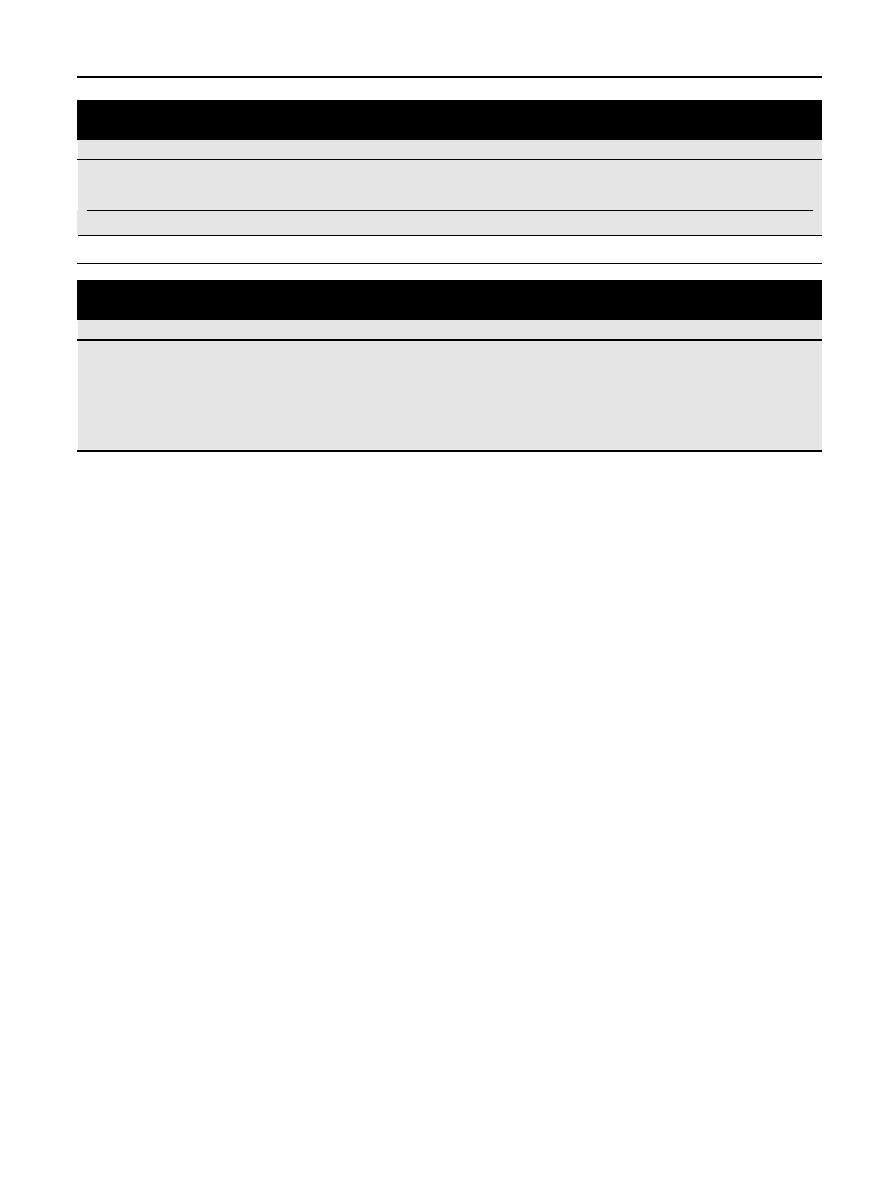

Table 2

e Data for field operations.

Operation

Tractor/Harvester

Machinery

Operating period

Comments

Name

Mass

(kg)

Power (kW)

(max/used)

Utilisation

of the

power

capacity

(%)

Name

Mass

(kg)

(h ha

1

)

Spraying

New Holland

TM 130 HP

5465

95.6/47.8

50

Krukowiak sprayer,

working width 18 m

2110

0.2

Glyphosate, Roundup

360 SL, 4 l ha

1

Disking

New Holland

TM 130 HP

5465

95.6/60.2

63

Kverneland disk

harrow, working

width 4 m

1160

1.4

2

coverage

Winter

ploughing

New Holland

TM 175 HP

7150

128.6/90.0

70

Kverneland PG 100

plough, working

width 2 m

1120

1.5

5-ridge plough,

ploughing depth 30 cm

Fertilisation

New Holland

TM 130 HP

5465

95.6/47.8

50

Rauch 3,0 t spreader,

working width 18 m

350

0.4

PRP Sol fertiliser, dose

300 kg ha

1

Harrowing

New Holland

TM 130 HP

5465

95.6/52.6

55

Harrow, working

width 6 m

530

1.0

2

coverage

Mechanical

planting of

cuttings

New Holland

TM 130 HP

5465

95.6/62.1

65

4-row step planter

2800

1.3

18,000 cuttings per ha

Spraying

New Holland

TM 130 HP

5465

95.6/47.8

50

Krukowiak sprayer,

working width 18 m

2110

0.2

Soil-applied herbicide,

Guardian CompleteMix

664 SE, 3.5 l ha

1

Weeding

New Holland

TM 90 HP

4410

66.0/33.0

50

Mechanical weeder P

430/2, working width

3 m

340

2.0

2

coverage

Spraying

New Holland

TM 130 HP

5465

95.6/47.8

50

Krukowiak sprayer,

working width 18 m

2110

0.2

Herbicide against

monocotyledon weeds,

Targa Super 05 EC,

2.5 l ha

1

Fertilisation

New Holland

TM 130 HP

5465

95.6/47.8

50

Rauch 3,0 t spreader,

working width 18 m

350

1.3

Mineral fertilisation in

spring 2011, N

e 90; P

2

O

5

e 30; K

2

O

e 60 kg ha

-

Liquidation of

plantation

New Holland

TM 175 HP

7150

128.6/90.0

70

Rototiller FV 4088,

working width 40 cm

1160

6.0

Breaking up larger

rootstocks along rows

Harvesting

Claas Jaguar

830

10,150 236.0/212.4

90

e

e

1

e4*

*Depending on the yield

of a given cultivar,

average productivity of

harvester 20 ton of chips

per hour

Field transport New Holland

TM 130 HP

5465

95.6/47.8

50

T 169/2 tractor

trailer, loading

capacity: 4 tons of

chips

1940

1

e4*

*To ensure continuity of

receipt of chips 3

transportation units

were used

b i o s y s t e m s e n g i n e e r i n g 1 2 3 ( 2 0 1 4 ) 1 9 e2 8

22

inputs related to the use of machines, human labour and

tractors accounted for smaller parts of the energy stream.

The accumulated material and energy input for production

of willow chips in a three-year harvest cycle, including setting

up and liquidating the plantation, NPK fertilisation and the

application of herbicide against monocotyledons, were the

same for each cultivar (

). The largest amounts of en-

ergy were consumed for mineral fertilisation (6.21 GJ ha

1

).

The range of values for energy input across cultivars resulted

from the plant harvest with a Claas Jaguar 830 harvester and

the field transport of the chips. The differences between the

cultivars were associated with their differing yields and the

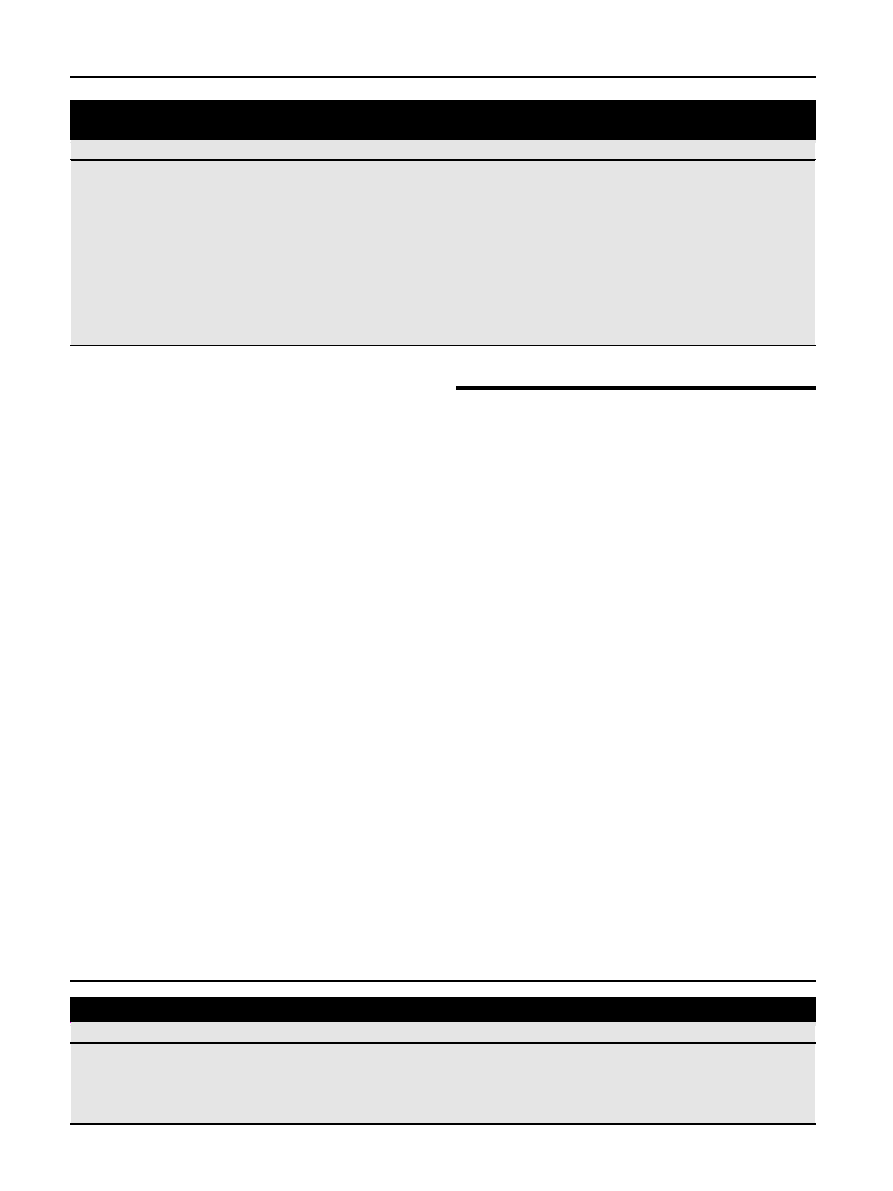

Table 3

e Time and accumulated material and energy input for setting up and running a willow plantation (per ha) in the

first year of vegetation and for its liquidation.

Operation

Labour

Machinery

Tractors

Diesel fuel

Materials

Total

Input structure

Hour

MJ

Hour

MJ

Hour

MJ

kg

MJ

kg

MJ

MJ

%

Spraying (glyphosate)

0.3

18.0

0.2

46.4

0.2

11.4

2.04

87.8

4.00

386.50 550.07

2.7

Disking (2

)

1.6

96.0

1.4

111.7

1.4

79.7

17.96

774.1

e

e

1061.4

5.2

Winter ploughing

1.7

102.0

1.5

154.0

1.5

111.7

29.30 1262.9

e

e

1630.6

8.0

Fertilisation

0.5

30.0

0.4

9.1

0.4

22.8

4.07

175.5

300.0

4569.0

4806.4

23.6

Harrowing (2

)

1.2

72.0

1.0

34.3

1.0

56.9

11.20

482.7

e

e

645.9

3.2

Mechanical planting of cuttings

5.2

312.0

1.3

235.5

1.3

74.0

17.21

741.6

337.5

1026.0

2389.1

11.7

Spraying (soil-applied herbicide)

0.3

18.0

0.2

46.4

0.2

11.4

2.04

87.8

3.5

617.3

780.9

3.8

Weeding (2

)

2.2

132.0

2.0

74.8

2.0

91.9

14.06

605.9

e

e

904.6

4.4

Spraying with herbicide

against monocotyledon weeds

0.3

18.0

0.2

46.4

0.2

11.4

2.04

87.8

2.50

33.55 197.12

1.0

Liquidation of plantation

6.2

372.0

6.0

1531.2

6.0

446.9

117.21 5051.6

e

e

7401.7

36.3

Total

19.5

1170.0

14.2

2289.8

14.2

918.0

217.1

9357.6

647.50 6632.37 20,367.8

100.0

Per year of plantation

cultivation 1/21

S

0.93

55.71

0.68

109.04

0.68

43.72

10.34

445.60

30.83

315.83 969.9

e

Input structure (%)

e

5.74

e

11.24

e

4.51

e

45.94

e

32.56 100.00

e

Table 4

e Time and accumulated material and energy input for production of willow chips (per ha) in a three-year harvest

rotation depending on the cultivar, at the farm gate.

Cultivar

Operation

Human labour

Machinery

Tractors

Diesel

Materials

Total

Hour

MJ

Hour

MJ

Hour

MJ

kg

MJ

kg

MJ

MJ

For each

cultivar

Setting up and

liquidation of

plantation

2.8

167.1

2.0

327.1

2.0

131.1

31.0

1336.8

92.5

947.5

2909.7

NPK fertilisation

1.5

90.0

1.3

29.4

1.3

74.0

13.24

570.5

425.5

5446.8

6210.7

Spraying with

herbicide against

monocotyledon

weeds

0.3

18.0

0.2

46.4

0.2

11.4

2.04

87.8

2.5

33.6

197.1

Start

Harvesting

2.1

123.7

2.1

1743.3

e

e

105.1

4528.2

e

e

6395.1

Field transport

6.2

371.0

6.2

219.9

6.2

352.0

63.0

2713.2

e

e

3656.1

Total

12.8

769.8

11.8

2366.1

9.7

568.5

214.3

9236.4

520.5

6427.8

19,368.7

Tur

Harvesting

1.0

62.8

1.0

884.7

e

e

53.3

2298.1

3245.6

Field transport

3.1

188.3

3.1

111.6

3.1

178.6

31.9

1377.0

1855.5

Total

8.8

526.2

7.7

1399.3

6.7

395.2

131.6

5670.2

520.5

6427.8

14,418.7

Turbo

Harvesting

2.1

128.0

2.1

1803.7

e

e

108.7

4685.2

6616.9

Field transport

6.4

383.9

6.4

227.5

6.4

364.2

65.1

2807.3

3782.9

Total

13.1

786.9

12.1

2434.3

9.9

580.7

220.1

9487.6

520.5

6427.8

19,717.4

UWM 006

Harvesting

4.3

259.1

4.3

3652.7

e

e

220.1

9488.0

13,399.9

Field transport

13.0

777.3

13.0

460.8

13.0

737.5

131.9

5685.1

7660.7

Total

21.9

1311.6

20.8

4516.5

16.5

954.1

398.3

17,168.2

520.5

6427.8

30,378.1

UWM 035

Harvesting

1.5

89.9

1.5

1267.1

e

e

76.4

3291.2

4648.1

Field transport

4.5

269.6

4.5

159.8

4.5

255.8

45.8

1972.0

2657.4

Total

10.6

634.7

9.5

1829.9

8.0

472.4

168.4

7258.3

520.5

6427.8

16,623.0

UWM 043

Harvesting

3.5

210.6

3.5

2969.3

e

e

179.0

7712.8

10,892.7

Field transport

10.5

631.9

10.5

374.6

10.5

599.5

107.2

4621.4

6227.4

Total

18.6

1117.7

17.6

3746.8

14.1

816.1

332.5

14,329.2

520.5

6427.8

26,437.6

UWM 155

Harvesting

0.9

53.6

0.9

755.8

e

e

45.5

1963.1

2772.4

Field transport

2.7

160.8

2.7

95.3

2.7

152.6

27.3

1176.3

1585.0

Total

8.2

489.6

7.1

1254.1

6.2

369.1

119.1

5134.4

520.5

6427.8

13,675.0

b i o s y s t e m s e n g i n e e r i n g 1 2 3 ( 2 0 1 4 ) 1 9 e2 8

23

consequent time of work of the harvester and the ancillary

equipment. Therefore, the total energy input in the three-year

cycle of the willow harvest ranged from 13.68 GJ ha

1

to

30.38 GJ ha

1

, for the UWM 155 and UWM 006 cultivars,

respectively. This can be compared to the energy input in the

extensive cultivation of willow as an energy crop without

fertilisation, weed control or irrigation, which was estimated

as 14.14 GJ ha

1

by

. Energy inputs in

the production of poplar biomass were 14.2 GJ ha

1

year

1

for

Manzone, Airoldi, and Balsari (2009)

, while those in the pro-

duction of miscanthus biomass, depending on the level of

nitrogen fertilisation, ranged from 17.82 to 27.39 GJ ha

1

year

1

for

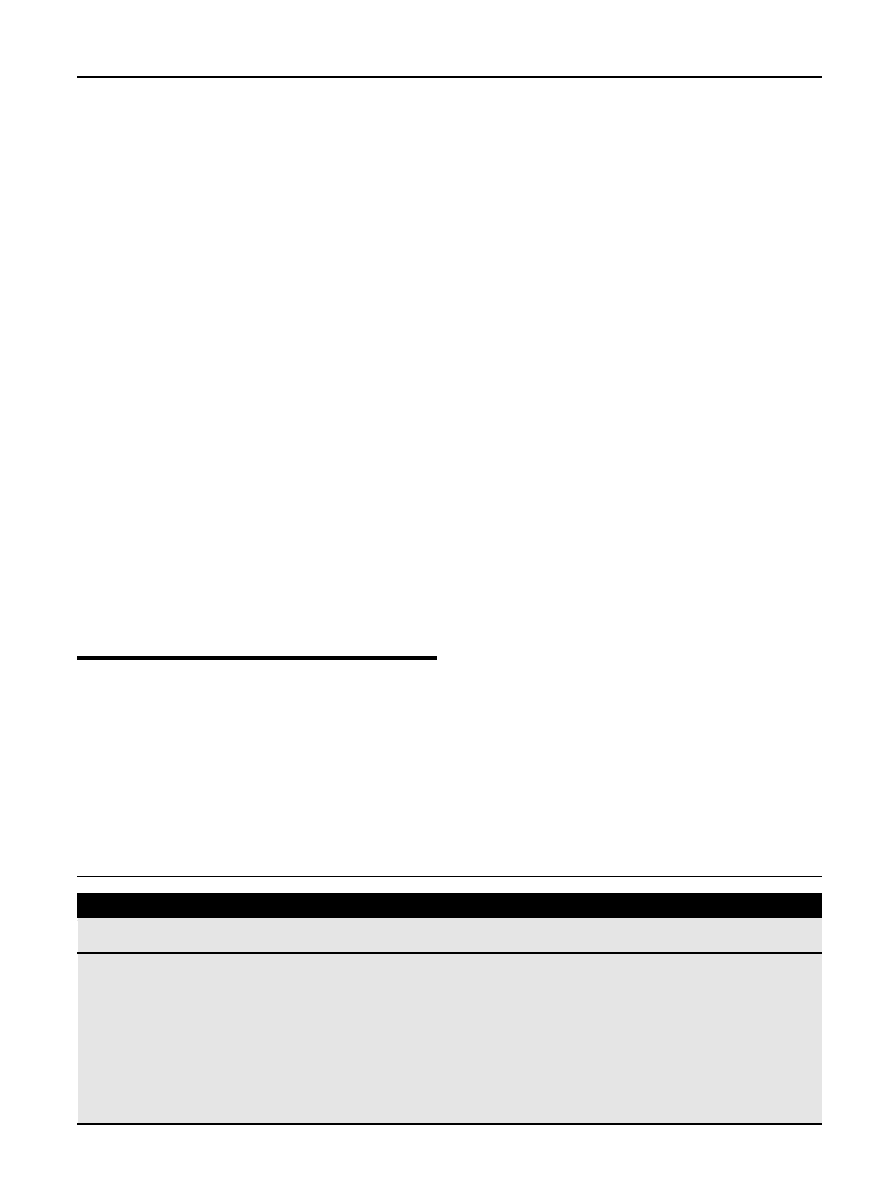

The structure of the energy stream for production opera-

tions in the highest-yielding cultivars (UWM 006 and UWM

043) was dominated (over 60%) by the total input attributable

to harvesting and field transport (

). On the other hand,

the largest part of the energy input for the lowest-yielding

cultivars (UWM 155 and Tur) was mineral fertilisation (over

40%). Similar relationships were observed in the energy

stream structure for these cultivars, which was dominated by

the inputs into fertilisers (42

e45%).

This part decreased in the highest-yielding cultivars and

was replaced by inputs of energy resulting from the con-

sumption of diesel fuel and the use of machines. A higher

yield required more intensive use of equipment and con-

sumption of fuel. For example for UWM 006 cultivar, the en-

ergy input of diesel fuel consumption accounted for 56.5% of

the total input and that of machines accounted for 14.9% of

the total input. The corresponding values for the UWM 043

cultivar were 54.2% and 14.2%. Also, the input of fertiliser use

was large and accounted for 20

e30% of the total input. In a

different study conducted by the present authors, the energy

stream in the production of willow chips was dominated by

the input of mineral fertilisation and fuels (

).

Moreover,

Heller, Keoleian, and Volk (2003)

reported that the

structure of energy carriers in production of willow biomass

was dominated by fuels (46%), followed by fertilisation (37%).

Therefore, replacement of mineral fertilisation by wastewater

sludge from local wastewater treatment stations and

introducing liquid renewable fuels, such as biodiesel, to the

process of willow biomass production could reduce the energy

input, resulting in an increase in the energy ratio of the pro-

duction of fuel from the plant species by as much as 40%

(

Heller et al., 2003; Keoleian & Volk, 2005

The total diesel fuel consumption (398.3 kg ha

1

) in the

process of willow chip production was the highest in the UWM

006 cultivar, whose yield amounted to 86 t f.m. ha

1

).

The fuel consumption for the UWM 043 cultivar was lower by

nearly 66 kg ha

1

, with a yield of 70 t f.m. ha

1

. On the other

hand, the lowest consumption of diesel of 119 kg ha

1

was

recorded for the lowest-yielding cultivar, UWM 155.

4.2.

Energy ratio

The yield energy value at the farm gate in a three-year willow

harvest cycle ranged widely, from 138.8 GJ ha

1

in UWM 155 to

727.4 GJ ha

1

in UWM 006 (

) and the energy gain at the

farm gate ranged from 125.2 to 697 GJ ha

1

, respectively. When

calculated per year of plantation use, it amounted to 41.7 and

232.3 GJ ha

1

year

1

, respectively. A high energy gain was also

achieved for the UWM 043 cultivar (186.3 GJ ha

1

year

1

). Ac-

cording to

, the mean net energy from willow

plantations in Sweden is approximately 170 GJ ha

1

year

1

.

This can be increased to over 200 GJ ha

1

year

1

by using

wastewater for irrigation of a plantation of willow (

). In another study, the energy value of the

yield obtained in two-year harvest cycle for Salix viminalis

ranged from 73 to 290 GJ ha

1

year

1

with the sludge dose of

0 and 300 kg N ha

1

, respectively (

reported that the energy

value of willow biomass in a three-year harvest rotation

amounted to 226 GJ ha

1

year

1

. On the other hand, the energy

value of poplar yield was 188 GJ ha

1

year

1

(

) and that of the miscanthus biomass, depending on the

level

of

nitrogen

fertilisation,

ranged

from

approx.

210

e231 GJ ha

1

year

1

The energy input and the yield significantly differentiate

the energy intensity of production per tonne of willow

biomass from different cultivars. It has been shown in this

Table 5

e Structure of accumulated material and energy input for production of willow chips in a three-year harvest

rotation, depending on cultivar, at the farm gate (%).

Item

Start

Tur

Turbo

UWM 006

UWM 035

UWM 043

UWM 155

By production operations

Setting up and liquidation of plantation

15.0

20.2

14.8

9.6

17.5

11.0

21.3

NPK fertilisation

32.1

43.1

31.5

20.4

37.4

23.5

45.4

Weed control

1.0

1.4

1.0

0.6

1.2

0.7

1.4

Harvest

33.0

22.5

33.6

44.1

28.0

41.2

20.3

Field transport

18.9

12.9

19.2

25.2

16.0

23.6

11.6

By energy stream

Human labour

4.0

3.6

4.0

4.3

3.8

4.2

3.6

Machinery

12.2

9.7

12.3

14.9

11.0

14.2

9.2

Tractors

2.9

2.7

2.9

3.1

2.8

3.1

2.7

Diesel fuel

47.7

39.3

48.1

56.5

43.7

54.2

37.5

Materials, including:

33.2

44.6

32.6

21.2

38.7

24.3

47.0

Seedlings

0.8

1.0

0.7

0.5

0.9

0.6

1.1

Pesticides

0.9

1.3

0.9

0.6

1.1

0.7

1.3

Fertilisers

31.5

42.3

30.9

20.1

36.7

23.1

44.6

Total

100.0

100.0

100.0

100.0

100.0

100.0

100.0

b i o s y s t e m s e n g i n e e r i n g 1 2 3 ( 2 0 1 4 ) 1 9 e2 8

24

study that the lowest consumption of diesel fuel for the pro-

duction of 1 tonne of fresh chips at the farm gate was recorded

in the production of the UWM 006 cultivar (4.6 kg t

1

f.m.),

which amounted to 9.3 kg t

1

d.m. Consumption of diesel fuel

per tonne of dry matter of the UWM 043 cultivar was higher by

3%. The value was higher by 14% and 53% for the Start and

UWM 155 cultivars, respectively. The consumption of diesel

fuel per tonne of willow chips in this study was higher than

has been found in other studies. Very low fuel consumption

(3.0 l t

1

of willow chips) was achieved by

. In a study conducted by

and by

Gonza´lez-Garcı´a, Mola-Yudego, Dimitriou, Aronsson, and

Murphy (2012)

consumption of fuel for willow chip production

amounted to 3.6 and 4.1 l t

1

, respectively. On the other hand,

the consumption of fuel in the production of chips from

poplar trees ranged from 6.4 to 7.5 l t

1

The energy intensity per tonne of fresh willow chips at the

farm gate was the lowest for the UWM 006 cultivar and it

amounted to 0.35 GJ t

1

f.m (

). This value was only

around 0.03 GJ t

1

f.m. higher for the production of the UWM

043 cultivar. On the other hand, it was twice as great for the

low-yielding cultivars: UWM 155 and Tur. In different studies,

the energy intensity of willow chip production in a three-year

harvest cycle ranged from 0.30 to 0.61 GJ t

1

f.m. (

). Much lower energy intensity was

achieved in harvesting 5-year-old poplar trees (

Schweier, & De Francesco, 2012

).

The energy ratio in the process of production of willow

chips at the farm gate varied depending on the cultivar (

). It was the highest in UWM 006 (at 23.9), followed by UWM

043, Start, Turbo, UWM 035, Tur and was lowest for UWM 155

(10.2). The energy ratios of willow production found in other

studies have covered a wide range, from about 12 to over 50

(

Heller et al., 2003; Matthews, 2001; Stolarski, 2009

). Varied

levels of energy ratio in the production of willow biomass

result from differences in the preparation of the production

site and the use of mineral fertilisers and pesticides. Other

important factors include cultivars, planting density, the

harvest cycle and its technology, as well as the biomass yield.

Willow biomass yield may be diverse in successive harvest

rotations.

report that subsequent harvest

rotations of willow biomass will give a higher yield by as

much as 30

e40% compared to the first harvest. However, our

multi-year studies have shown that this depends on multiple

factors and, in agricultural practice, an increase in yield is

indeed achieved in the second and third rotation of willow

harvest. However, the yield may decrease in subsequent

(4

e7) harvest rotations due to accumulation of diseases, pests

and plant loss; therefore, such a large increase is not always

achieved in subsequent harvest rotations. In consequence, it

was assumed in this study that mean biomass yield in sub-

sequent harvest rotations would be similar to the first har-

vest rotation, which is achievable in agricultural practice.

Obviously, any higher yield would result in better energy

intensity and energy ratio values. This study focused mainly

on an assessment of the effect of the choice of a cultivar on

these indexes and it showed that the effect of cultivar can be

very important, because the energy ratio at the farm gate in

the production of willow chips of the UWM 006 cultivar was

2.3 times higher than in the UWM 155 cultivar. Much higher

levels of energy ratio were achieved when harvesting 5-year-

old poplar trees (

). On the other hand, in

the studies by

, the energy ratio in

poplar production was 13, while in the production of mis-

canthus biomass this ratio was ranged from 7.72 to 11.79, at

200 and 0 kg ha

1

N of nitrogen fertilisation, respectively

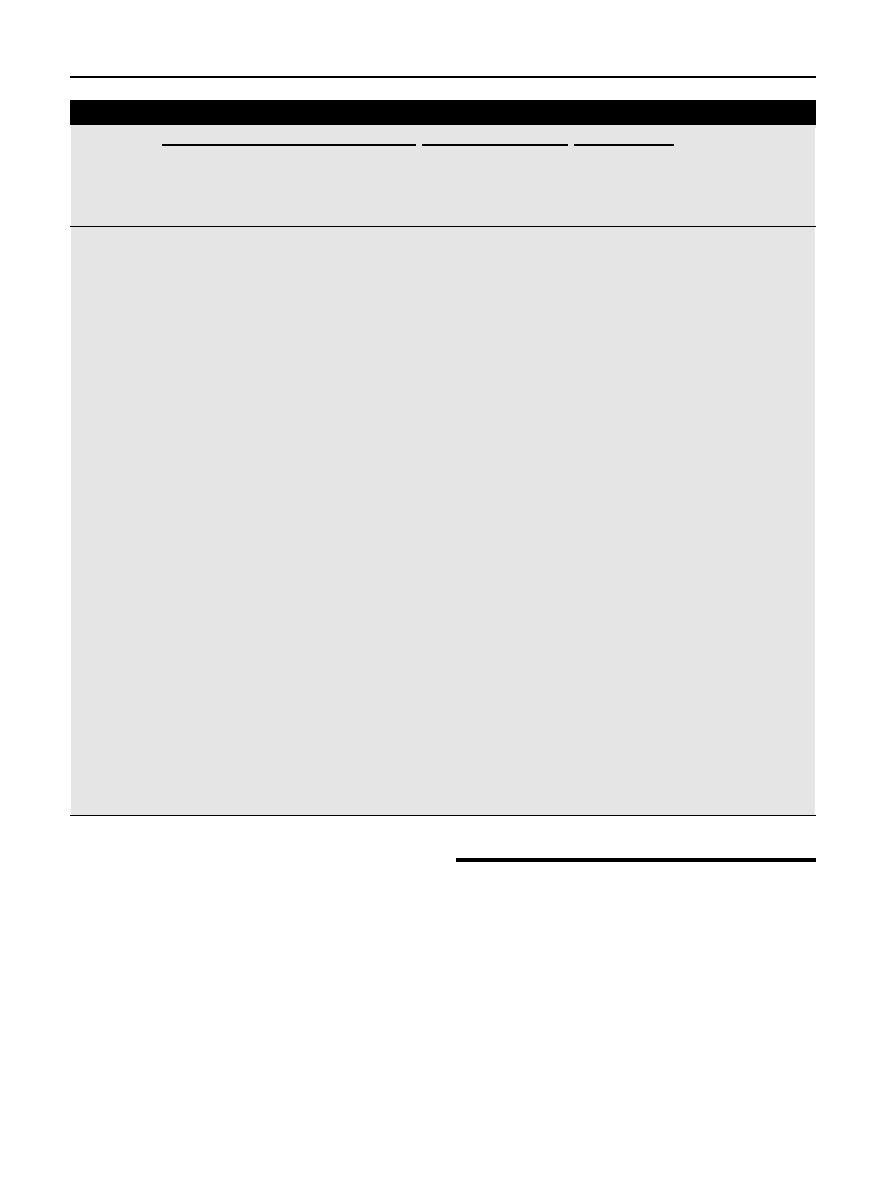

Selected production effectiveness ratios for willow chips

at the biorefinery gate are shown in

. Obviously, they

strongly depended on the distance that had to be covered in

biomass transport between the plantation and the bio-

refinery. The parameters were worse with increasing

transport distance. The total accumulated material and

energy input at the biorefinery gate ranged from 14.1 GJ ha

1

for UWM 155 cultivar at a distance of 25 km to 46.4 GJ ha

1

when chips of the UWM 006 are transported a distance of

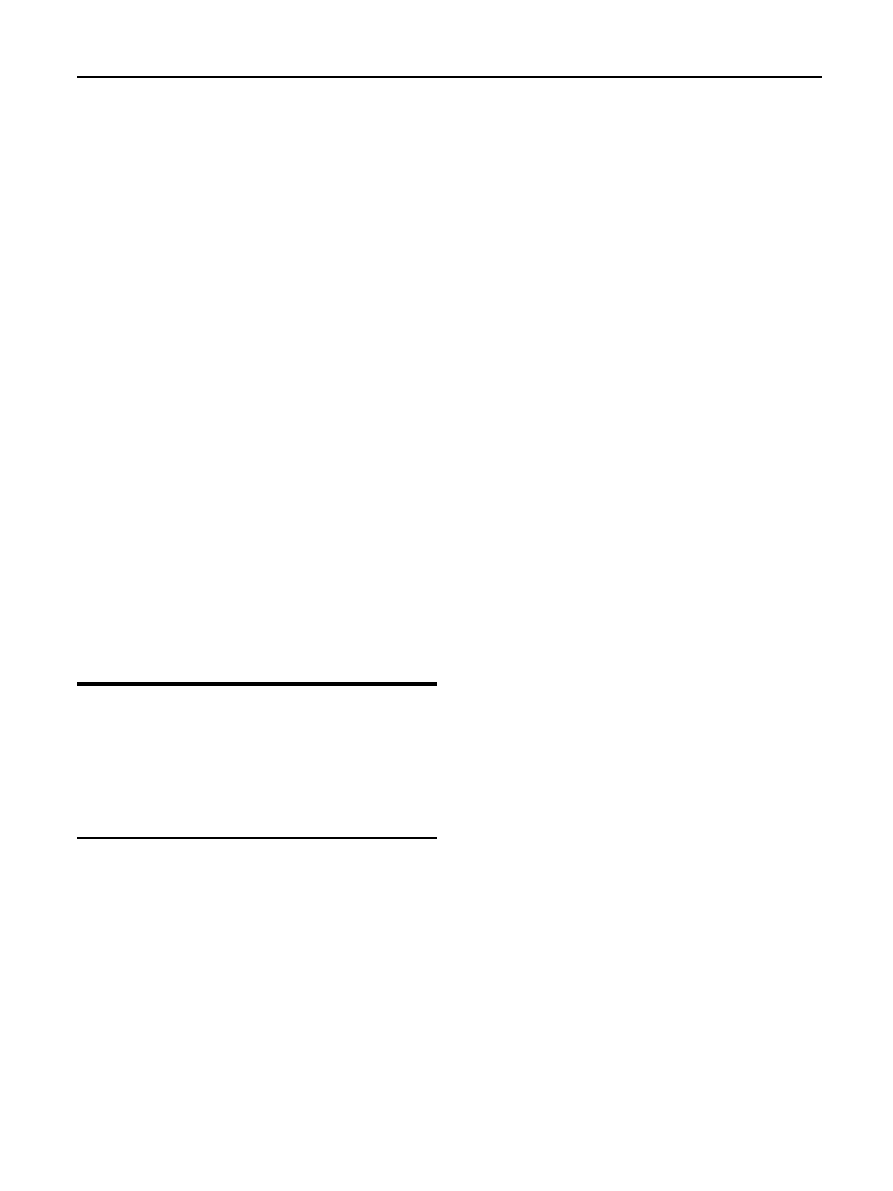

Table 6

e The yield of fresh and dry matter and consumption of diesel fuel for the production of willow chips in a three-year

harvest rotation at the farm gate.

Item

Start

Tur

Turbo

UWM 006

UWM 035

UWM 043

UWM 155

Diesel fuel consumption (kg ha

1

)

214.3

131.6

220.1

398.3

168.4

332.5

119.1

Yield (t f.m. ha

1

)

41.2

4.4

c

20.9

1.6

e

42.7

4.9

c

86.4

4.9

a

30.0

4.2

d

70.2

8.7

b

17.9

0.8

e

Yield (t d.m. ha

1

)

20.3

2.5

c

11.0

0.9

e

20.3

2.5

c

42.7

2.5

a

15.1

2.2

d

34.5

4.3

b

8.4

0.4

e

Standard deviation;

a, b, c

.

Homogenous groups.

Table 7

e Selected efficiency indexes in the production of willow chips of different cultivars in a three-year harvest rotation,

at the farm gate.

Item

Start

Tur

Turbo

UWM 006

UWM 035

UWM 043

UWM 155

Energy inputs (GJ ha

1

)

19.4

14.4

19.7

30.4

16.6

26.4

13.7

Energy value of yield (GJ ha

1

)

344.6

191.6

341.5

727.4

259.7

585.4

138.8

Energy gain (GJ ha

1

)

325.2

177.2

321.8

697.0

243.0

559.0

125.2

Diesel fuel consumption (kg t

1

f.m.)

5.2

6.3

5.2

4.6

5.6

4.7

6.7

Diesel fuel consumption (kg t

1

d.m.)

10.6

11.9

10.8

9.3

11.1

9.6

14.2

Energy intensity (GJ t

1

f.m.)

0.47

0.69

0.46

0.35

0.56

0.38

0.77

Energy ratio

17.8

13.3

17.3

23.9

15.6

22.1

10.2

b i o s y s t e m s e n g i n e e r i n g 1 2 3 ( 2 0 1 4 ) 1 9 e2 8

25

200 km. Therefore, in the last case, the biomass transport

consumed about 16 GJ ha

1

.

An increase in the transport distance resulted in an increase

in the energy intensity per tonne of chips (

). When chips

were transported for 25 km, the energy intensity increased by

3

e7% compared to its value at the farm gate. A further increase

in the distance to 50 km meant an increase in the index by

7

e13%. When biomass was transported a distance of 100 km,

the increase ranged from 14 to 26%. The energy intensity in the

option with a transport distance of 200 km increased by 23

e53%

compared to its level at the farm gate.

Furthermore, the energy ratio for each cultivar decreased

significantly for each cultivar with increasing transport dis-

tance. When chips were transported the shortest distance, the

ratio decreased by 3

e6%. On the other hand, it decreased by

19

e35% with the longest transport distance (

also found the transport dis-

tance to be one of the most important factors affecting the

energy ratio. They showed that when chips were transported

up to 38 km, the energy ratio decreased by less than 8.3%.

When chips were transported for over 38 km, the ratio

decreased significantly (25.9%). A decrease in energy ratio with

increasing transport distance was also found by

. Another important factor pointed out in other research

is the effect of the willow yield on the energy contained in the

yield and energy ratio (

). With a yield of

10 t ha

1

, the energy ratio was 19.3, whereas with a yield of

14 t ha

1

it was 23.5. In our research we also found that the

choice of a cultivar for chip production is significant for the

amount of energy produced and the final energy effectiveness

of its production. The energy ratio for the highest-yielding

UWM 006 cultivar was 2.2 times higher on average than the

lowest-yielding UWM 155 cultivar.

5.

Conclusions

These findings clearly show that the choice of willow cultivar

is vitally important from the point of view of its energy in-

tensity and energy ratio in biomass production when pro-

ducing chips as feedstock for an integrated biorefinery. The

energy input at the stage of setting up a plantation and its

potential liquidation was the same for every cultivar. On the

other hand the yield of the cultivars in the three-year harvest

cycle significantly modified the total energy input for pro-

duction of willow chips (13.7

e30.4 GJ ha

1

). This was associ-

ated with the energy use of the harvester and the field

transport of the chips. The energy stream in the lowest-

yielding cultivars was dominated by the cost of fertilisers

(42

e45%) and in the highest-yielding ones it was dominated by

diesel fuel consumption (54

e56%). It was found that the

cultivation of high-yielding willow cultivars can lead to much

lower energy intensity in willow chip production (diesel fuel

consumption, energy intensity) and a higher energy ratio

compared to low-yielding cultivars.

As was expected, the distance of biomass transport to a

biorefinery significantly changed the energy effectiveness for

the production of willow chips. When chips were transported

for 25 km, the energy intensity increased slightly (by 3

e7%)

compared to its value at the farm gate. The energy intensity

for a transport distance of 200 km increased considerably (by

23

e53%) compared to its level at the farm gate. Furthermore,

the energy ratio for each cultivar decreased significantly for

each cultivar with increasing transport distance. When chips

were transported for the shortest distance, the ratio decreased

slightly (by 3

e6%). On the other hand, it decreased by as much

as 19

e35% with the longest transport distance.

Table 8

e Selected efficiency indexes in the production of willow chips of different cultivars in a three-year harvest rotation,

at the biorefinery gate.

Item

Transport distance (km)

Start

Tur

Turbo

UWM 006

UWM 035

UWM 043

UWM 155

Energy inputs (GJ ha

1

)

25

20.3

14.9

20.7

32.4

17.3

28.1

14.1

50

21.3

15.5

21.6

34.4

18.0

29.7

14.5

100

23.2

16.5

23.5

38.4

19.5

32.9

15.2

200

27.0

18.6

27.4

46.4

22.3

39.4

16.8

Energy intensity (GJ t

1

f.m.)

25

0.49

0.71

0.49

0.38

0.58

0.40

0.79

50

0.52

0.74

0.51

0.40

0.60

0.42

0.81

100

0.56

0.79

0.55

0.45

0.65

0.47

0.85

200

0.66

0.89

0.64

0.54

0.75

0.56

0.94

Energy ratio

25

17.0

12.8

16.5

22.5

15.0

20.9

9.9

50

16.2

12.4

15.8

21.2

14.4

19.7

9.6

100

14.9

11.6

14.5

18.9

13.3

17.8

9.1

200

12.8

10.3

12.5

15.7

11.6

14.9

8.3

Table 9

e Changes in the energy ratio (%) depending on the transport distance (0 km [ 100%).

Transport distance (km)

Start

Tur

Turbo

UWM 006

UWM 035

UWM 043

UWM 155

0

100.0

100.0

100.0

100.0

100.0

100.0

100.0

25

95.3

96.5

95.4

93.8

95.9

94.2

97.2

50

91.0

93.3

91.2

88.3

92.1

89.1

94.6

100

83.5

87.4

83.8

79.1

85.4

80.3

89.7

200

71.7

77.7

72.1

65.4

74.5

67.1

81.3

b i o s y s t e m s e n g i n e e r i n g 1 2 3 ( 2 0 1 4 ) 1 9 e2 8

26

One of the project objectives was to achieve a 30% reduc-

tion of energy input in the particular processes. In the present

study, it was demonstrated that the willow cultivar chosen

affects to a very large degree the efficiency indicator values in

the production of lignocellulose biomass for an integrated

biorefinery. Therefore, the application of an appropriate wil-

low cultivar could allow a greater energy ratio of final product

production to be achieved. The results obtained will be helpful

in the assessment of the chip transport distance to a

biorefinery.

These data emphasise the key importance of the selection

of a willow cultivar for the production of willow chips and the

transport distance to a biorefinery for the energy intensity of

the production process and the energy ratio of the biomass

supplied. From a practical point of view, this study suggests

that UWM 006 and UWM 043 cultivars can be the most useful

source of lignocellulosic feedstock for integrated biorefineries.

Moreover, when choosing a location for a biorefinery, one

should take into account the fact that transporting chips to a

biorefinery for a distance of up to 50 km can generate a loss of

up to 10%, whereas when chips have to be transported for

200 km, the decrease in the energy ratio can reach 30%

compared to its level at the farm gate.

It should be emphasised that the obtained results should

be cross-referenced to similar climatic and soil conditions. For

willow plantations situated on better quality soils and fertil-

ised with wastewater sludge or digestate from a biogas plant,

the biomass yields could be higher and lead to potentially

better biomass production efficiency indicators. On the other

hand, willow biomass production on sandy soils with water

deficiencies could result in a reduction in yield and value of

biomass production efficiency indicators.

Acknowledgements

This research received funding from the European Union

Seventh Framework Programme (FP7/2007

e2013) under grant

agreement n

241718 EuroBioRef.

r e f e r e n c e s

glu, M., & Aksoy, A. S. (2005). The cultivation and energy

balance of Miscanthus x giganteus production in Turkey.

Biomass and Bioenergy, 29, 42

e48

Ahlgren, S., Baky, A., Bernesson, S., Nordberg, A

Hansson, P. A. (2008). Future fuel supply systems for organic

production based on Fischer

ether from on-farm-grown biomass. Biosystems Engineering,

99(1), 145

Boehmel, C., Lewandowski, I., & Claupein, W. (2008). Comparing

e236

.

Bo¨rjesson, P. I. I. (1996). Energy analysis of biomass production

and transportation. Biomass and Bioenergy, 11(4), 305

Bo¨rjesson, P., & Berndes, G. (2006). The prospects for willow

plantations for wastewater treatment in Sweden. Biomass and

Bioenergy, 30(5), 428

Bridge 2020, B. (2014). Biobased industries consortium. Retrieved 23/

02/2014, from

http://bridge2020.eu/about/about-bbi

.

Carroll, J. P., & Finnan, J. (2012). Physical and chemical properties

of pellets from energy crops and cereal straws. Biosystems

Engineering, 112(2), 151

e159

Carroll, J., & Finnan, J. (2013). Emissions and efficiencies from the

.

EuroBioRef. (2013). Retrieved 22.10.2013, from

org/index.php/about-eurobioref

European Commission. (2012). Joint technology initiative in the field

of bio-based industries.

e Roadmap. Retrieved 23/02/2014, from

http://ec.europa.eu/smart-regulation/impact/planned_ia/

docs/2013_rtd_007_biobased_industries_en.pdf

.

Goglio, P., & Owende, P. M. O. (2009). A screening LCA of short

e394

Gonza´lez-Garcı´a, S., Mola-Yudego, B., Dimitriou, I., Aronsson, P.,

Heller, M. C., Keoleian, G. A., & Volk, T. A. (2003). Life cycle

assessment of a willow bioenergy cropping system. Biomass

and Bioenergy, 25(2), 147

IBMER (2007). Catalog of agricultural machines. IBMER, Warsaw

(cd-rom).

IEA. (2012). Key world energy statistics 2012. Paris: International

IPCC. (2013). Climate change: The physical science basis. New York:

Keoleian, G. A., & Volk, T. A. (2005). Renewable energy from

sniewski, D. (2010). Energy efficiency of biomass production

from a 3-year-old willow (in Polish). In

Labrecque, M., Teodorescu, T. I., & Daigle, S. (1997). Biomass

e417

.

Manzone, M., Airoldi, G., & Balsari, P. (2009). Energetic and

e1264

Manzone, M., Bergante, S., & Facciotto, G. (2014). Energy and

e170

.

Matthews, R. W. (2001). Modelling of energy and carbon budgets of

wood fuel coppice systems. Biomass and Bioenergy, 21(1), 1

.

Neeft, J., Gagnepain, B., Bacovsky, D., Lauranson, R.,

Georgakopoulos, K., & Fehrenback, H. (2011). Harmonized

calculations of biofuel greenhouse gas emissions in Europe.

Retrieved 25.10.2013, from

.

Spinelli, R., Schweier, J., & De Francesco, F. (2012). Harvesting

techniques for non-industrial biomass plantations. Biosystems

Engineering, 113(4), 319

e324

Stolarski, M. (2009). Agrotechnical and economic aspects of biomass

.

Stolarski, M. J., Krzyzaniak, M., Waliszewska, B., Szczukowski, S.,

.

Stolarski, M. J., Szczukowski, S., Tworkowski, J., & Klasa, A. (2013).

Yield, energy parameters and chemical composition of short-

b i o s y s t e m s e n g i n e e r i n g 1 2 3 ( 2 0 1 4 ) 1 9 e2 8

27

rotation willow biomass. Industrial Crops and Products, 46(0),

60

e65

.

Stolarski, M. J., Szczukowski, S., Tworkowski, J., Wro´blewska, H.,

_zaniak, M. (2011). Short rotation willow coppice

biomass as an industrial and energy feedstock. Industrial Crops

and Products, 33(1), 217

e223

.

Stolarski, M., Szczukowski, S., Tworkowski, J., & Klasa, A. (2008).

Szeptycki, A., & Wo´jcicki, Z. (2003). Technological development and

energy inputs in agriculture till 2020 (in Polish). Warsaw: IBMER

.

Tworkowski, J., Kus, J., Szczukowski, S., & Stolarski, M. (2010).

technologie pozyskiwania i energetycznego wykorzystania biomasy

(pp. 34

e49). Warsaw: Instytut Energetyki

Tworkowski, J., Szczukowski, S., & Stolarski, M. (2006).

.

Vande Walle, I., Van Camp, N., Van de Casteele, L., Verheyen, K.,

emission reduction potential. Biomass and Bioenergy,

e283

.

Wang, Z., Dunn, J. B., & Wang, M. Q.. (2012). GREET model short

rotation woody crops (SRWC) parameter development.

Retrieved 25.10.2013, from Argonne National Laboratory

website:

greet.es.anl.gov/files/greet-SRWC-Development

.

b i o s y s t e m s e n g i n e e r i n g 1 2 3 ( 2 0 1 4 ) 1 9 e2 8

28

Document Outline

Wyszukiwarka

Podobne podstrony:

Wartość energetyczna SRWC Stolarski et al 2015

Review Santer et al 2008

Arakawa et al 2011 Protein Science

Byrnes et al (eds) Educating for Advanced Foreign Language Capacities

Huang et al 2009 Journal of Polymer Science Part A Polymer Chemistry

Mantak Chia et al The Multi Orgasmic Couple (37 pages)

5 Biliszczuk et al

[Sveinbjarnardóttir et al 2008]

II D W Żelazo Kaczanowski et al 09 10

2 Bryja et al

Ghalichechian et al Nano day po Nieznany

4 Grotte et al

6 Biliszczuk et al

ET&AL&DC Neuropheno intro 2004

3 Pakos et al

7 Markowicz et al

Bhuiyan et al

Agamben, Giorgio Friendship [Derrida, et al , 6 pages]

Gao et al

więcej podobnych podstron