DIESEL INJECTION

Fault finding - Introduction

13B

13B-1

113B

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DIESEL INJECTION

Fault finding - Introduction

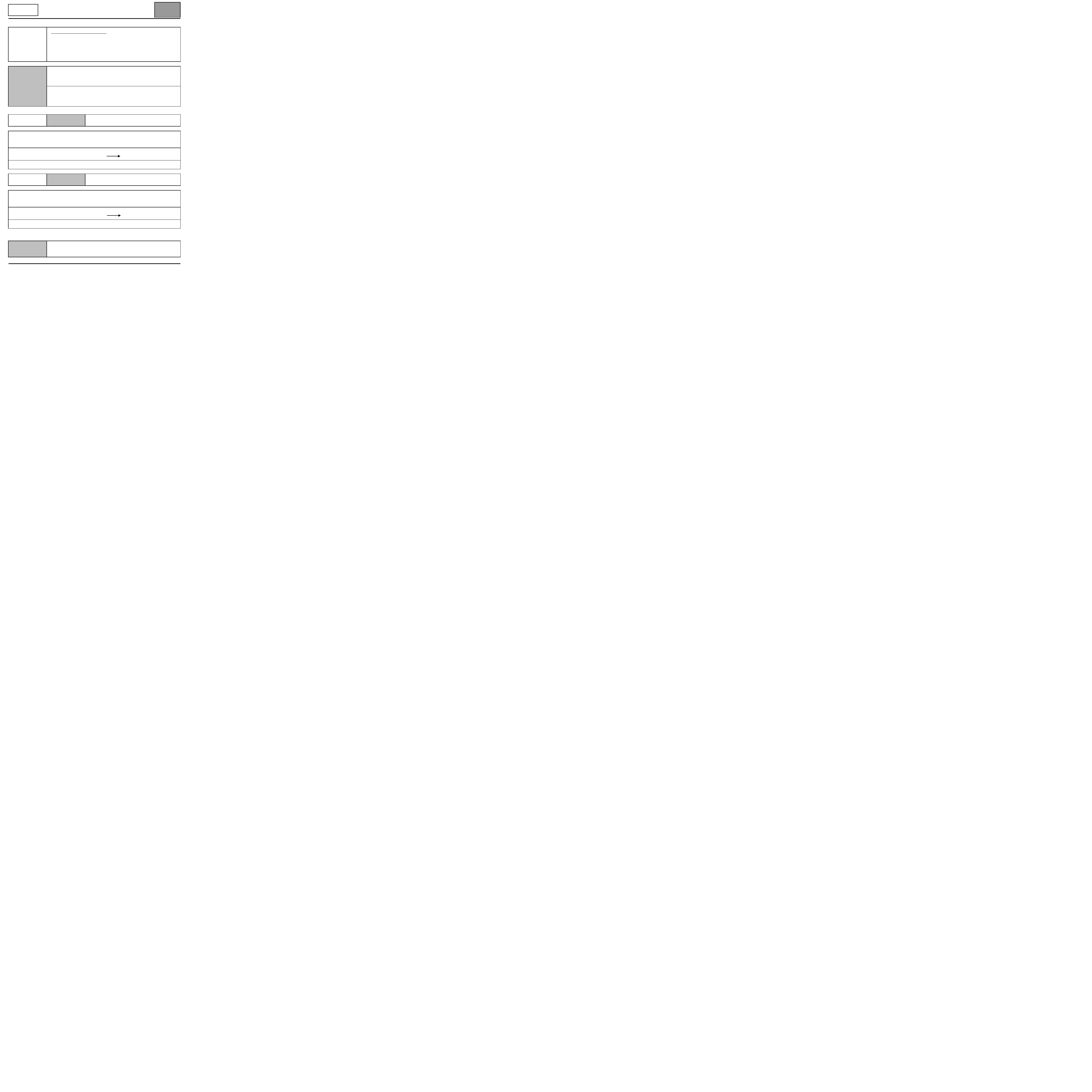

1. SCOPE OF THIS DOCUMENT

This document presents the fault finding method applicable to all computers with the following characteristics:

2. PREREQUISITES FOR FAULT FINDING

Documentation type

Fault finding procedures (this manual):

– Assisted fault finding (incorporated into the diagnostic tool), paper version (Workshop Repair Manual

or Technical Note) and Dialogys.

Wiring diagrams:

– Visu-Diagram (CD-ROM), paper.

Type of diagnostic tools:

– CLIP

Special tooling required:

Vehicle(s): MEGANE II

Function involved: DELPHI K9 DIESEL DIRECT

COMMON RAIL INJECTION (DDCR)

Computer name: DDCR INJECTION

Program no.: BE 88

VDIAG No.: 44

Special tooling required

Multimeter.

Elé. 1590

112 track computer bornier

Mot. 1711

PLUGGED RAIL tools

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Introduction

13B

13B-2

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

3. REMINDERS

Procedure:

Switch on the ignition in fault finding mode to diagnose the vehicle computers (+ after ignition imposed).

Proceed as follows:

– Renault card on the card holder (keyless vehicle scenario 1, basic, not hands-free and scenario 2, top of the

range, hands-free),

– Press and hold start button (longer than 5 seconds) with start-up conditions not fulfilled,

– Connect the diagnostic tool and perform the required operations.

Proceed as follows to cut off the + after ignition:

– disconnect the diagnostic tool,

– press the start button twice briefly (less then 3 seconds),

– ensure that the + after ignition feed has been cut off by checking that the computer warning lights on the

instrument panel have gone out.

Faults:

Faults are declared either present or stored (depending on whether they appeared in a certain context and have

disappeared since, or whether they remain present but are not diagnosed within the current context).

The present or stored state of faults should be taken into consideration when the diagnostic tool is used after the

+ after ignition feed (without acting on the system components).

Apply the procedure shown in the Interpreting faults section for a present fault.

For a stored fault, note the faults displayed and apply the instructions section.

If the fault is confirmed when the instructions in the Notes section are applied, the fault is present. Deal with the

fault.

If the fault is not confirmed, check:

– the electrical lines which correspond to the fault,

– the connectors on these lines (corrosion, bent pins, etc.),

– the resistance of the faulty component,

Conformity check

The conformity check is designed to check the states and parameters which do not display any faults on the

diagnostic tool when inconsistent. This phase therefore allows:

– diagnosis of faults that do not have a fault display, and which may correspond to a customer complaint.

– checks that the system is operating correctly and that there is no risk of a fault reappearing after repairs.

This section gives the fault finding procedures for states and parameters and the conditions for checking them.

If a state is not behaving normally or a parameter is outside permitted tolerance values, you should consult the

corresponding fault finding page.

Note:

The left and right-hand Xenon bulb computers are supplied when the dipped headlights are lit. Fault finding

procedures can only be carried out on them after the ignition has been switched on in fault finding mode (+ after

ignition imposed) and the dipped headlights are on.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Introduction

13B

13B-3

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

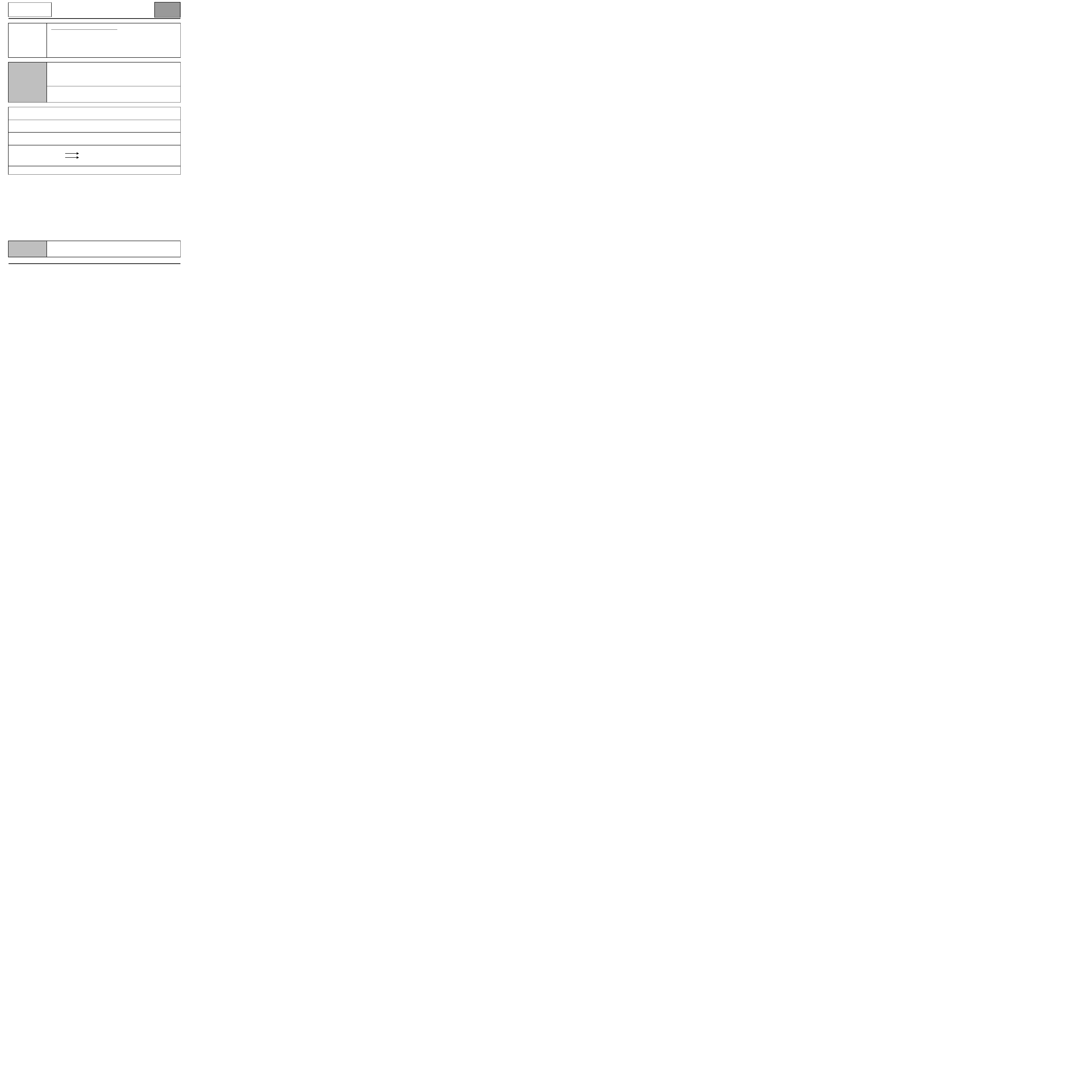

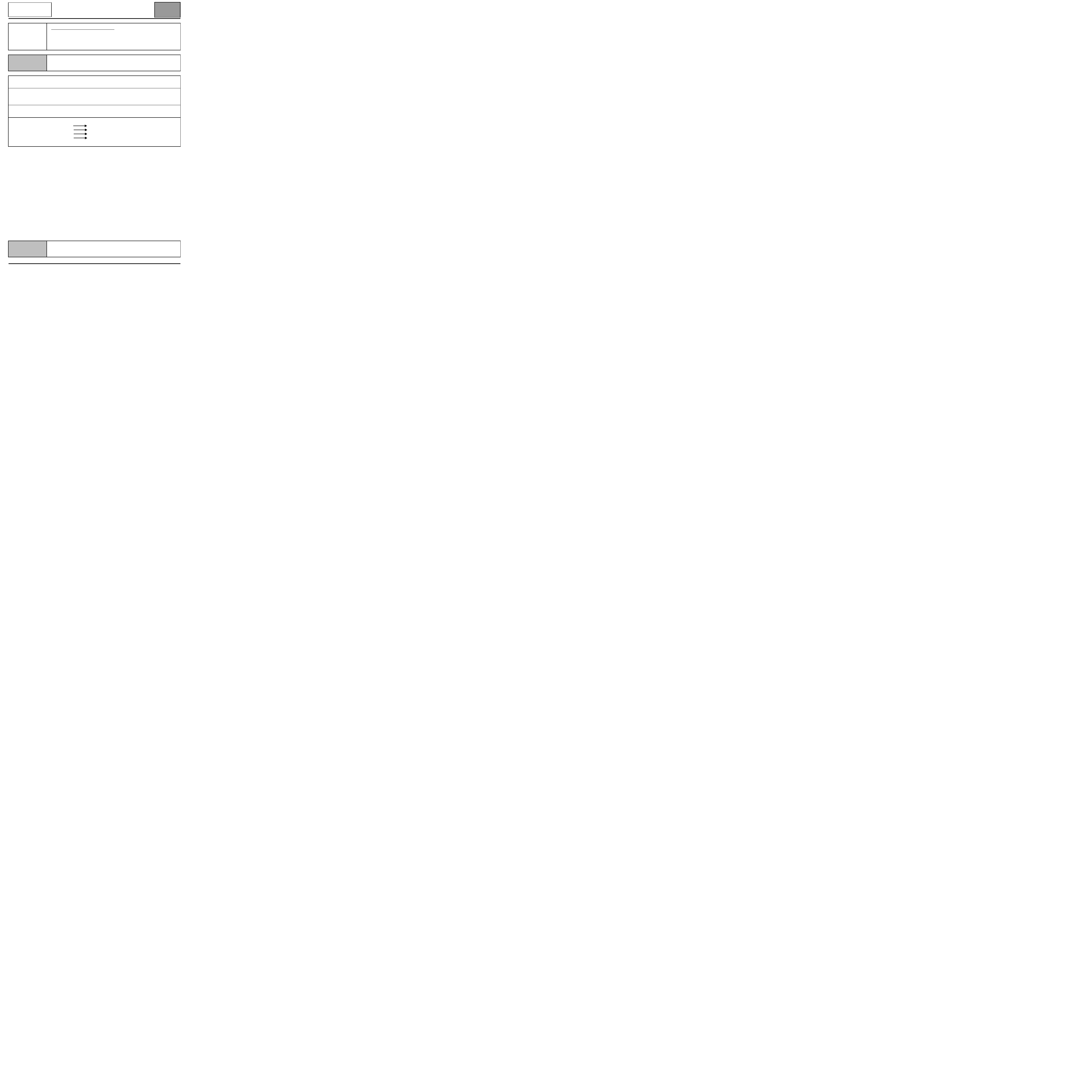

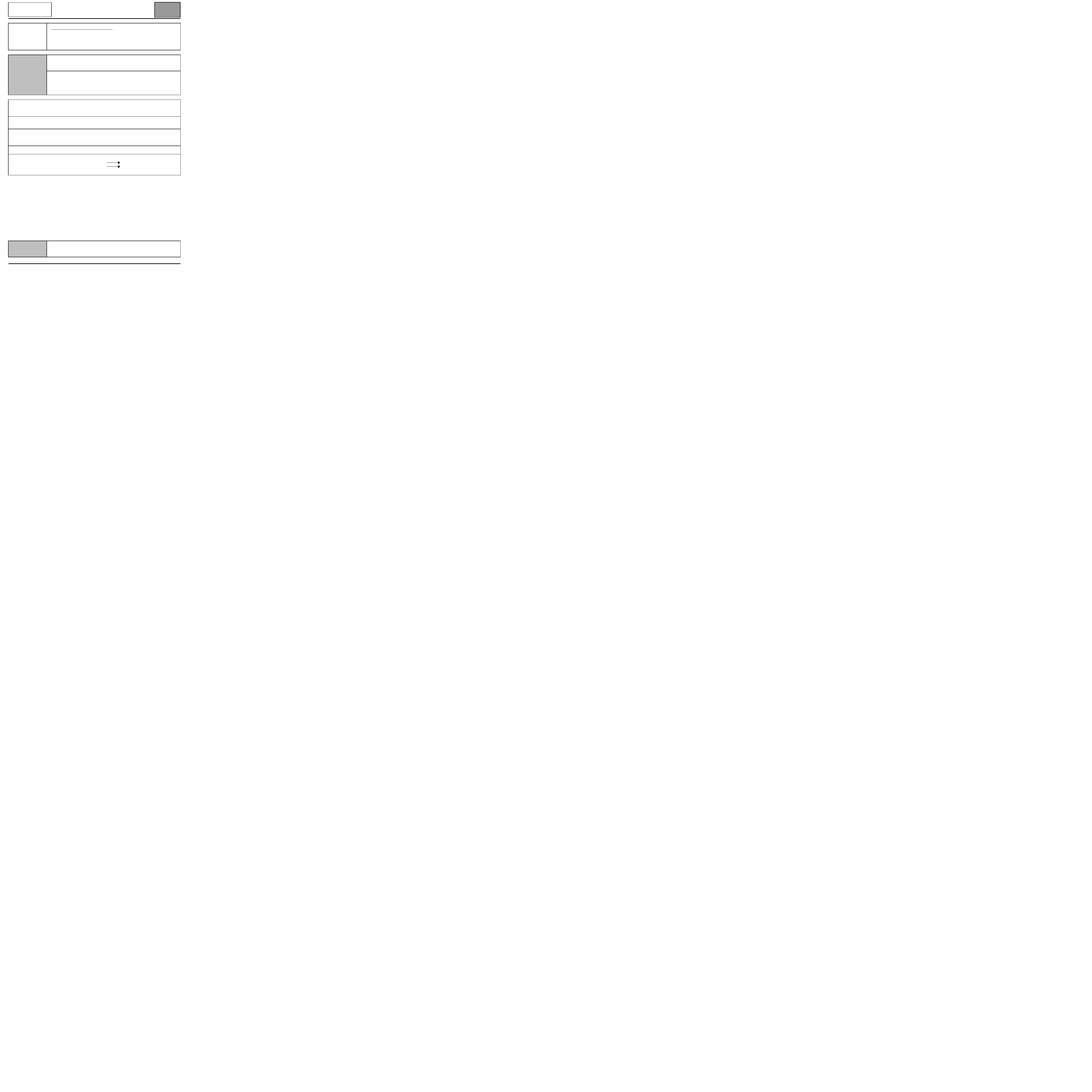

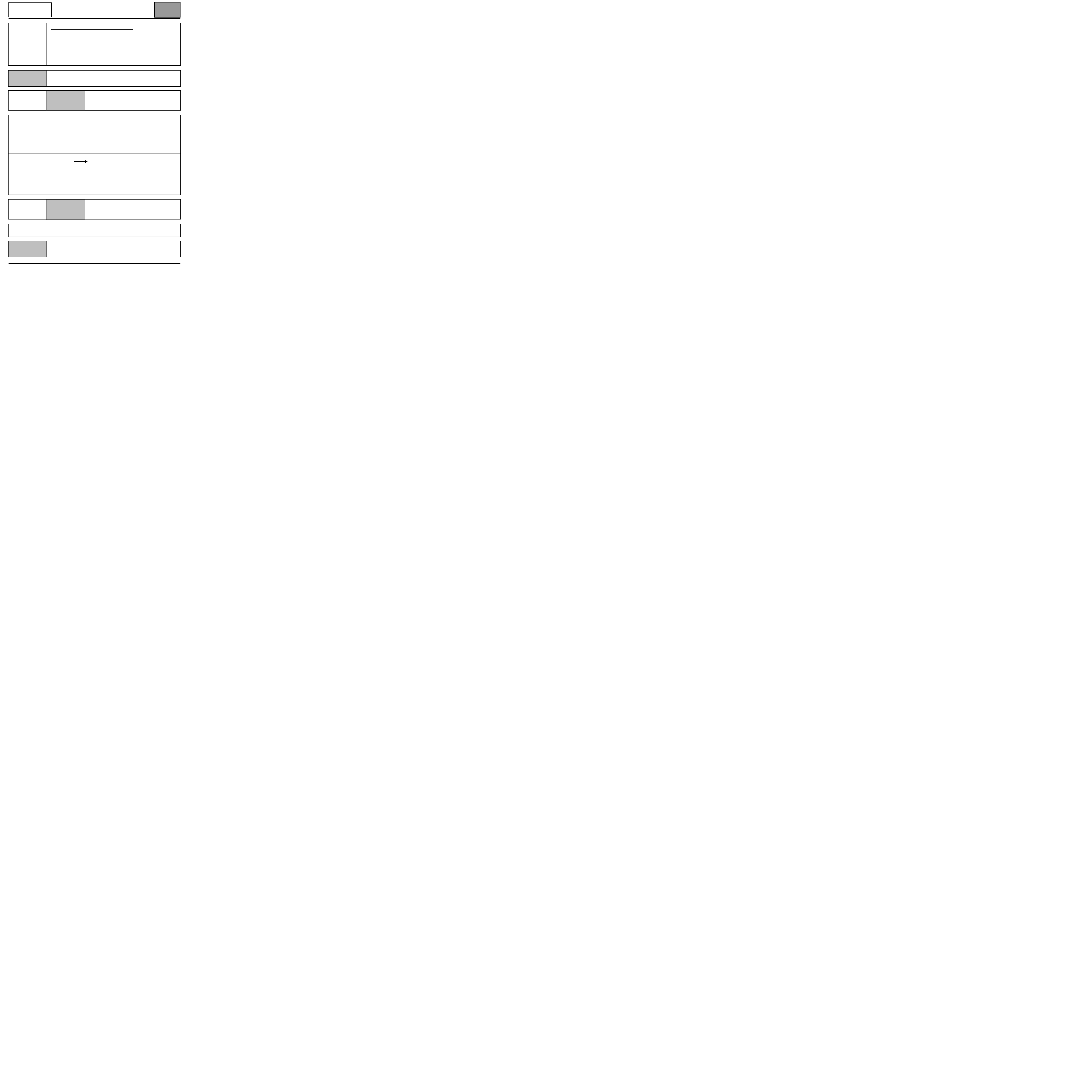

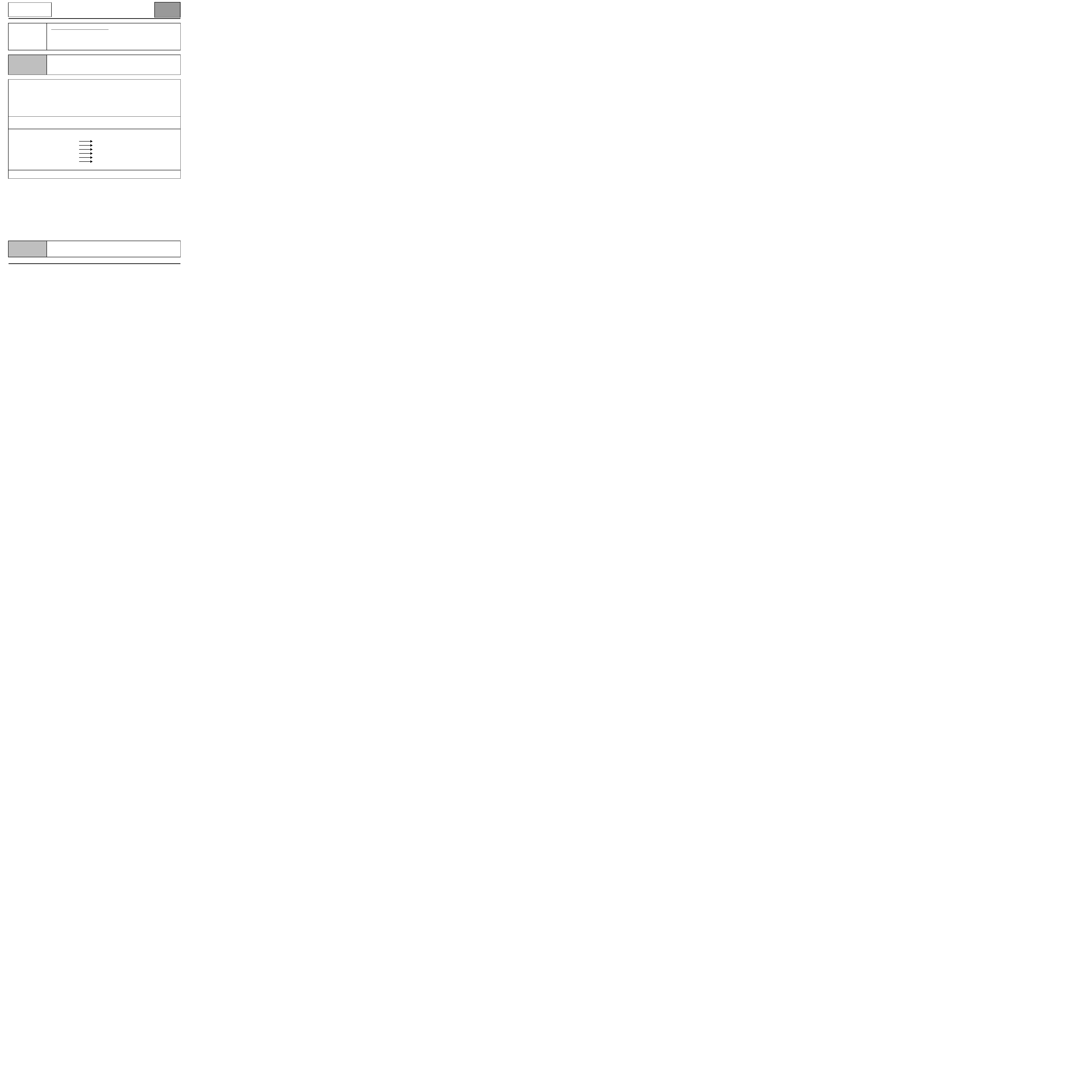

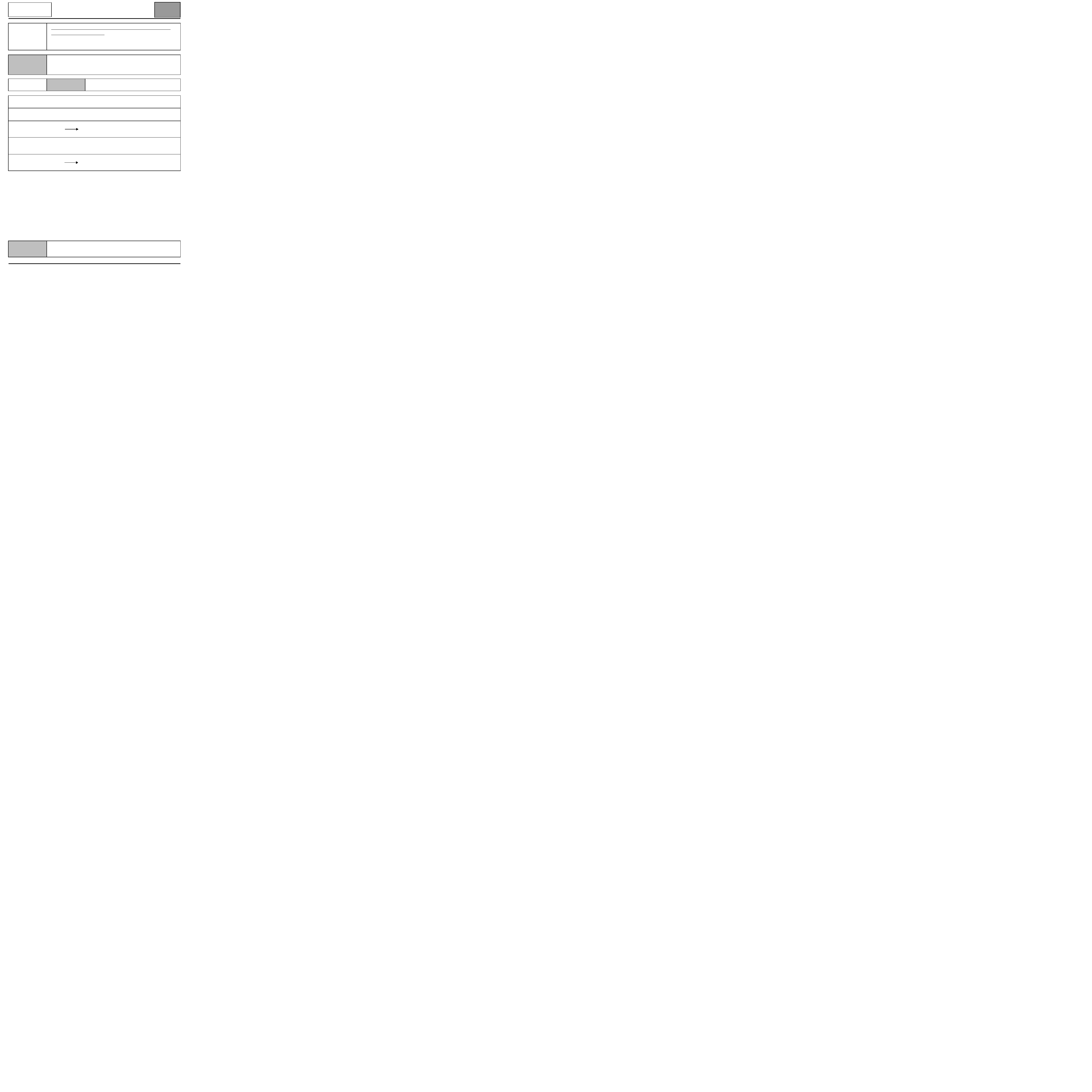

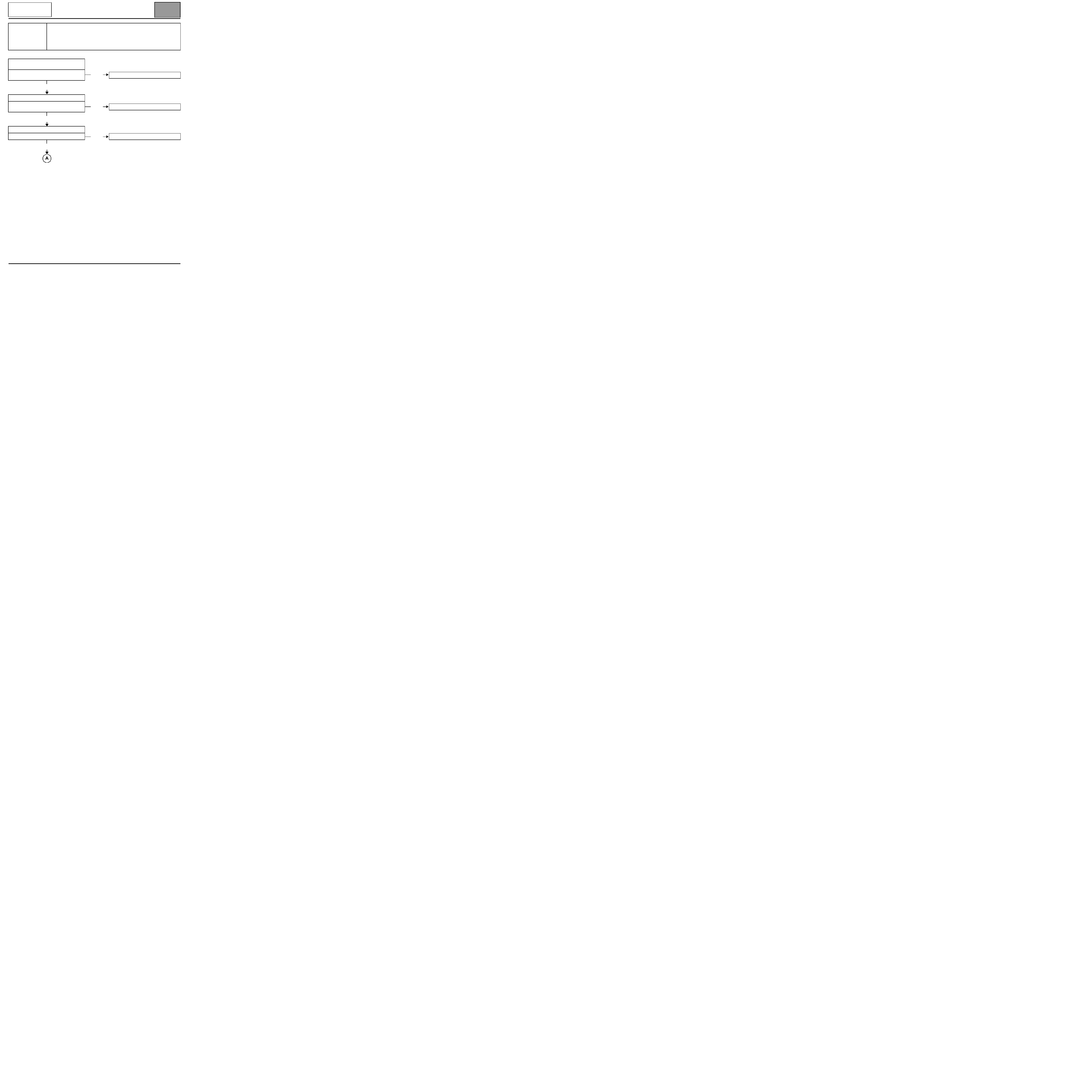

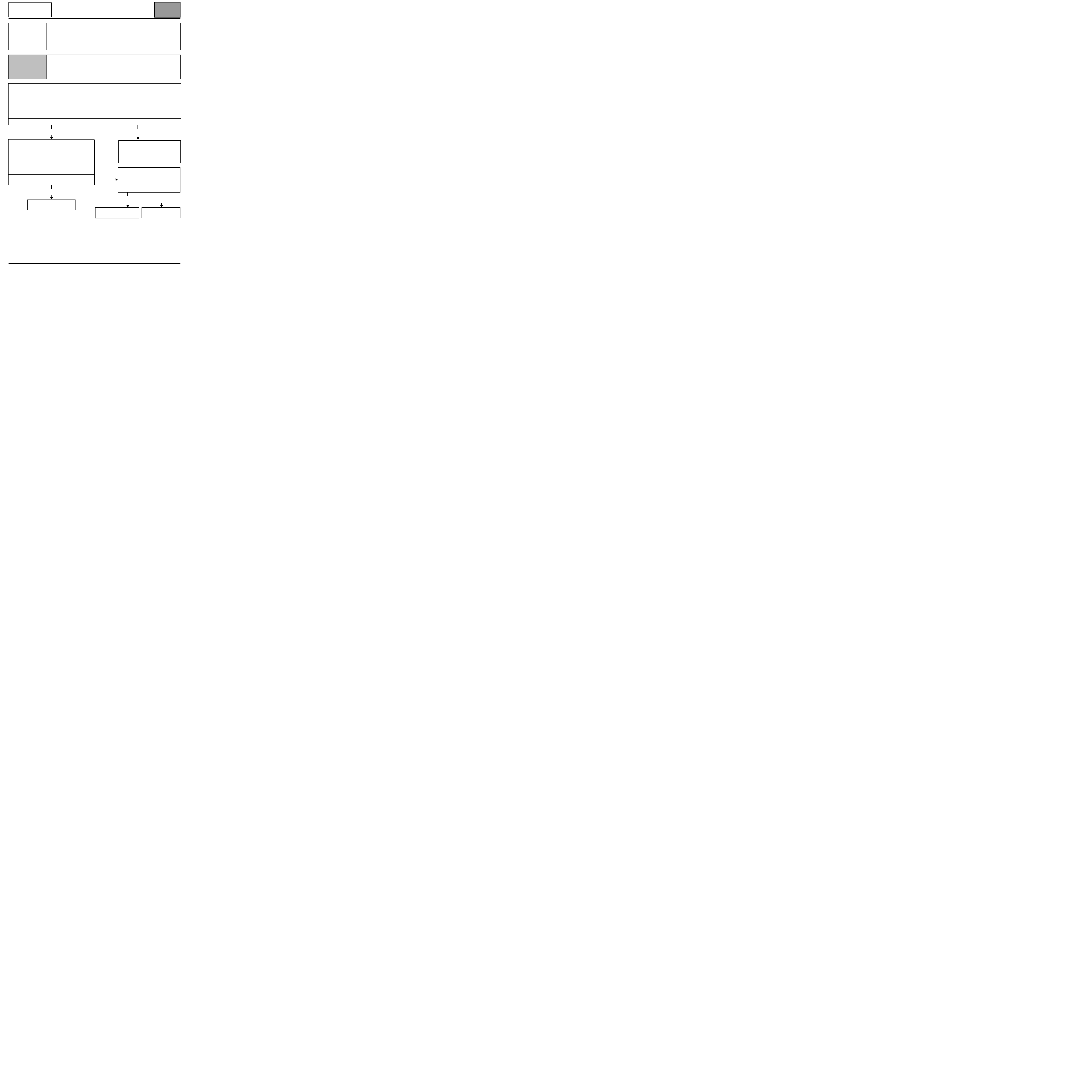

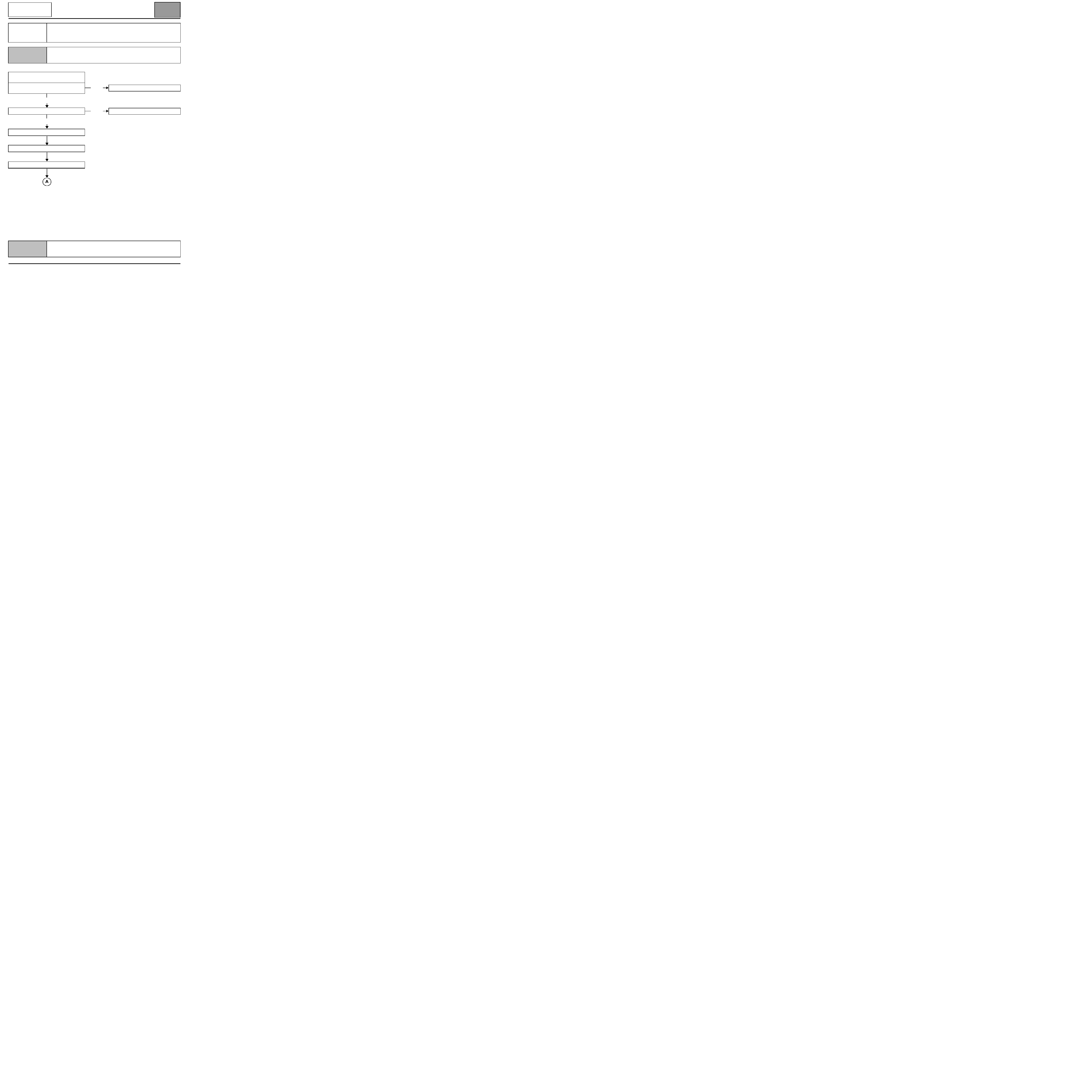

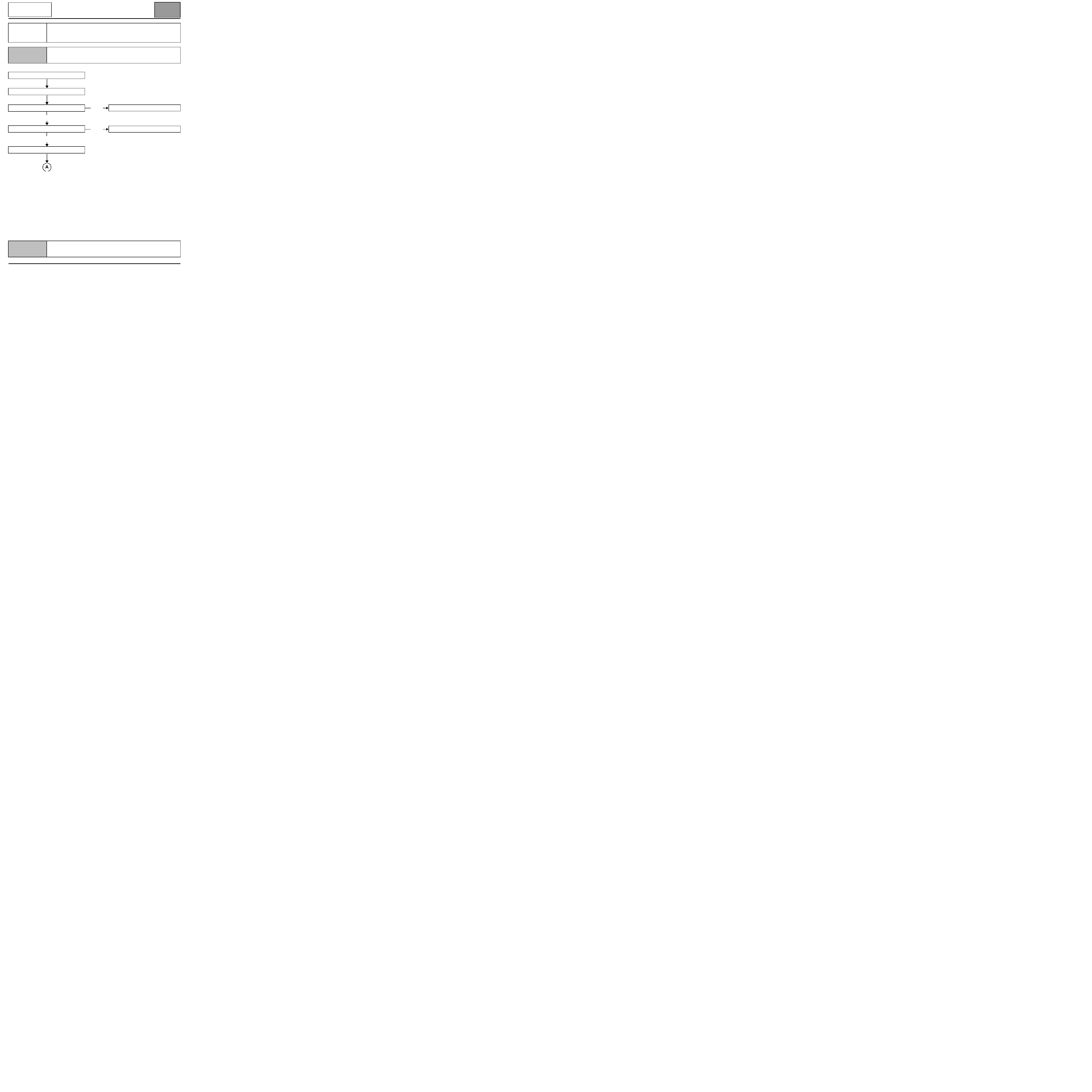

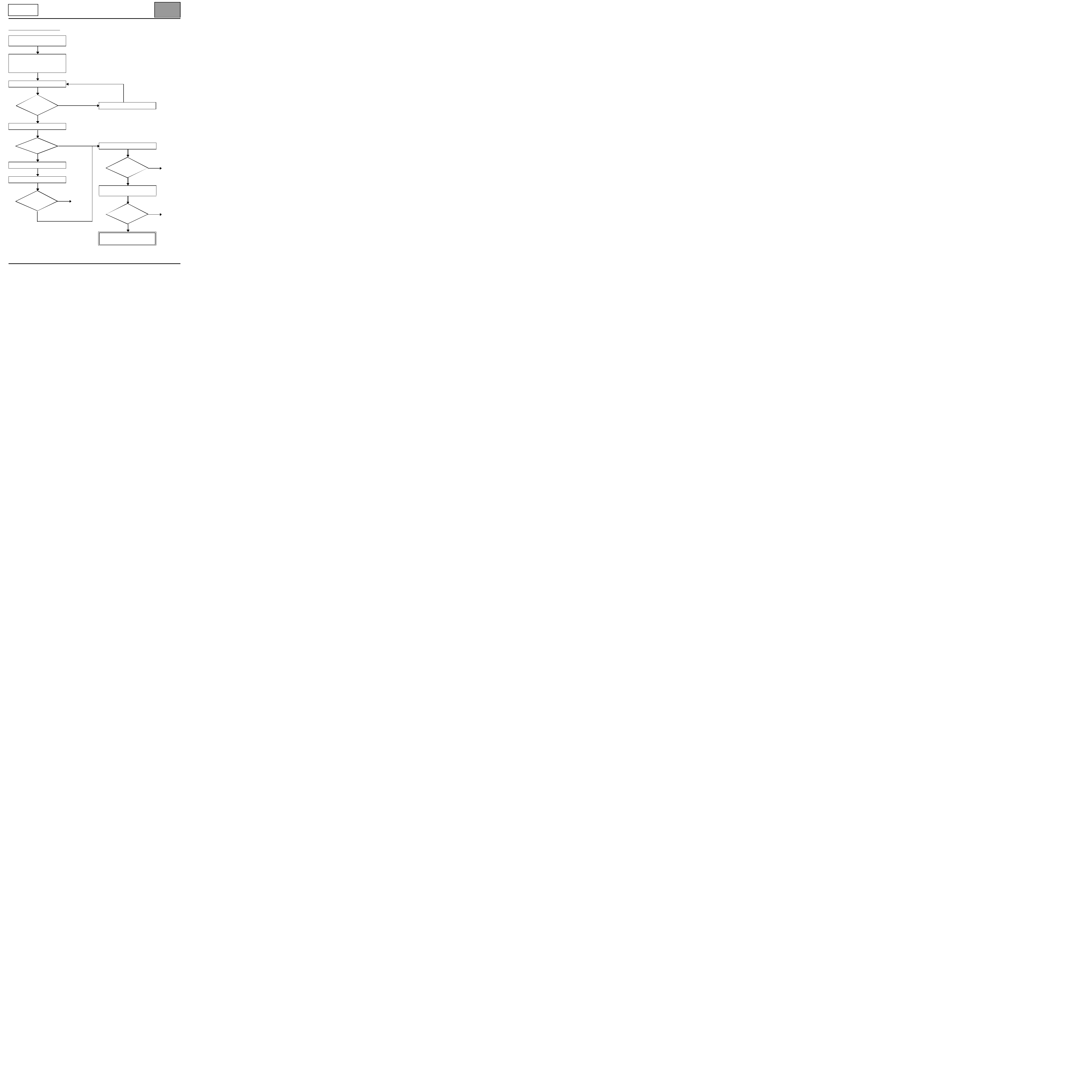

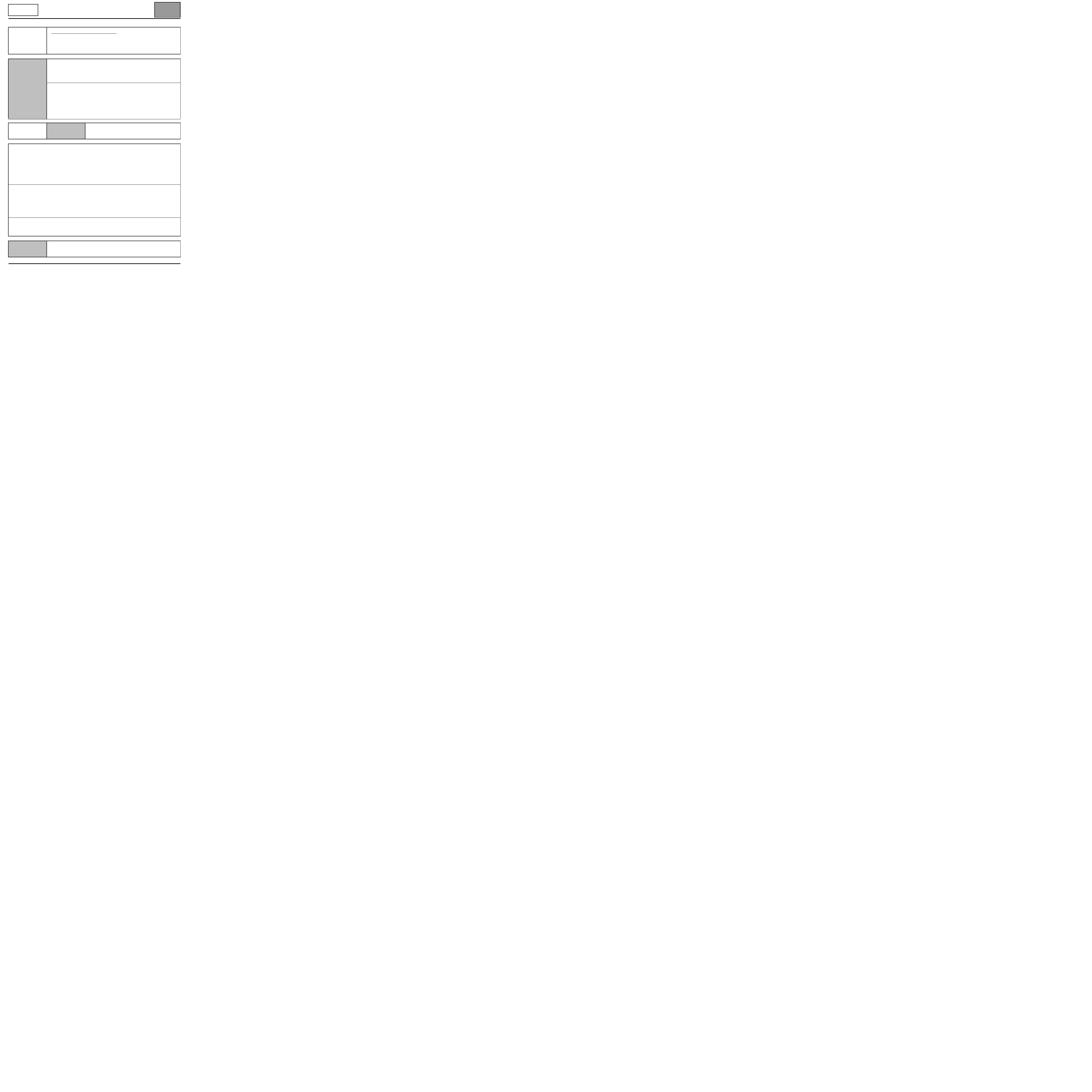

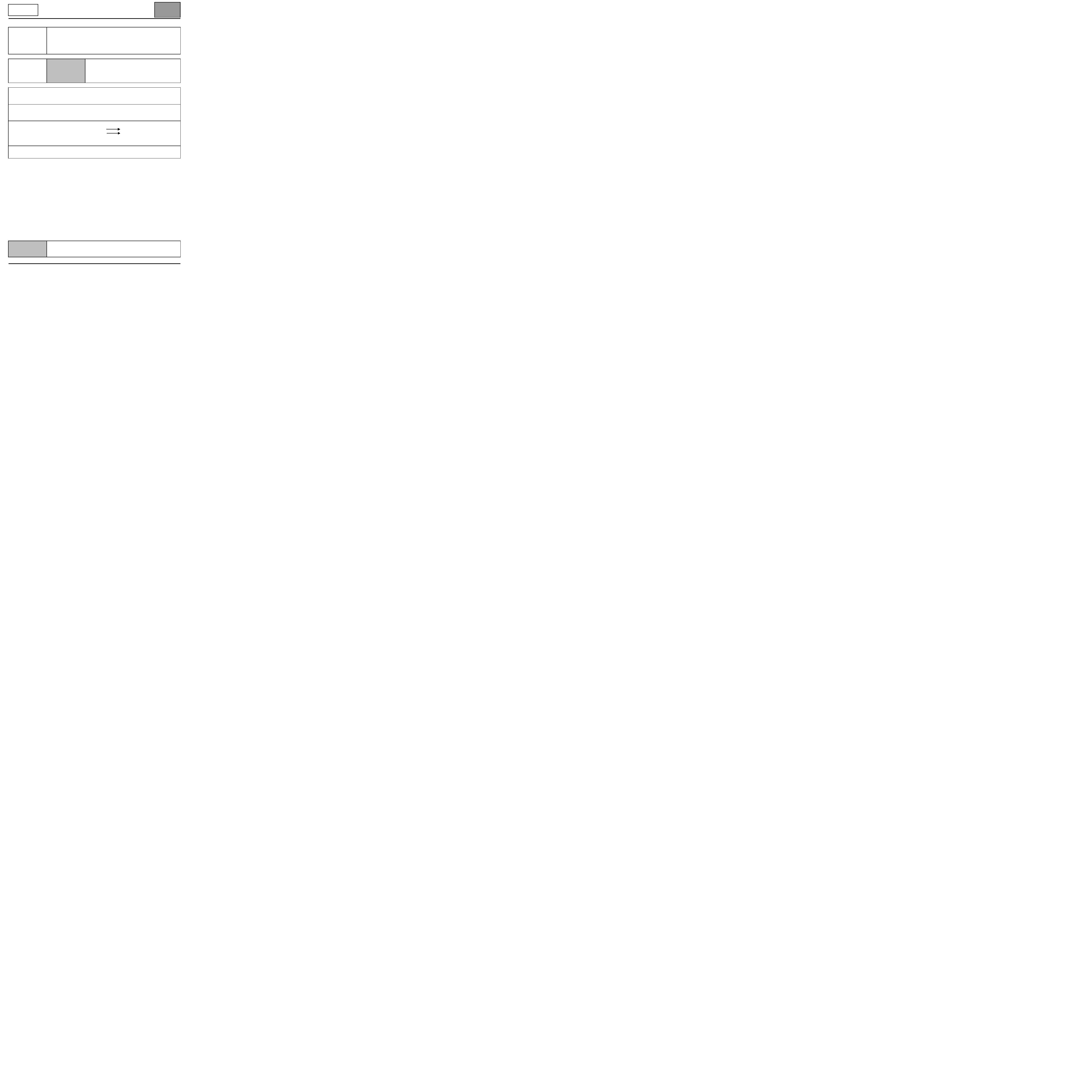

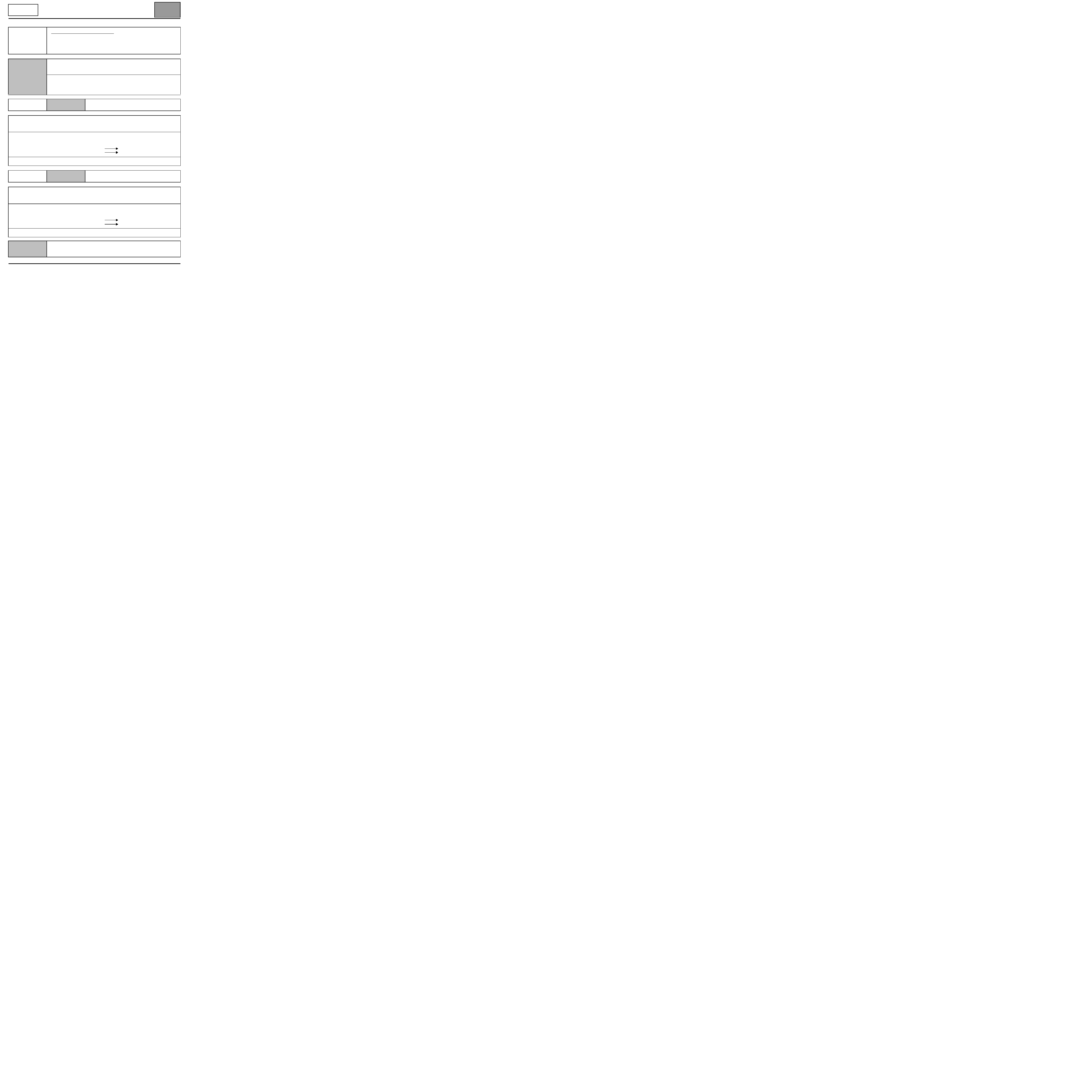

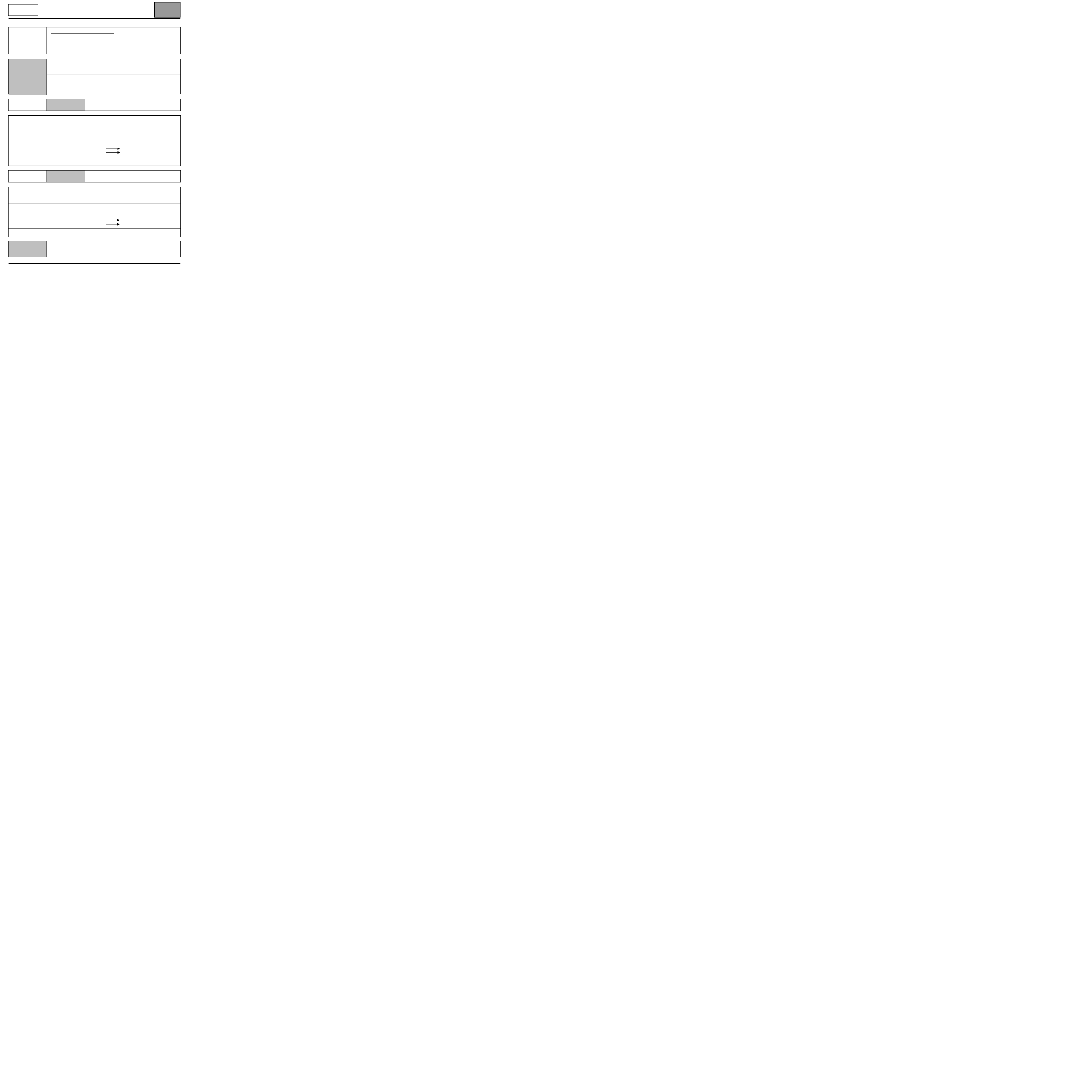

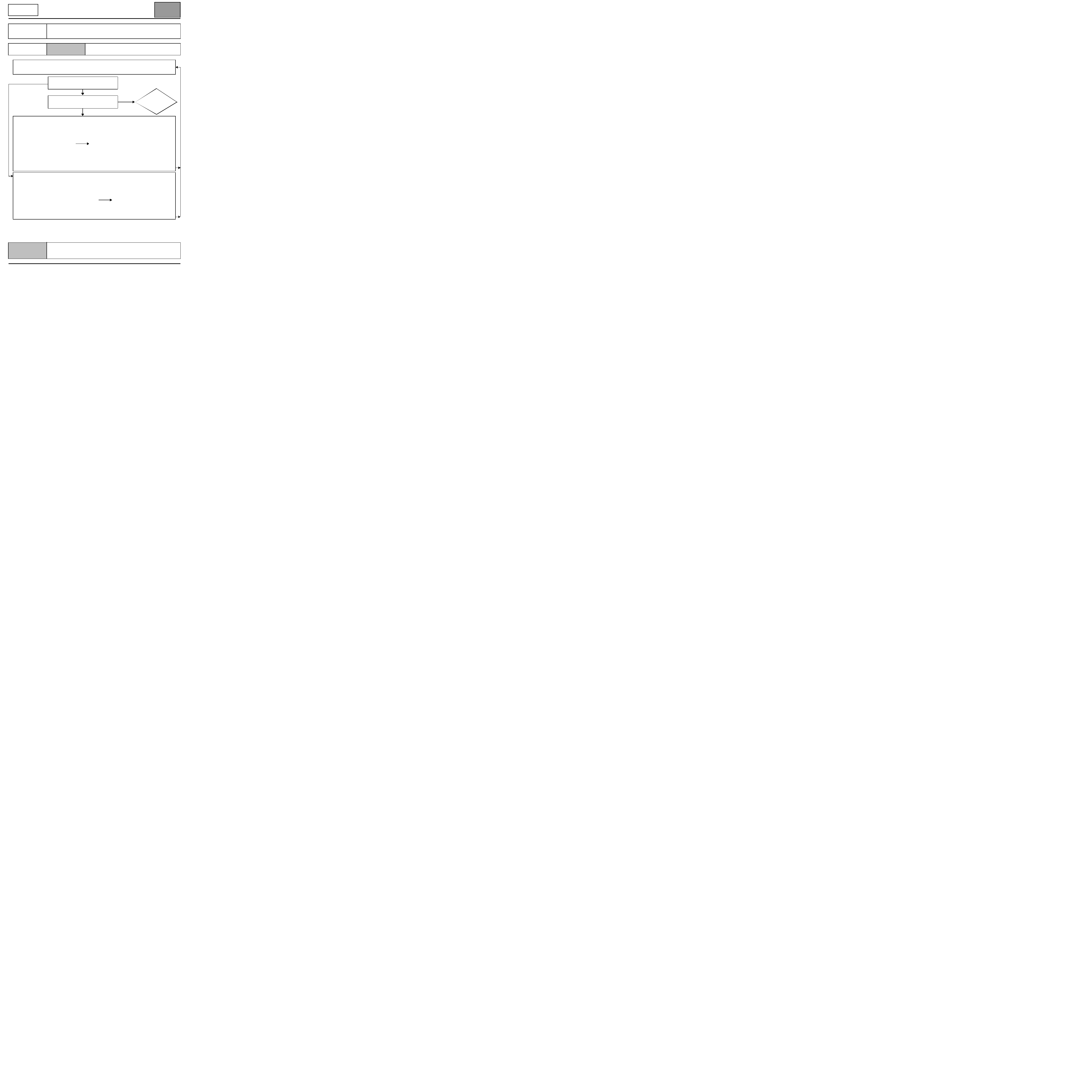

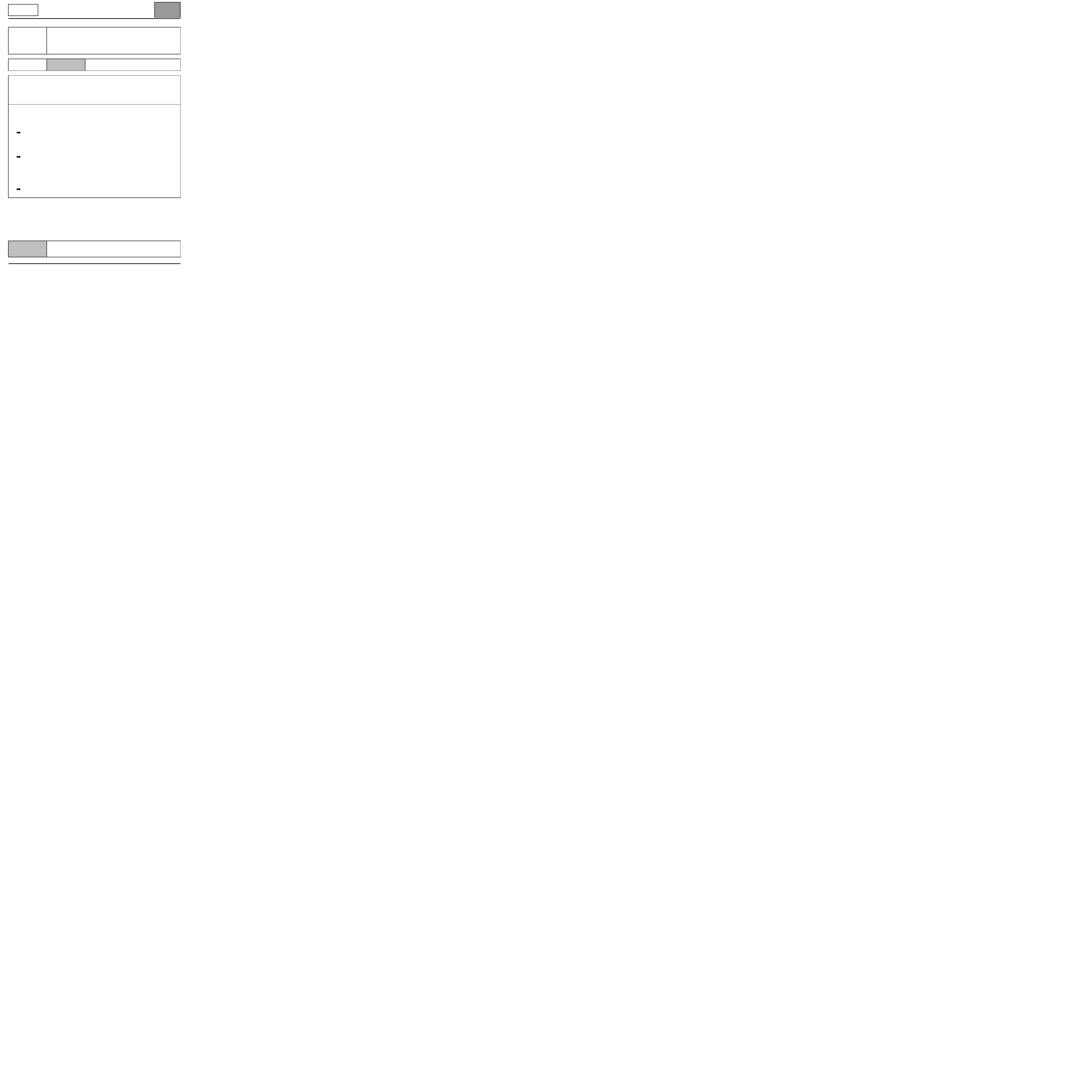

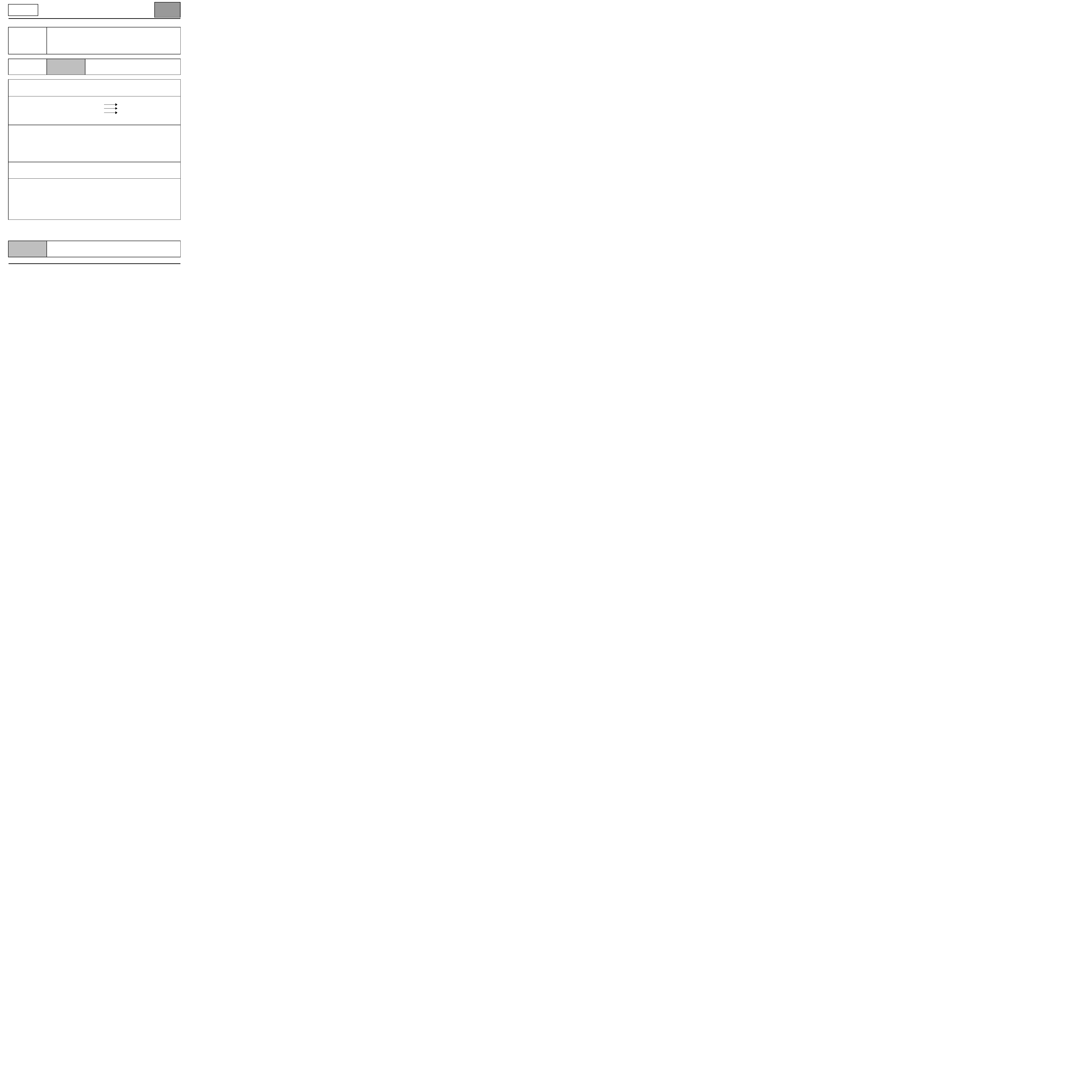

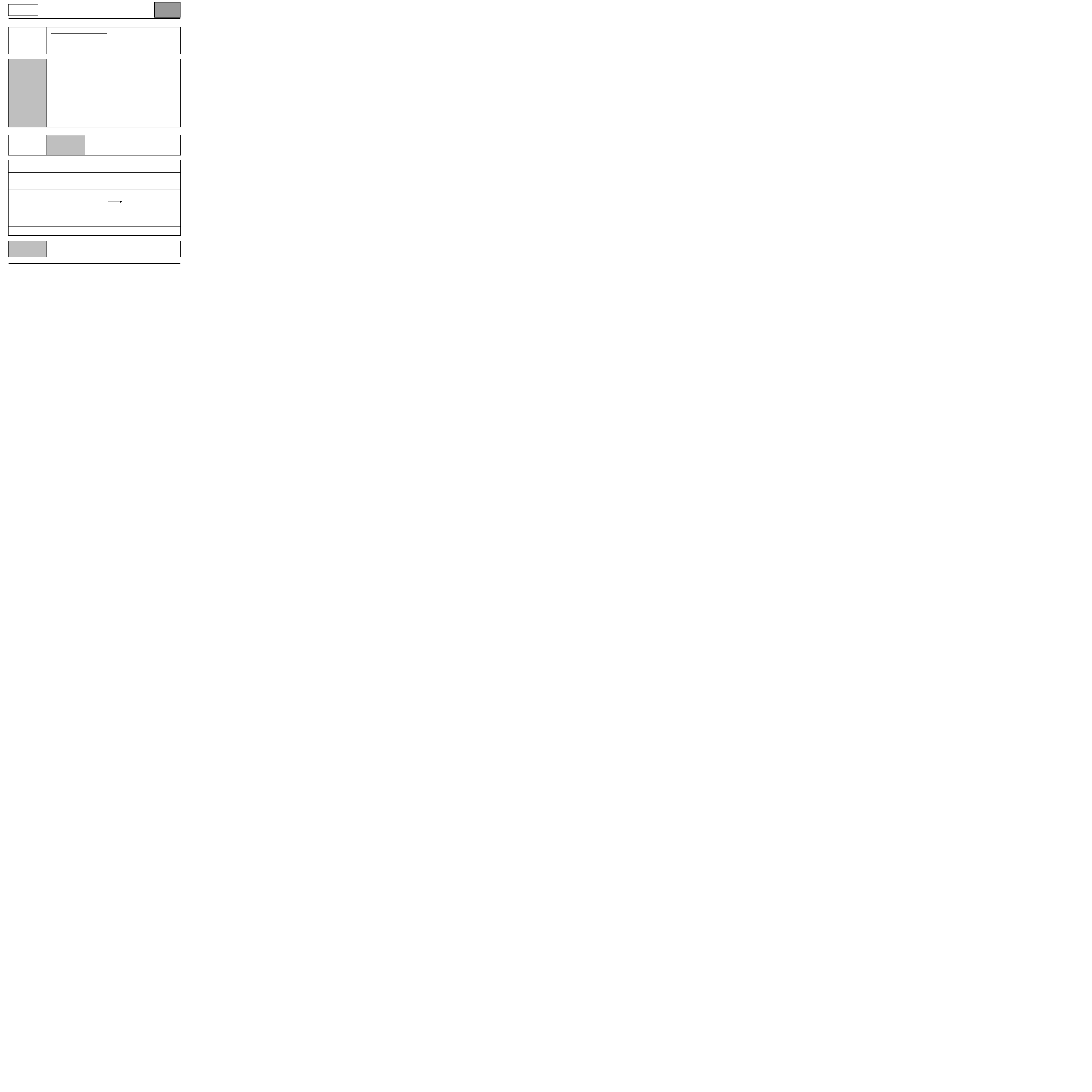

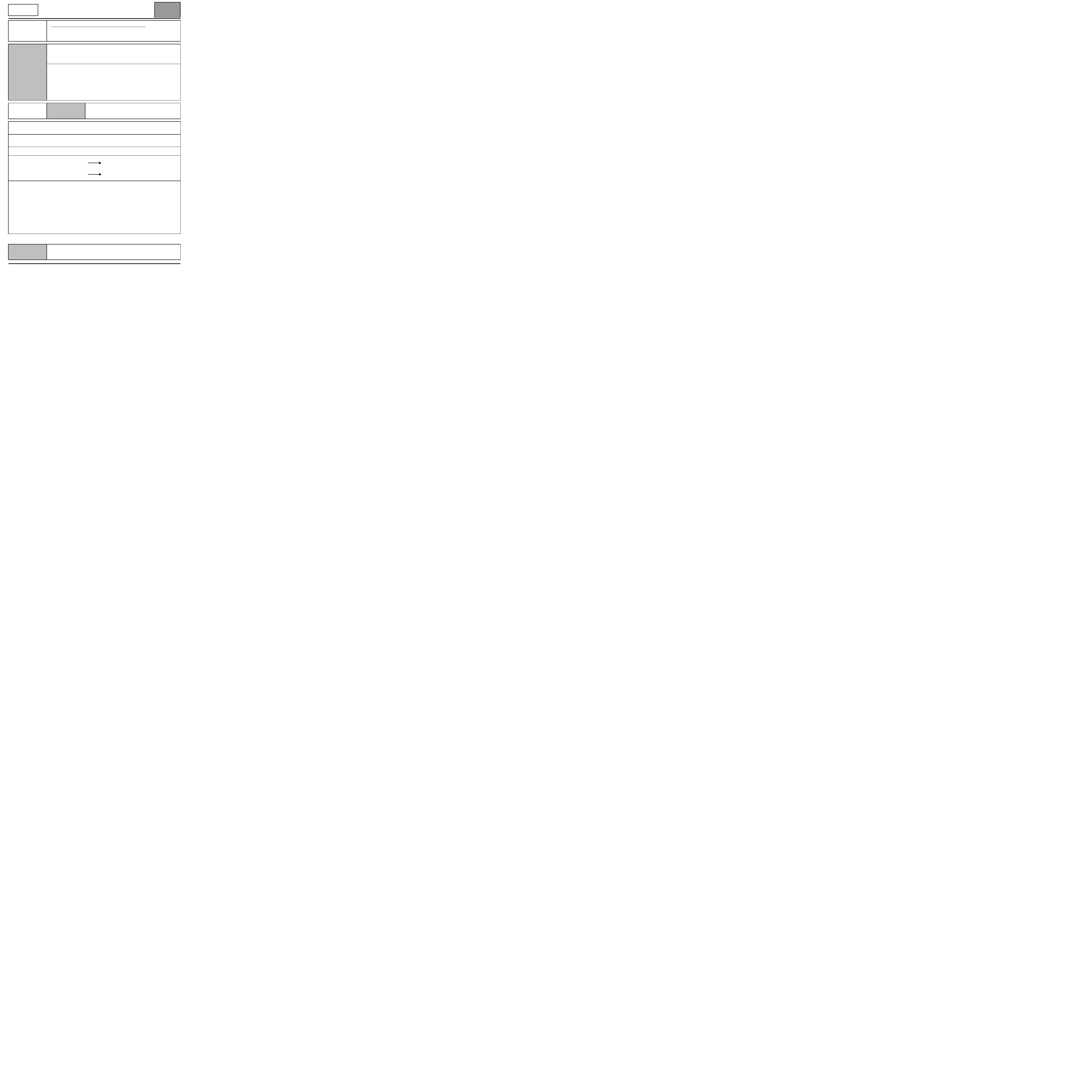

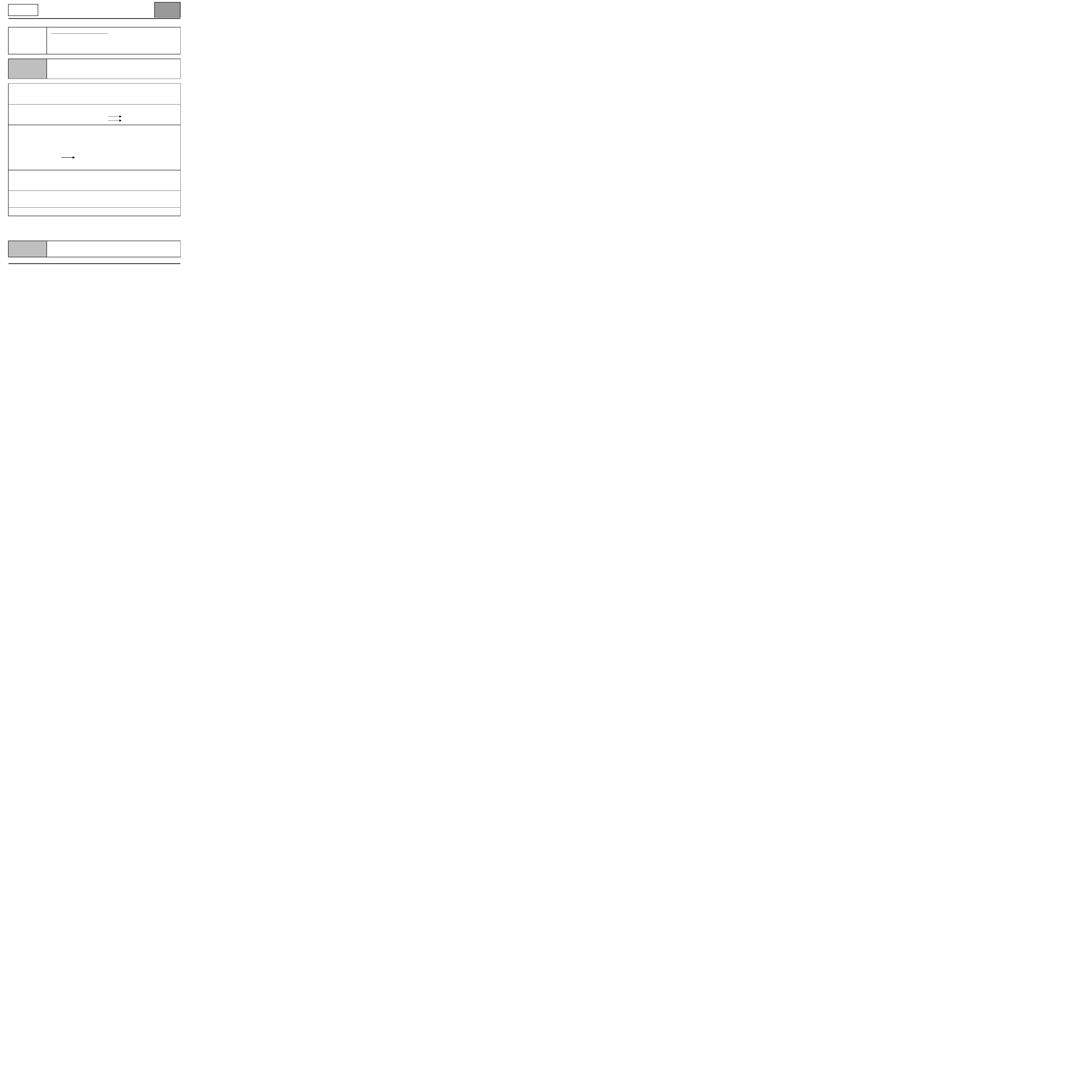

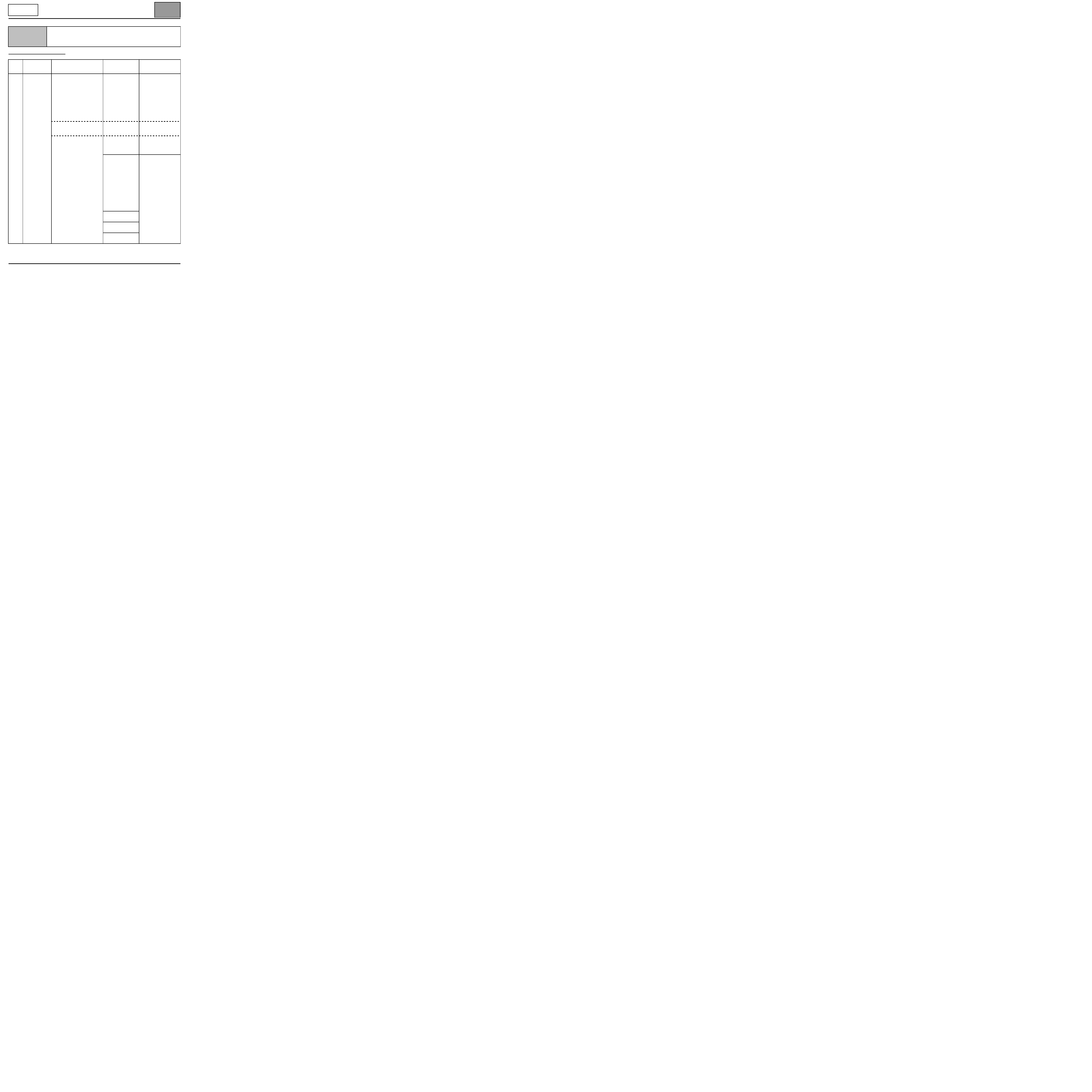

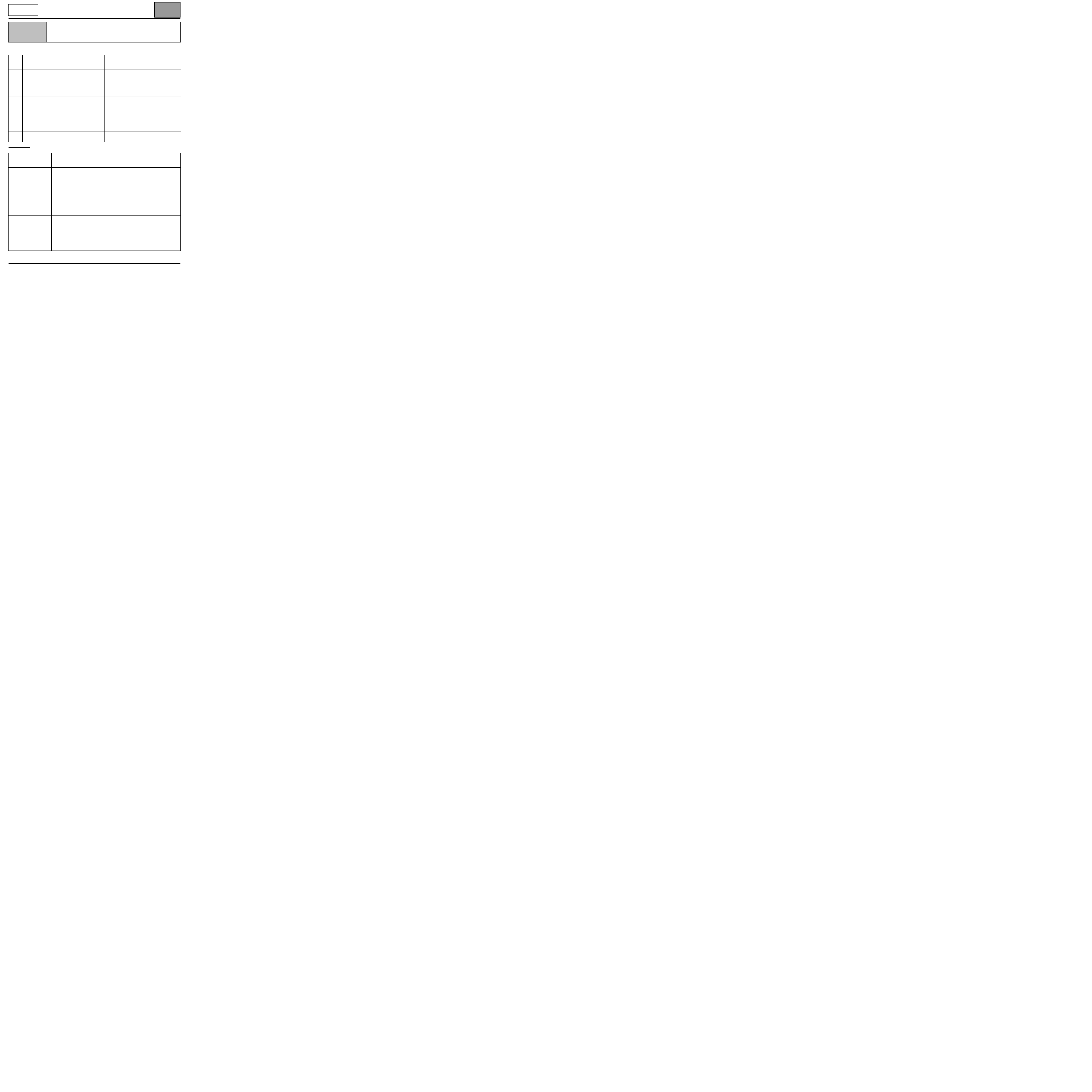

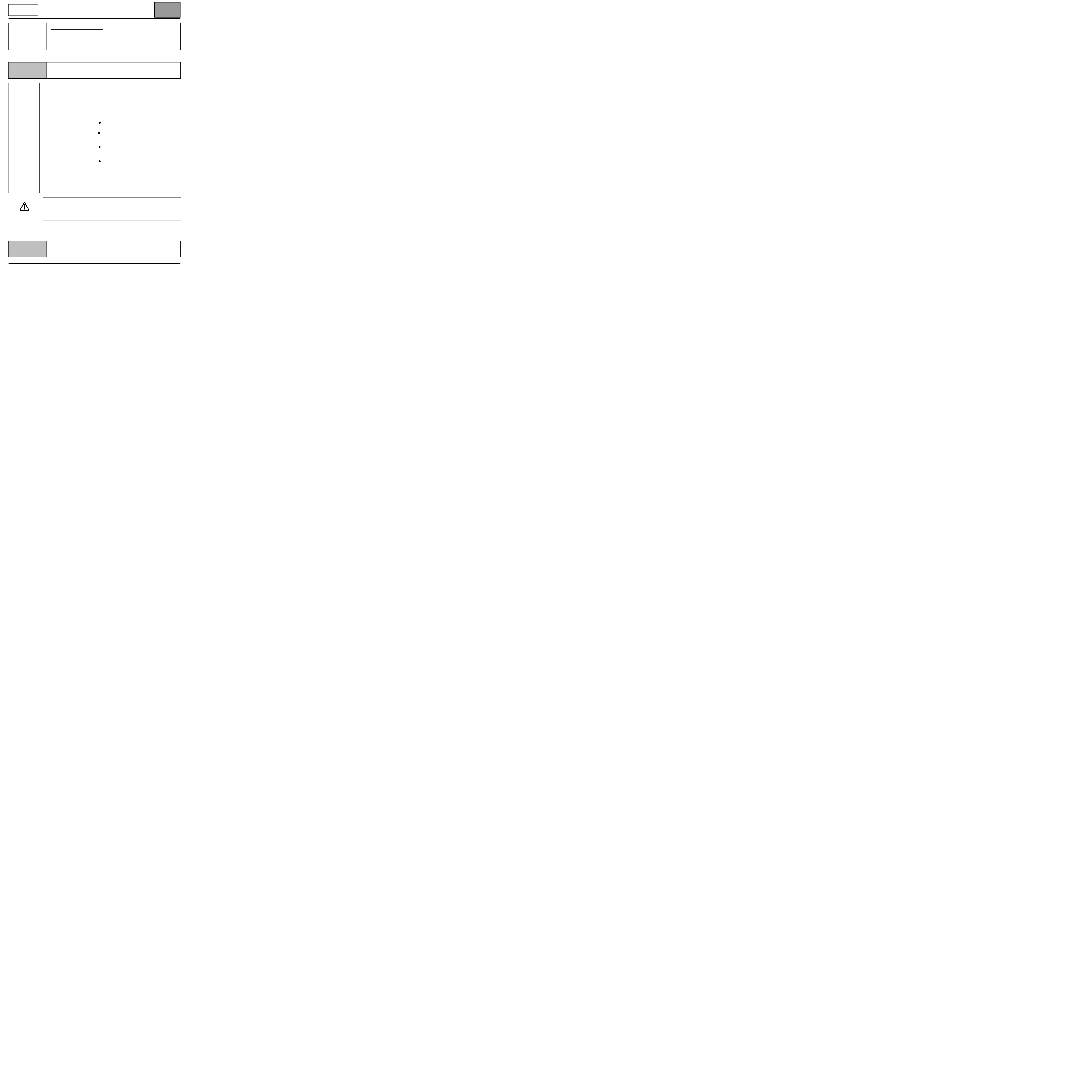

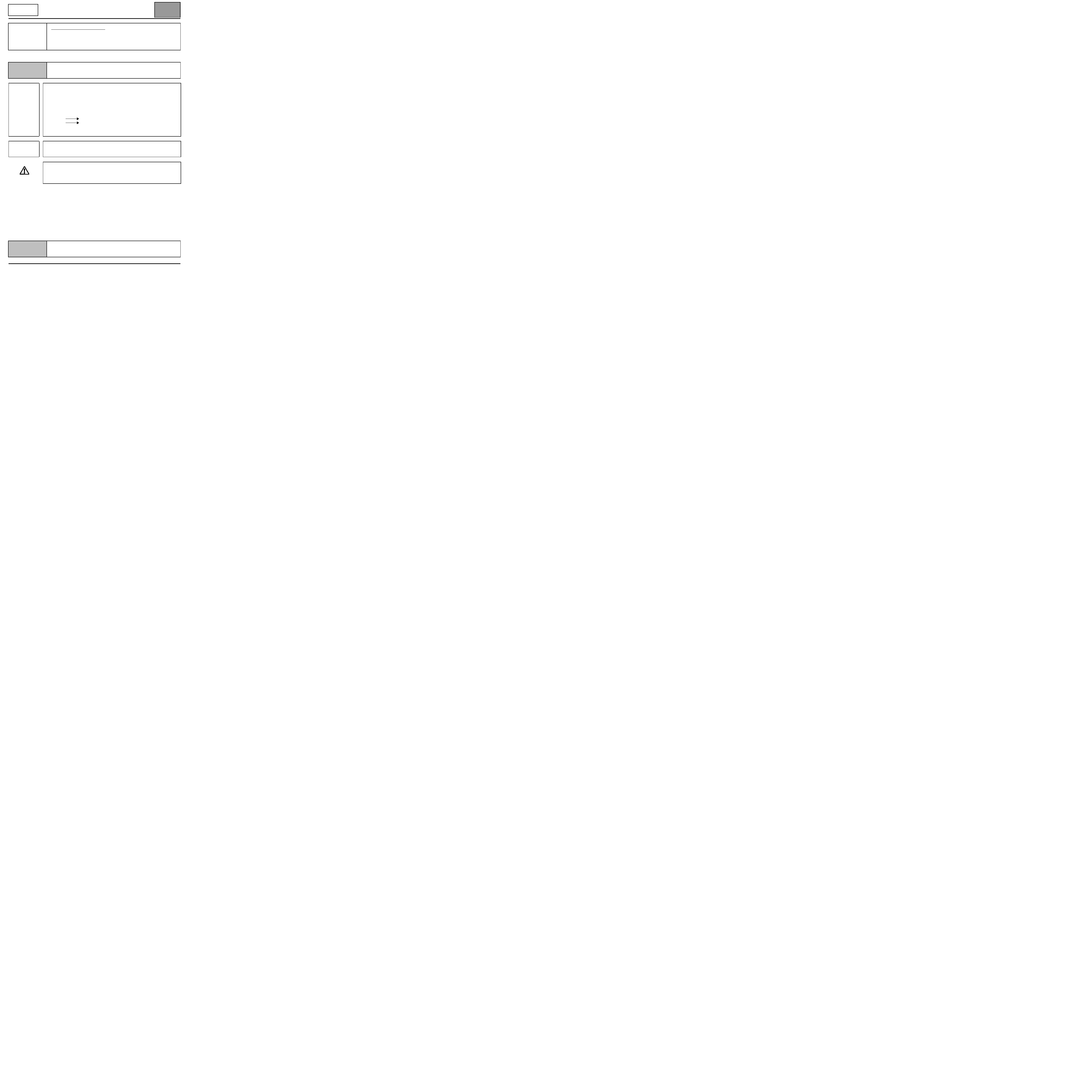

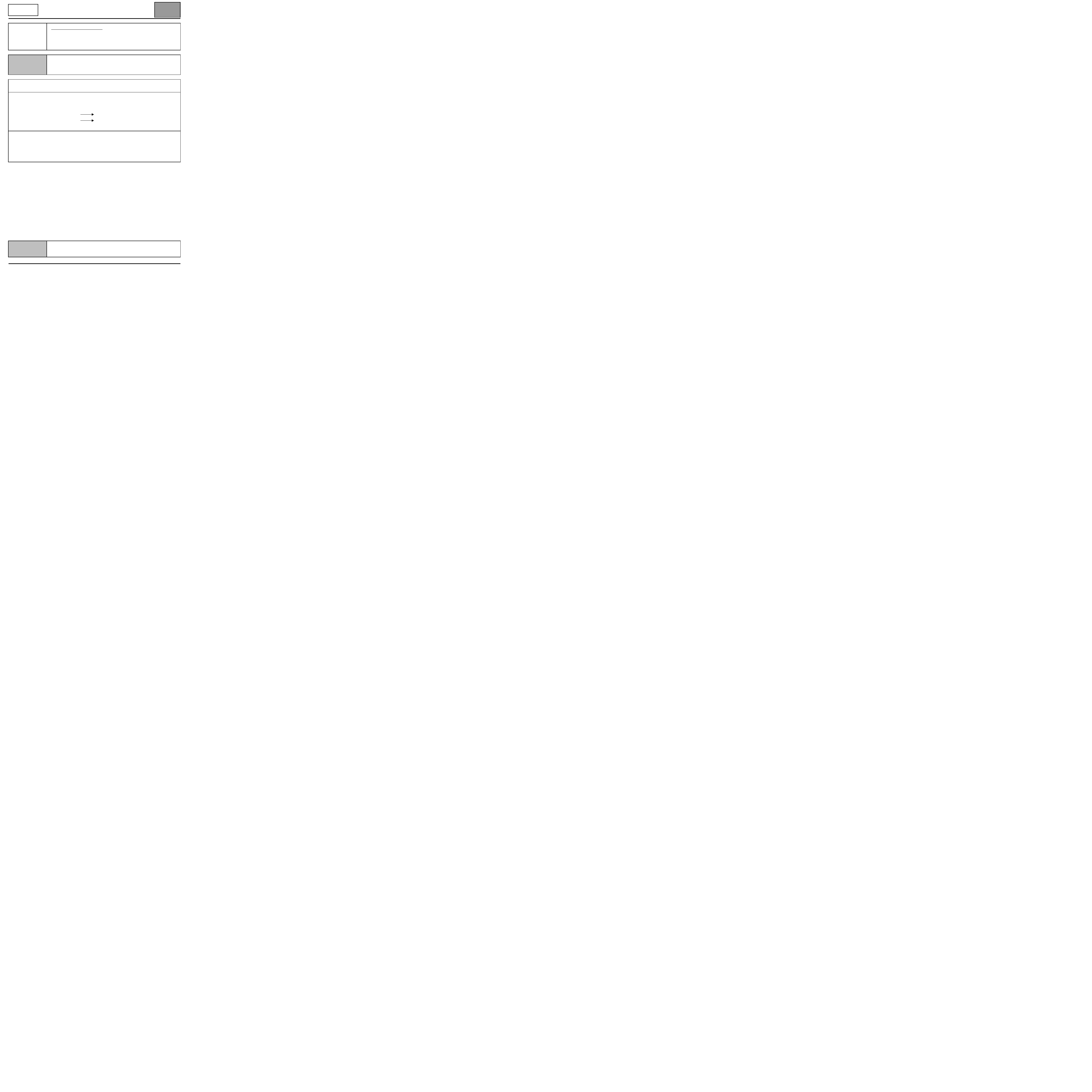

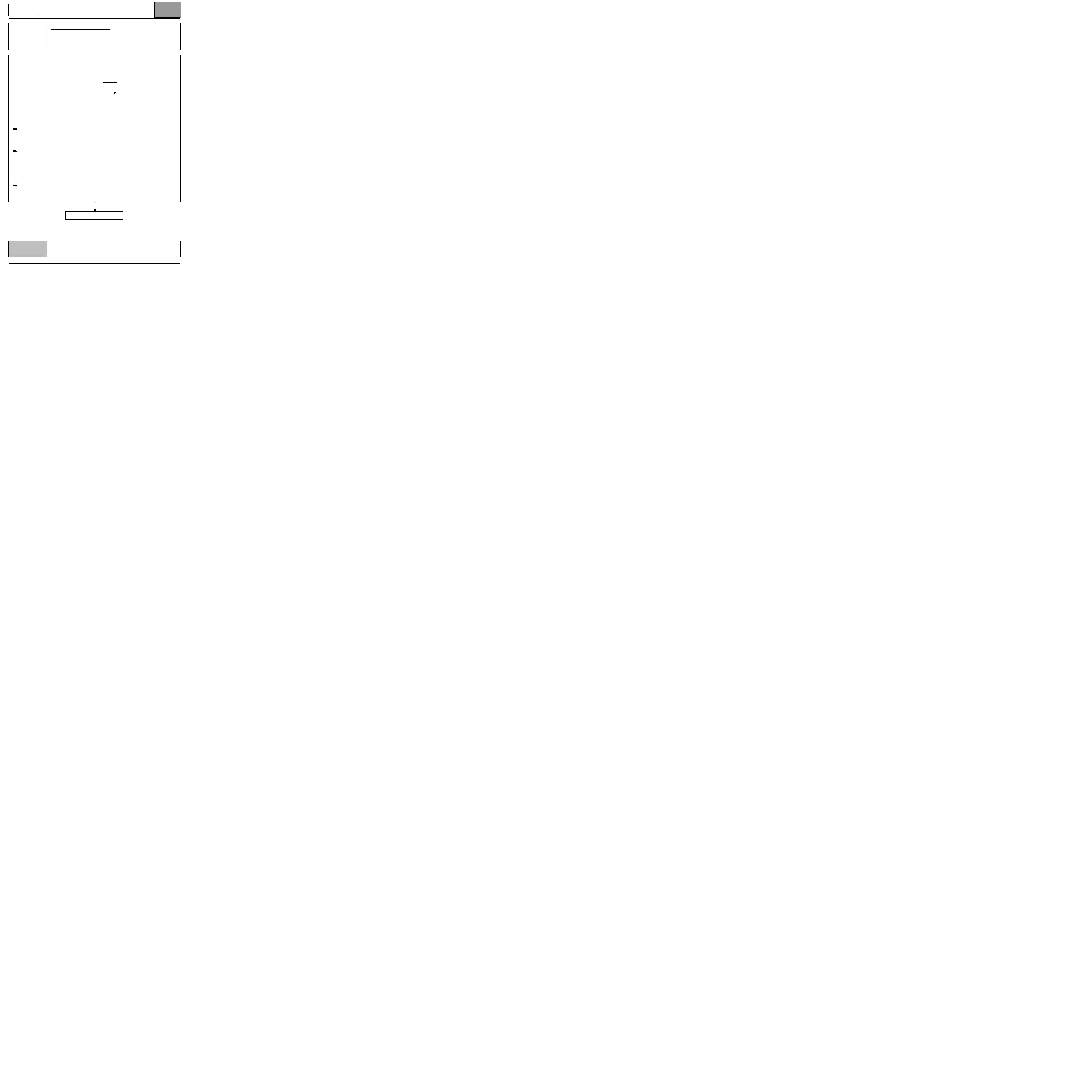

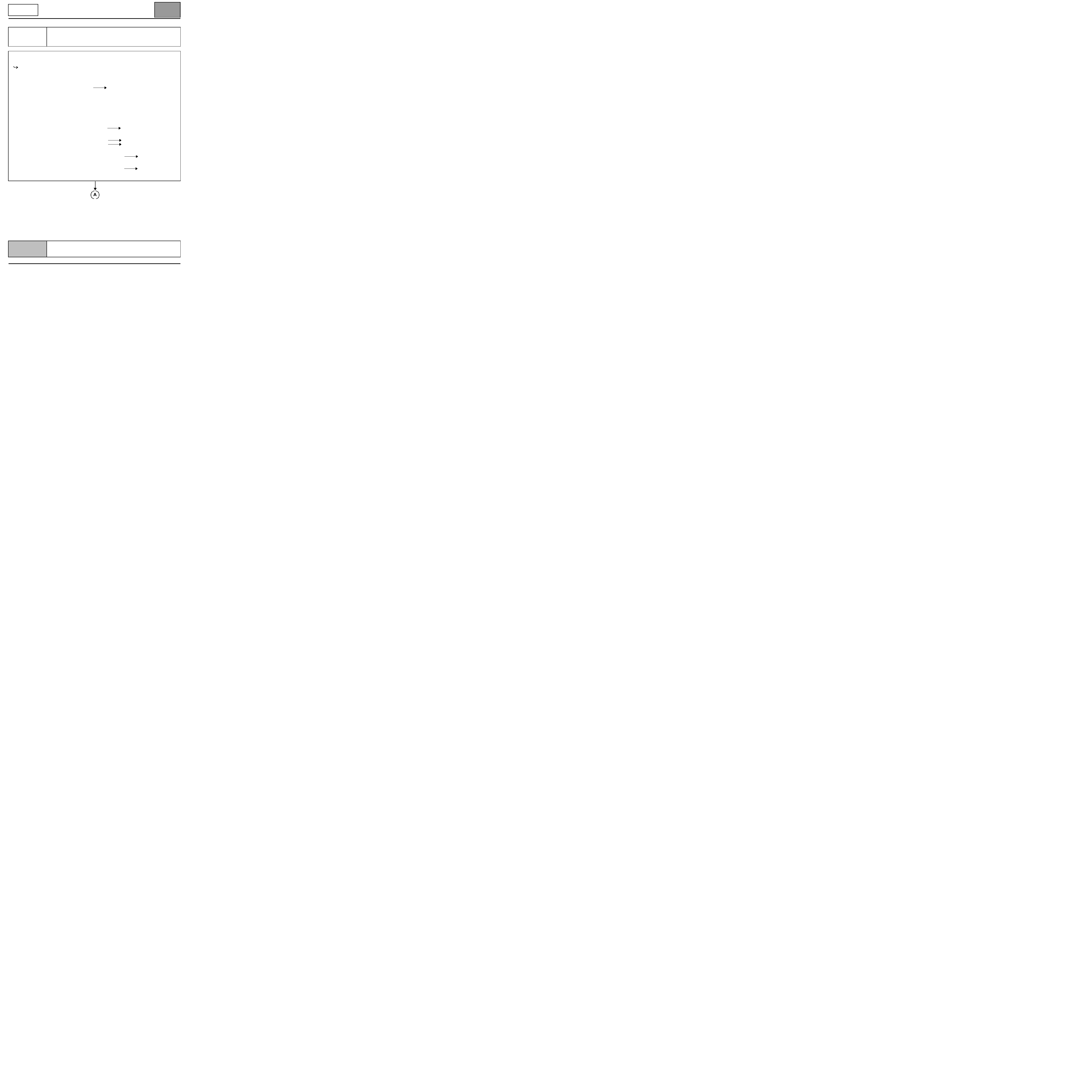

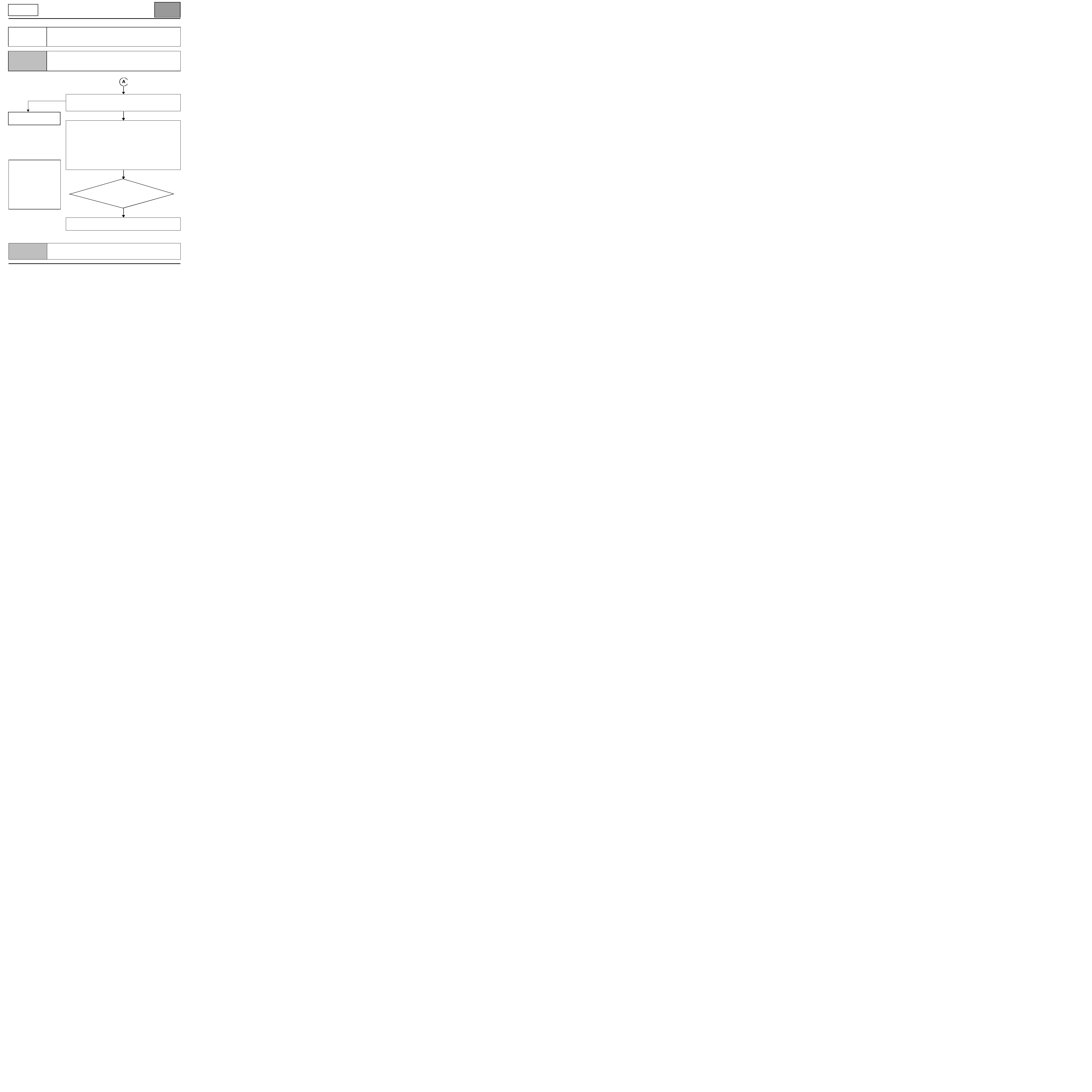

Customer complaints - Fault finding chart

If the diagnostic tool check is correct, but the customer complaint persists, it should be dealt with according to the

customer complaint.

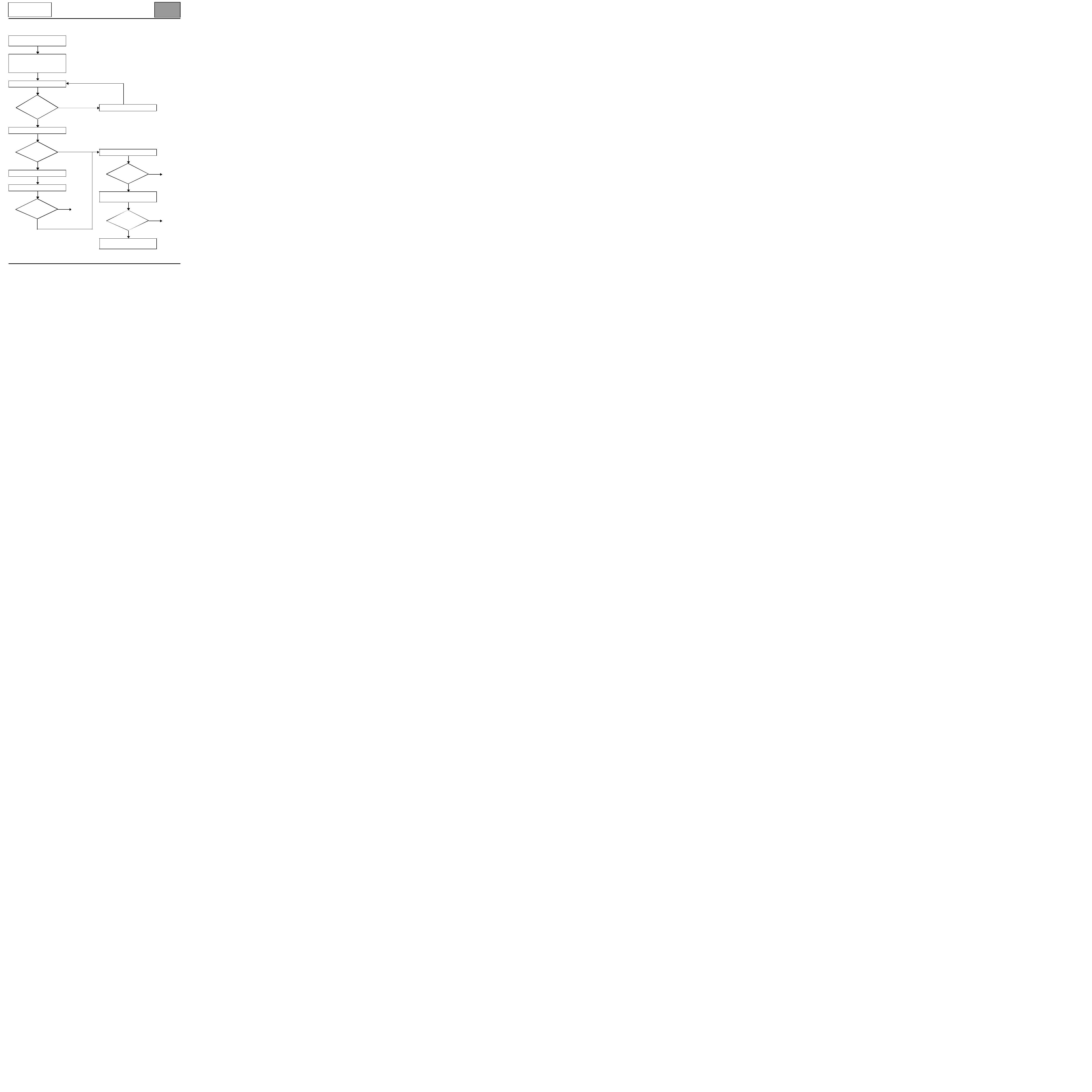

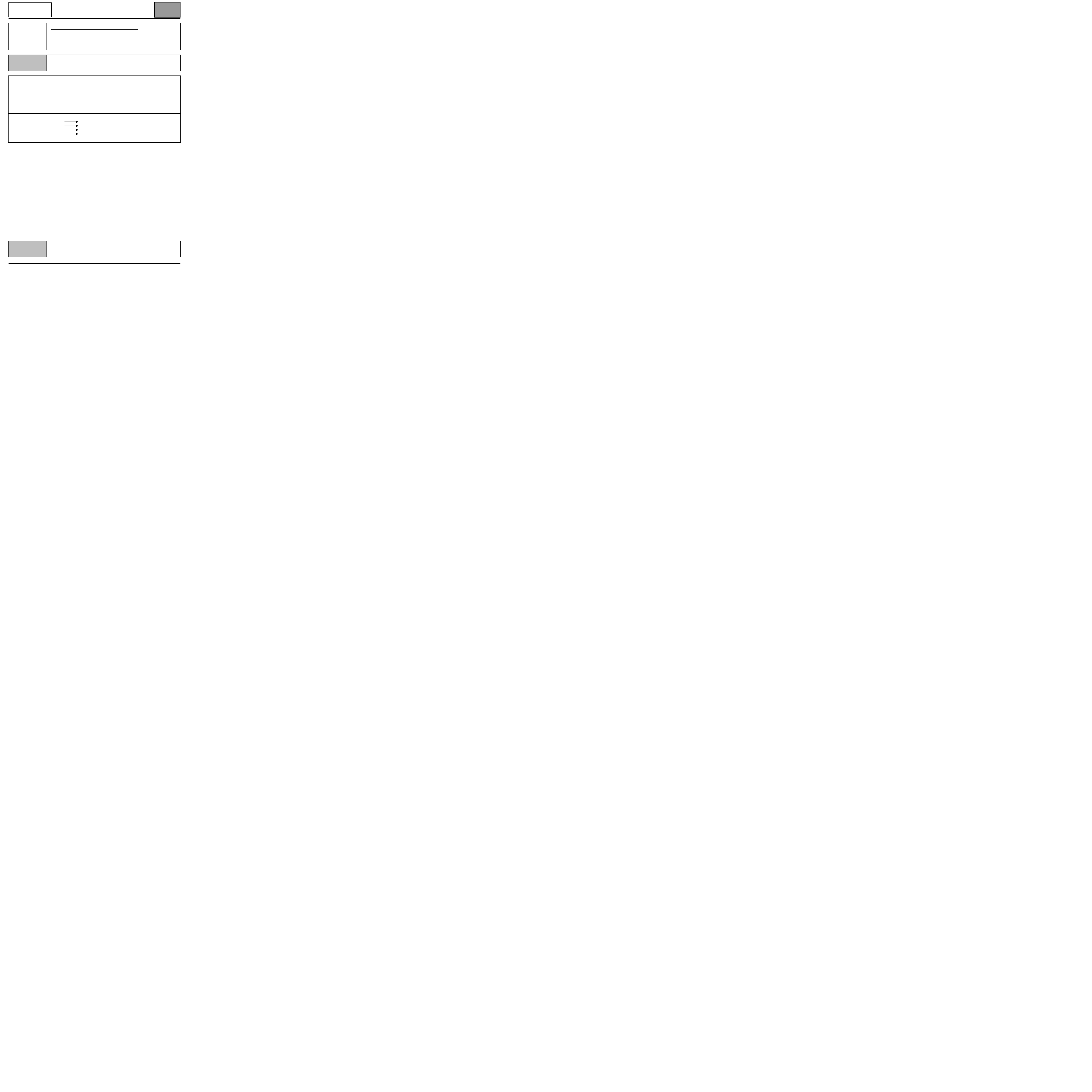

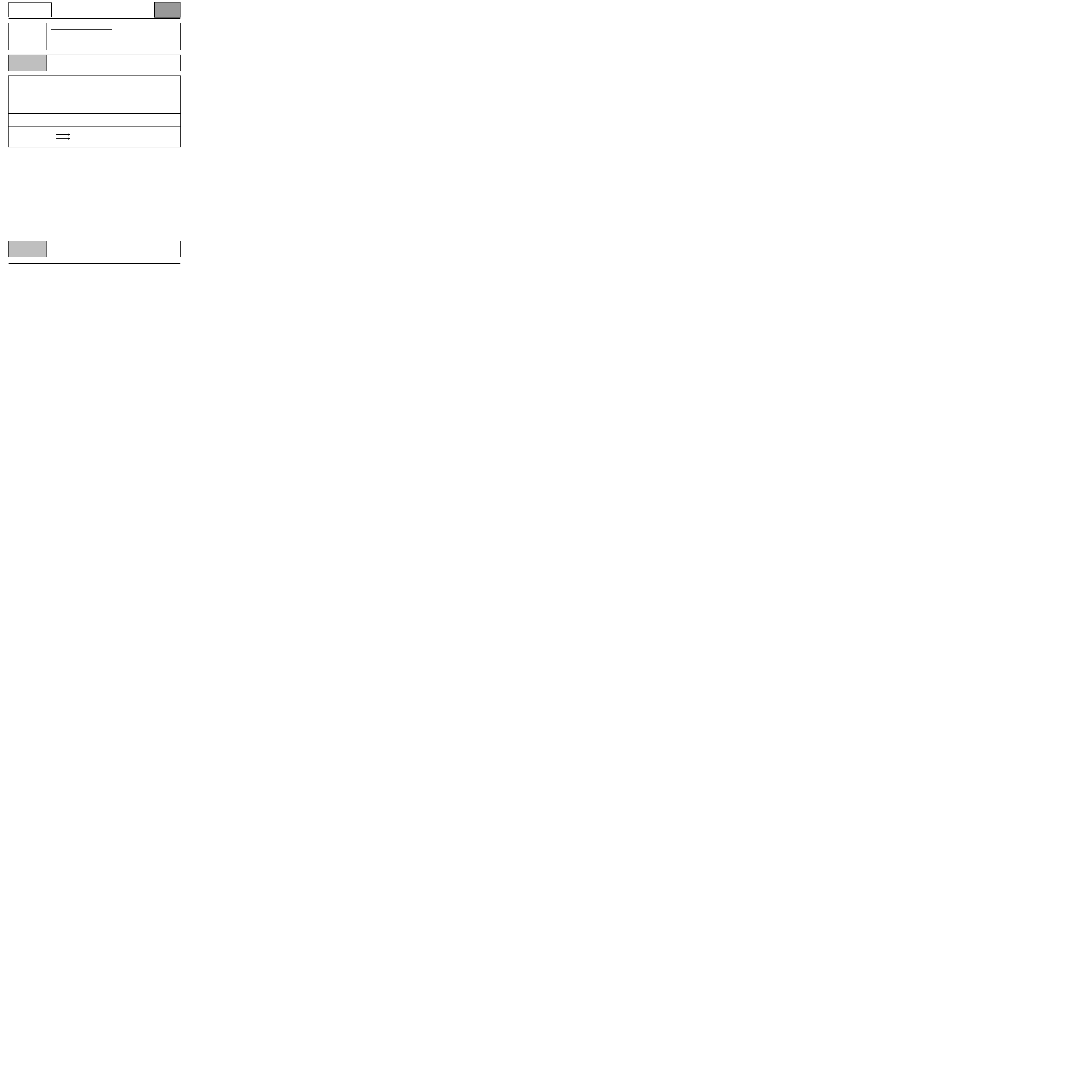

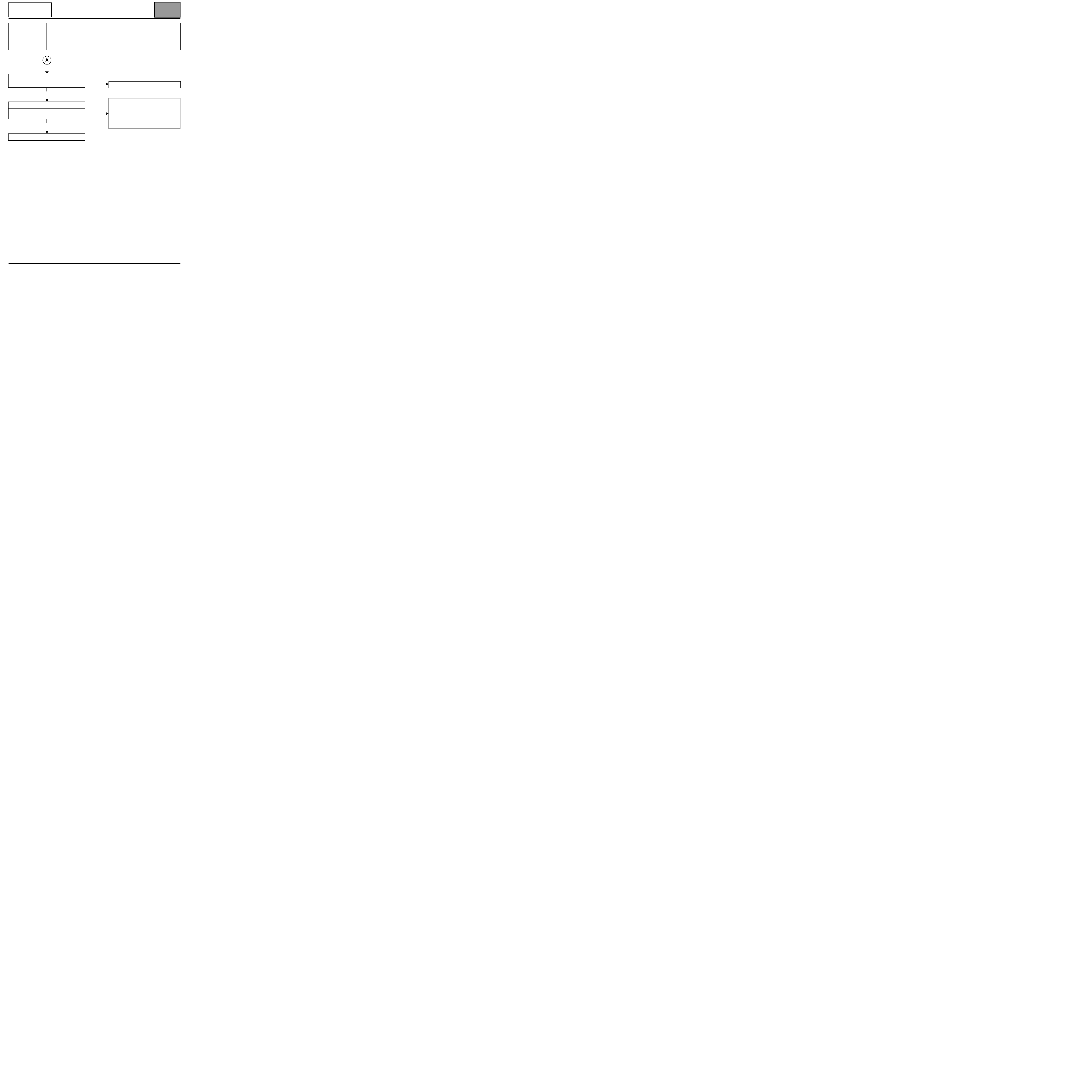

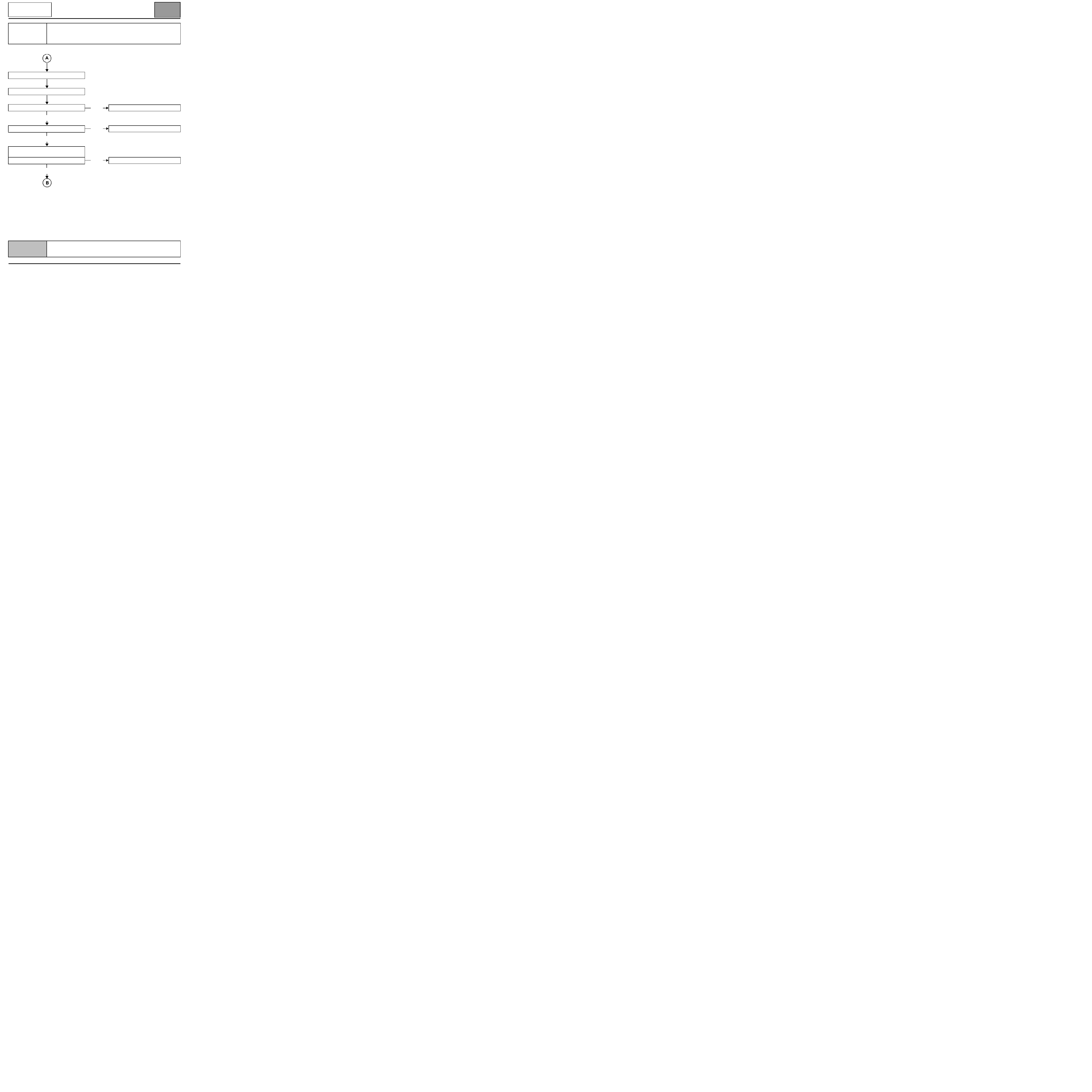

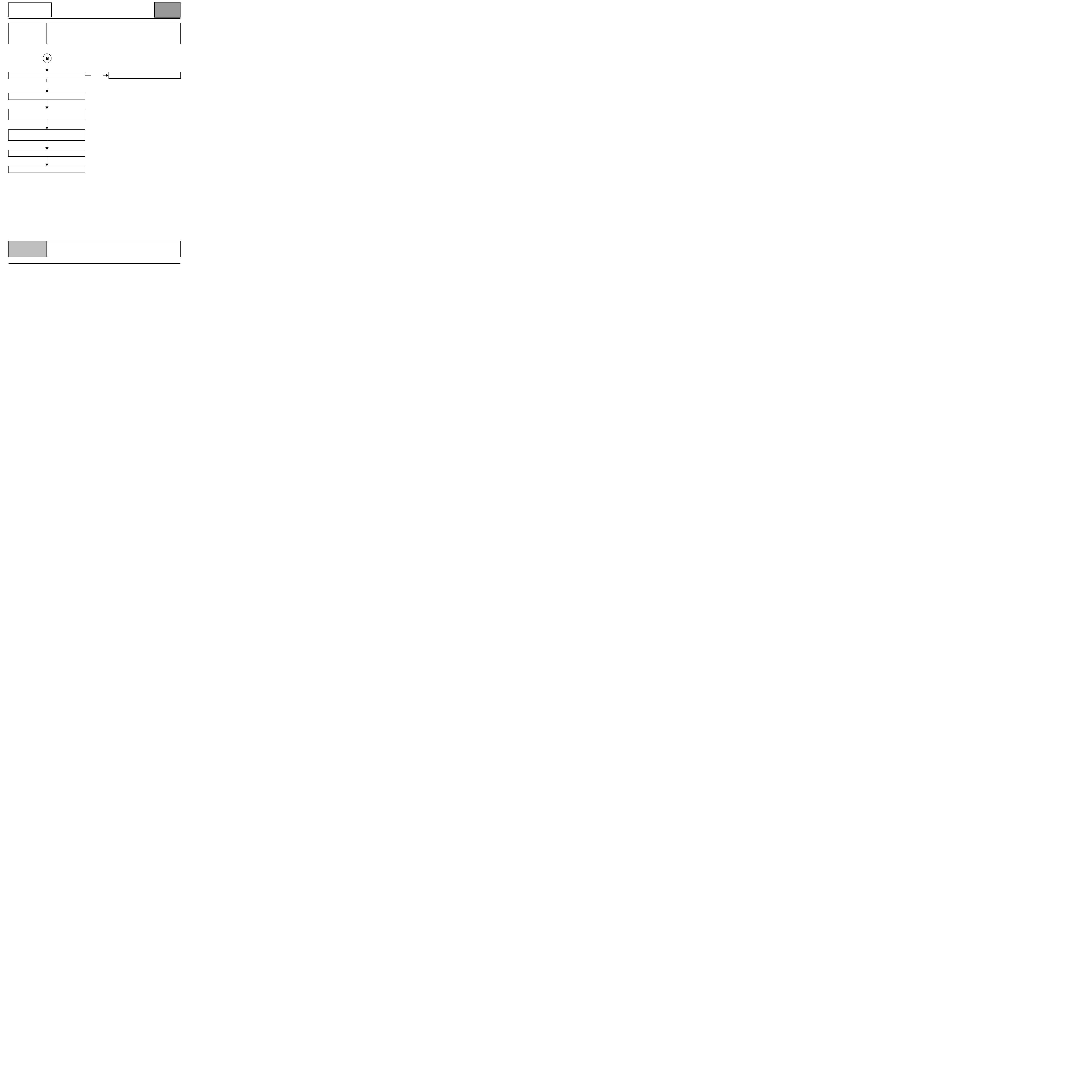

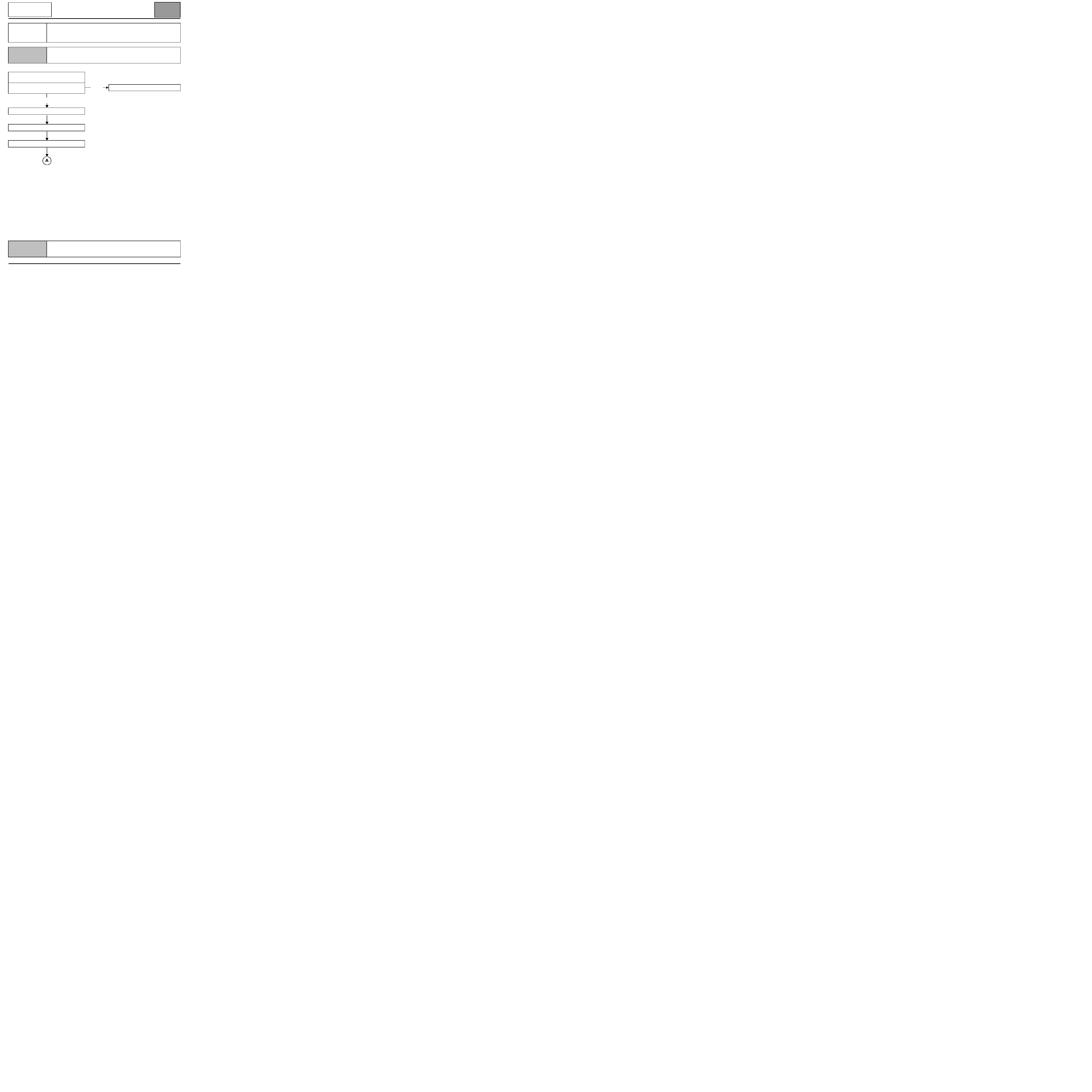

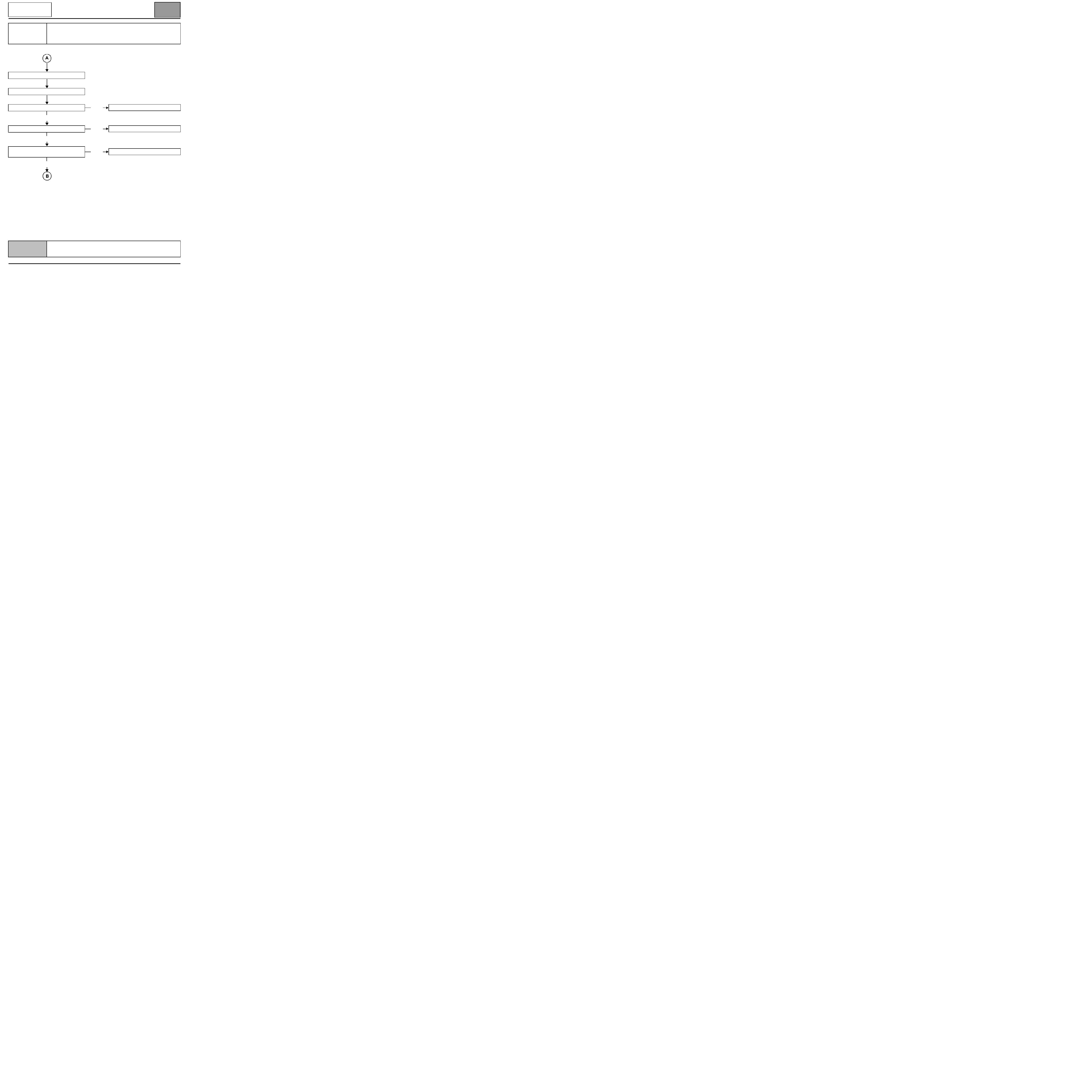

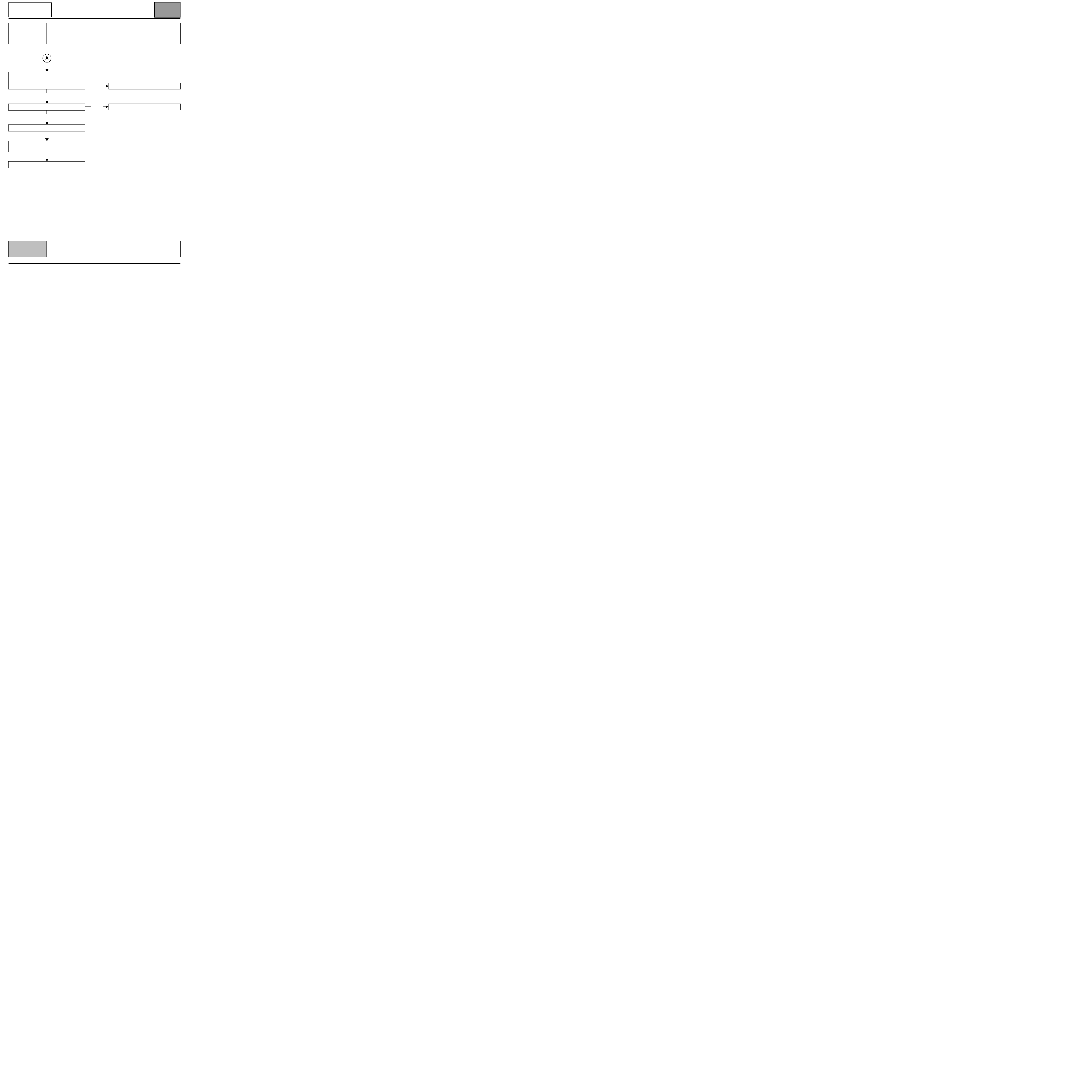

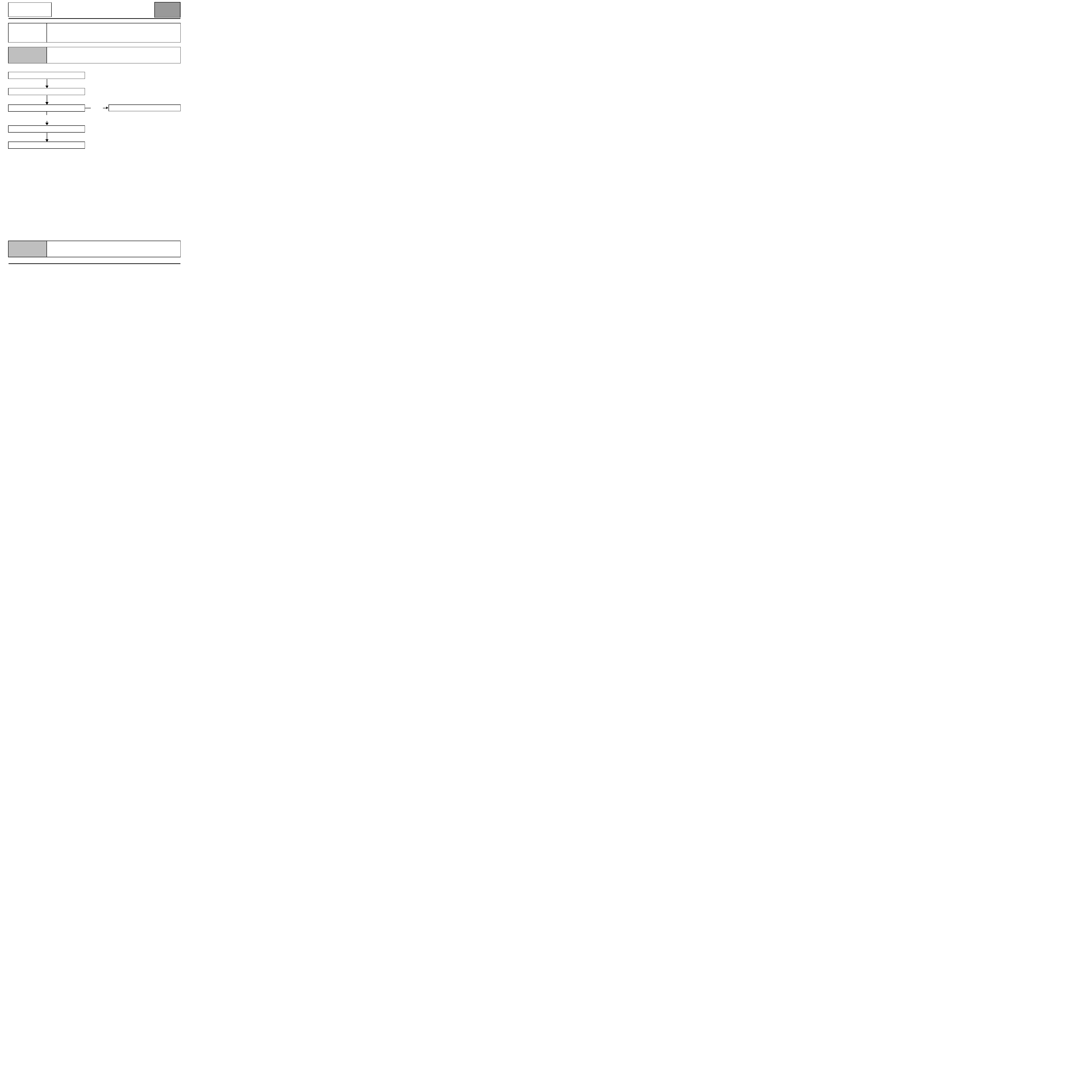

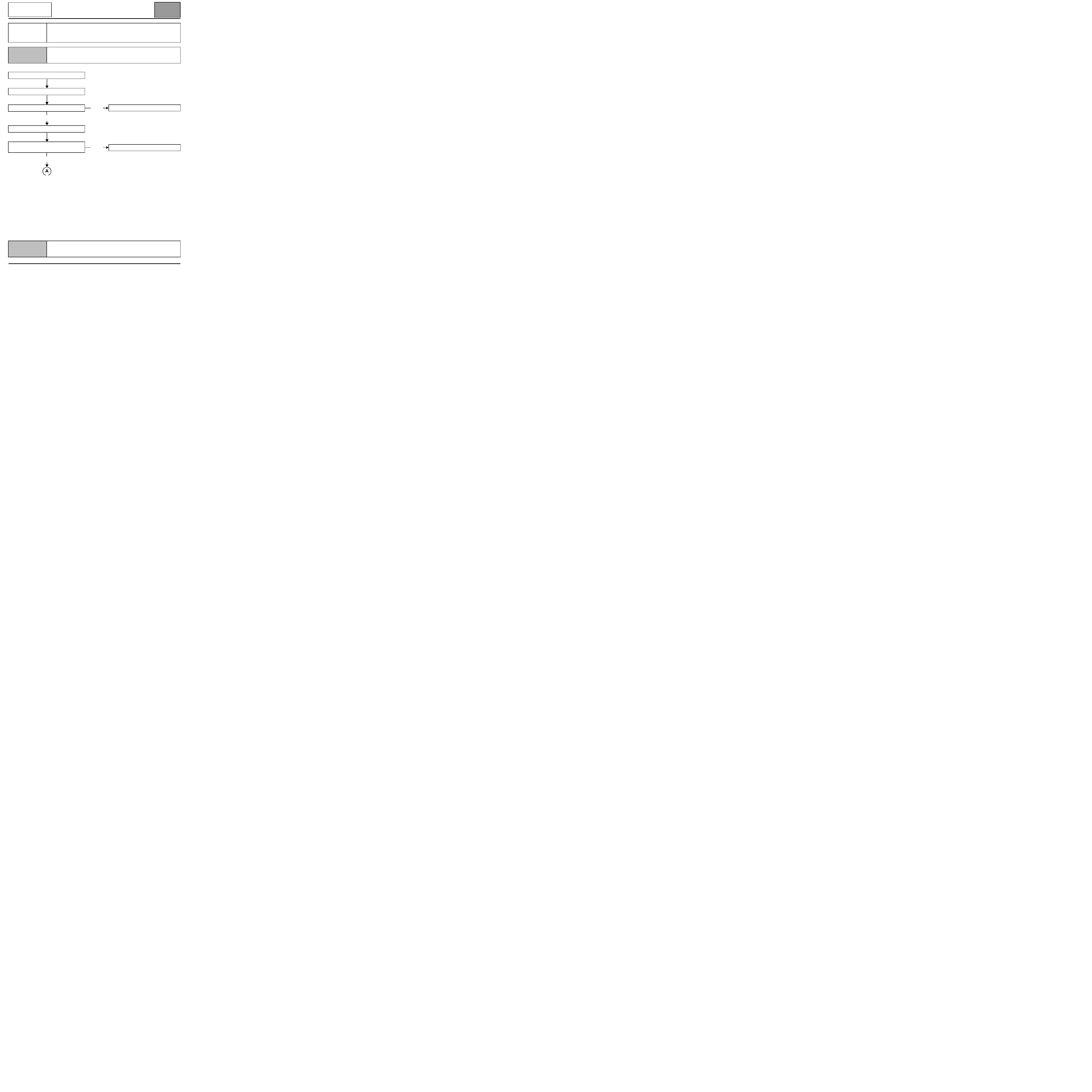

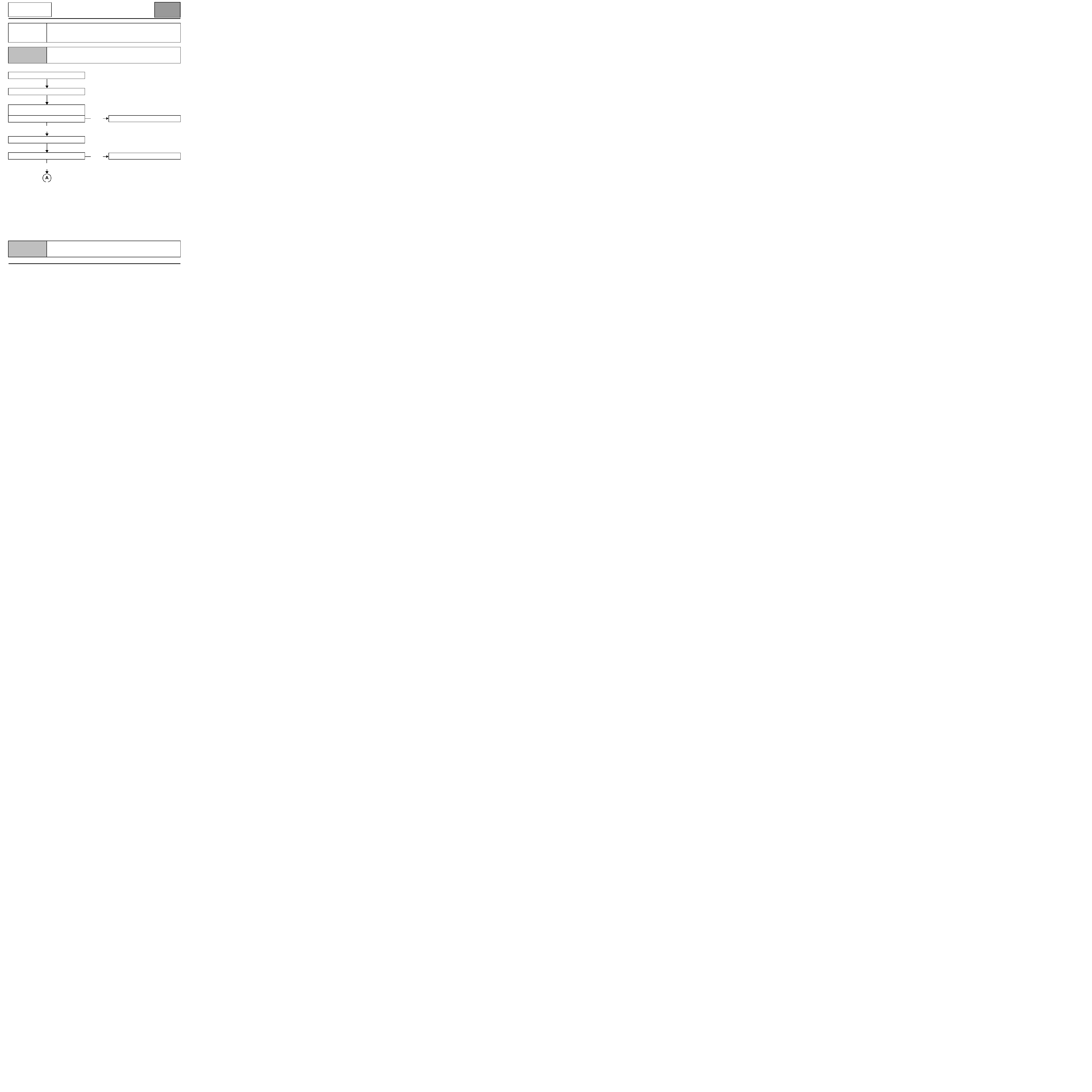

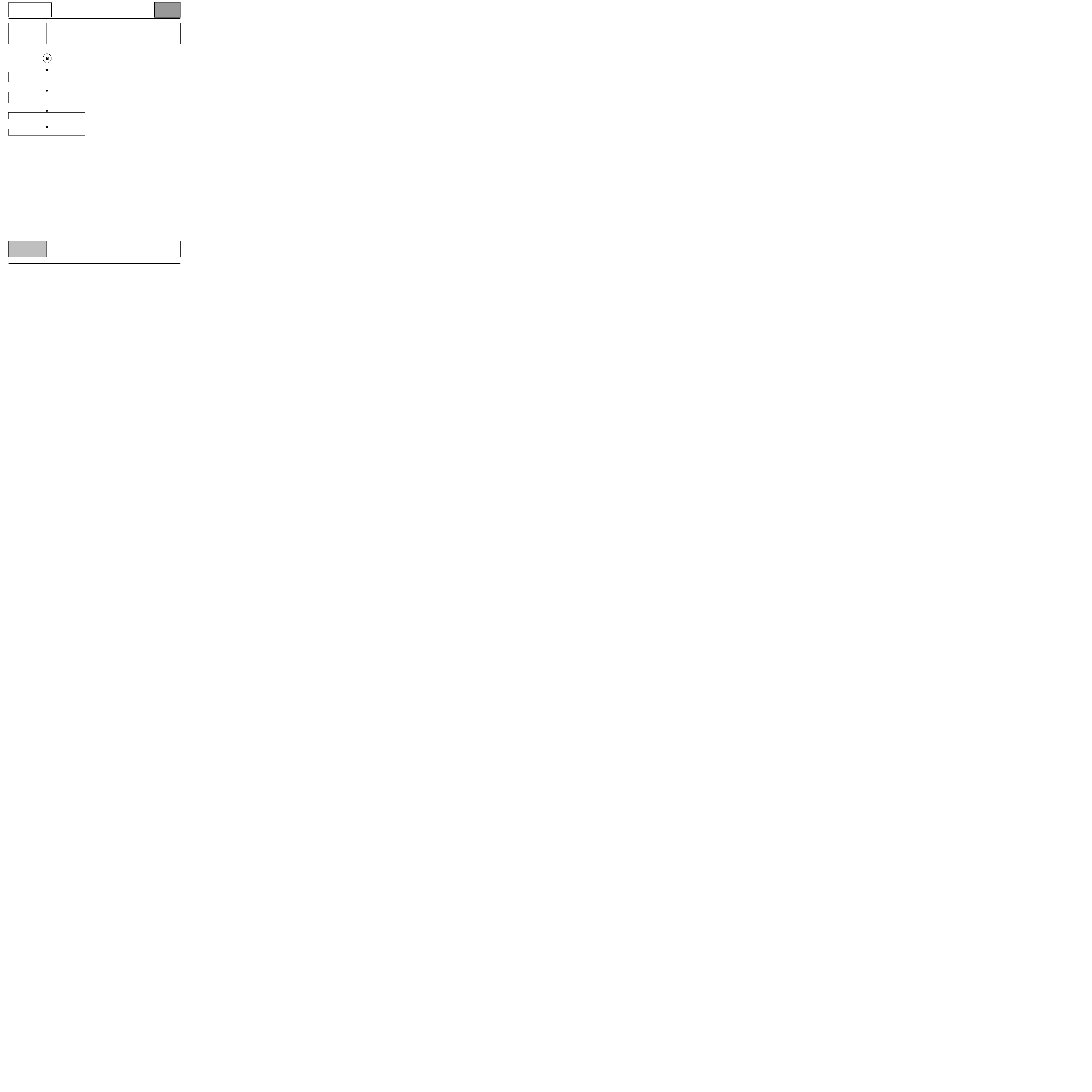

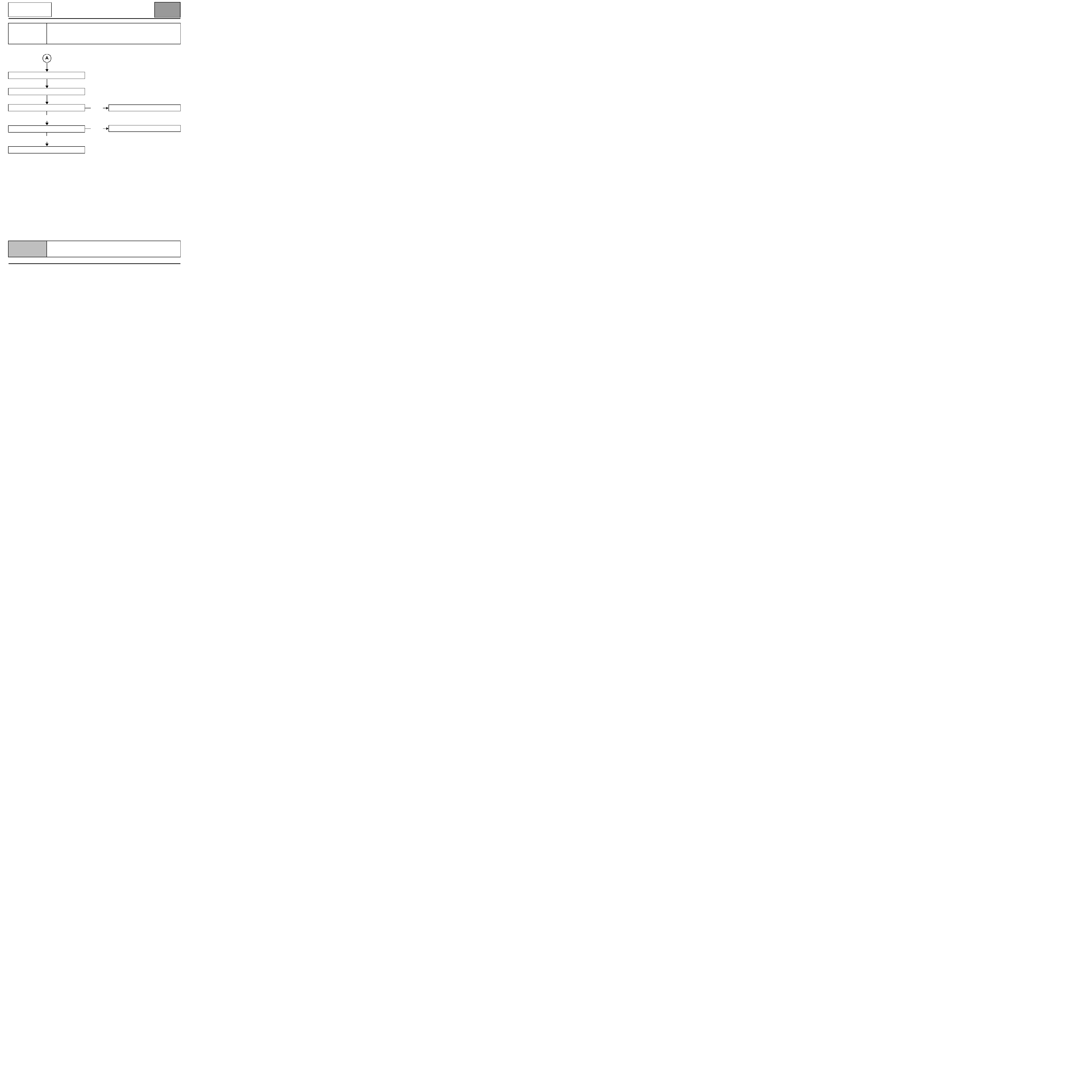

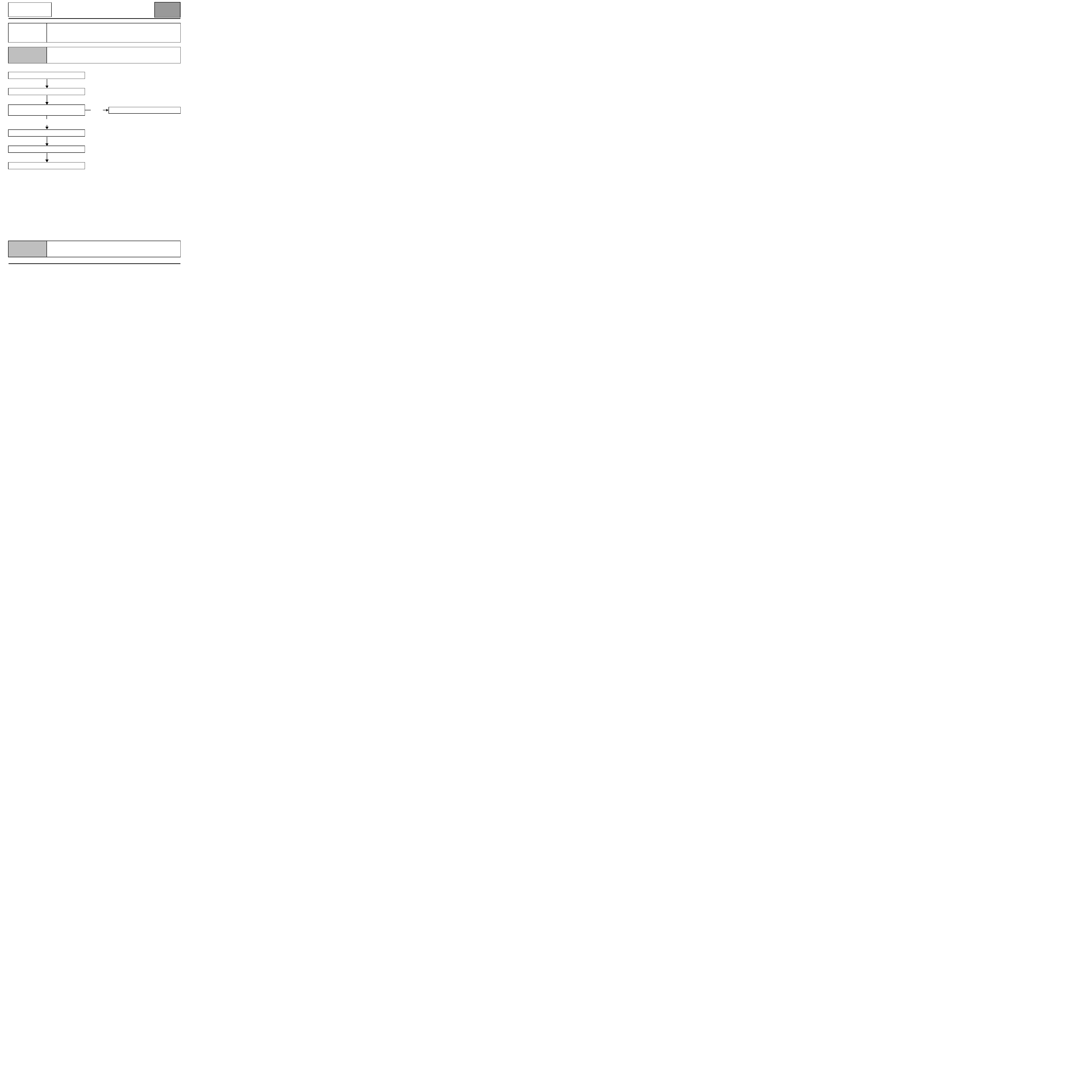

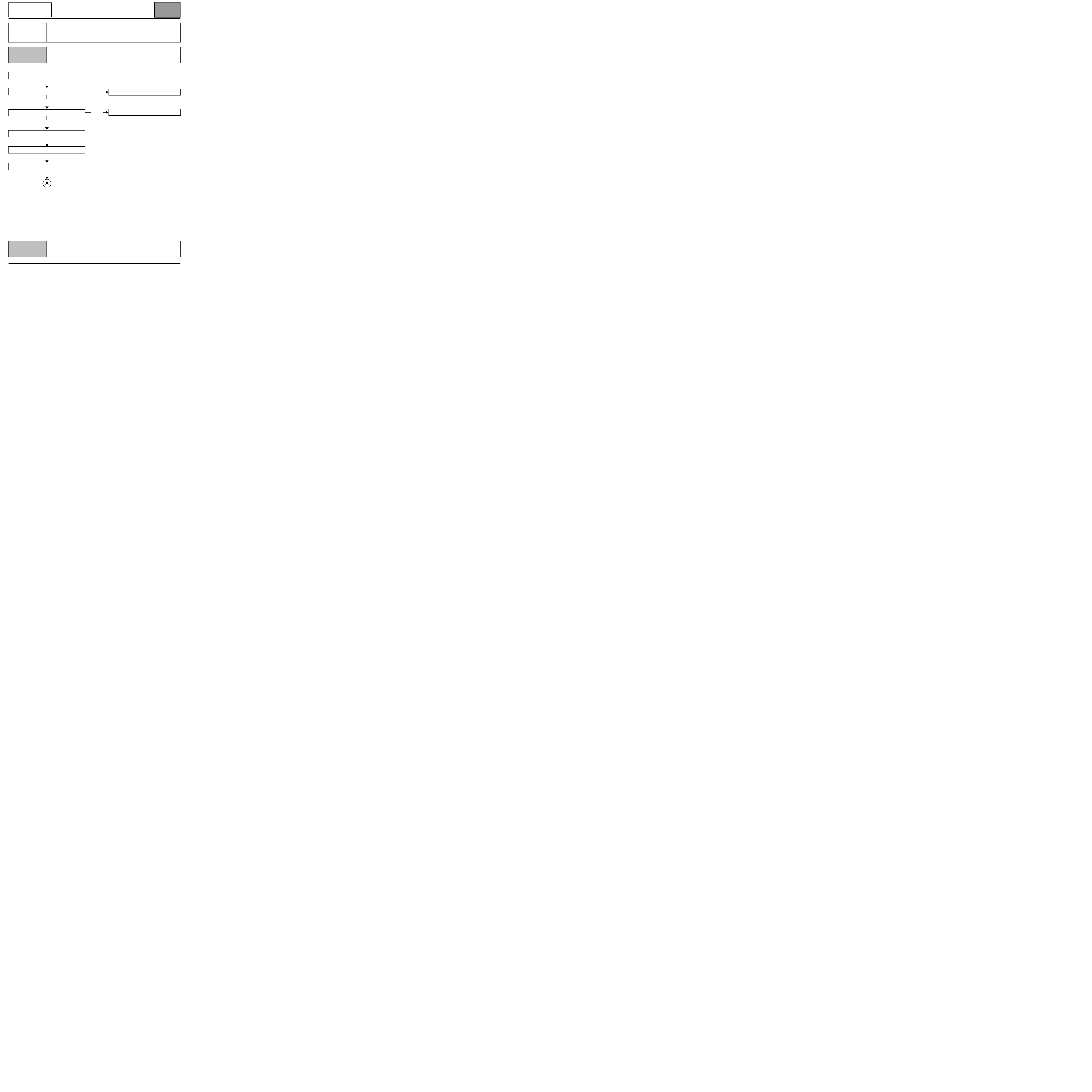

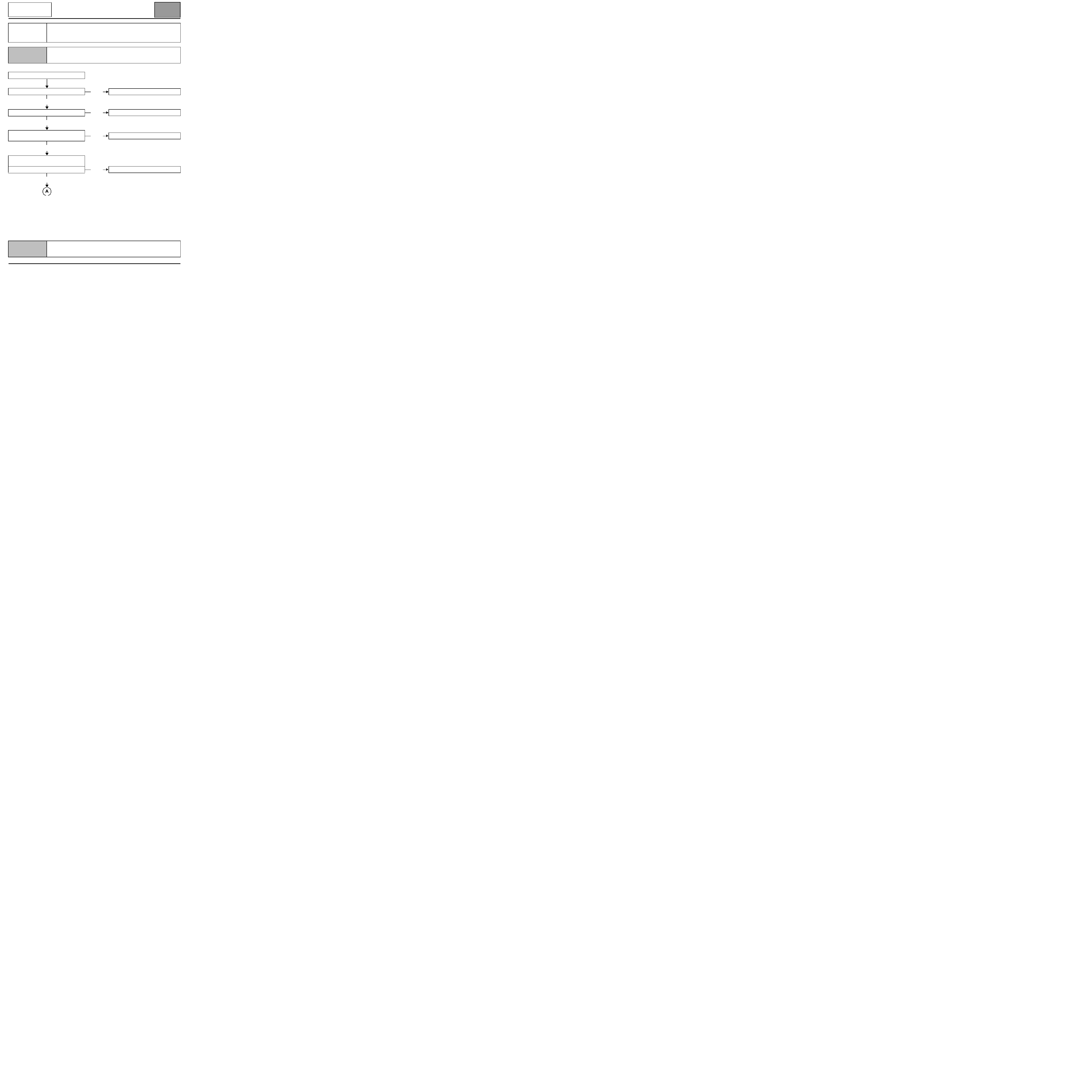

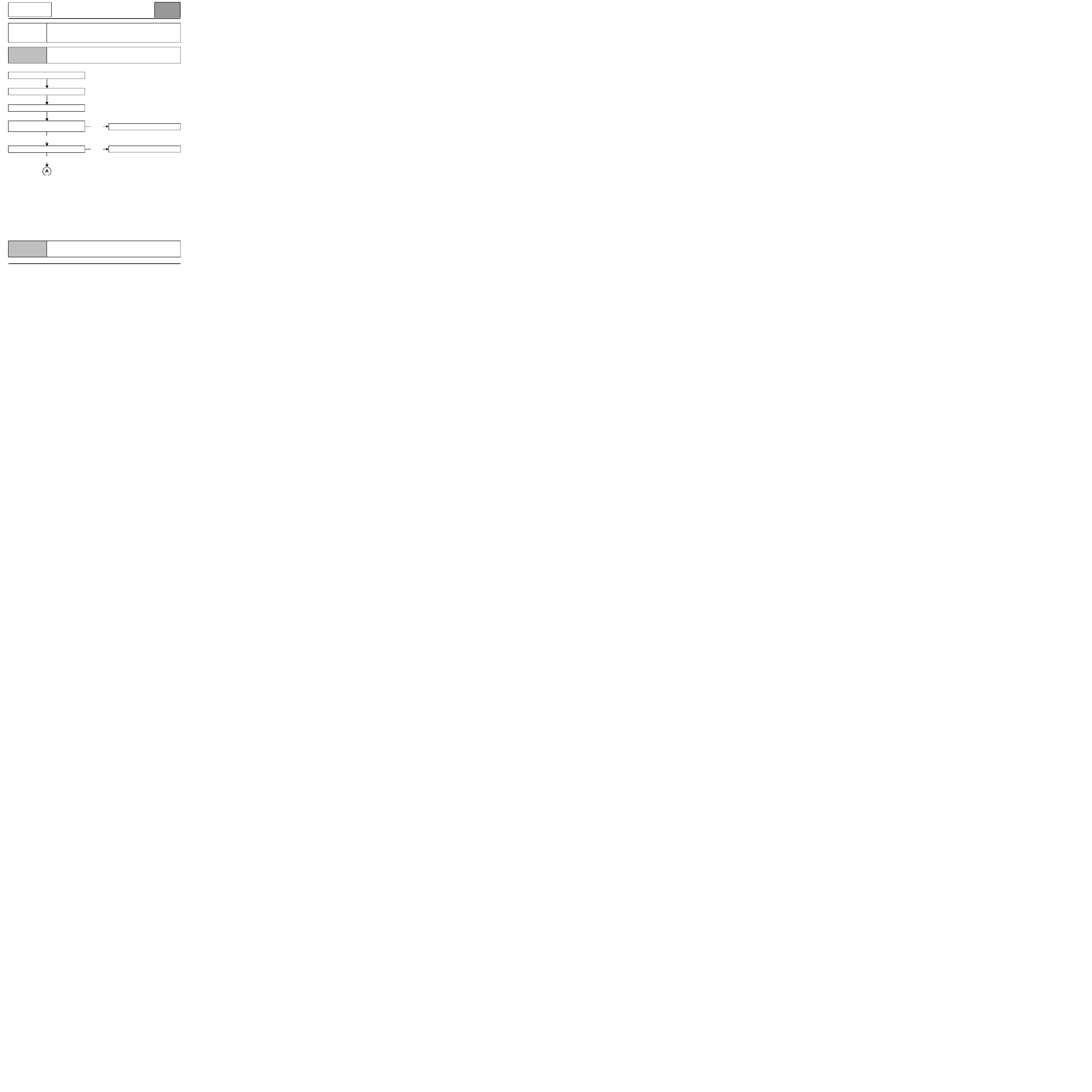

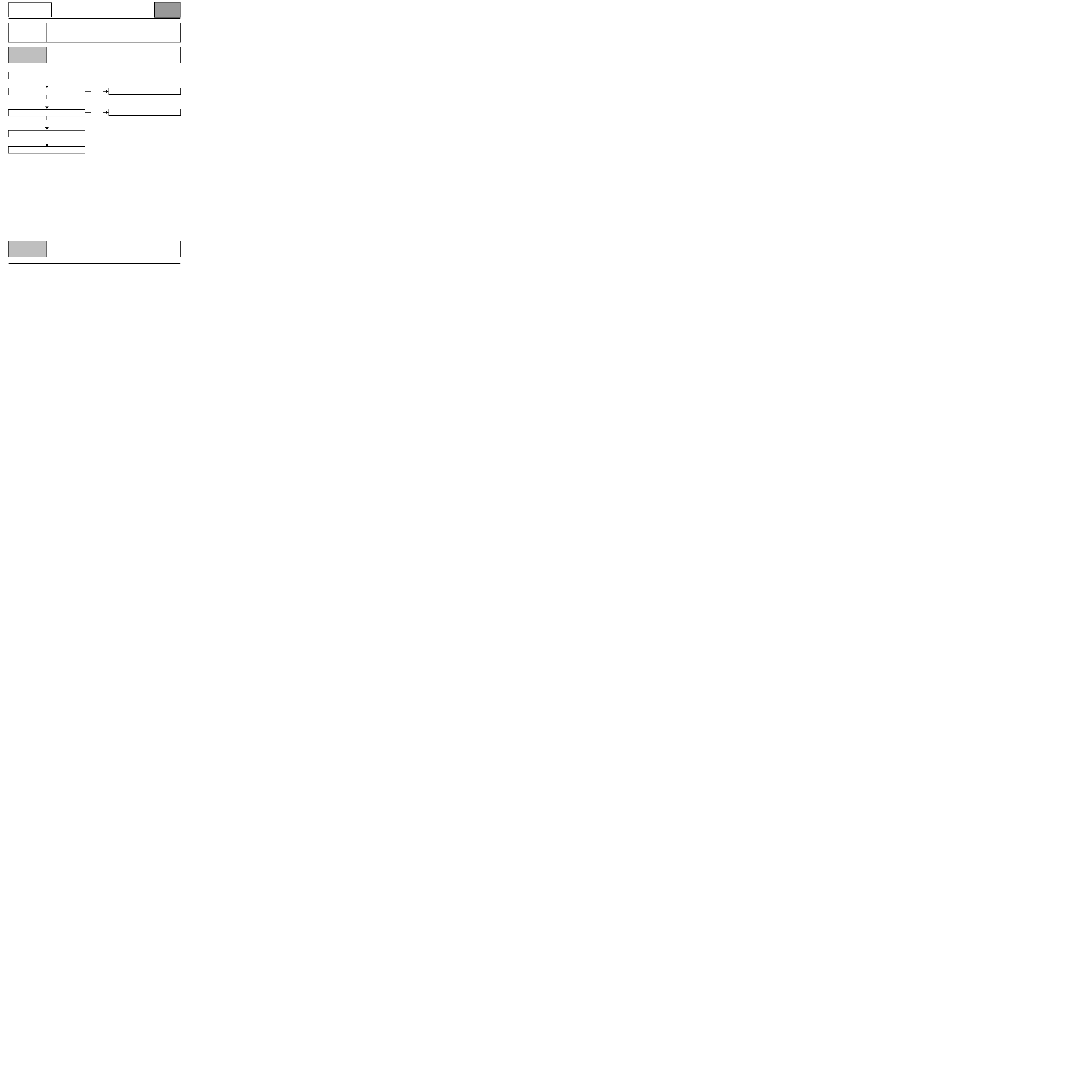

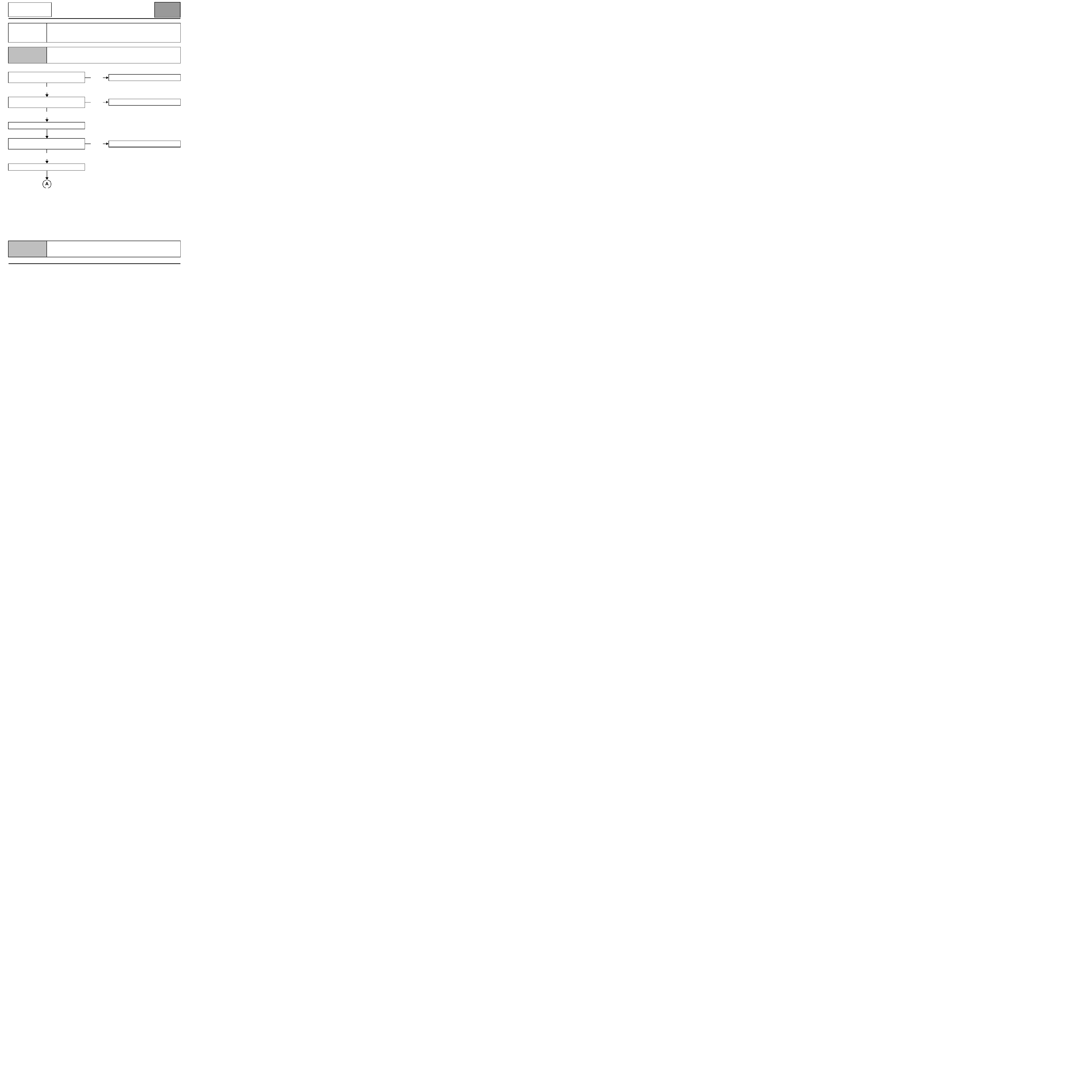

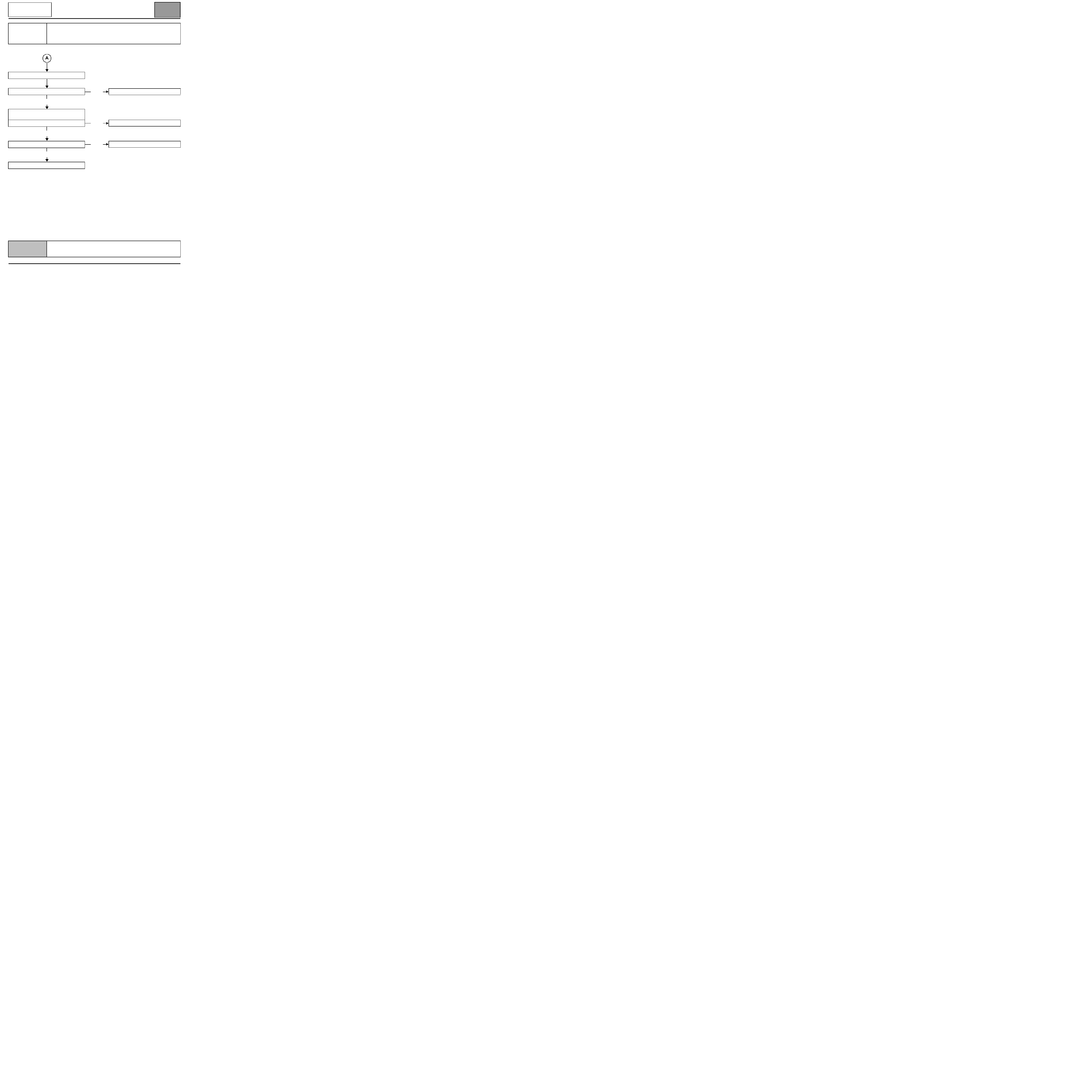

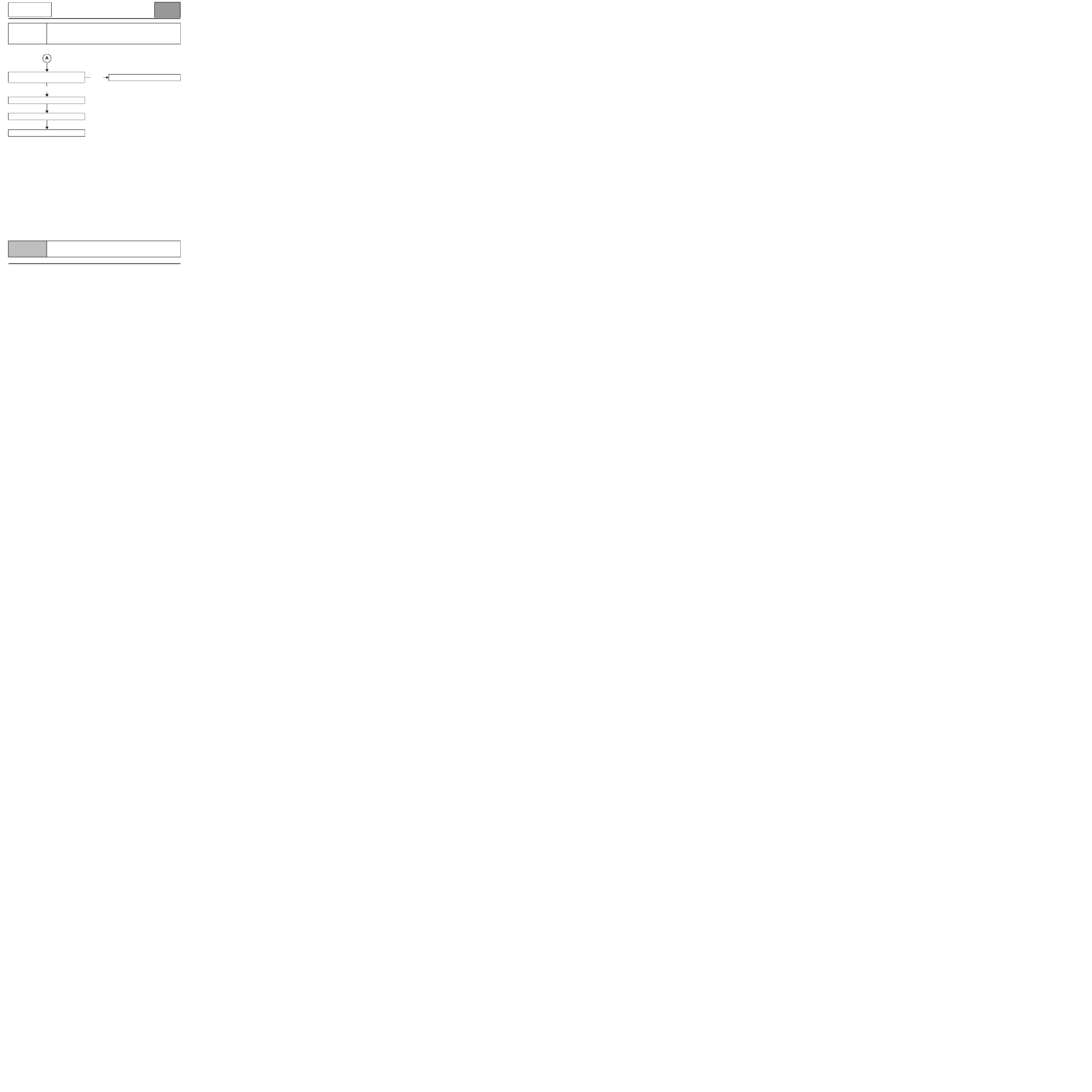

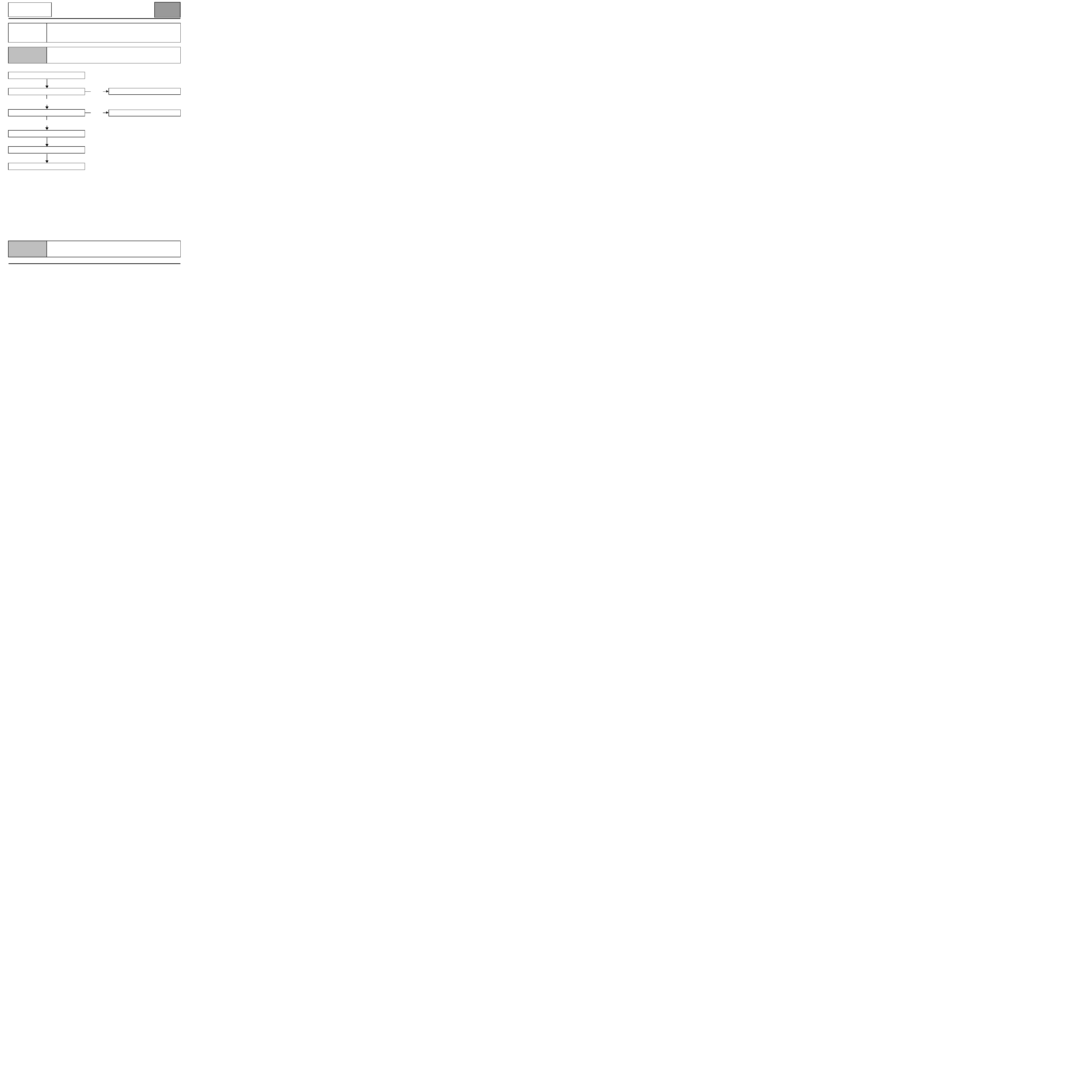

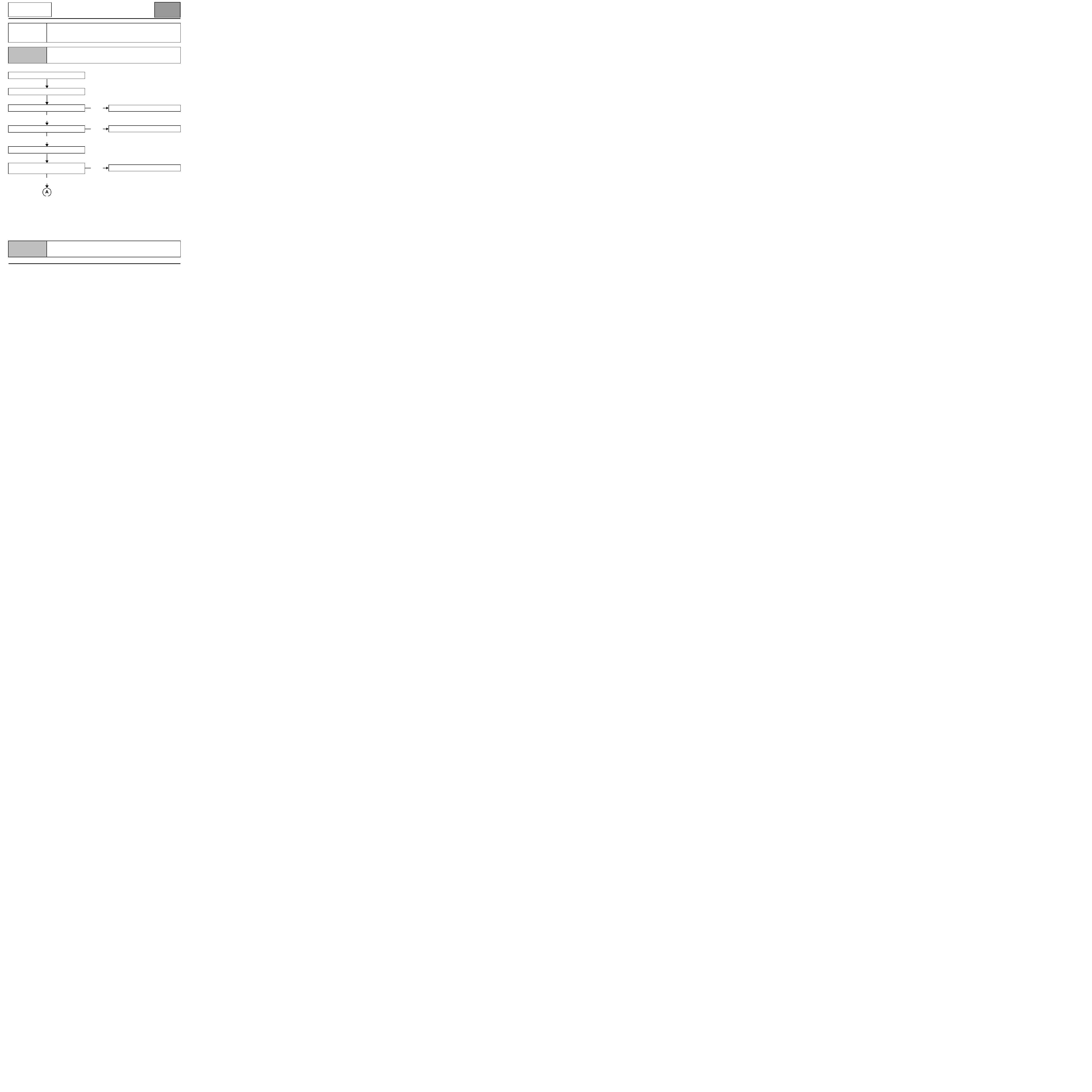

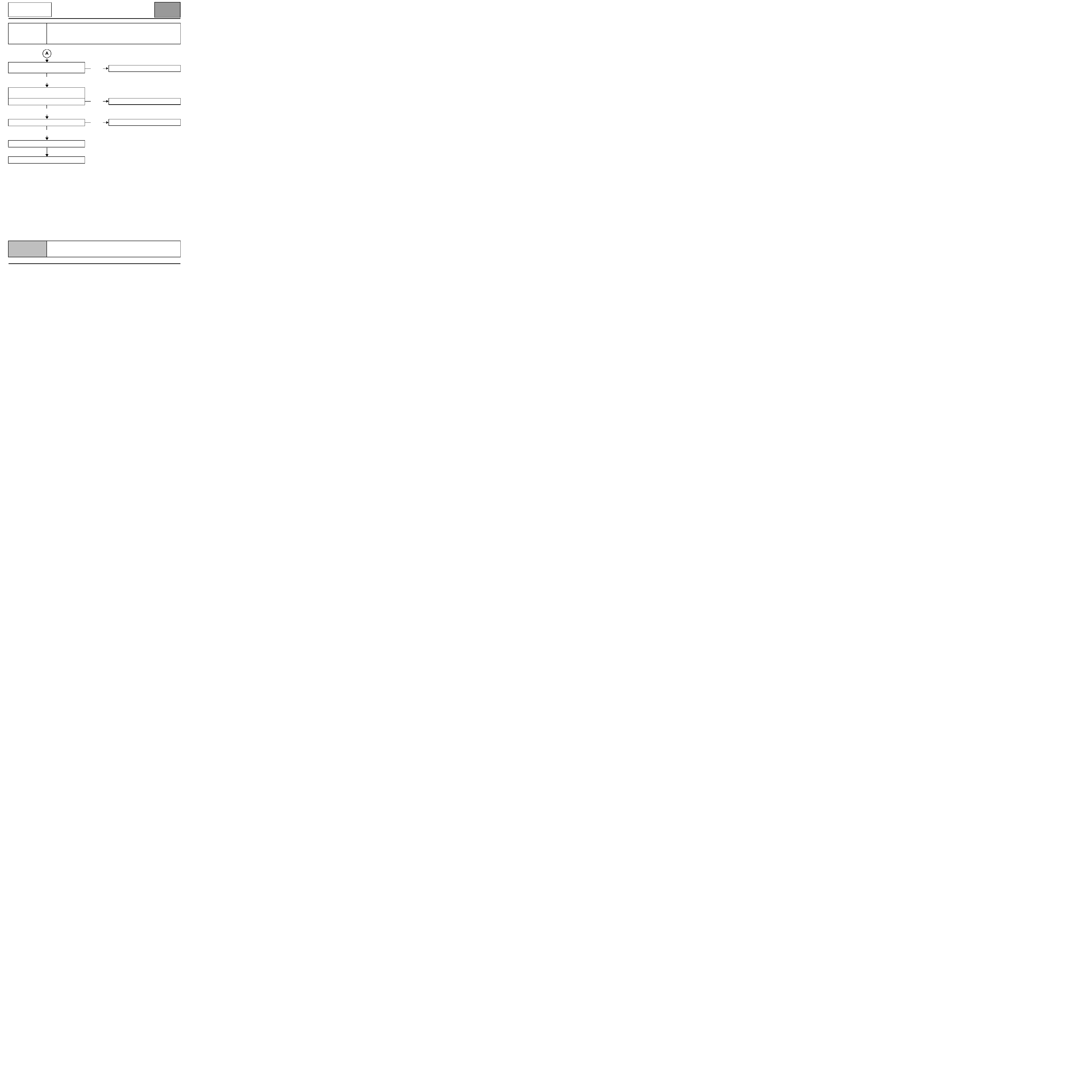

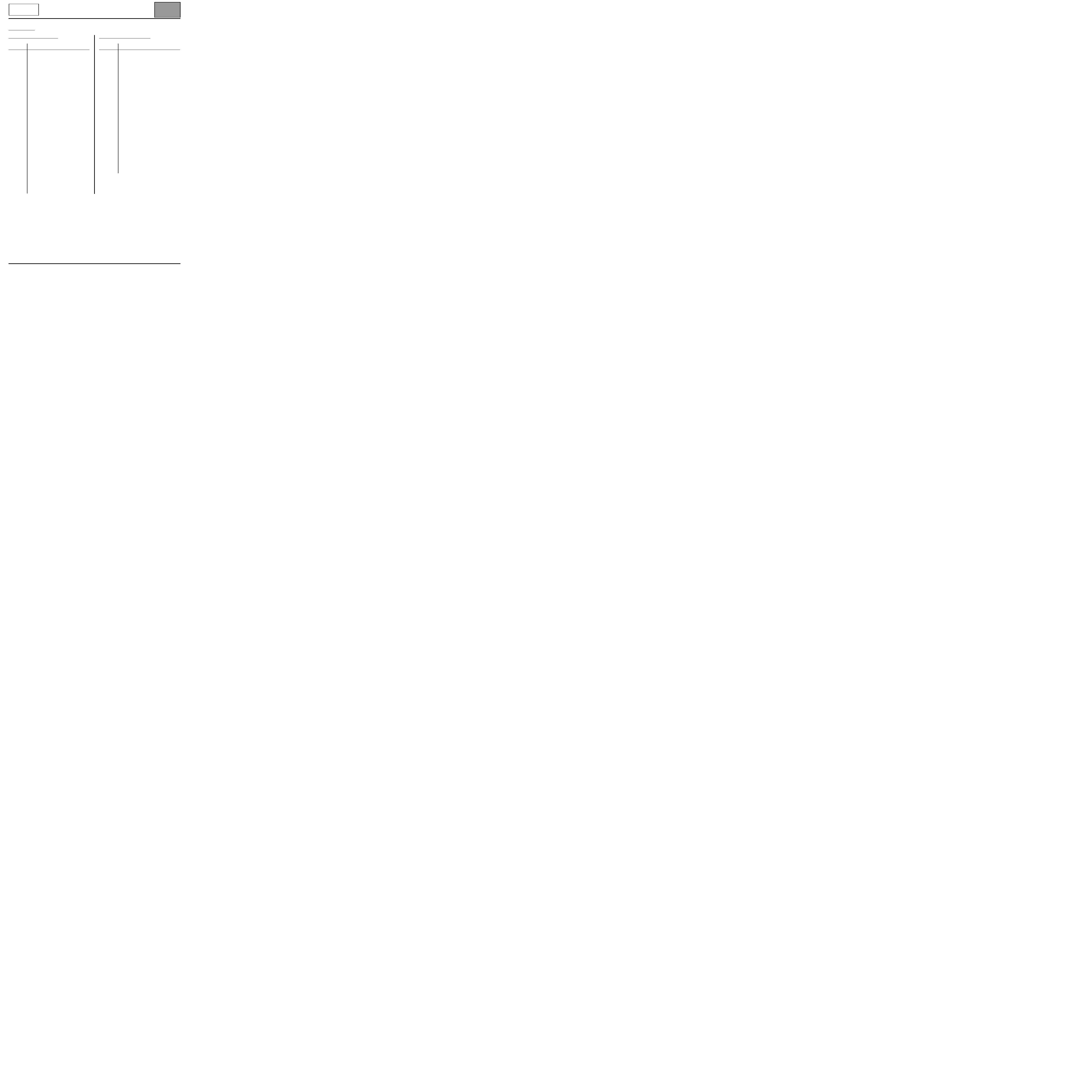

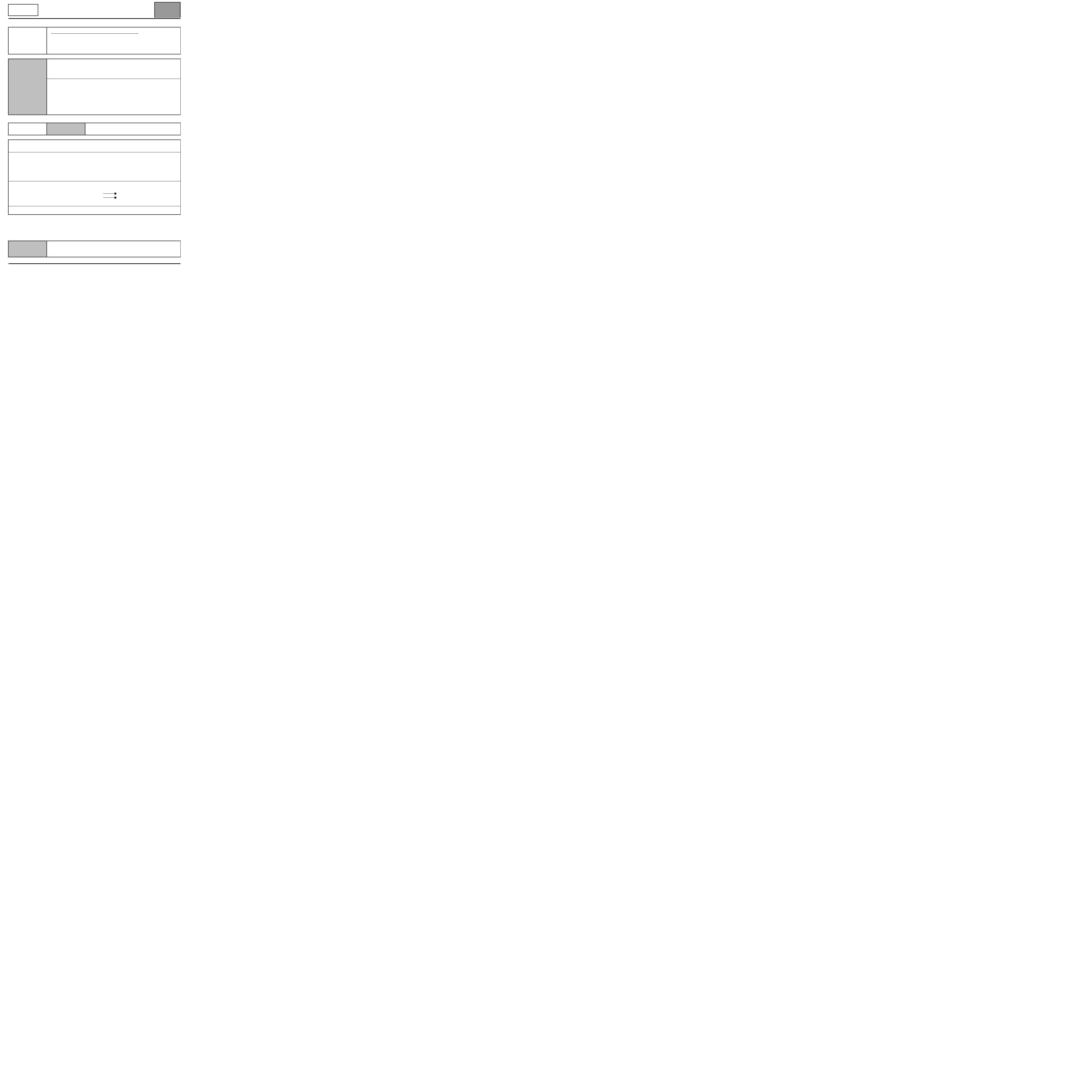

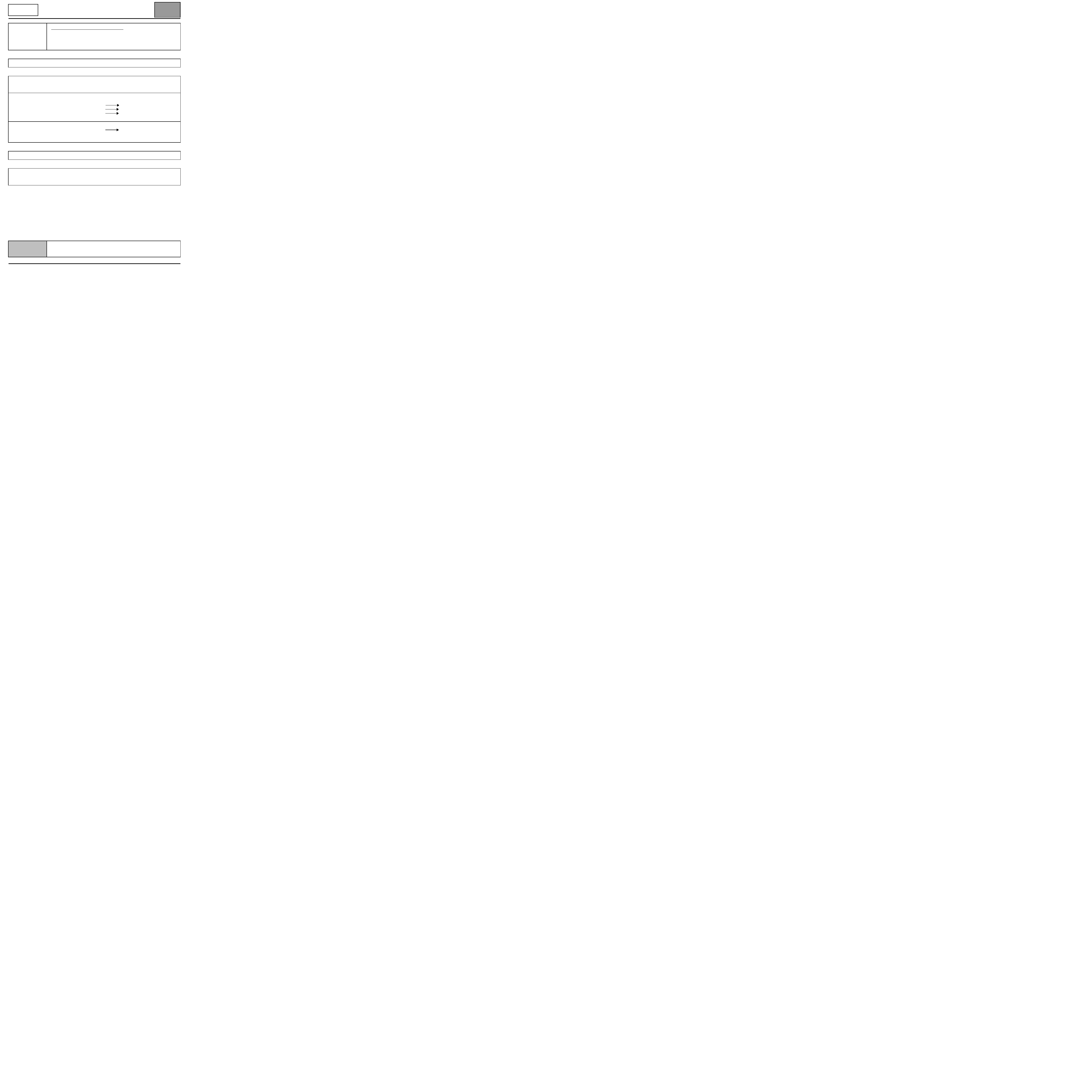

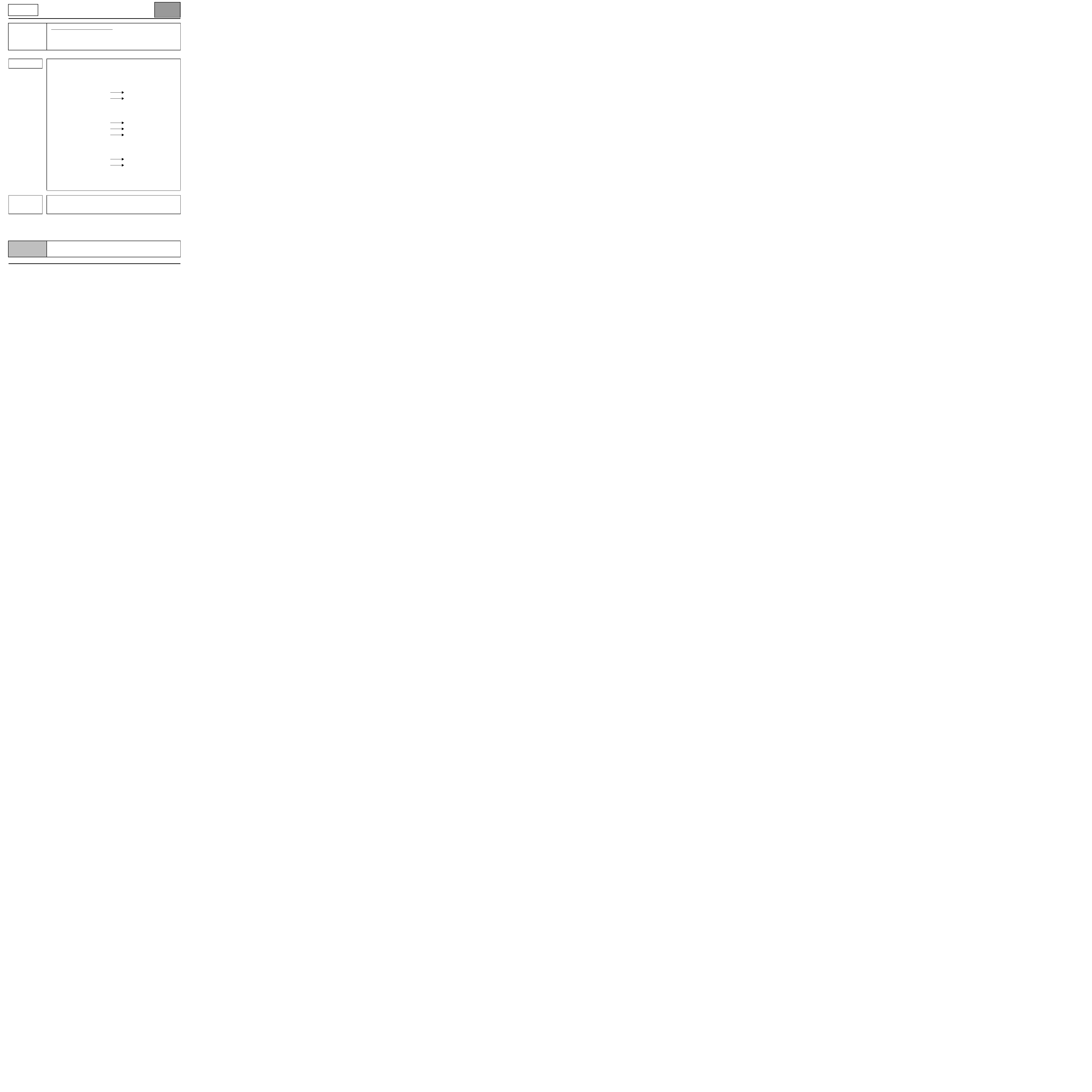

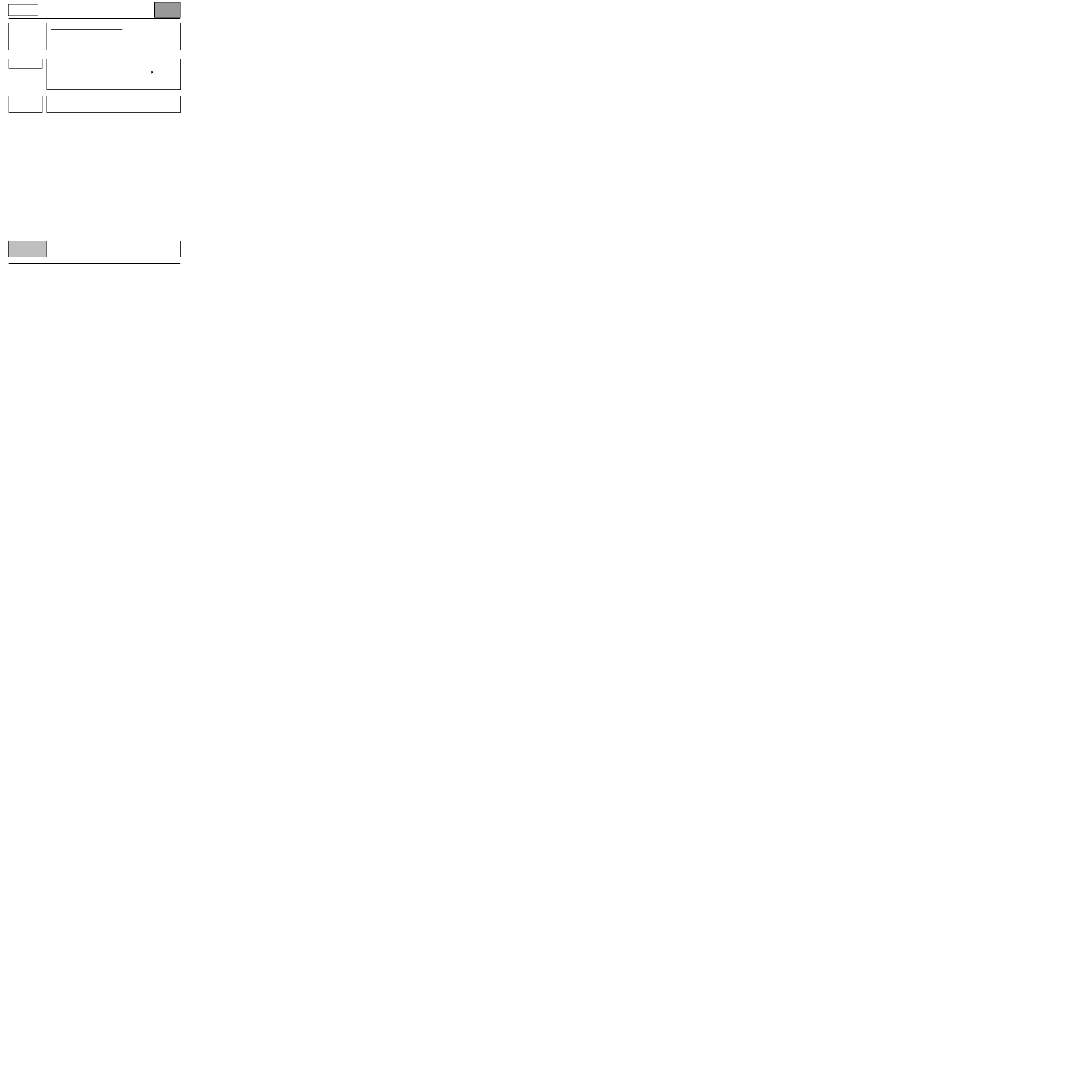

A synopsis of the general procedure to follow is provided on the following page in the form of a flow

chart.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Introduction

13B

13B-4

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

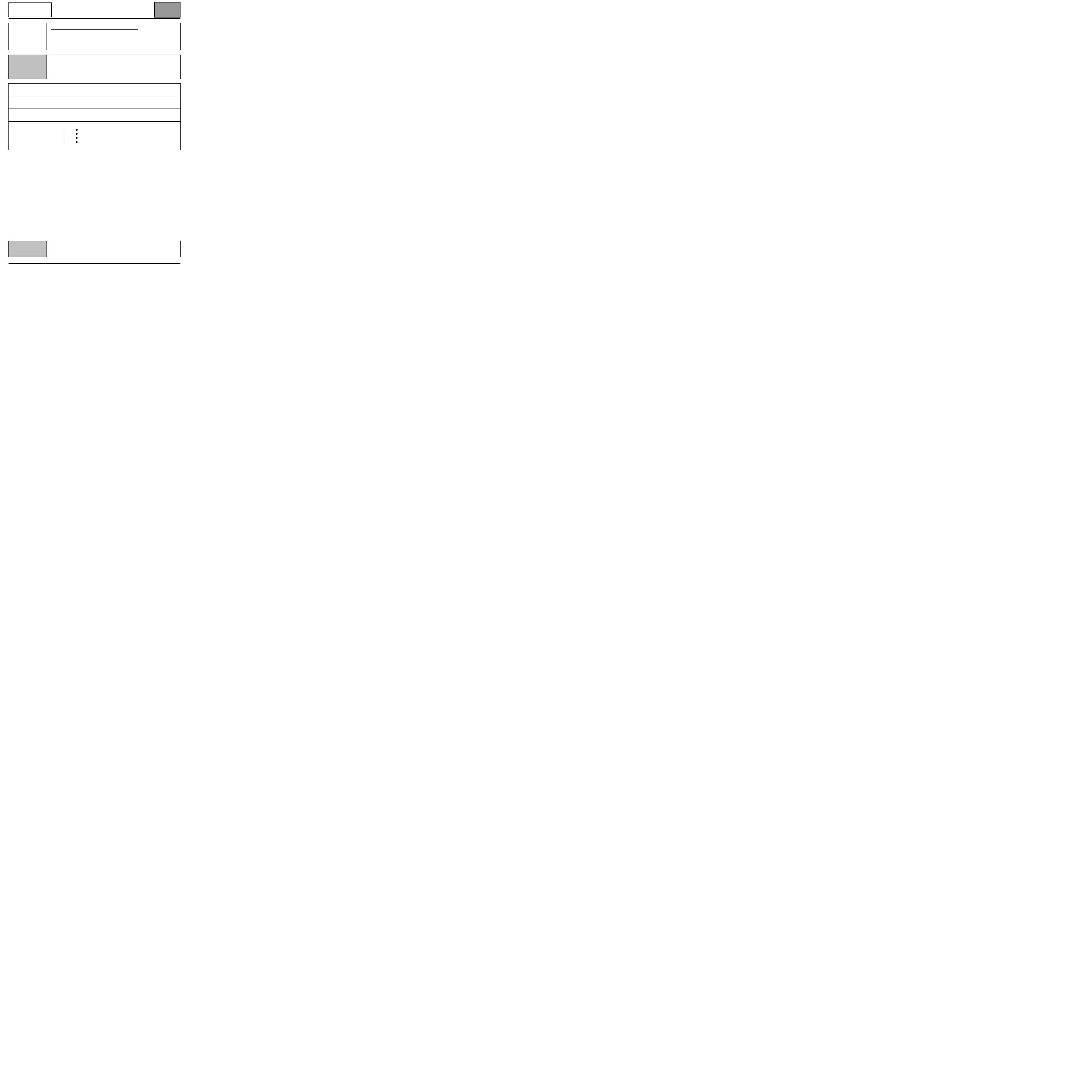

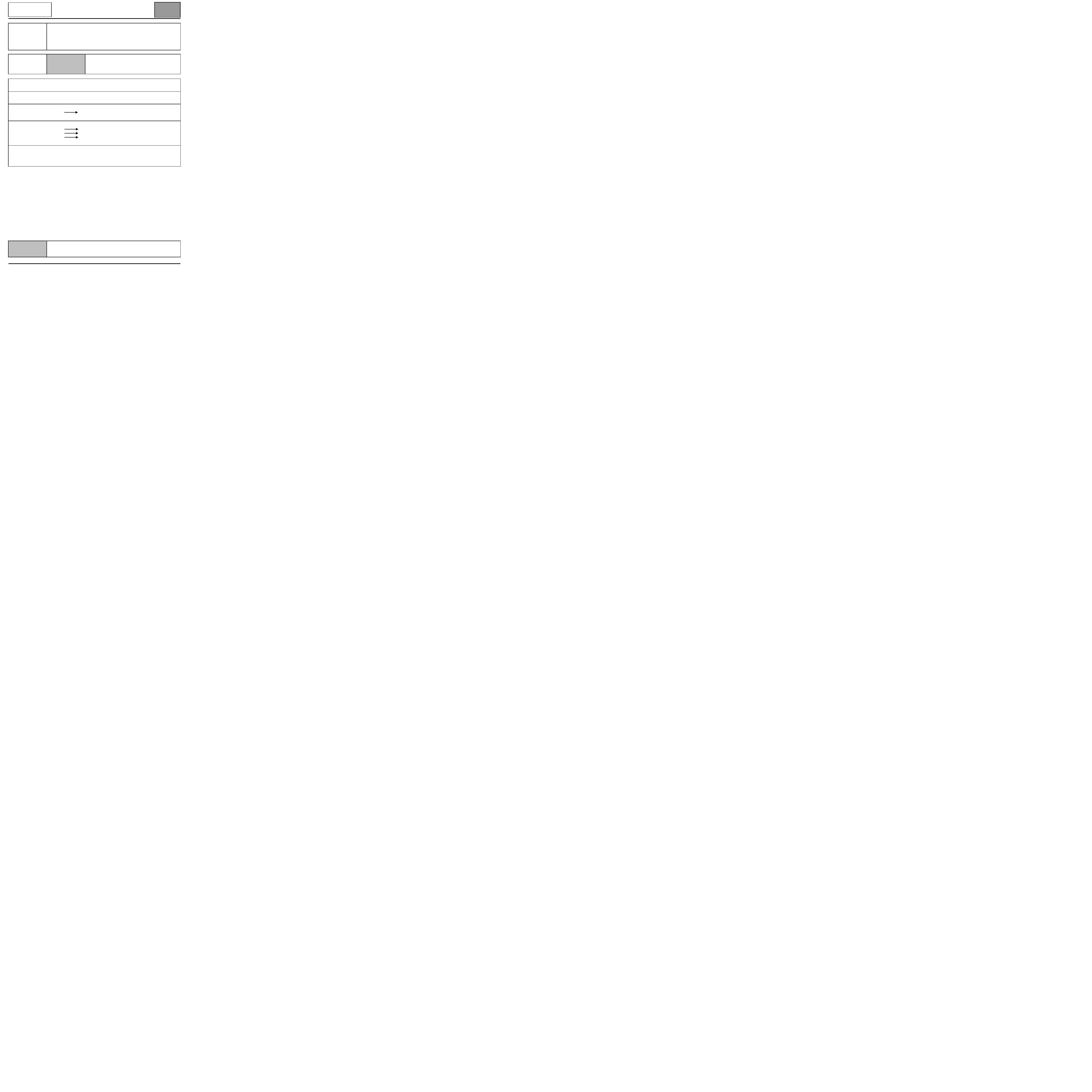

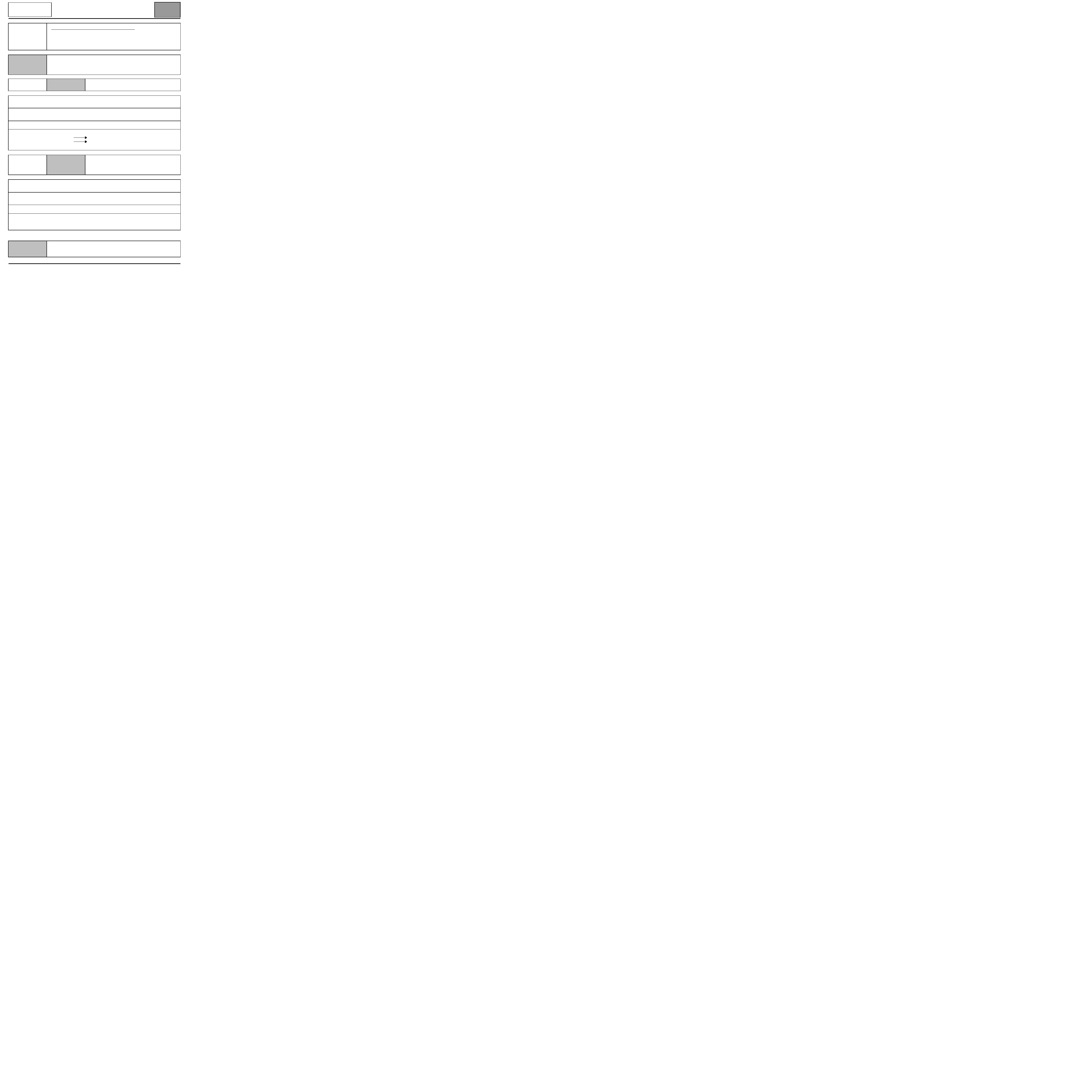

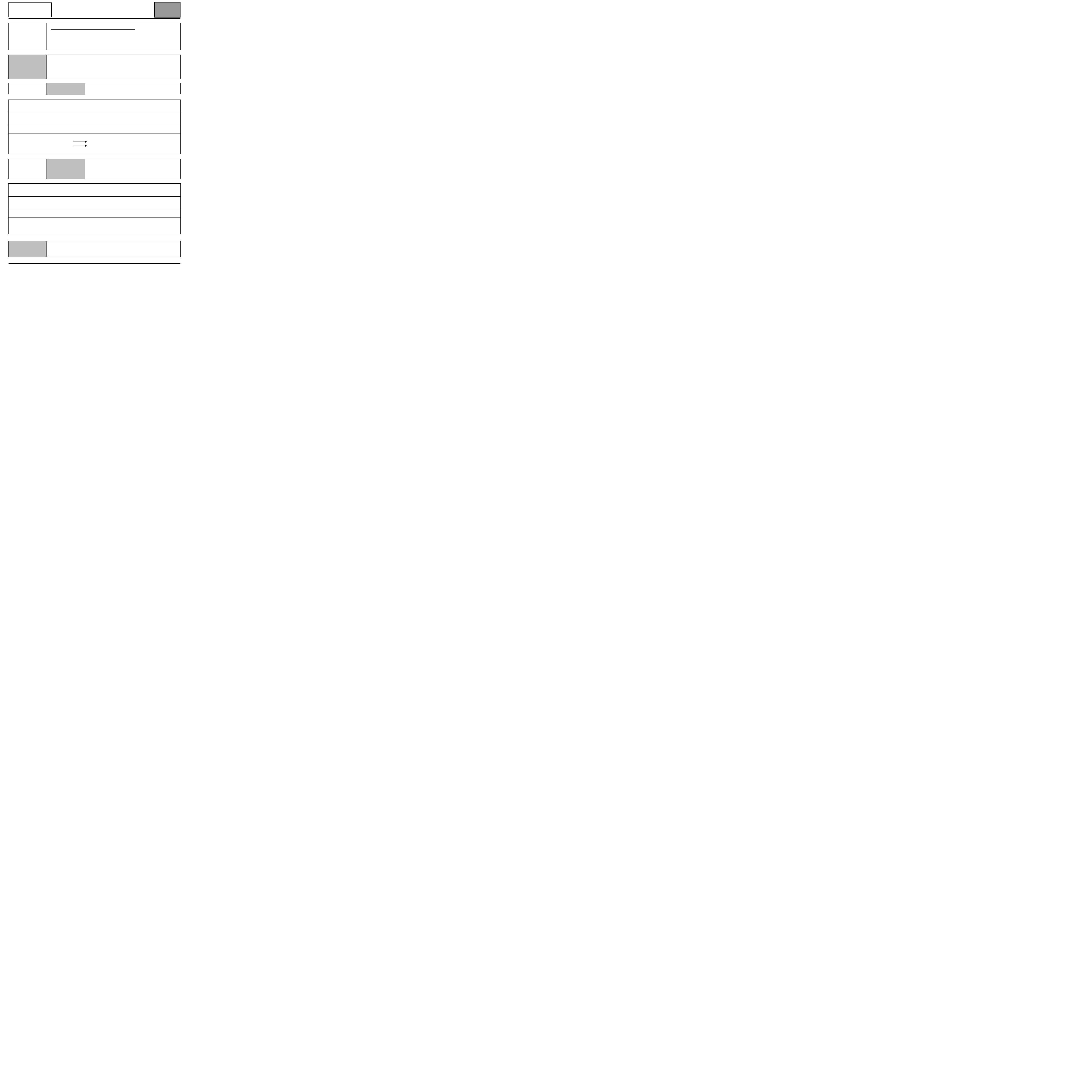

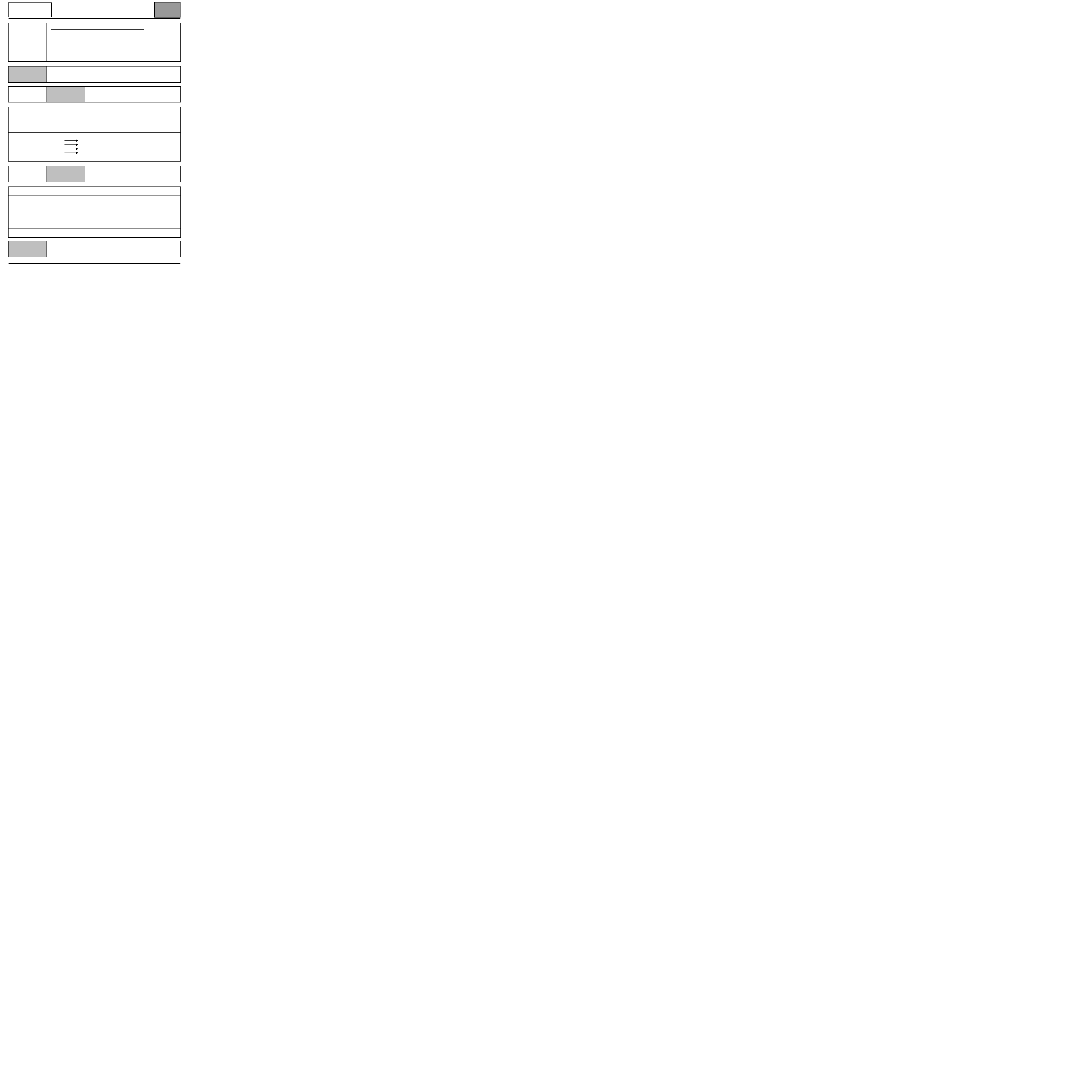

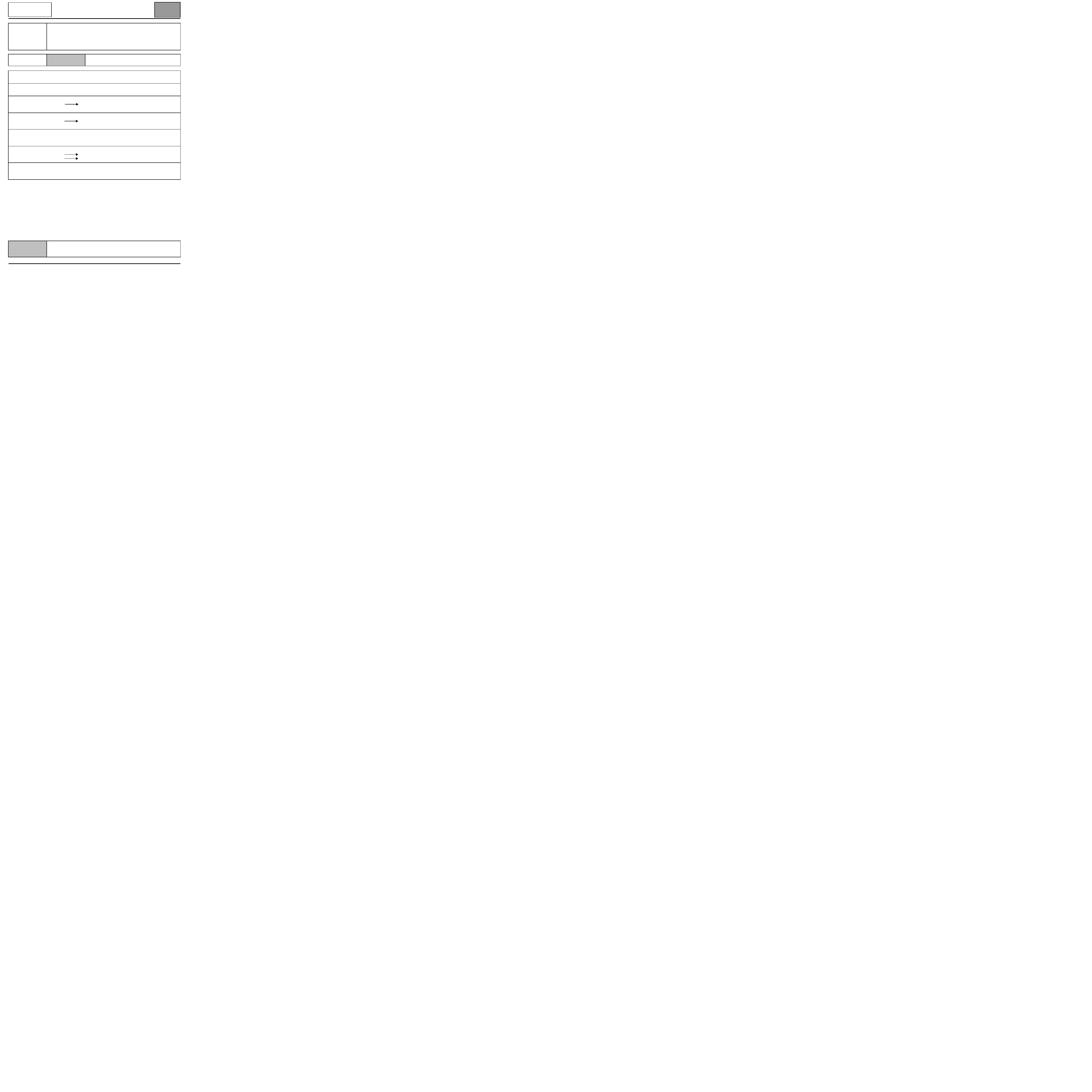

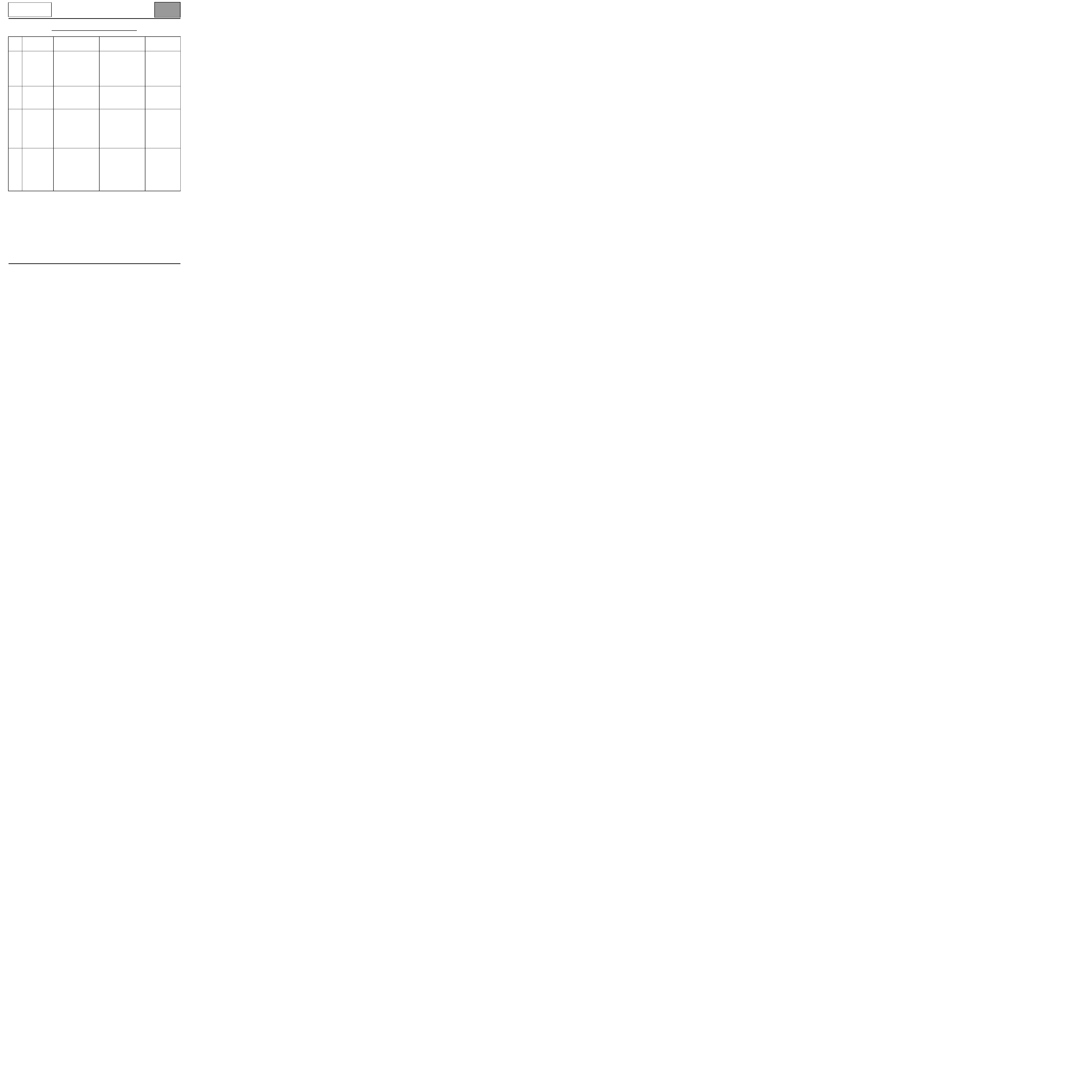

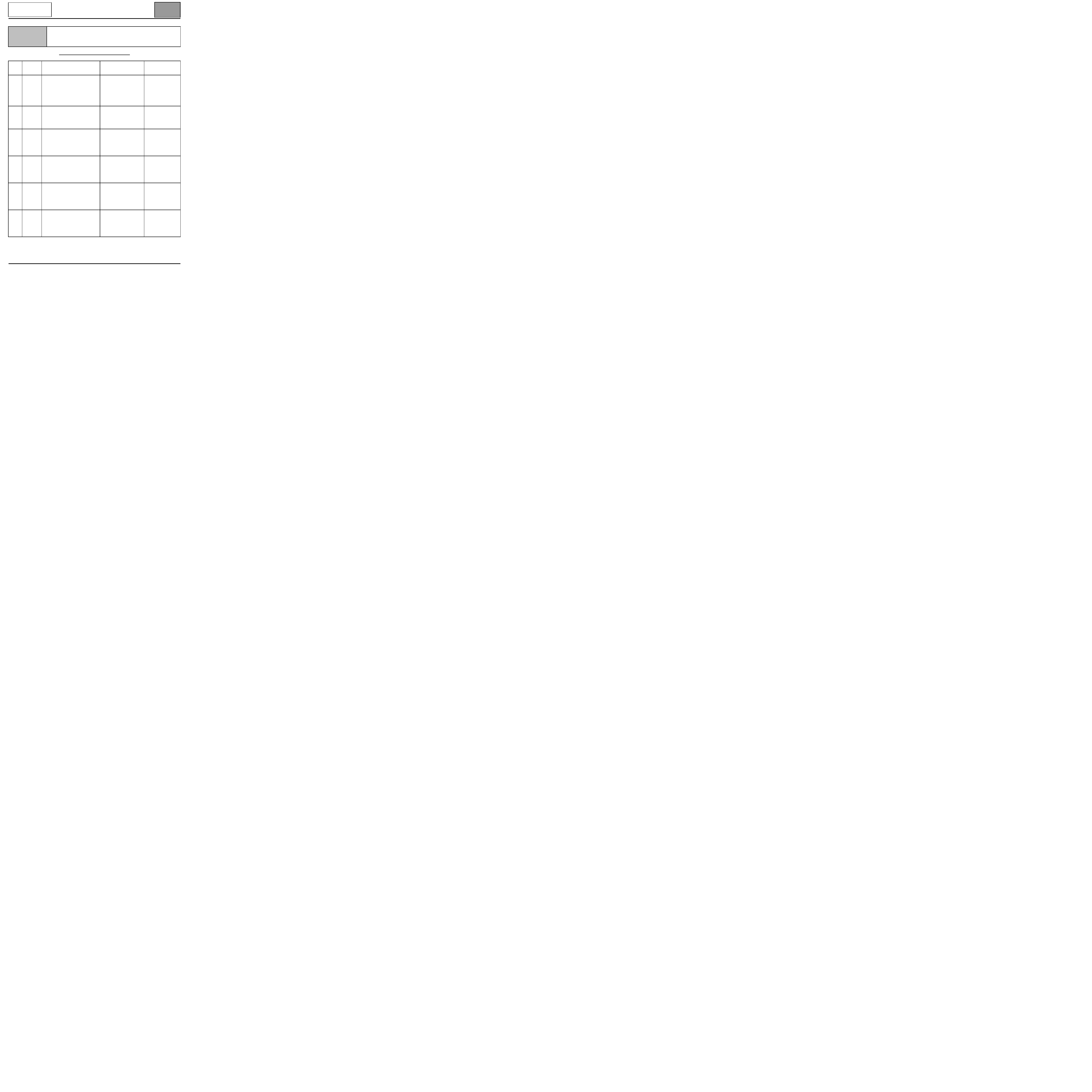

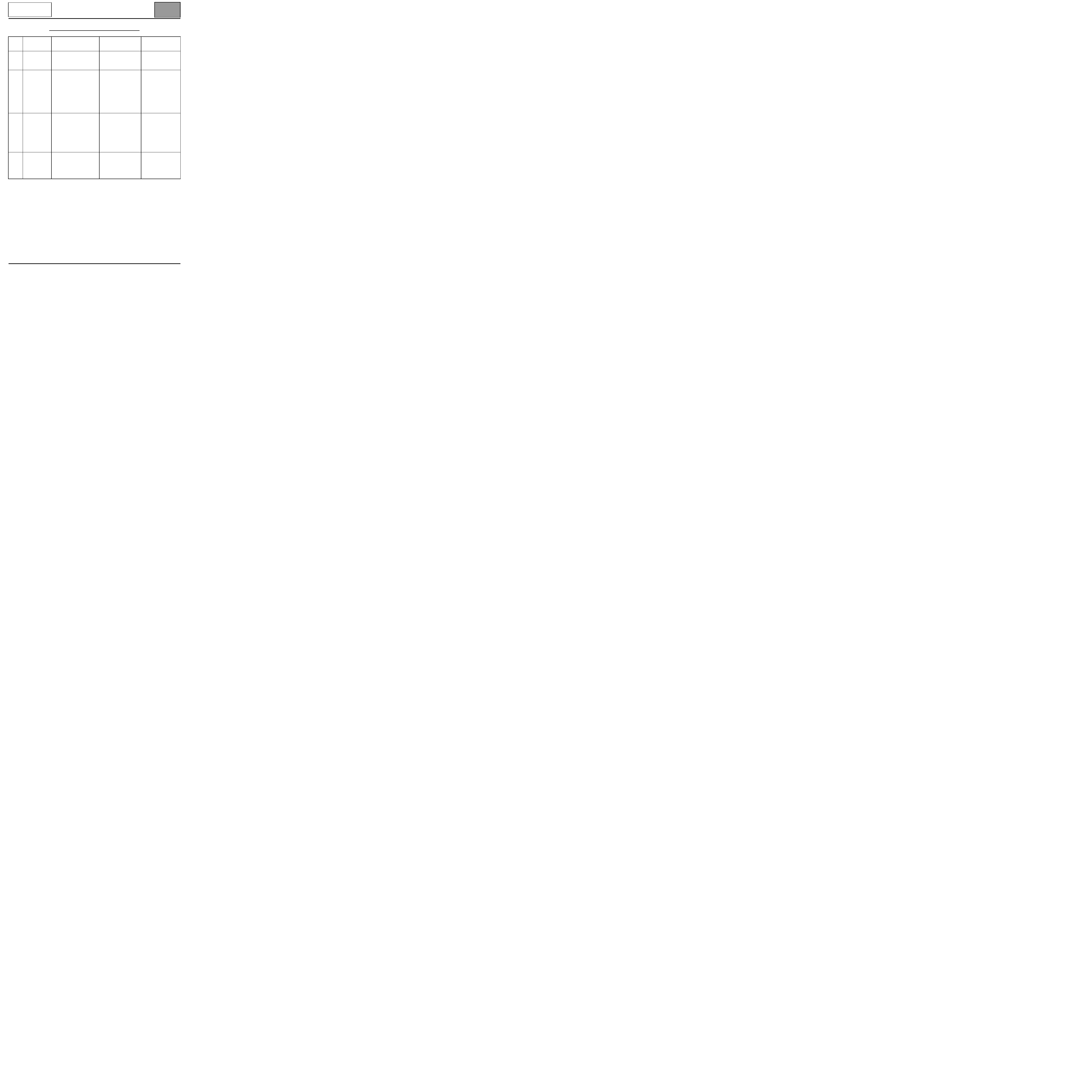

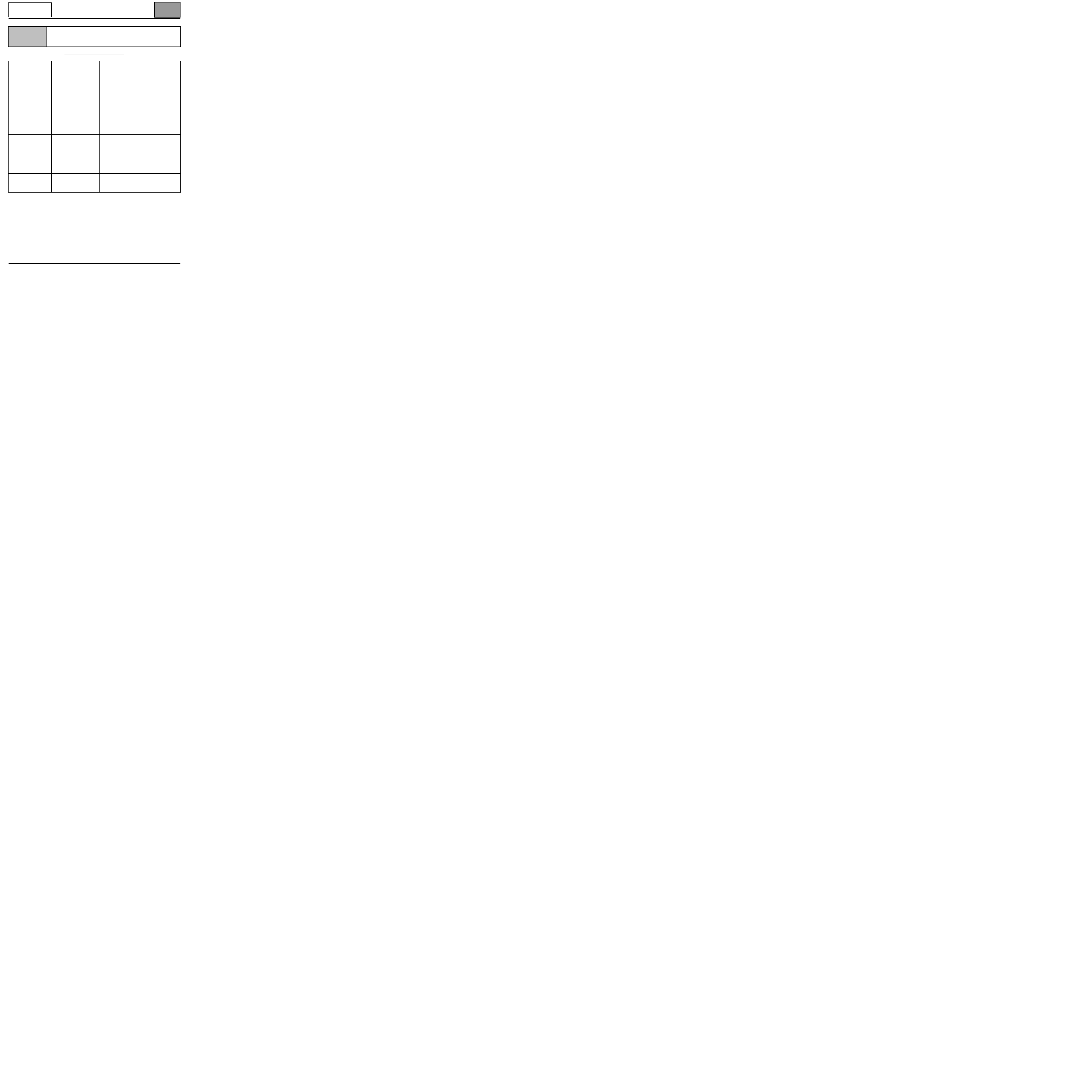

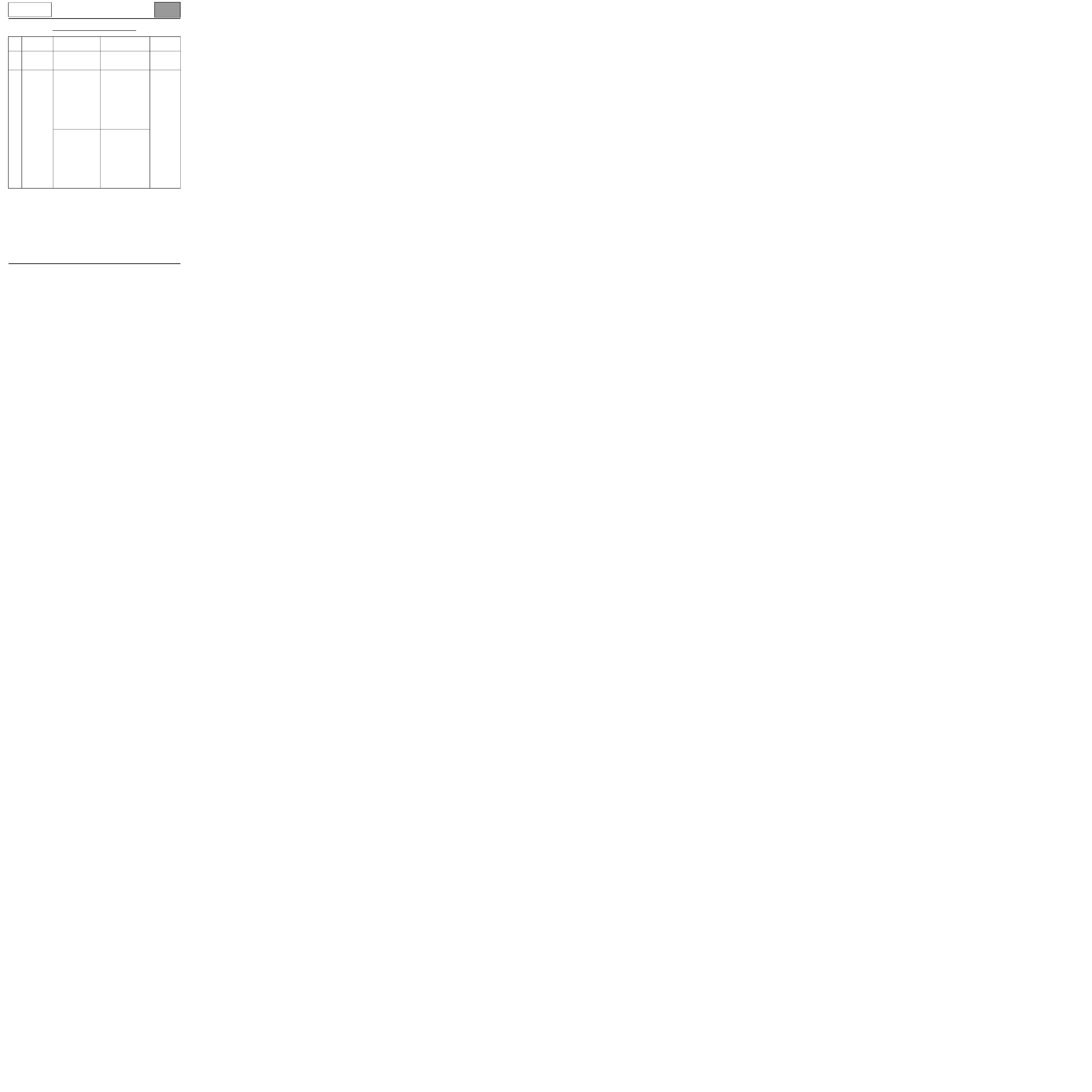

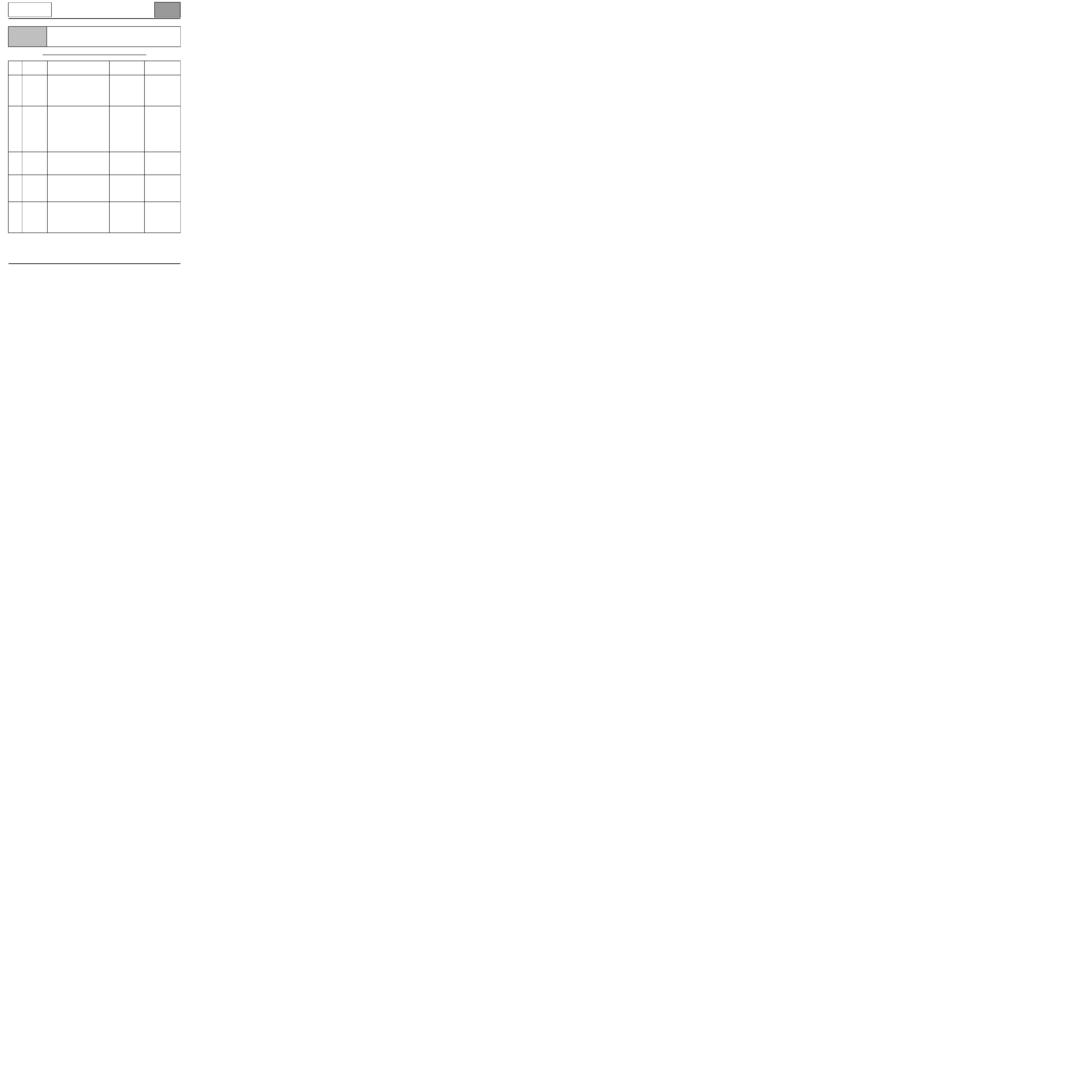

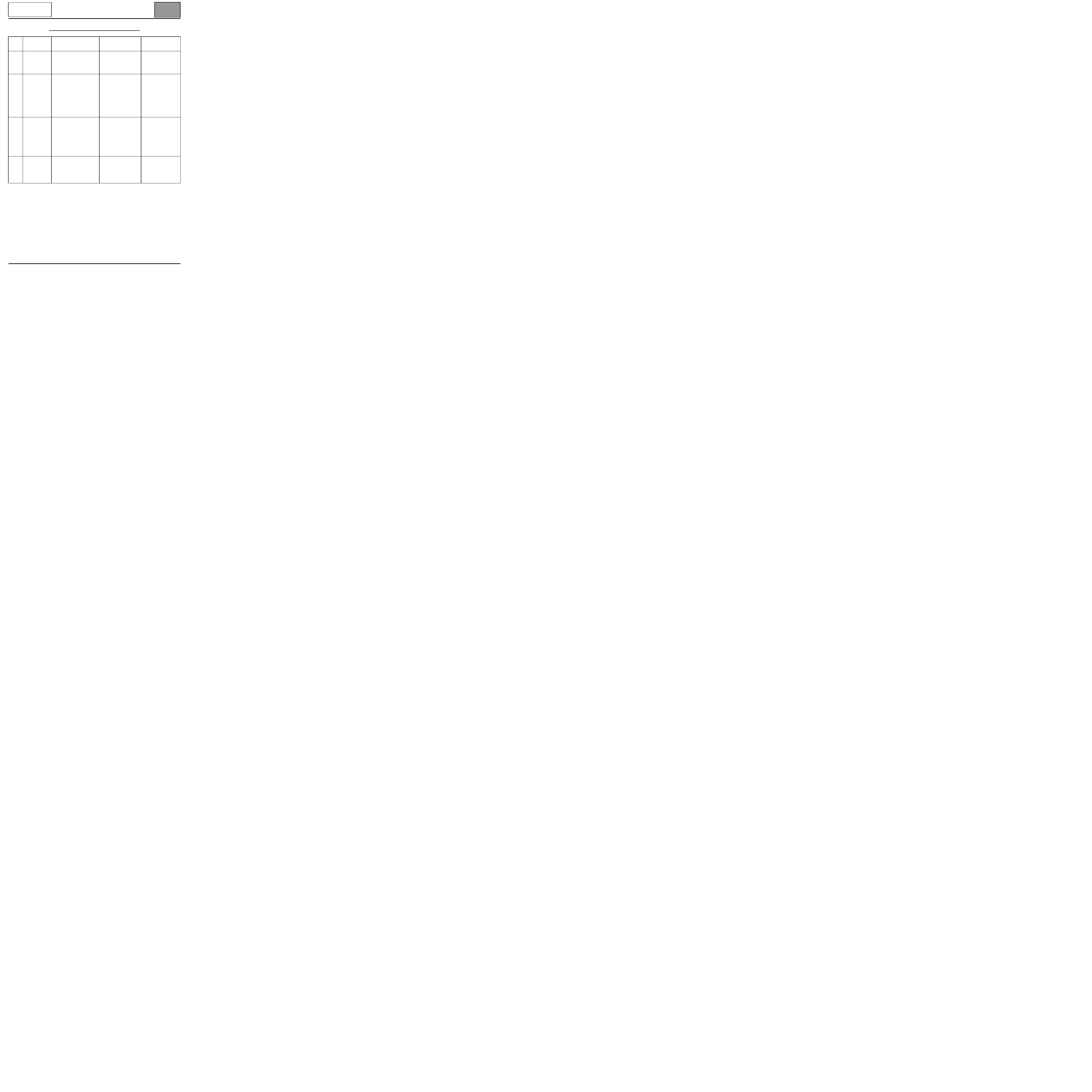

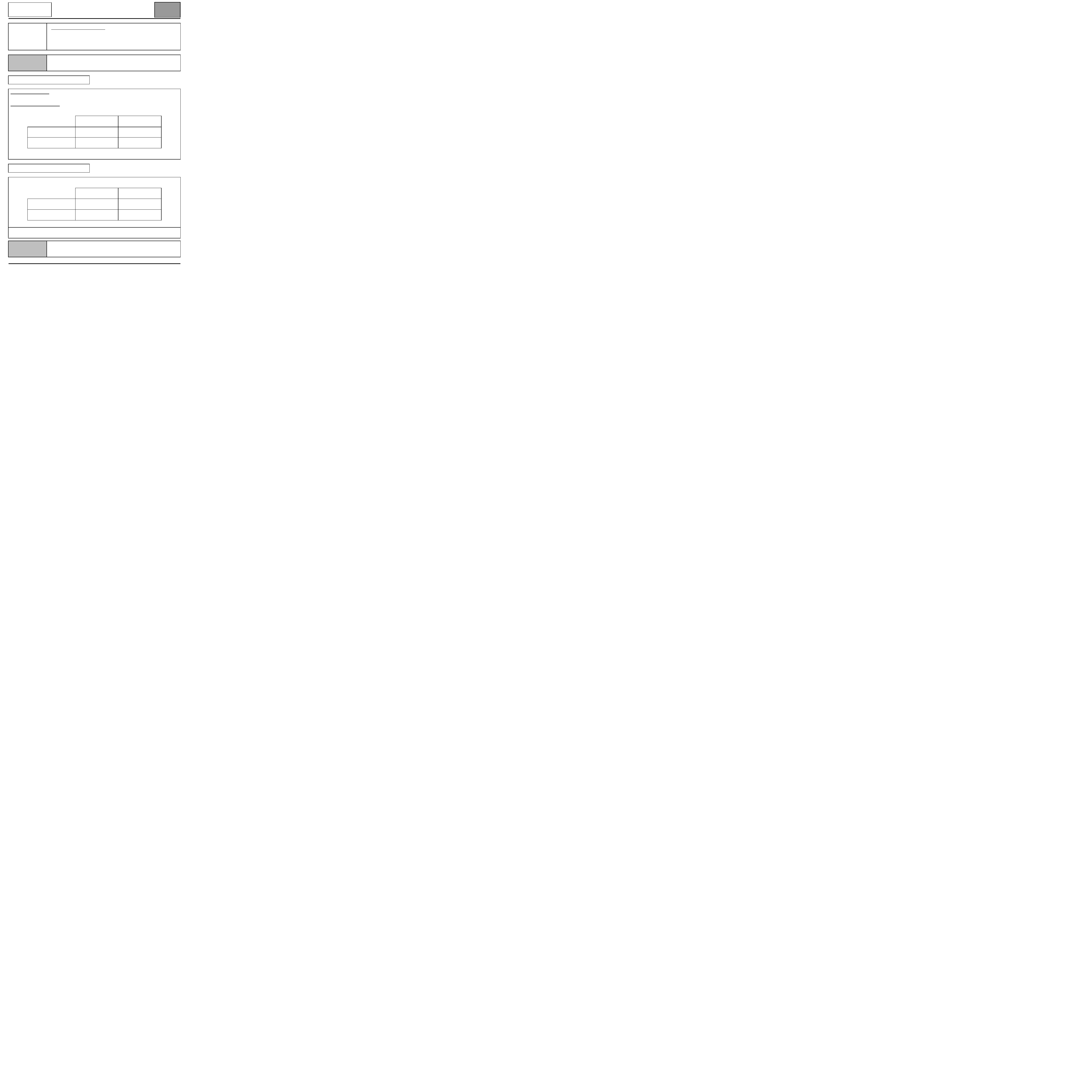

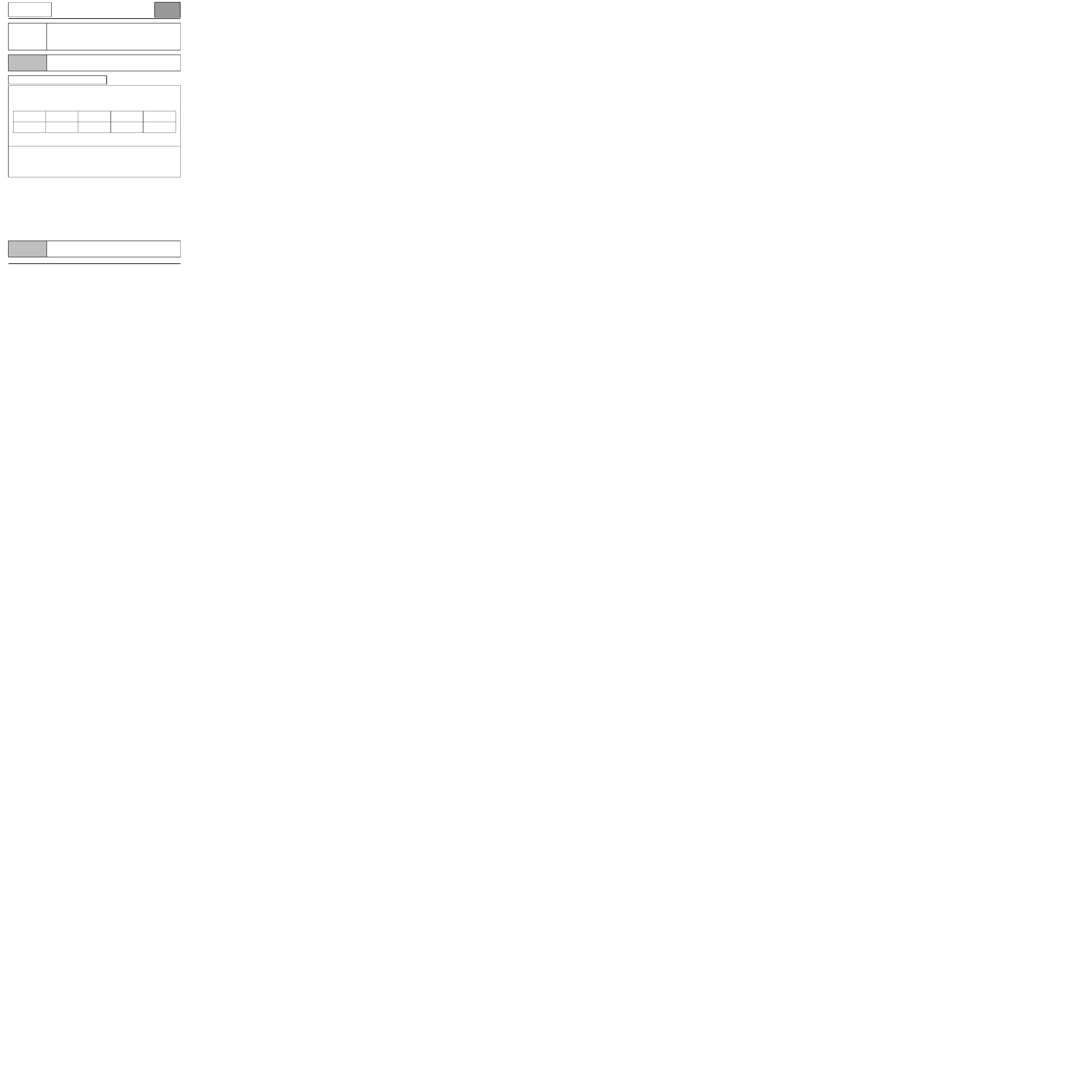

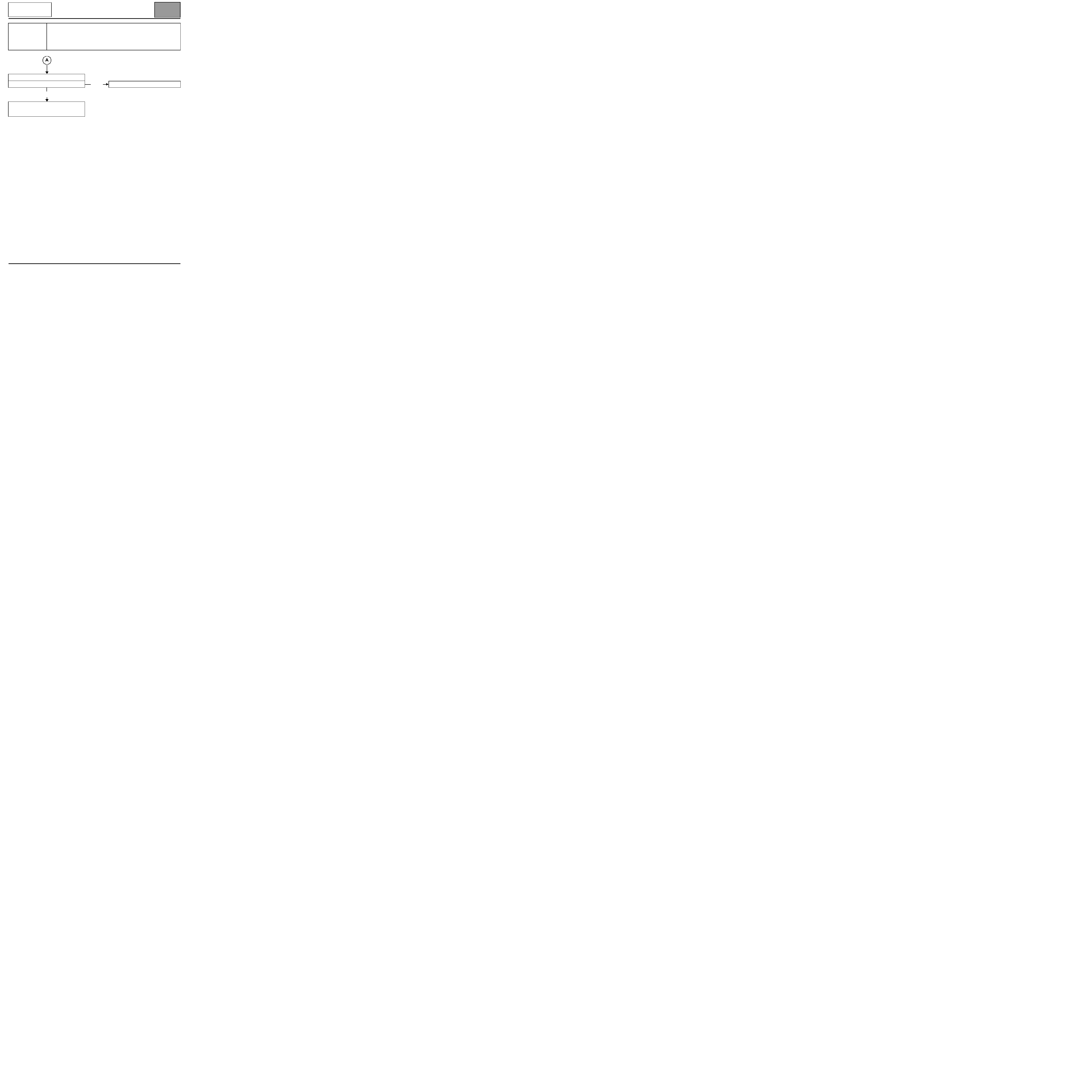

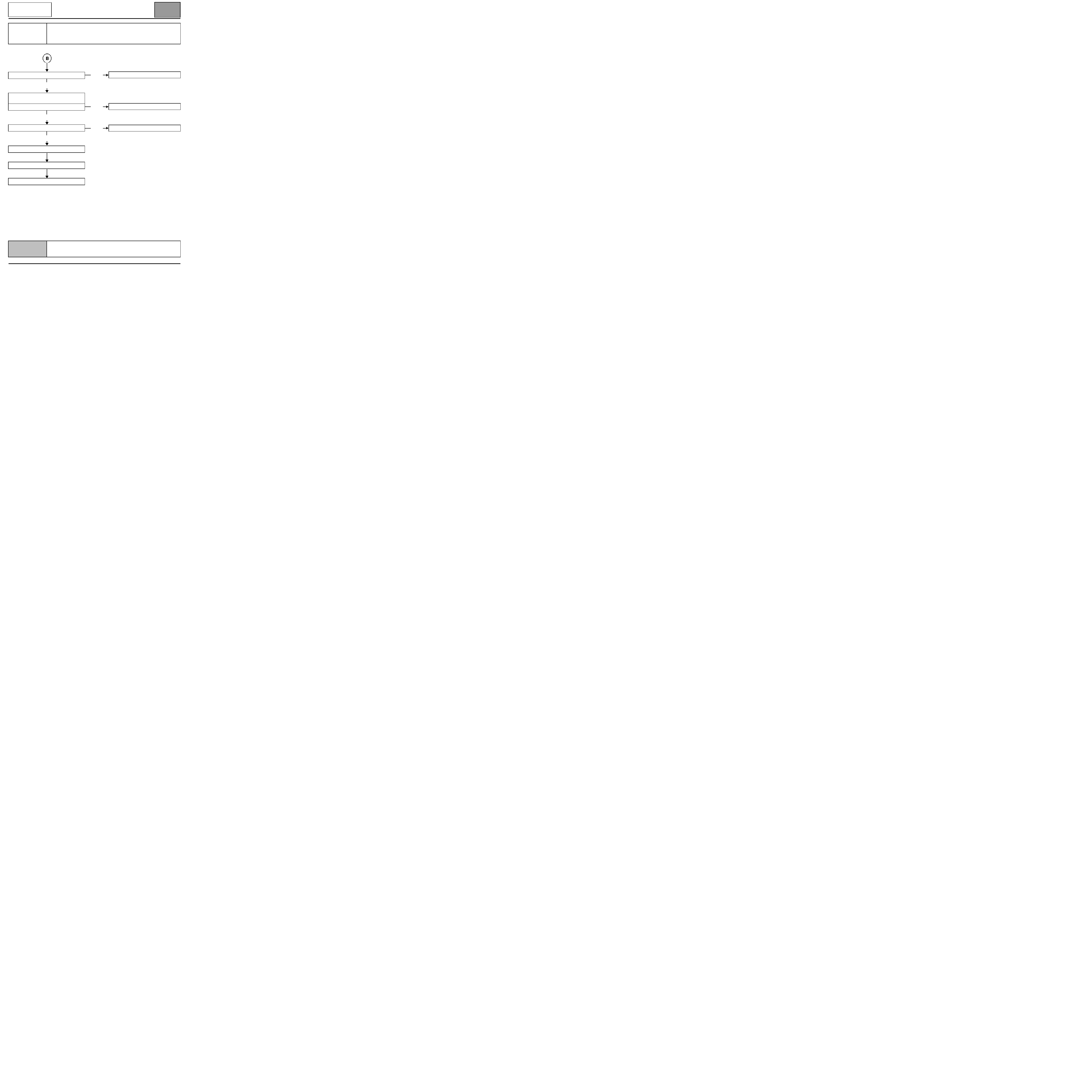

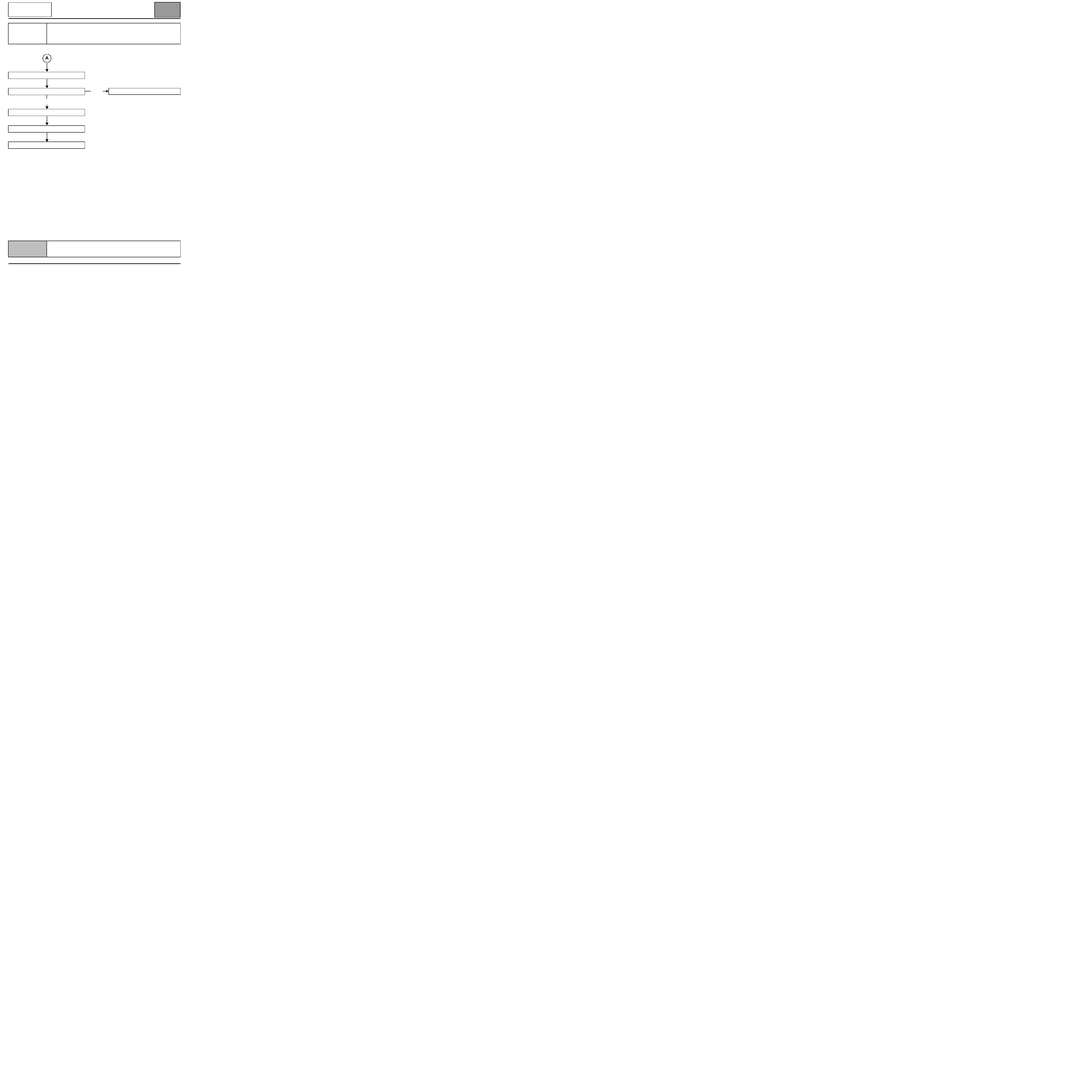

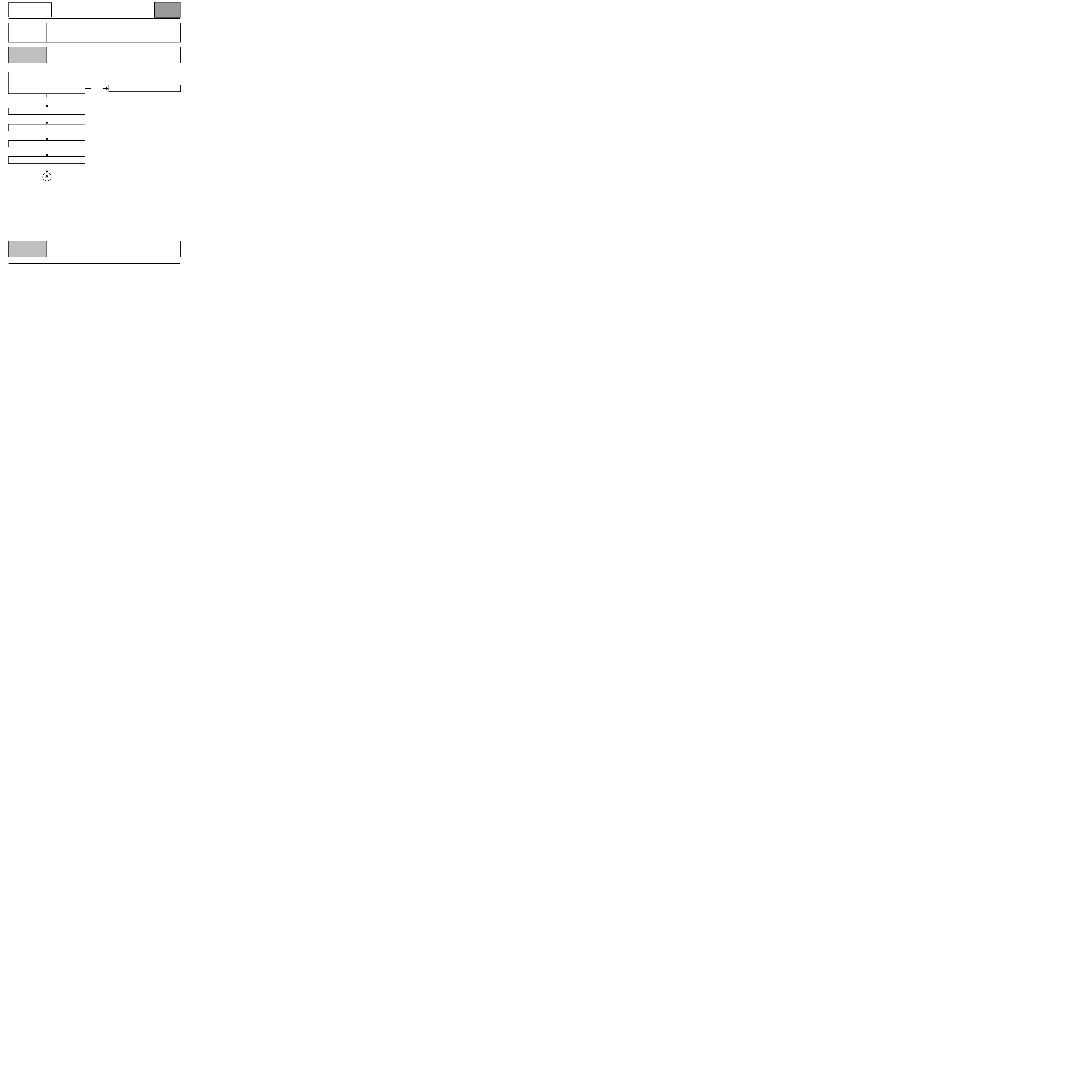

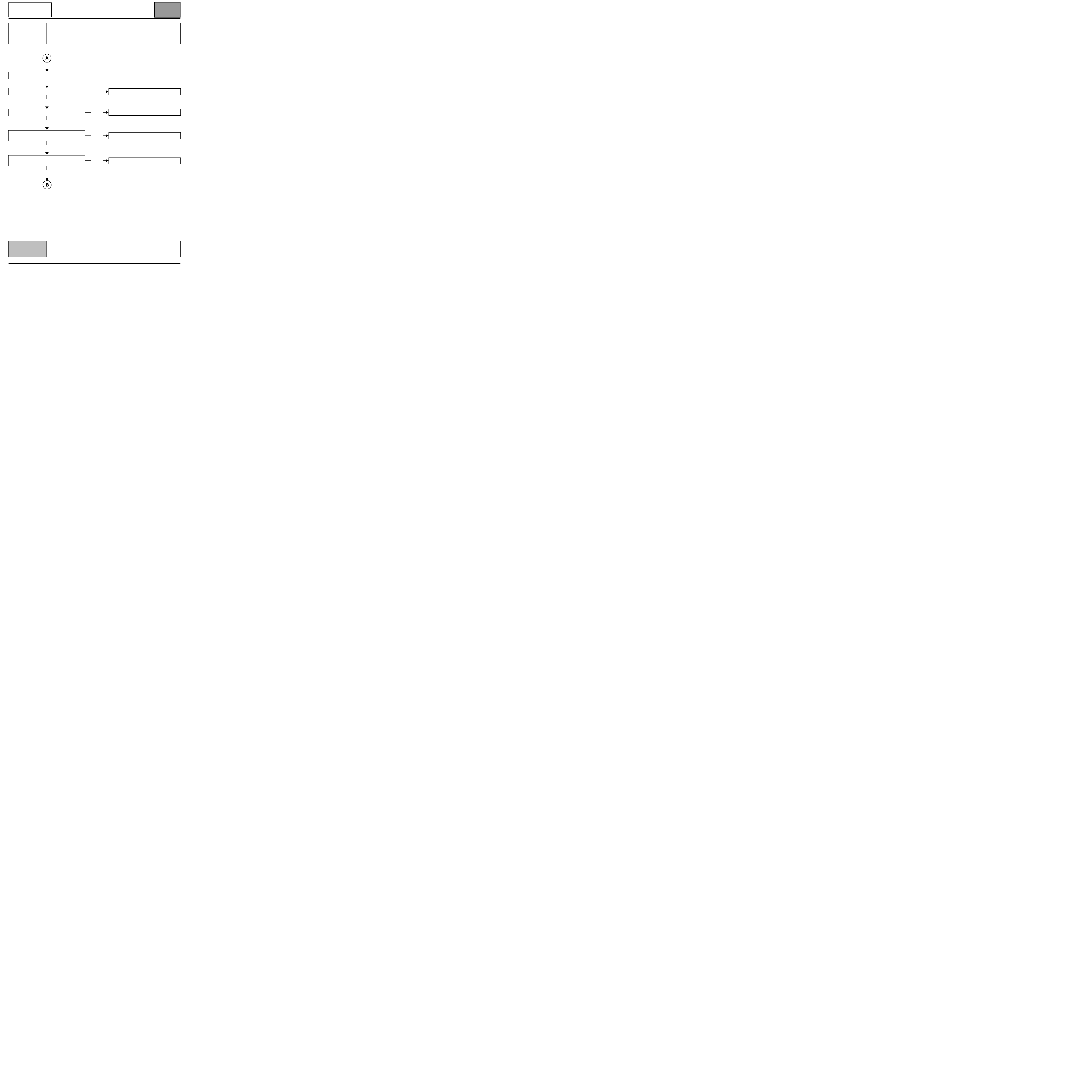

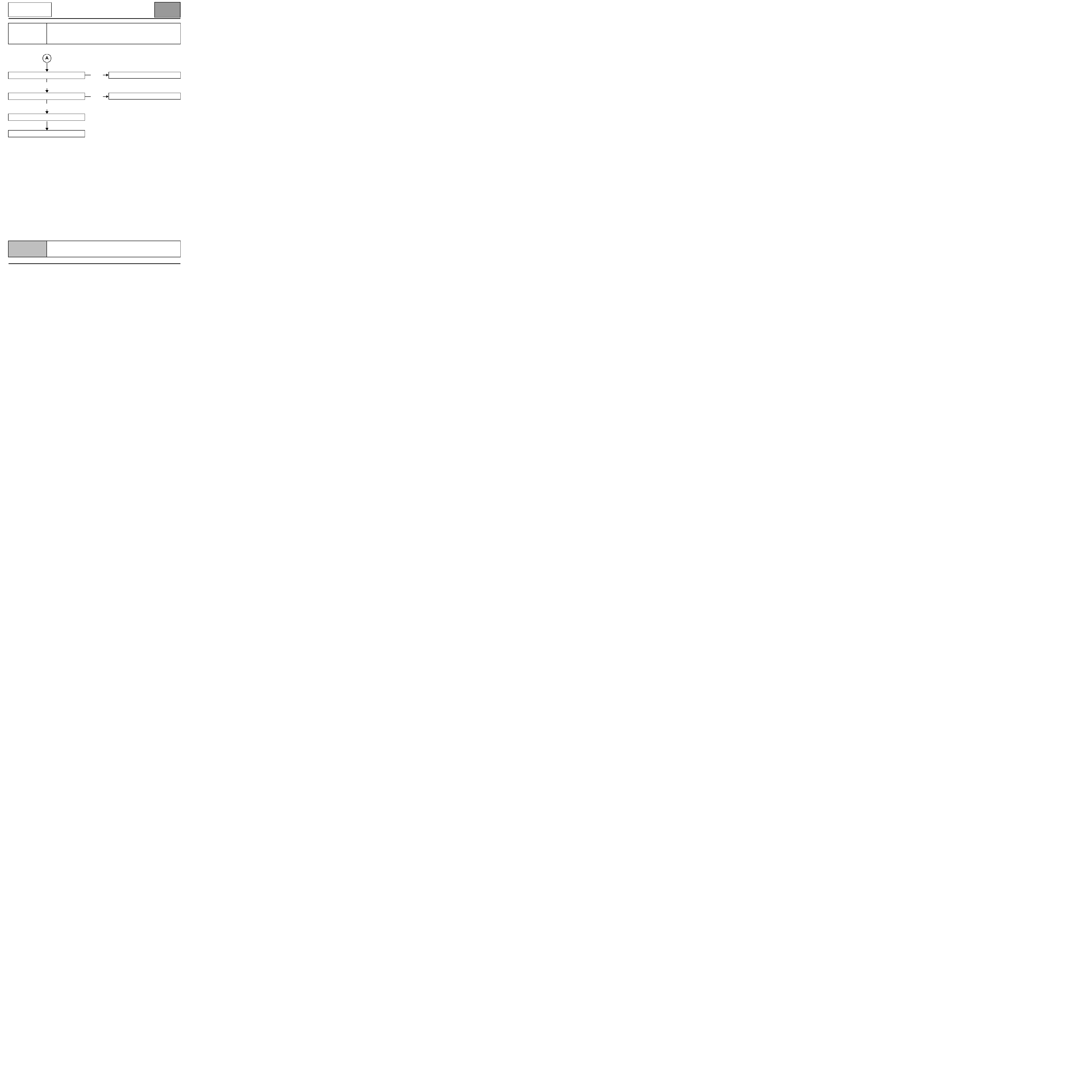

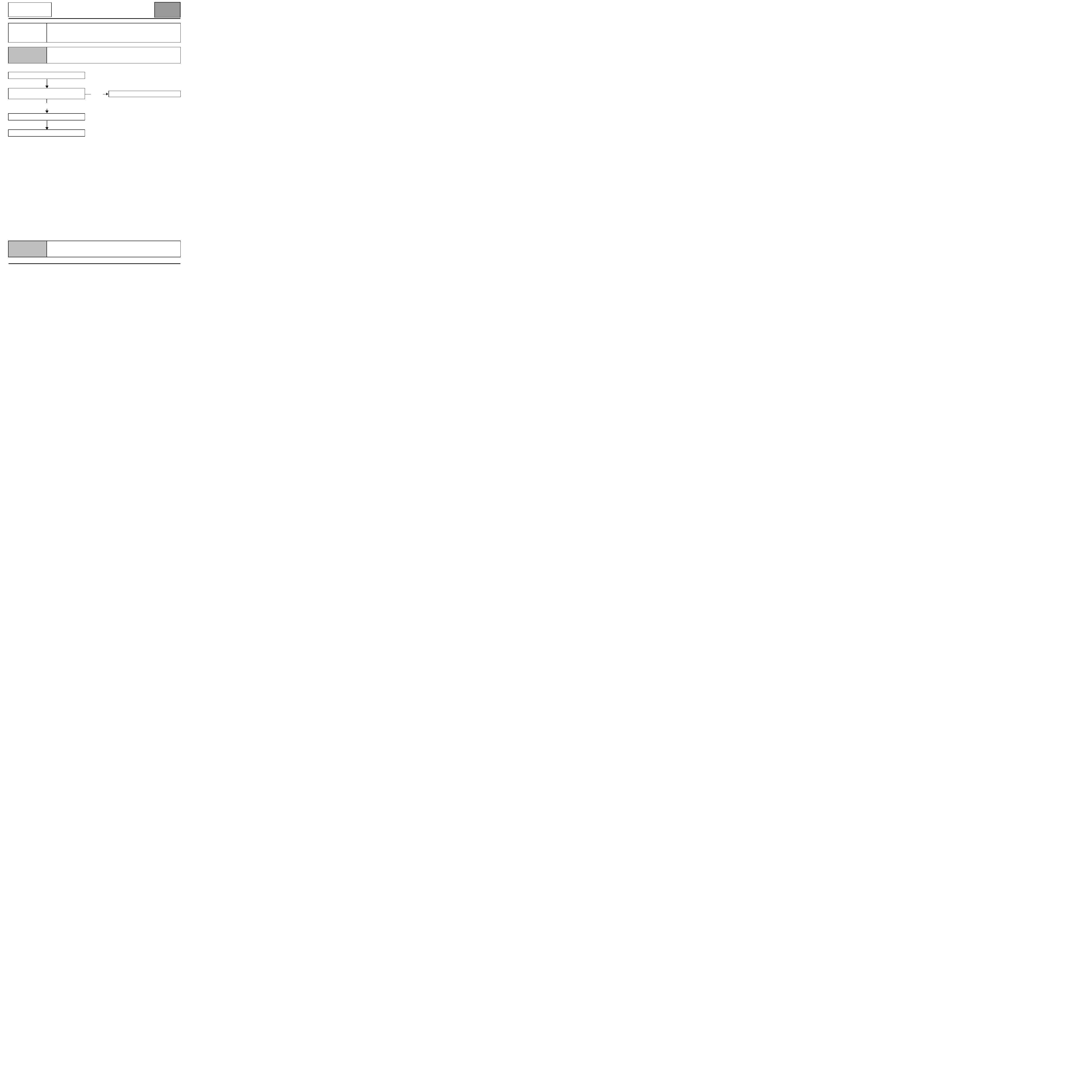

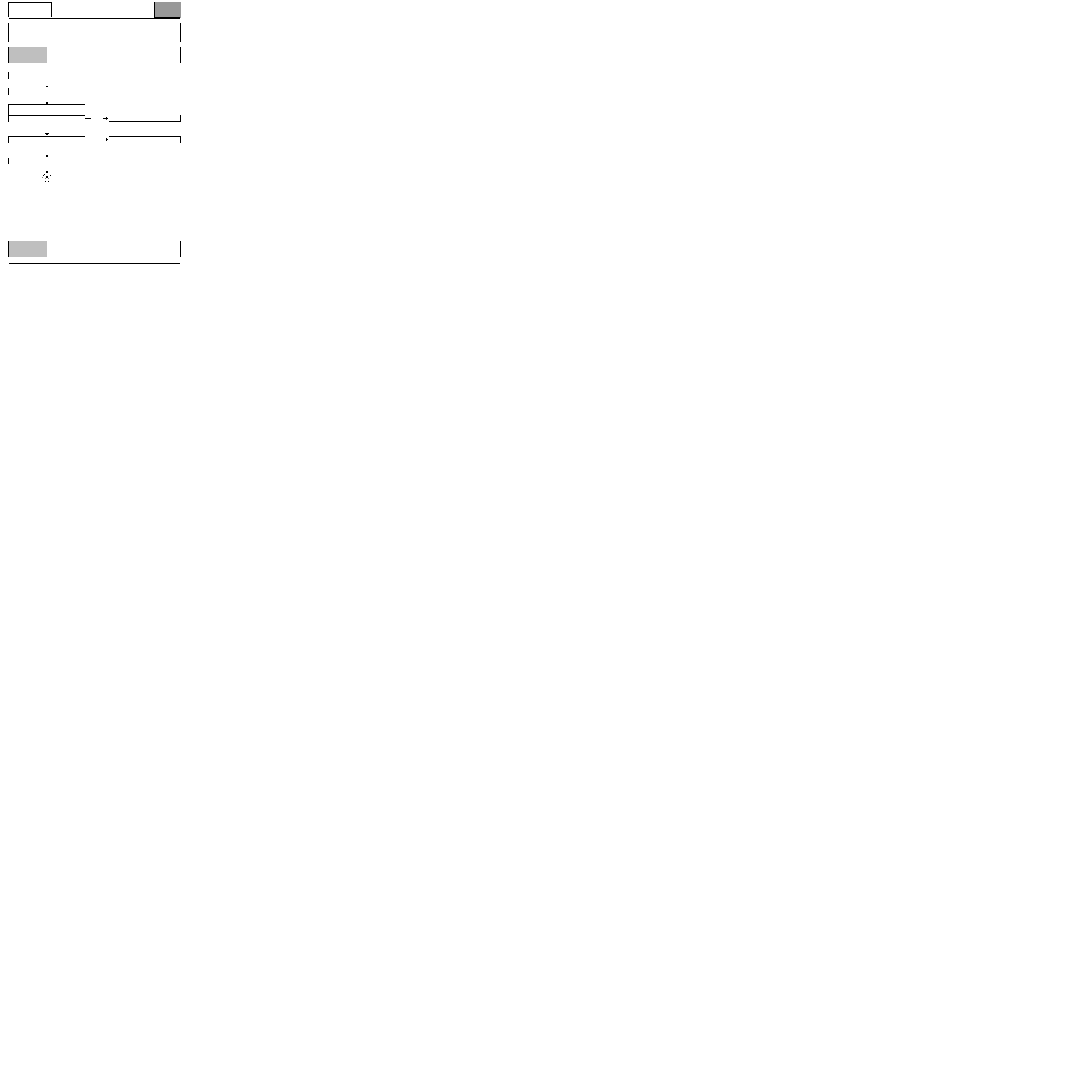

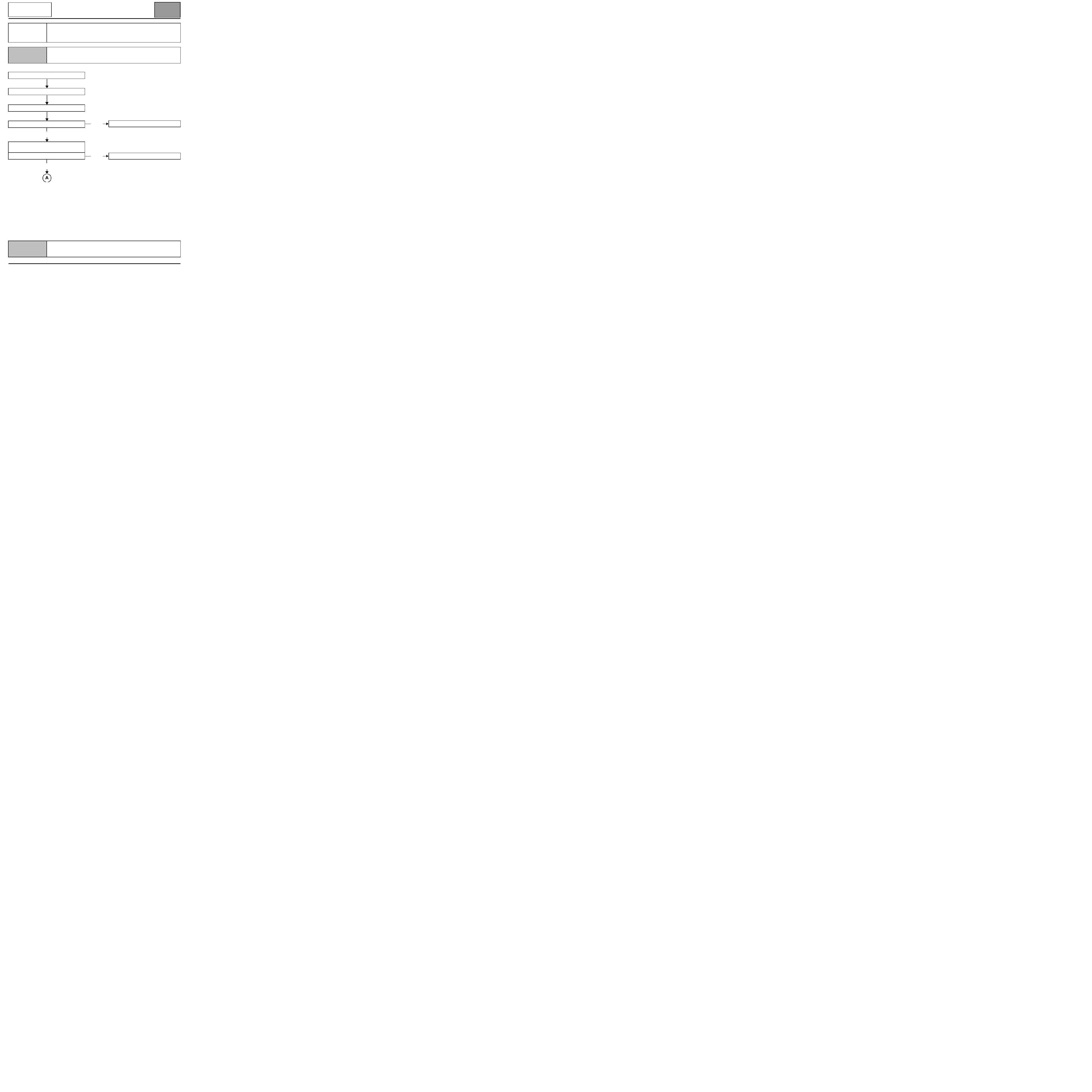

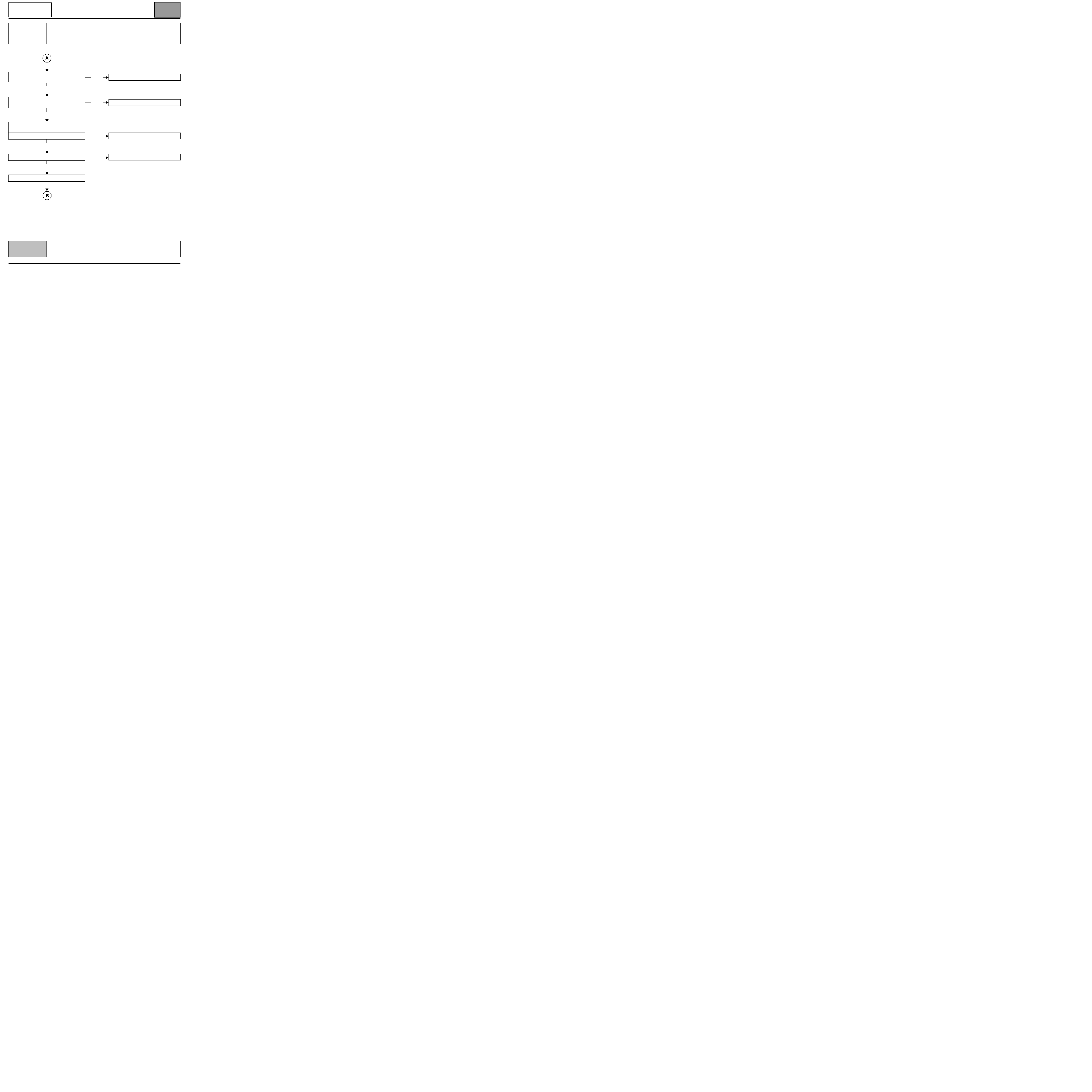

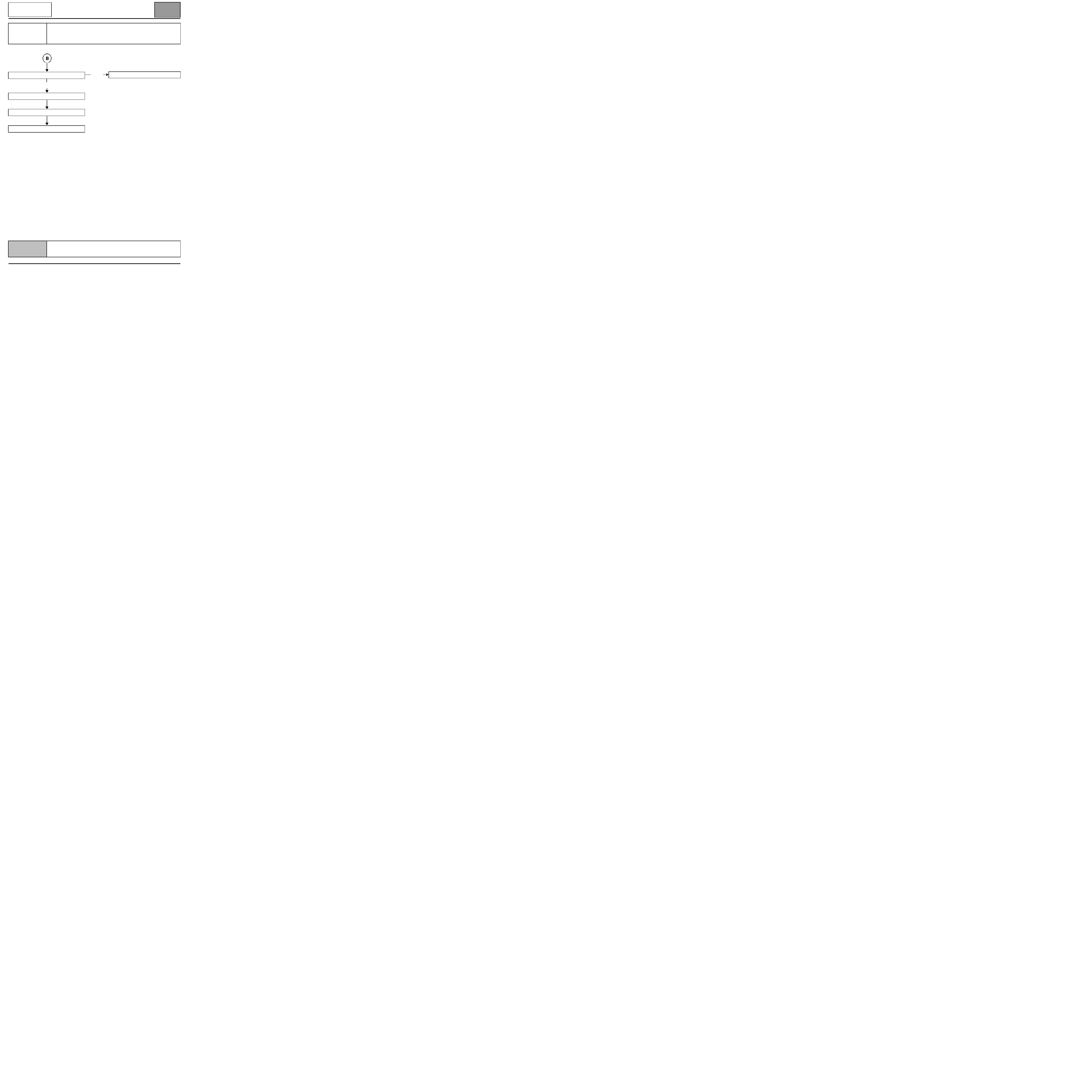

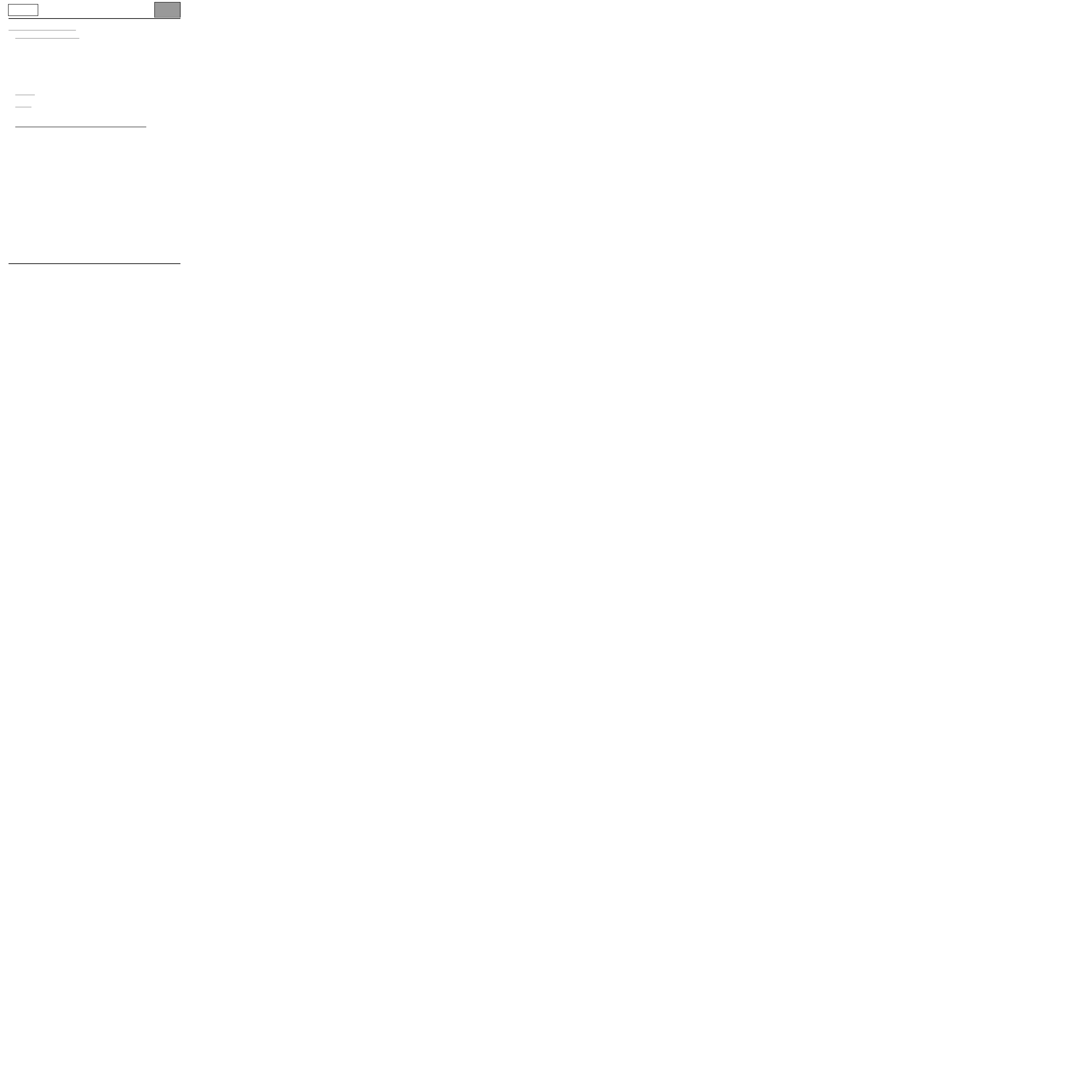

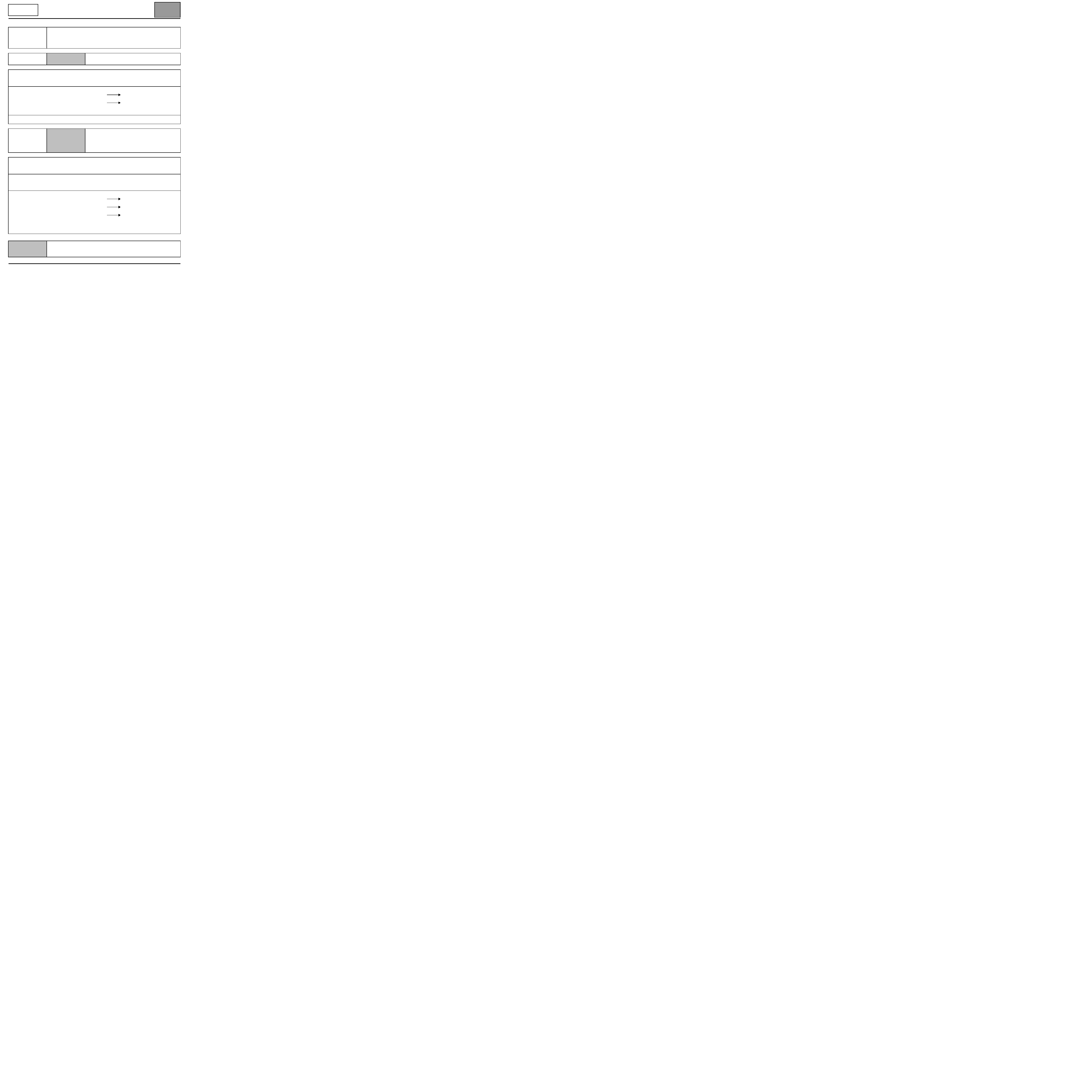

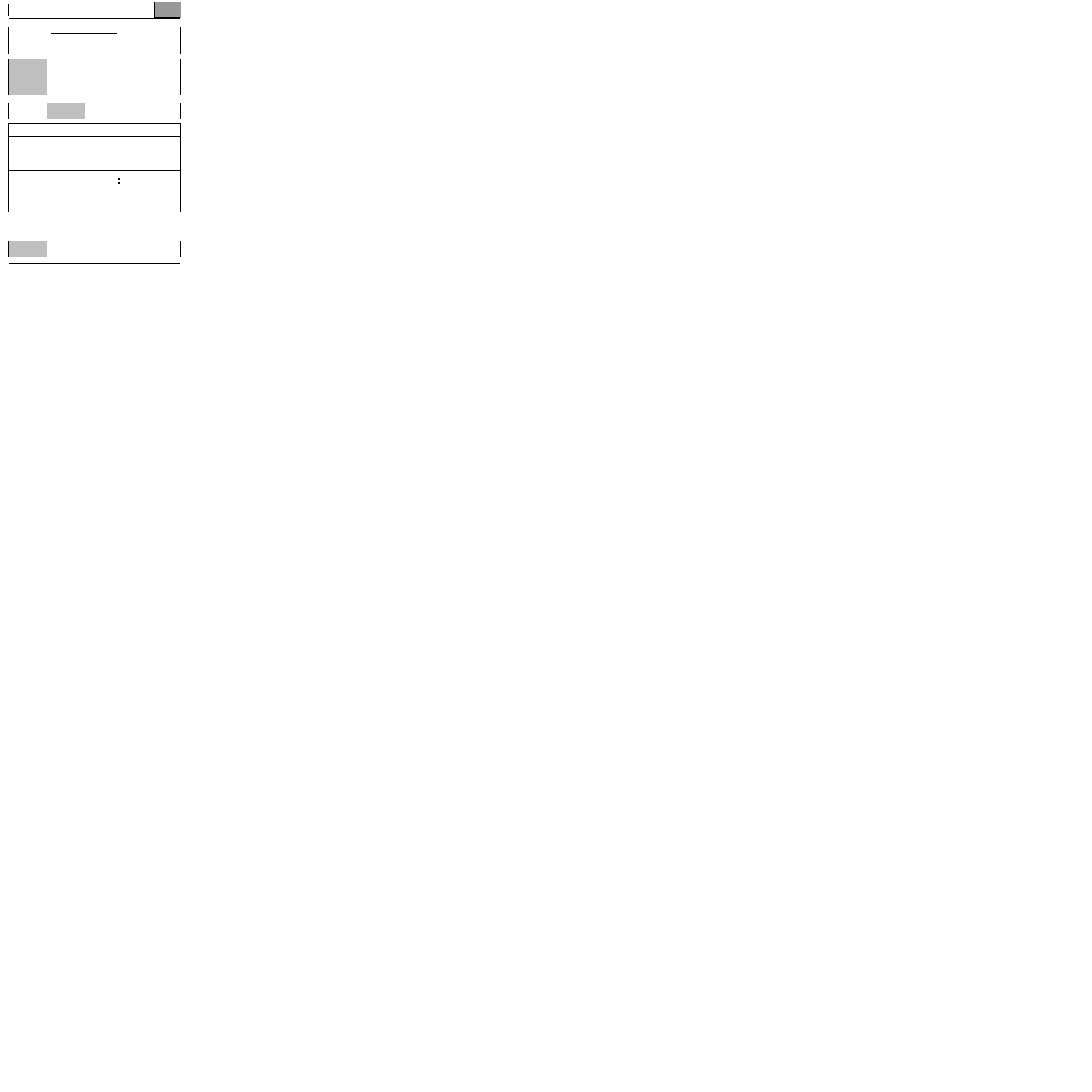

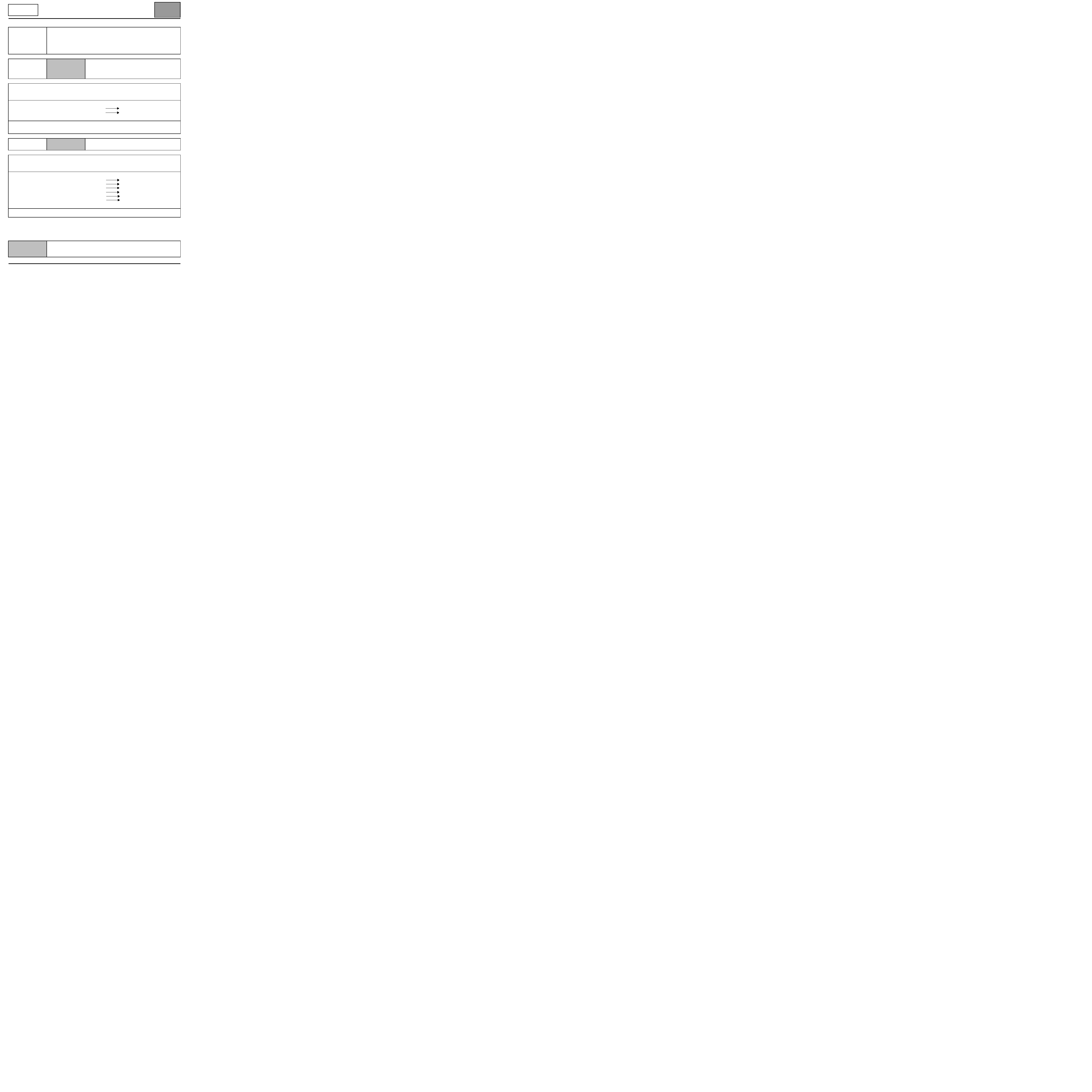

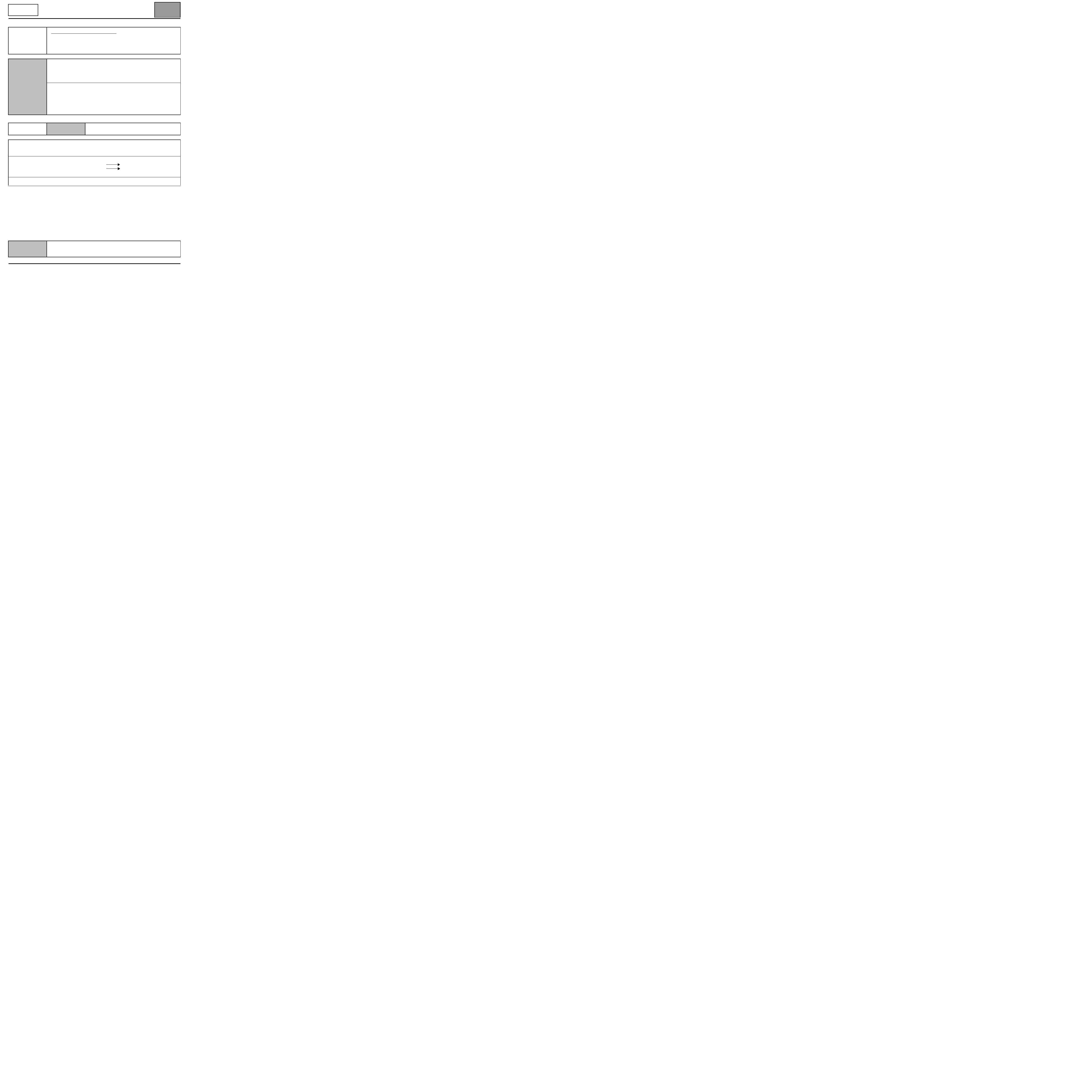

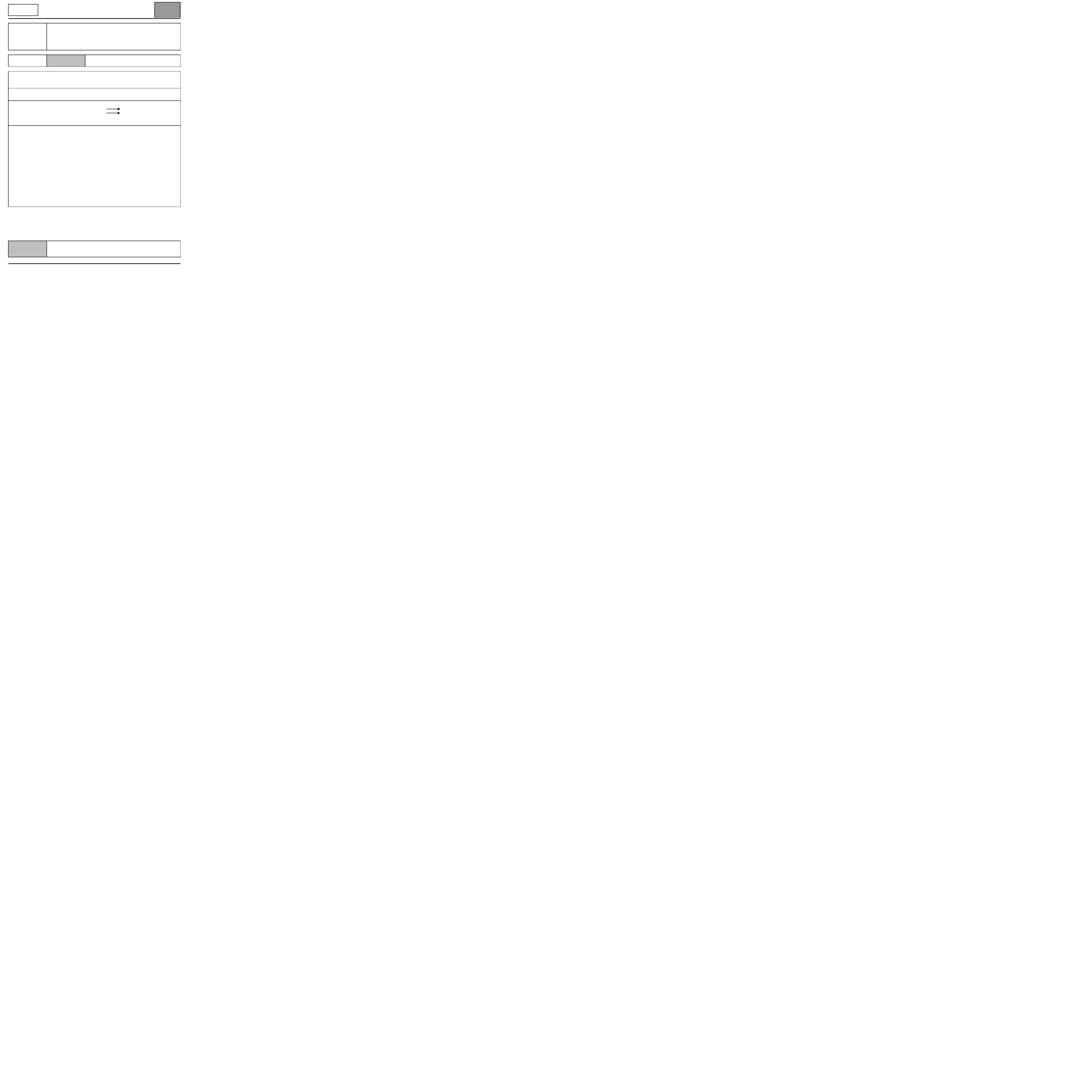

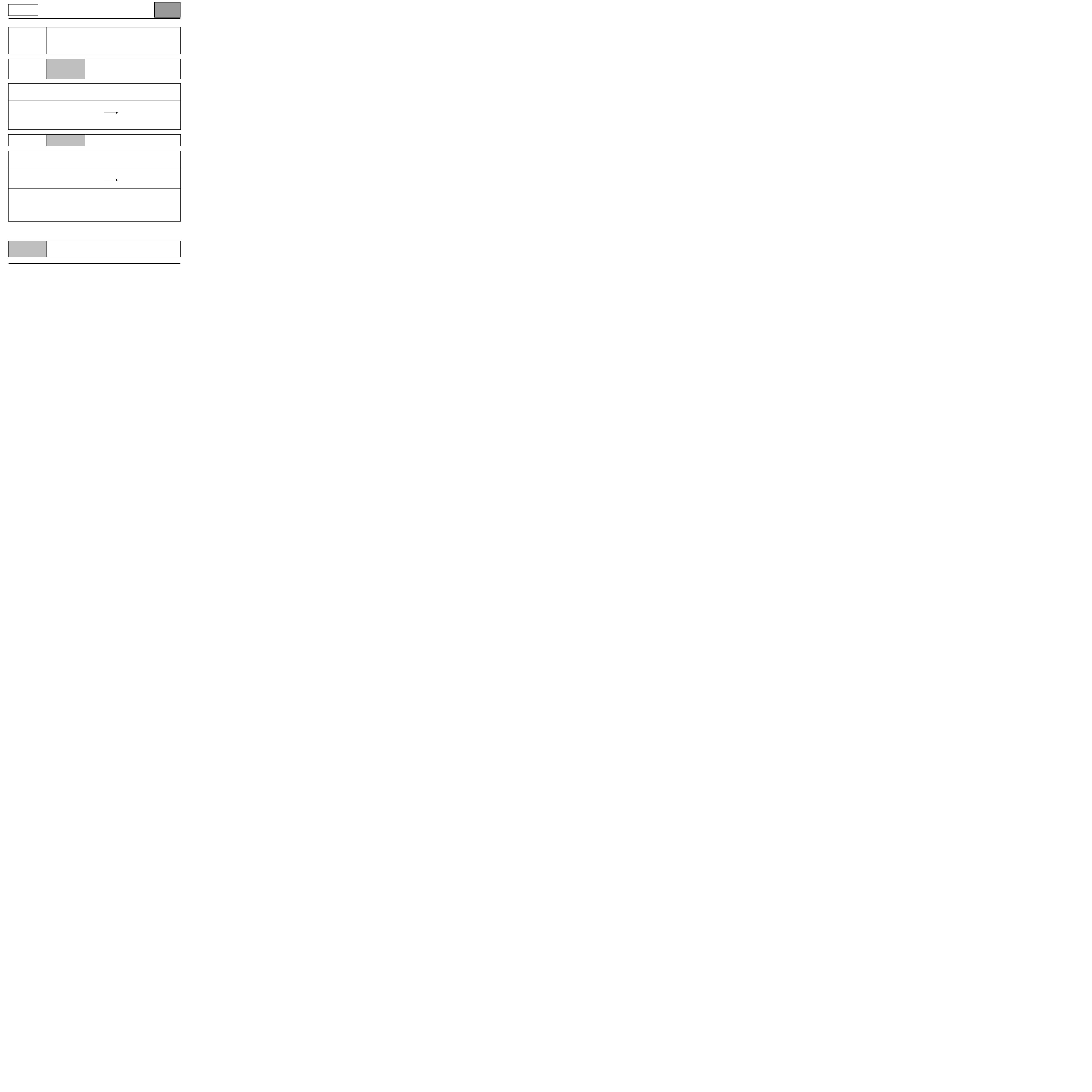

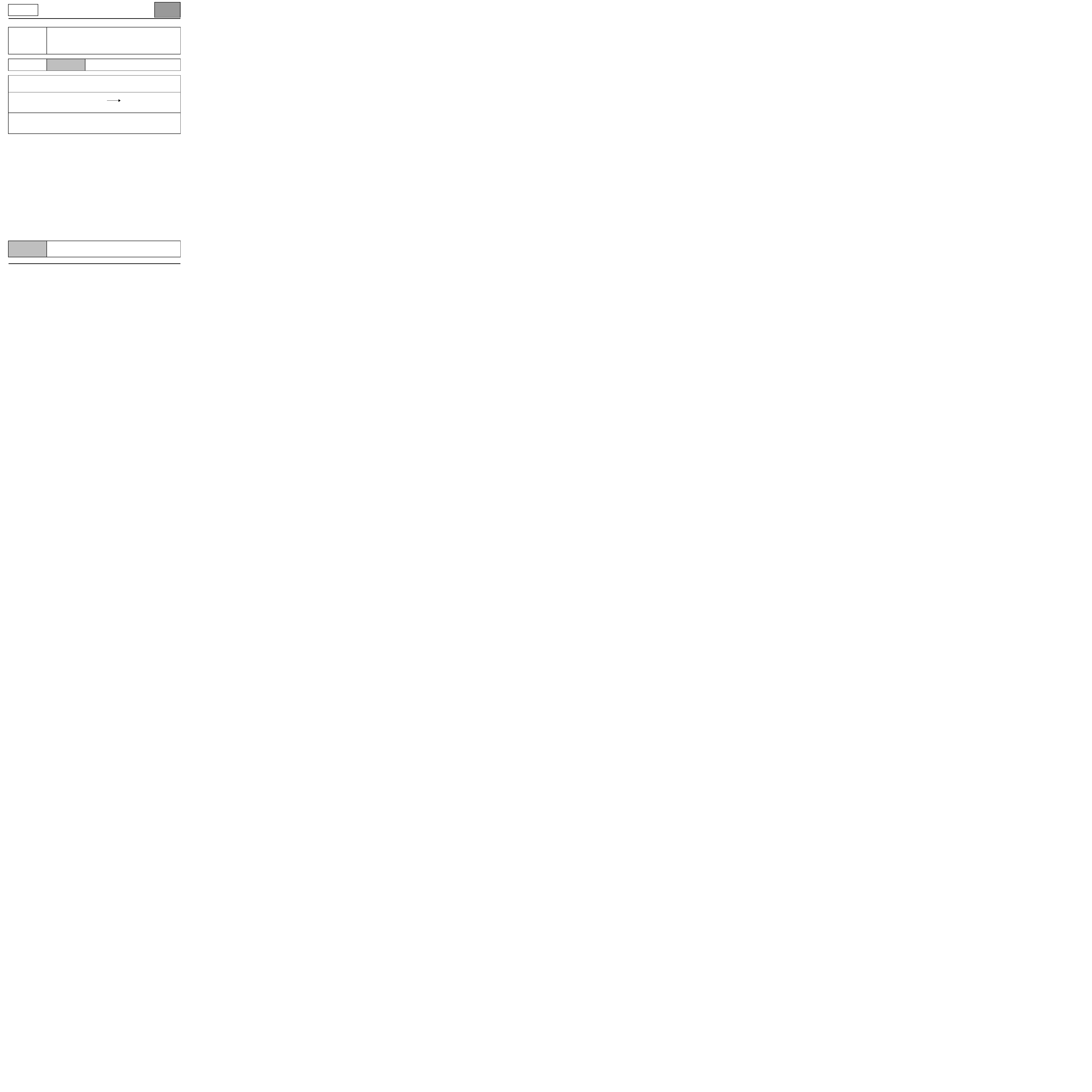

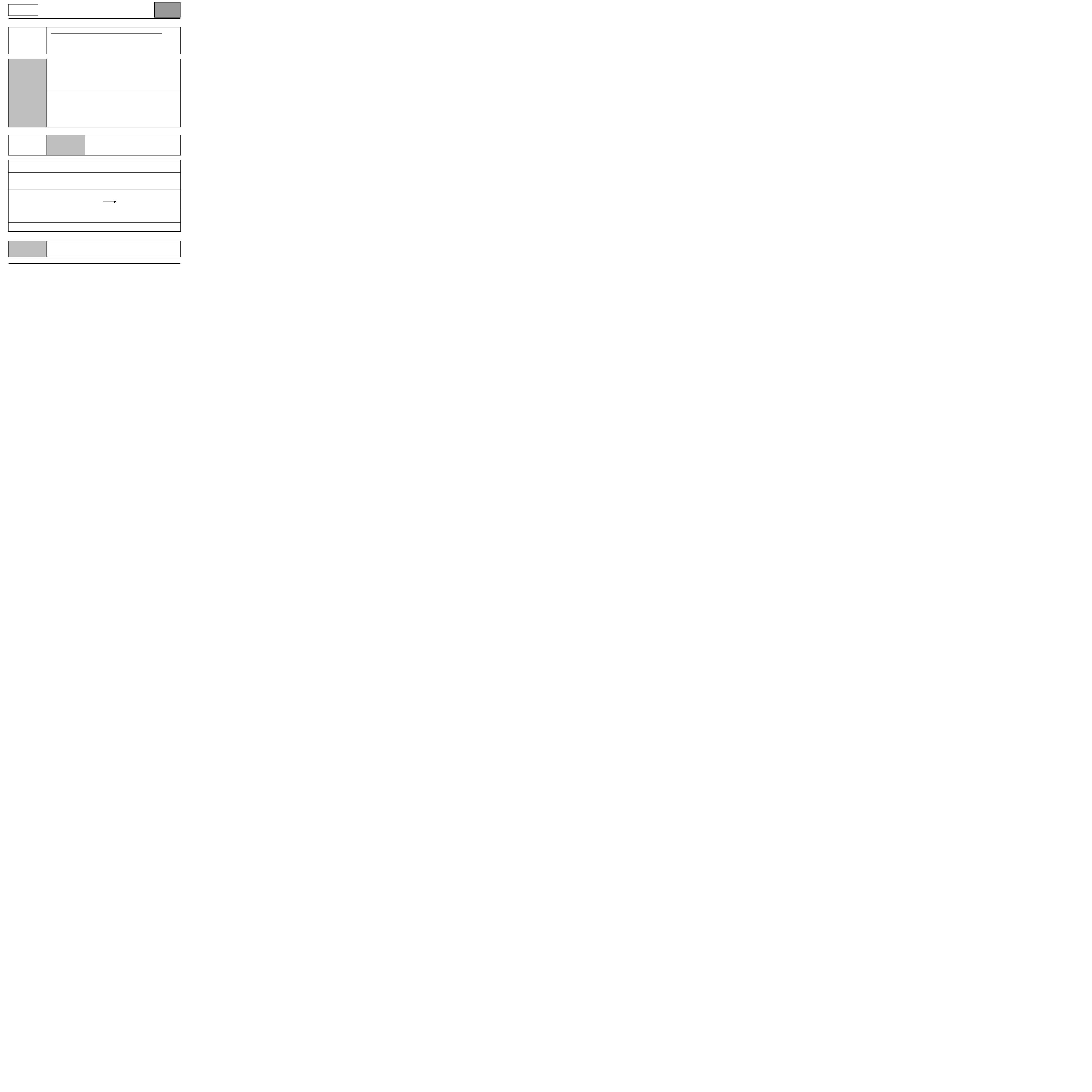

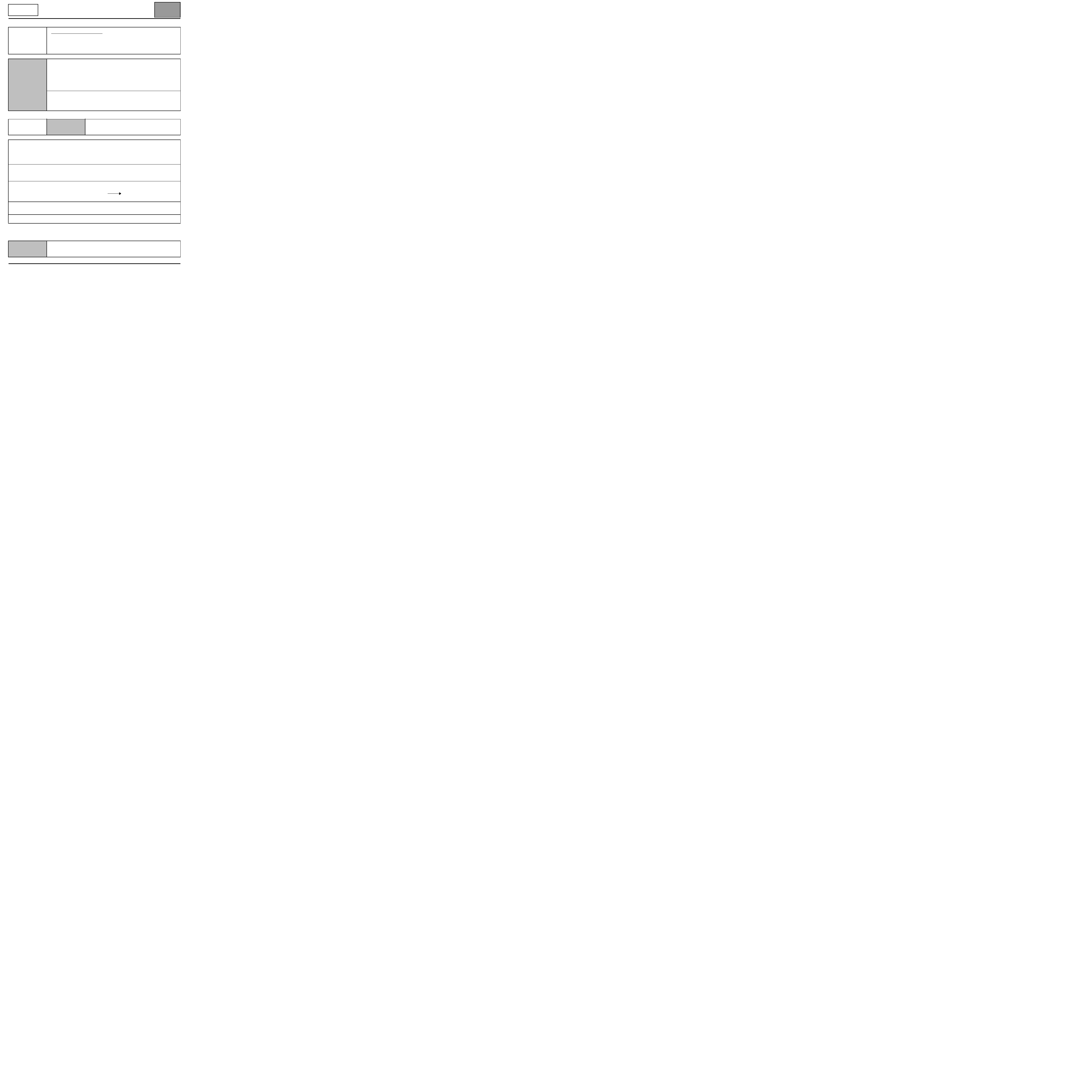

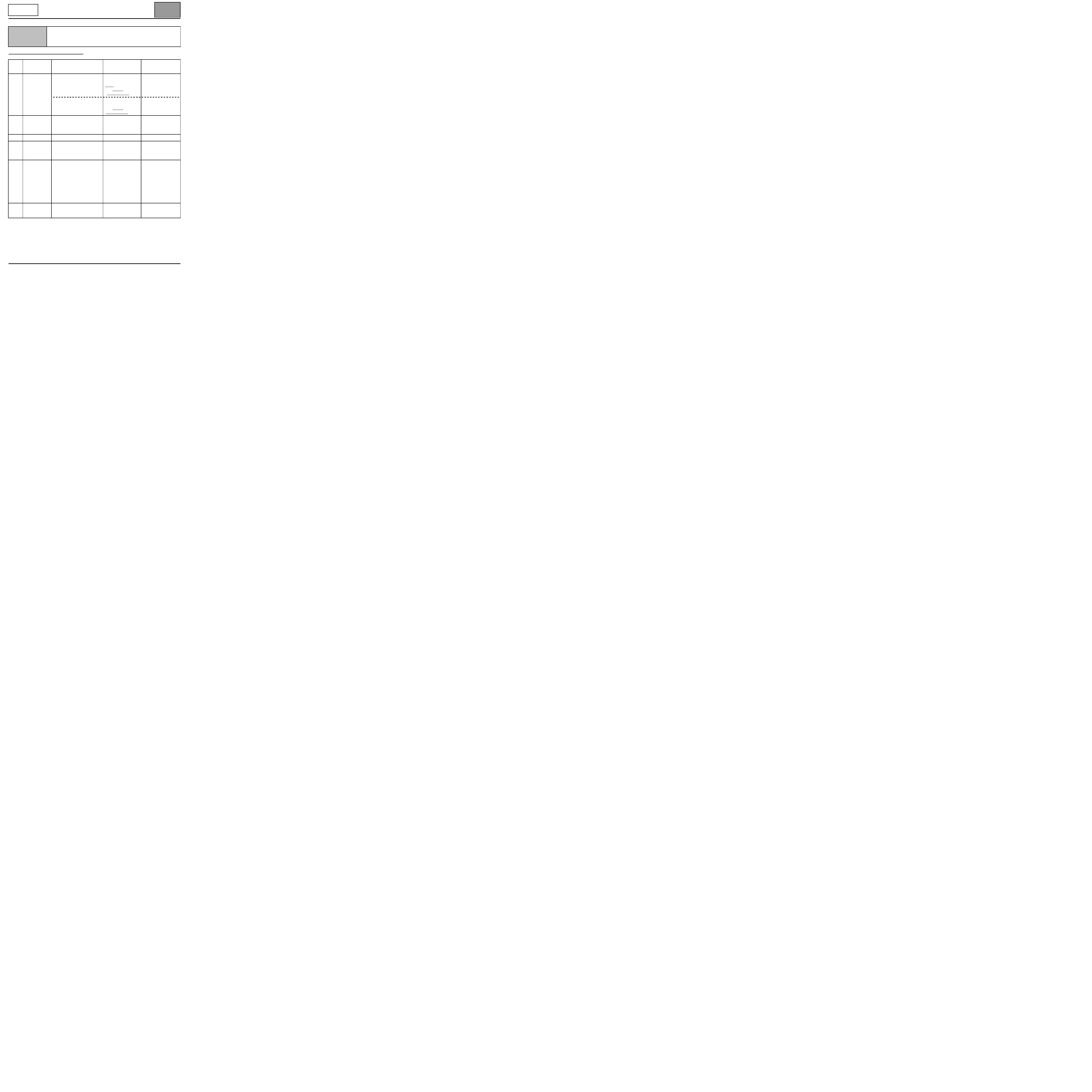

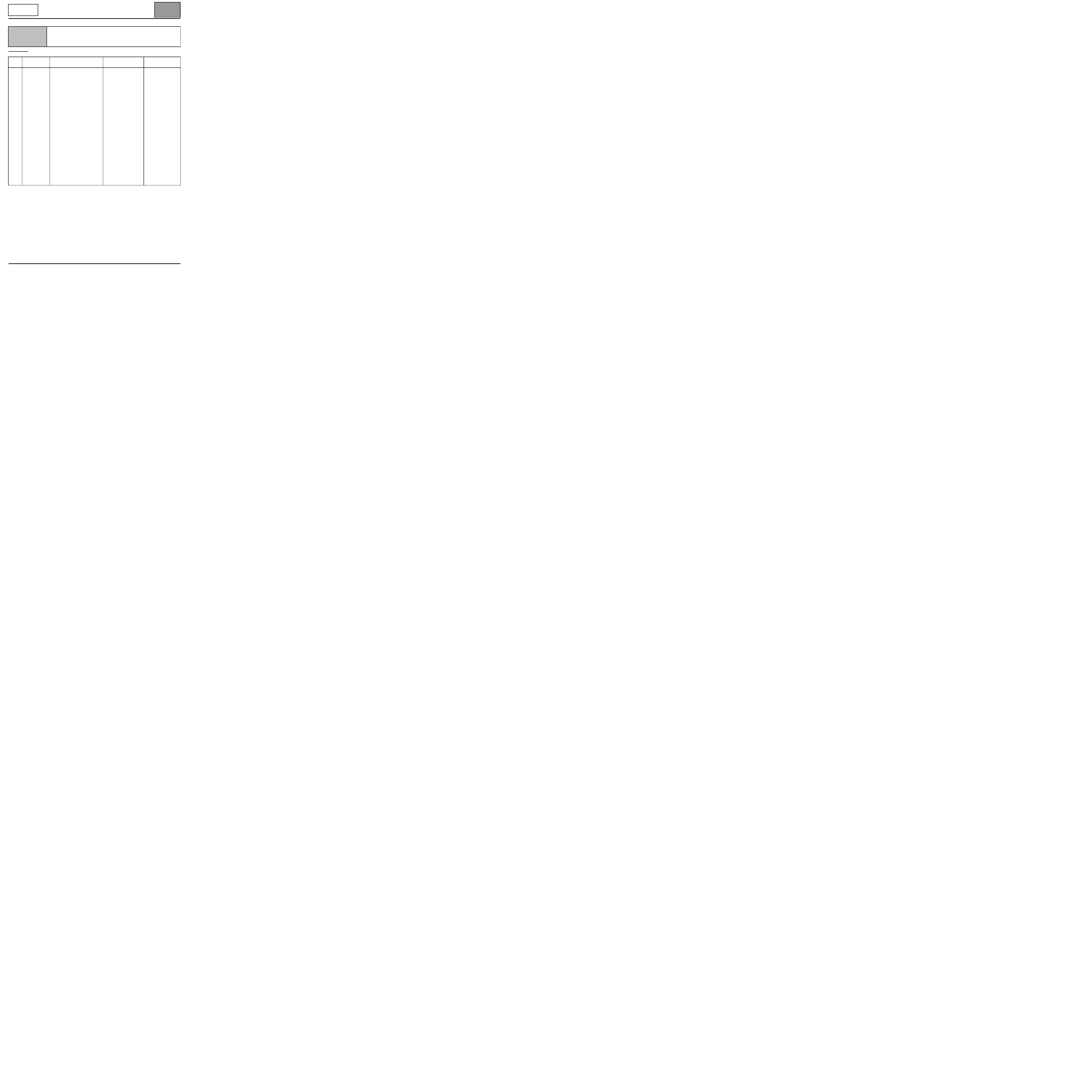

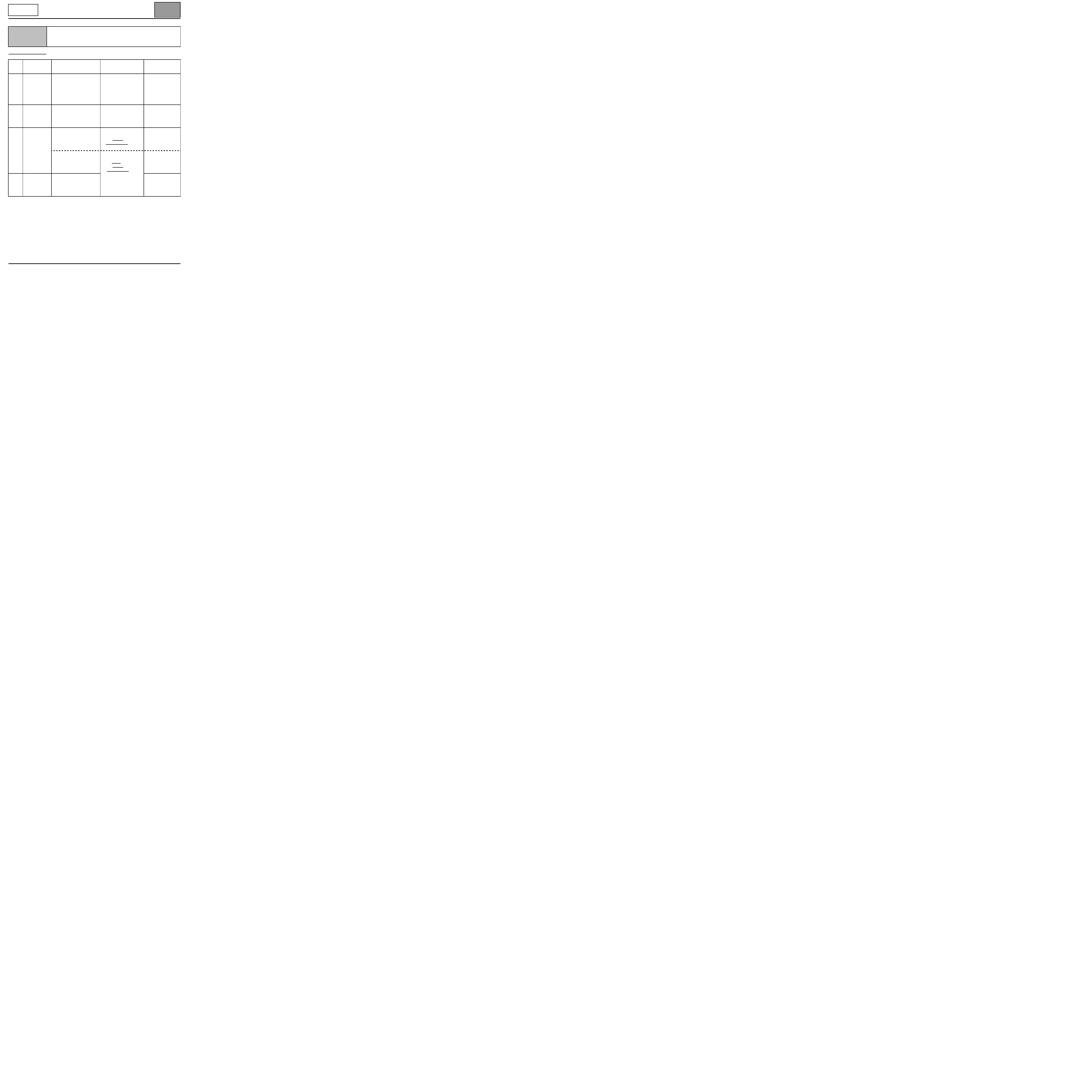

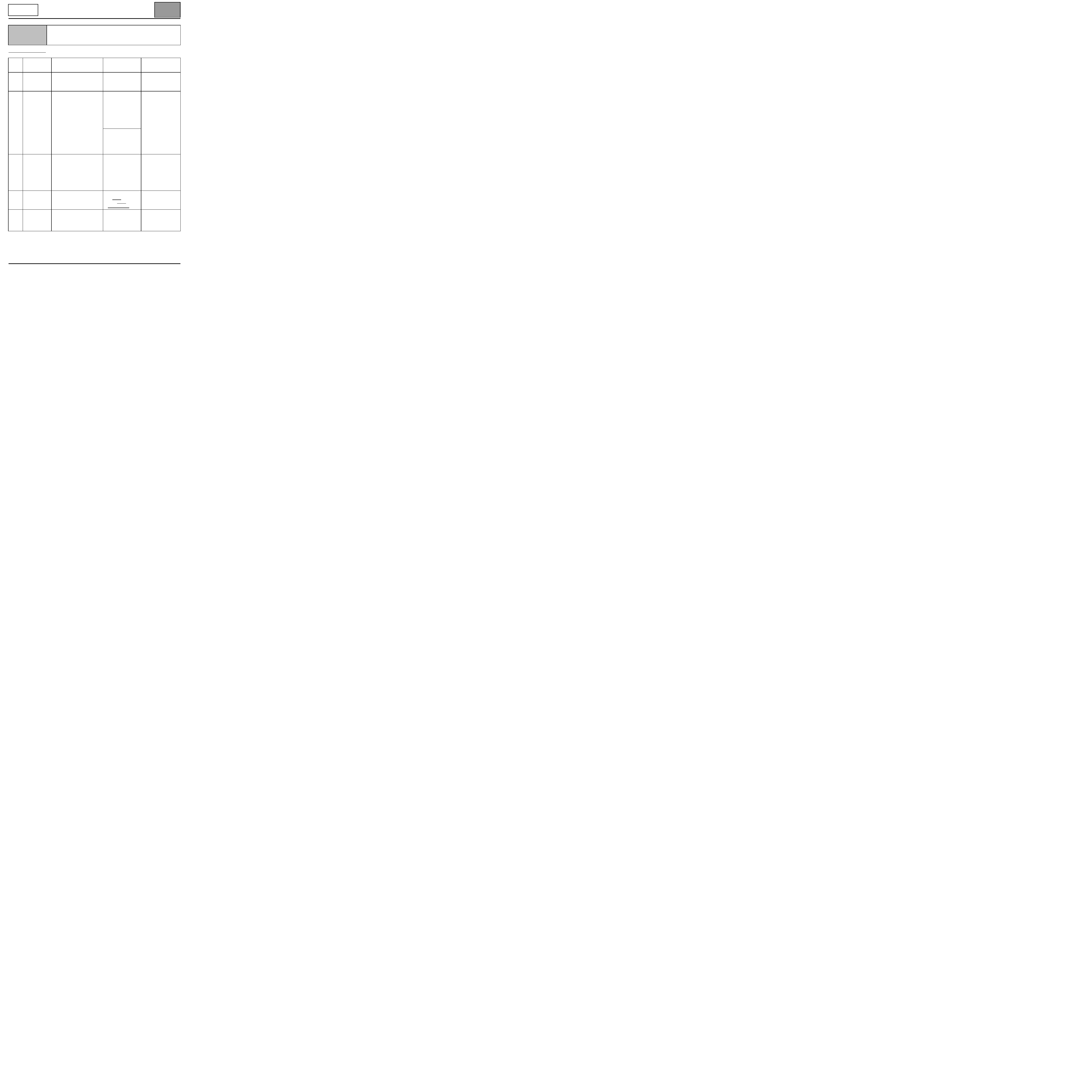

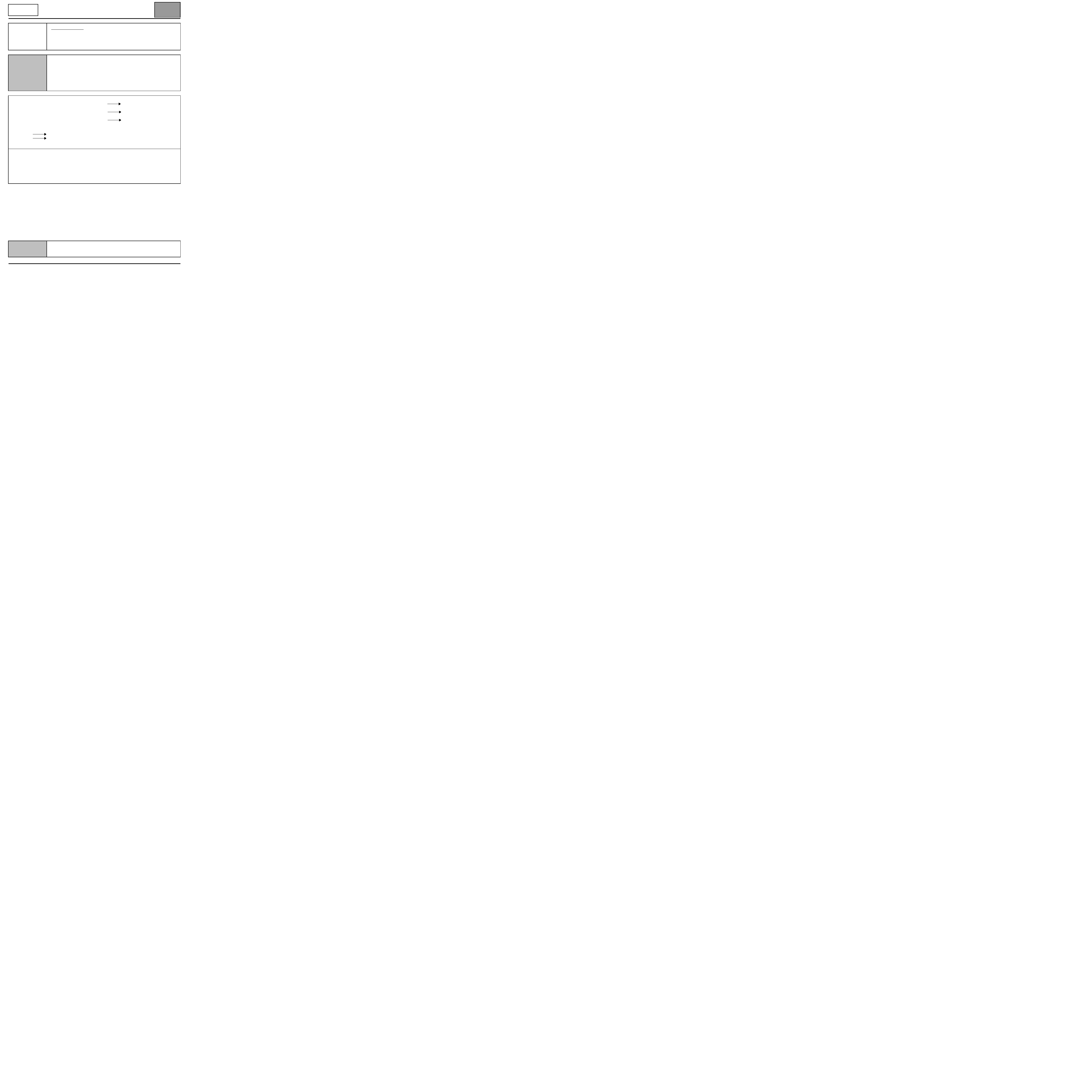

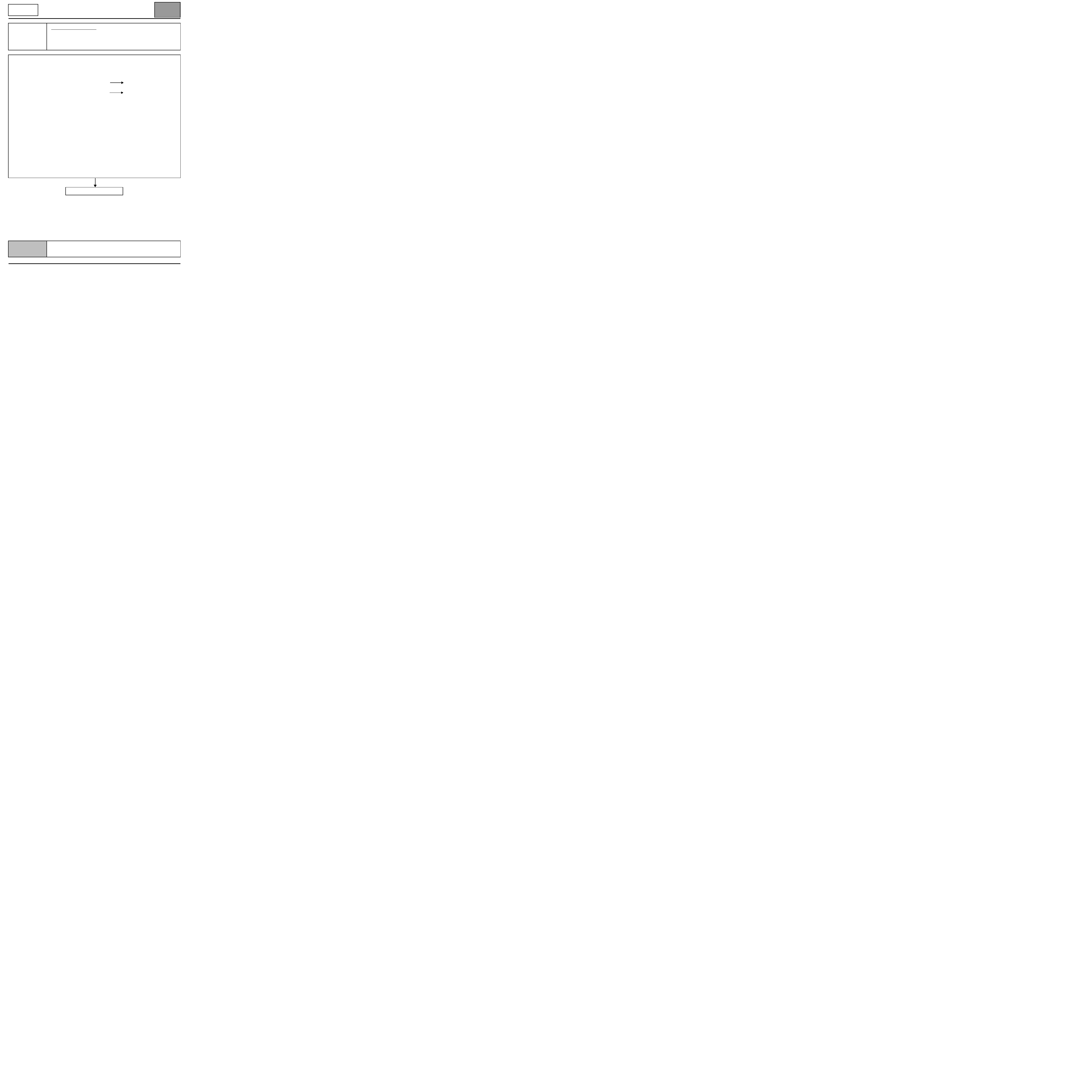

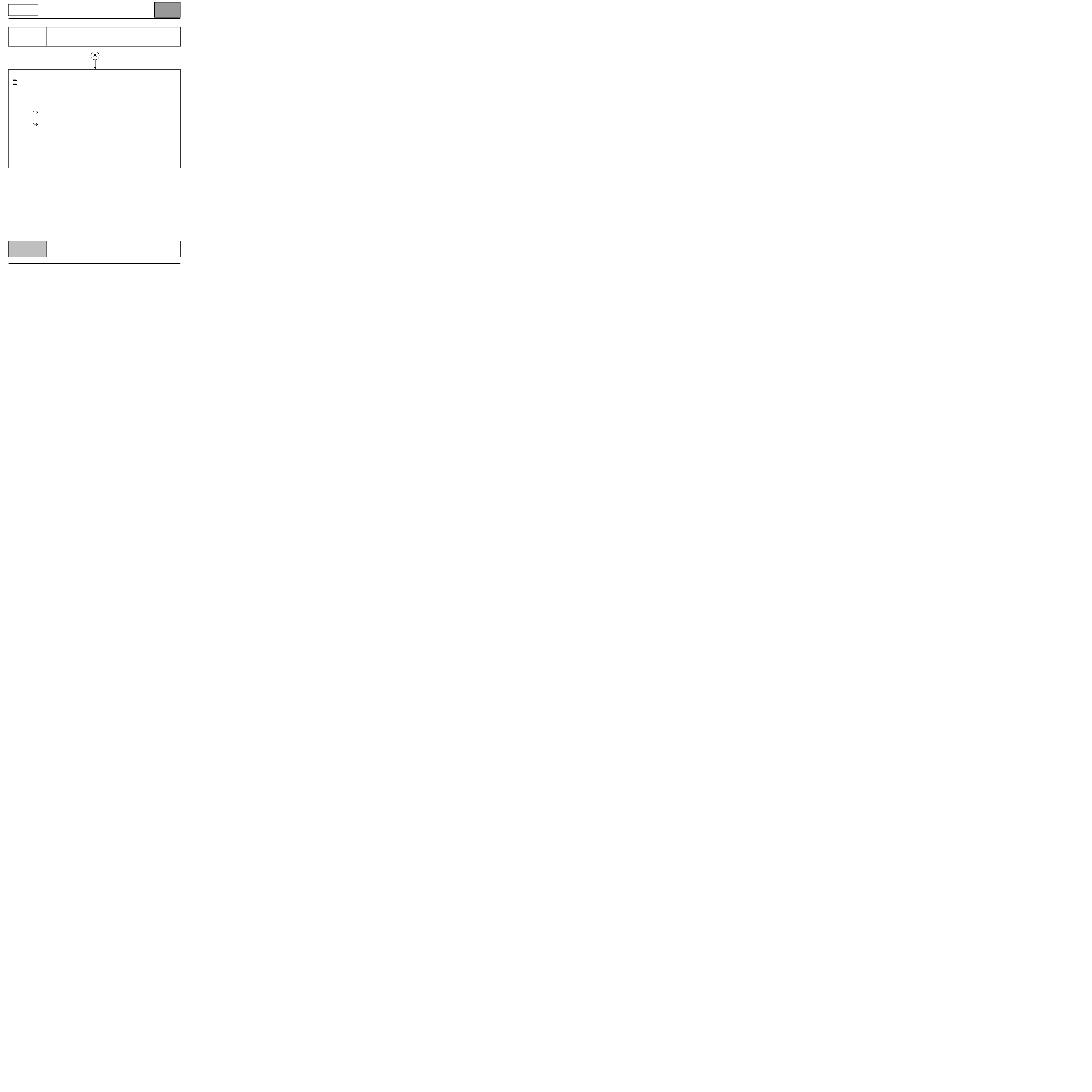

4. FAULT FINDING PROCEDURE

Check the battery charge and

condition of the fuses

Print the system diagnostic sheet

(available in CLIP and in the

Workshop Repair Manual or

Technical Note)

Connect CLIP

Dialogue

with

computer?

no

yes

Read faults

Faults

present

no

yes

Deal with faults found

Deal with stored faults

The symptom

persists

no

Fault

solved

yes

See CHART 1

Conformity check

The symptom

persists

no

Fault

solved

Use the fault

finding charts.

The symptom

persists

no

Fault

solved

Contact the Techline with the

completed fault finding sheet

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Introduction

13B

13B-5

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

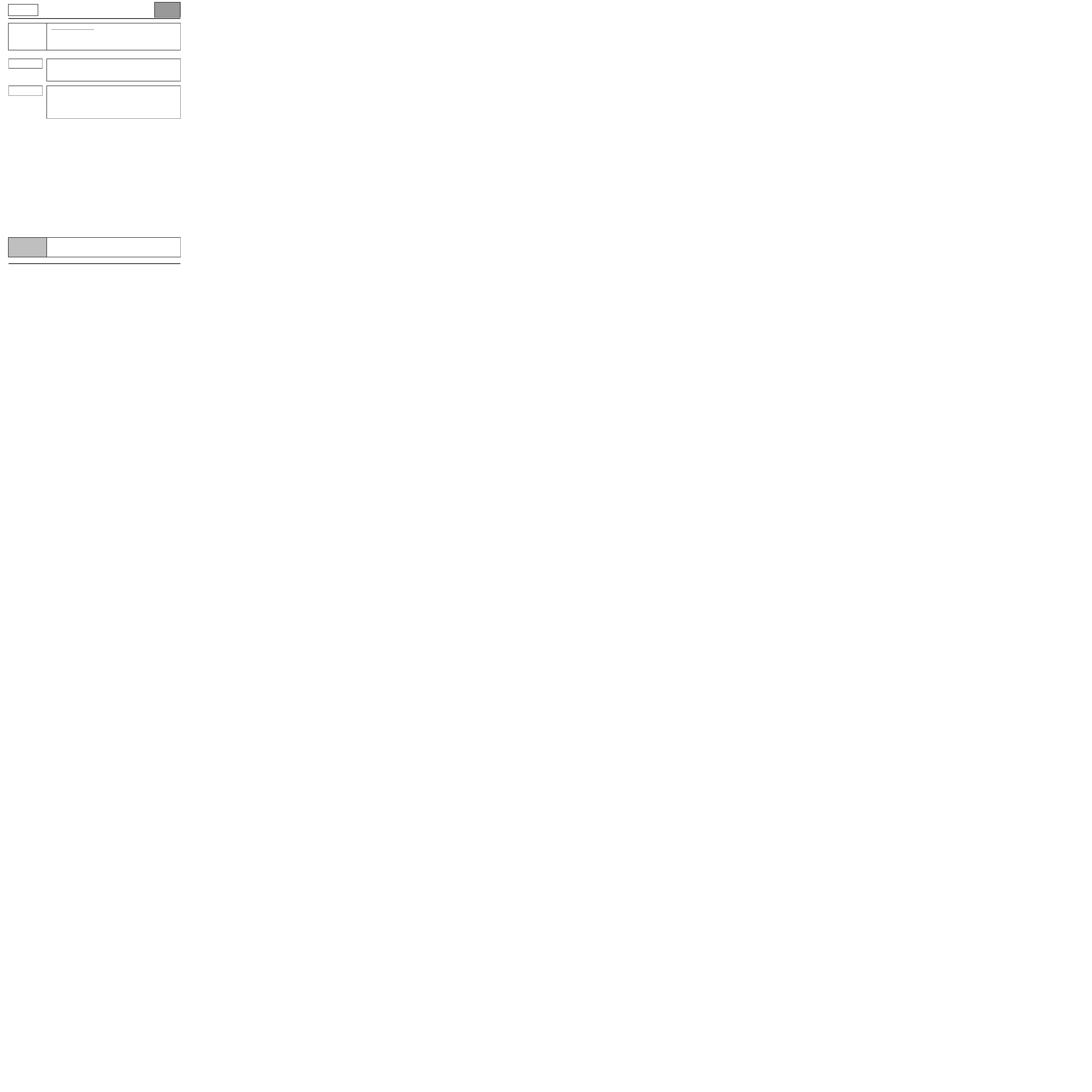

You will always be asked for this report:

– When requesting technical assistance from the Techline.

– For certification requests when replacing parts that must be certified.

– Which must be attached to monitored parts for which reimbursement is requested. It is therefore used to

decide whether a reimbursement will be made under warranty and leads to improved analysis of the

removed parts.

6. SAFETY INSTRUCTIONS

All work on components requires obeying safety rules to prevent physical damage or human injury:

– Make sure the battery is properly charged to avoid damaging the computers with a low charge.

– Use the proper tools.

CLEANLINESS INSTRUCTIONS WHICH MUST BE FOLLOWED WHEN WORKING ON THE HIGH-PRESSURE

DIRECT INJECTION SYSTEM

Risks relating to contamination

The system is very sensitive to contamination. The risks engendered by the introduction of pollution are: damage or

destruction to the high-pressure injection system and the engine, seizing or a component no longer being sealed.

All After-Sales operations must be performed under very clean conditions. This means that no impurities (particles a

few microns in size) get into the system during dismantling or into the circuits via the fuel unions.

The cleanliness guidelines must be applied from the filter through to the injectors.

WARNING!

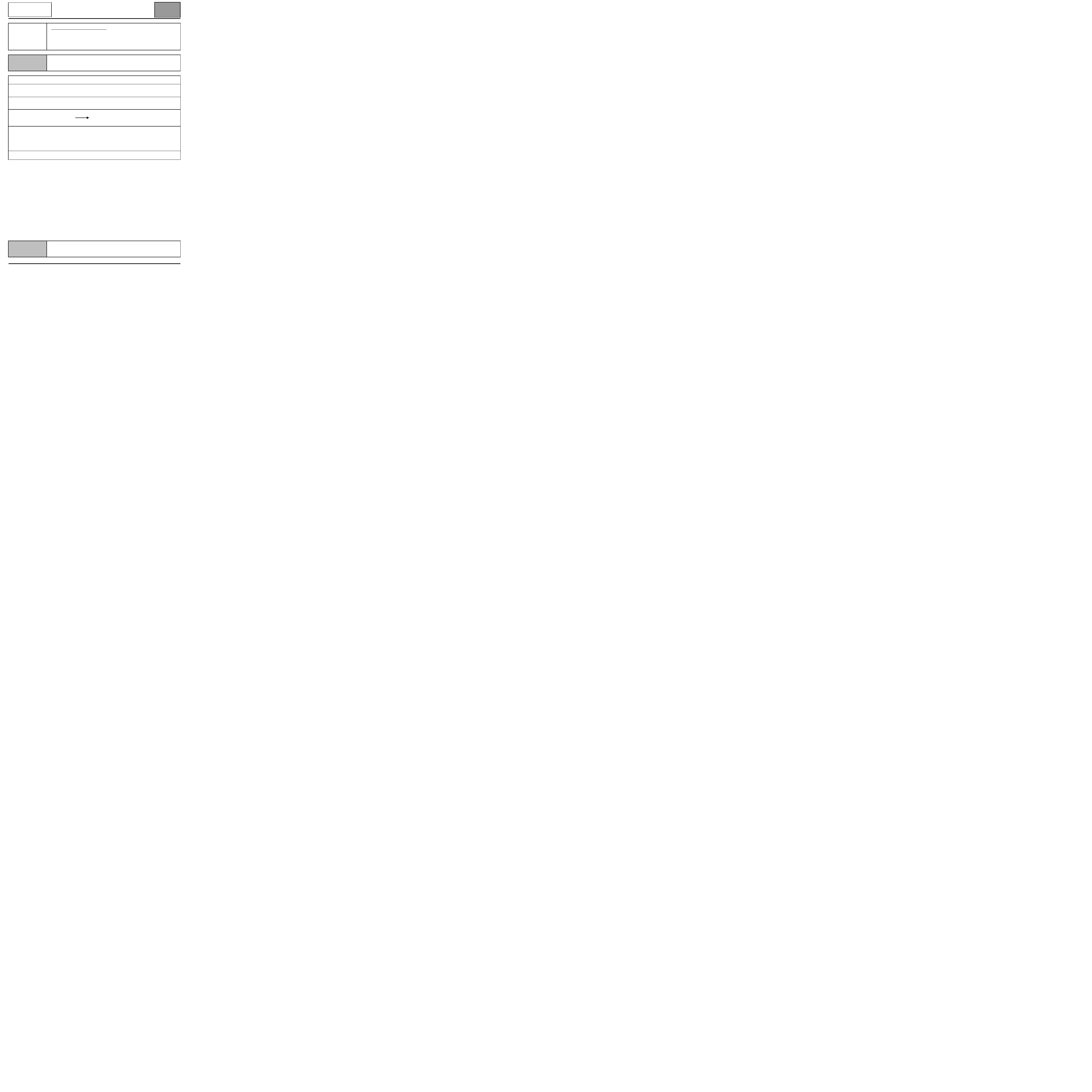

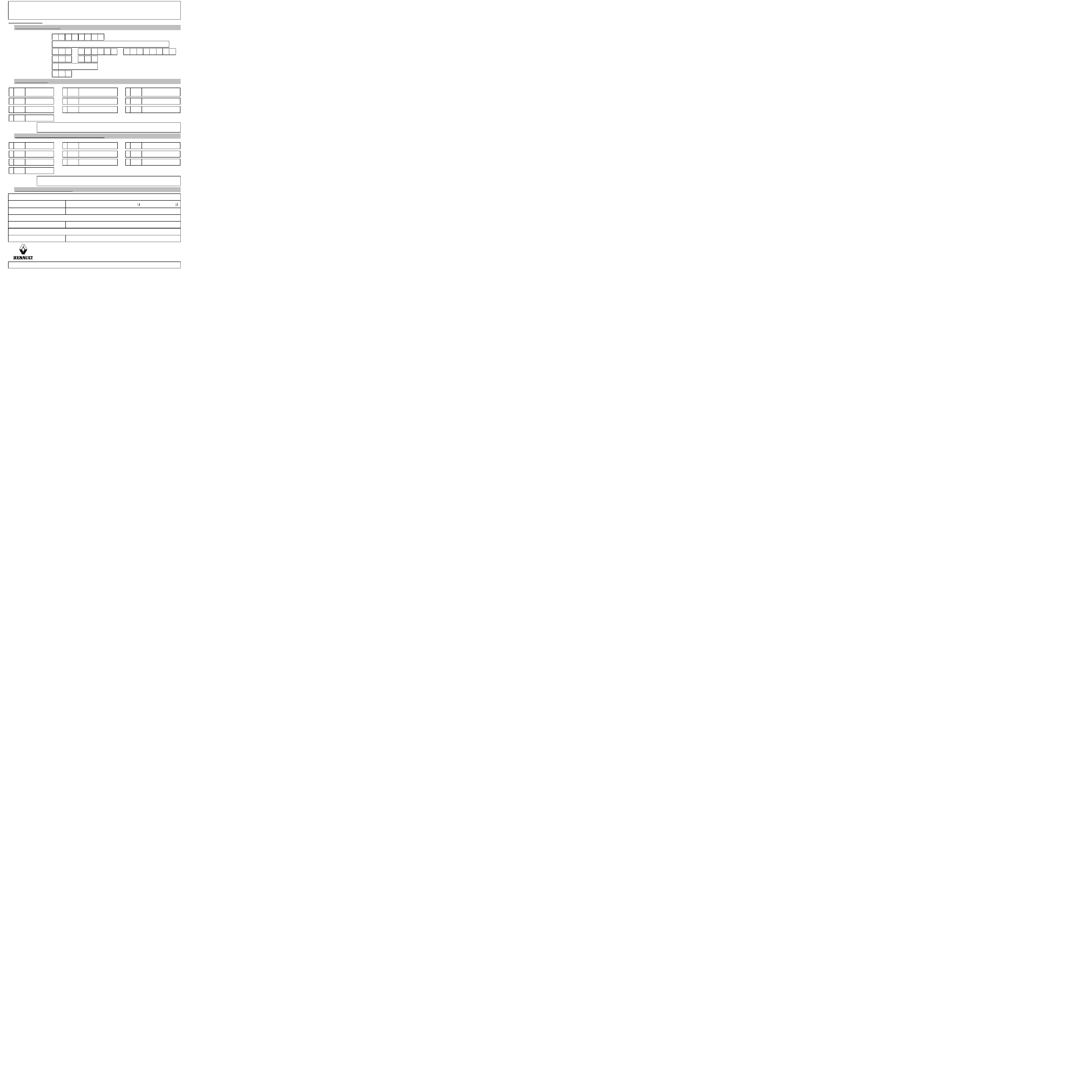

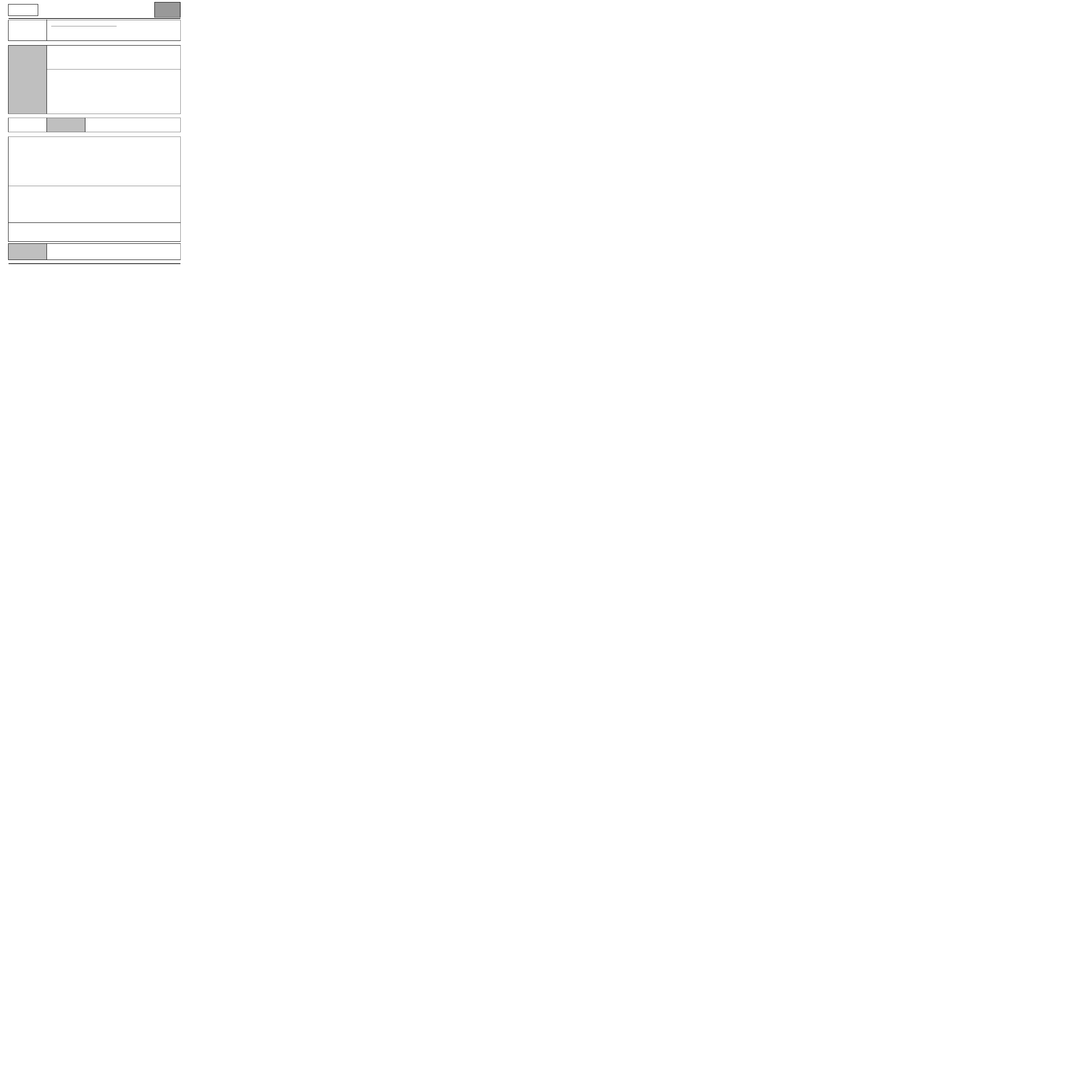

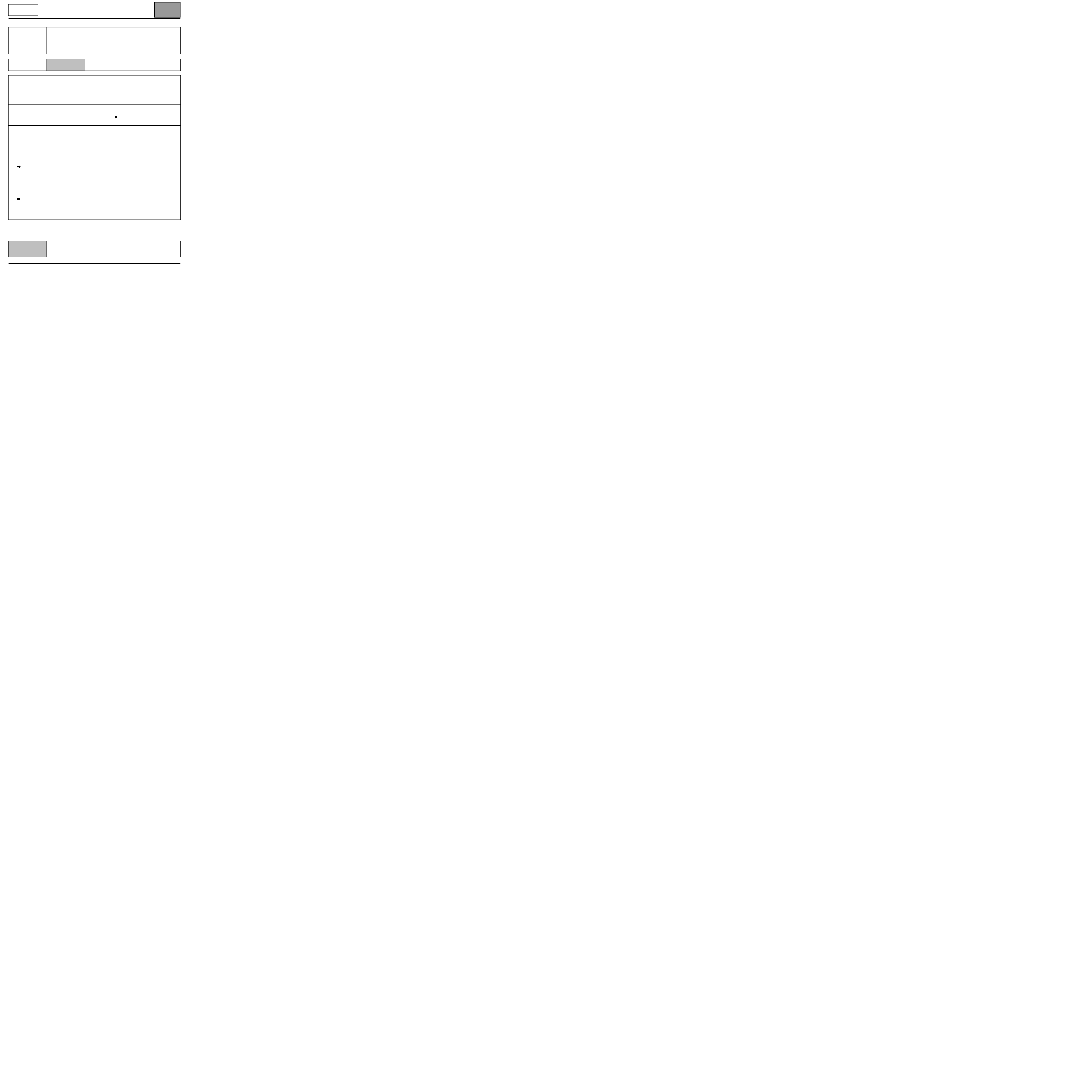

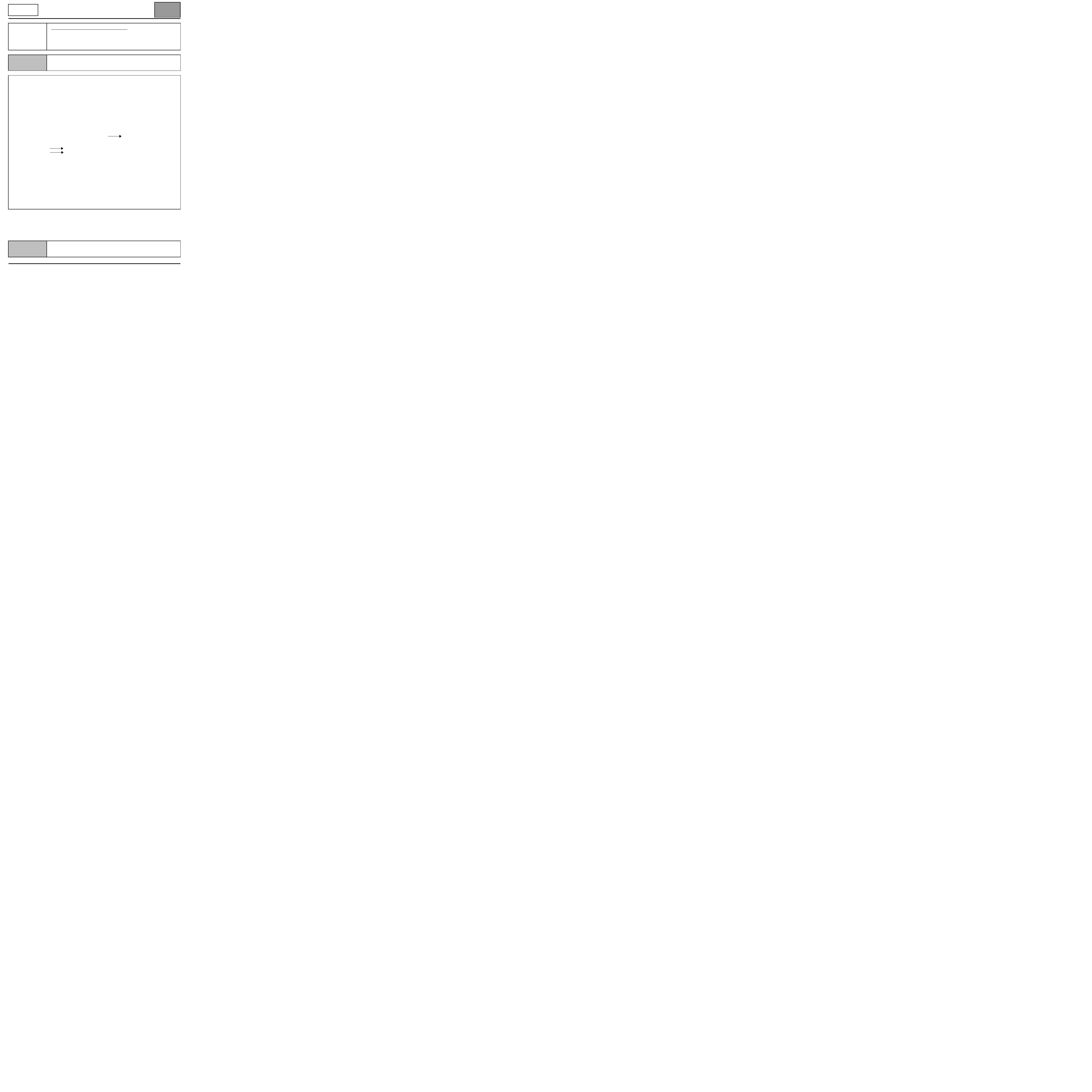

5. FAULT FINDING LOG

WARNING

All problems involving a complex system call for thorough diagnostics with the appropriate tools.

The FAULT FINDING LOG, which should be completed during the fault finding procedure,

ensures a record is kept of the procedure carried out. It is an essential item when discussing the

fault with the constructor.

IT IS THEREFORE MANDATORY TO FILL OUT A FAULT FINDING SHEET EACH TIME FAULT FINDING

IS DONE.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Introduction

13B

13B-6

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

6. SAFETY INSTRUCTIONS (CONTINUED):

BEFORE WORKING ON THE INJECTION SYSTEM, ENSURE THAT THE SYSTEM PRESSURE IS CLOSE TO

0 BAR.

What are the sources of contamination?

Contamination is caused by:

– metal or plastic chips,

– paint,

– fibres: from cardboard

from brushes,

from paper,

from clothing,

from cloths,

– foreign bodies such as hair,

– ambient air,

– etc.

Instructions to be followed before any work is carried out on the injection system:

Ensure that you have the plugs for the unions to be opened (bag of plugs available from the Parts Stores, Part no.:

77 01 206 804). Plugs are to be used once only. After use, they must be thrown away (once used they are soiled and

cleaning is not sufficient to make them reusable). Unused plugs must be thrown away.

Ensure that you have hermetically resealable plastic bags for storing removed parts. Stored parts will therefore be

less subject to the risk of impurities. The bags must be used only once, and after use they must be thrown away.

Make sure that lint-free towelettes are available (part number 77 11 211 707). The use of a normal cloth or paper for

cleaning purposes is forbidden. They are not lint-free and may contaminate the fuel circuit of the system. Each lint-

free cloth should only be used once.

WARNING

Never clean the engine using a high pressure washer because of the risk of damaging connections. In addition,

moisture may collect in the connectors and create electrical connection problems.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Introduction

13B

13B-7

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

6. SAFETY INSTRUCTIONS (CONTINUED):

Instructions to be followed before opening the fuel circuit

Use new thinner for each operation (used thinner contains impurities). Pour it into a clean receptacle.

For each operation, use a clean brush in good condition (the brush must not shed its bristles).

Use a brush and thinners to clean the connections to be opened.

Blow compressed air over the cleaned parts (tools, cleaned the same way as the parts, connections and injection

system zone). Check that no bristles remain adhering.

Wash your hands before and during the operation if necessary.

When wearing leather protective gloves, cover them with latex gloves.

Instructions to be followed during the operation

As soon as the circuit is open, all openings must be plugged to prevent impurities from entering the system.

The plugs to be used are available from the Parts Stores. They must not, under any circumstances, be reused.

Close the hermetically sealed bag, even if it has to be reopened shortly afterwards. The ambient atmosphere carries

impurities.

All components removed from the injection system must be stored in a hermetically sealed plastic bag once the

plugs have been inserted.

The use of a brush, thinner, bellows, sponge or normal cloth is strictly prohibited once the circuit has been opened.

These items are likely to allow impurities to enter the system.

A new component replacing an old one must not be removed from its packaging until it is to be fitted to the vehicle.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Introduction

13B

13B-8

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

7. ABBREVIATIONS

12 Volts APC: 12 Volts supply after ignition.

12 Volts AVC: 12 Volts supply before ignition.

ABS: Anti-lock braking system

BVA: Automatic transmission.

C2I: Individual injector correction.

CAN: Controller Area Network.

COSLA: Discharge bulb (xenon bulb) beam test.

EGR: Exhaust gas recirculation.

ESP: Electronic Stability Program.

TDC: Top Dead Centre.

BDC: Bottom Dead Centre.

POWER LATCH: maintained supply phase.

RCH: Passenger compartment heater resistance.

UCH: Passenger Compartment Control Unit.

UPC: Switching and protection unit.

VIN: Vehicle Identification Number.

K9K044 X 84 1.0

Edition 2

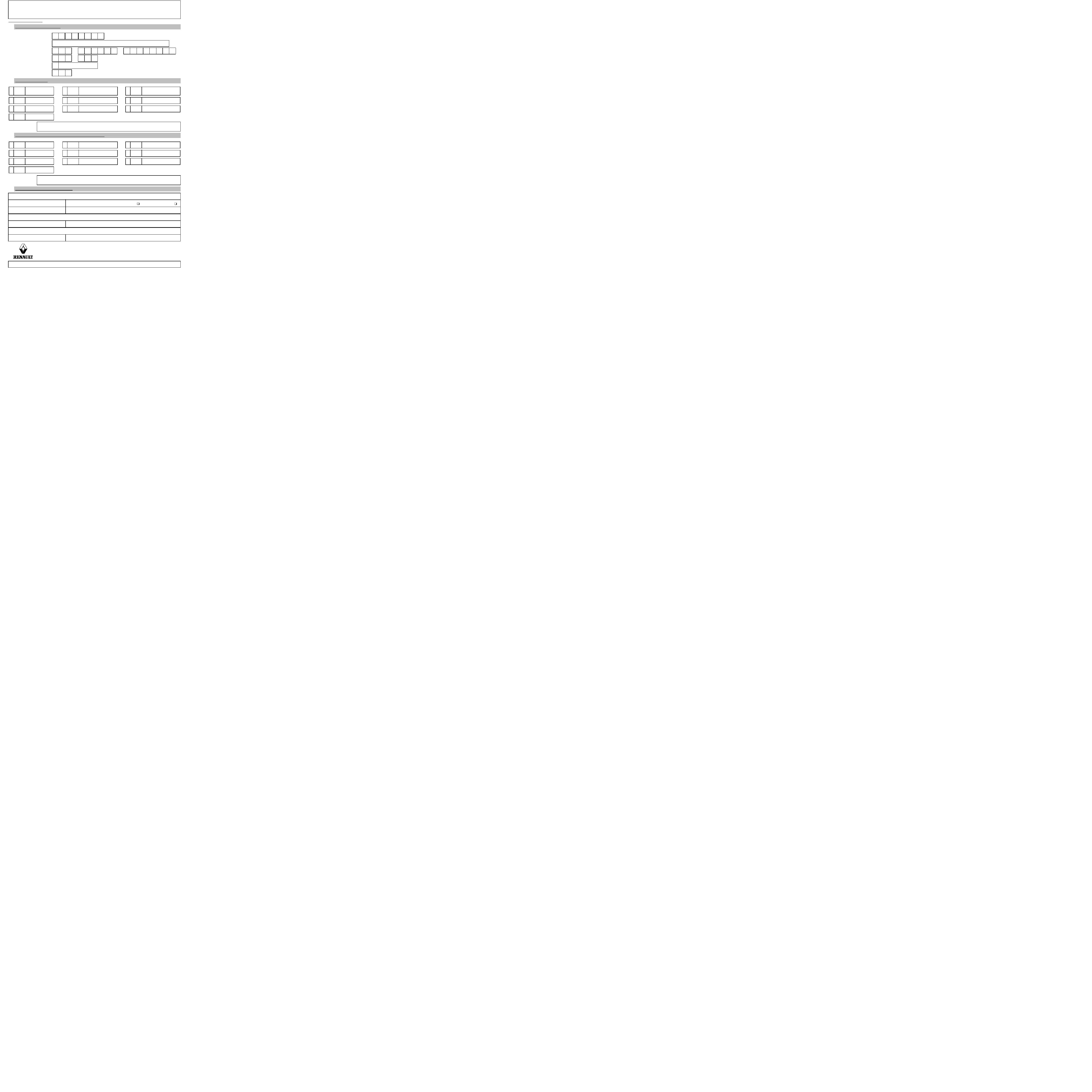

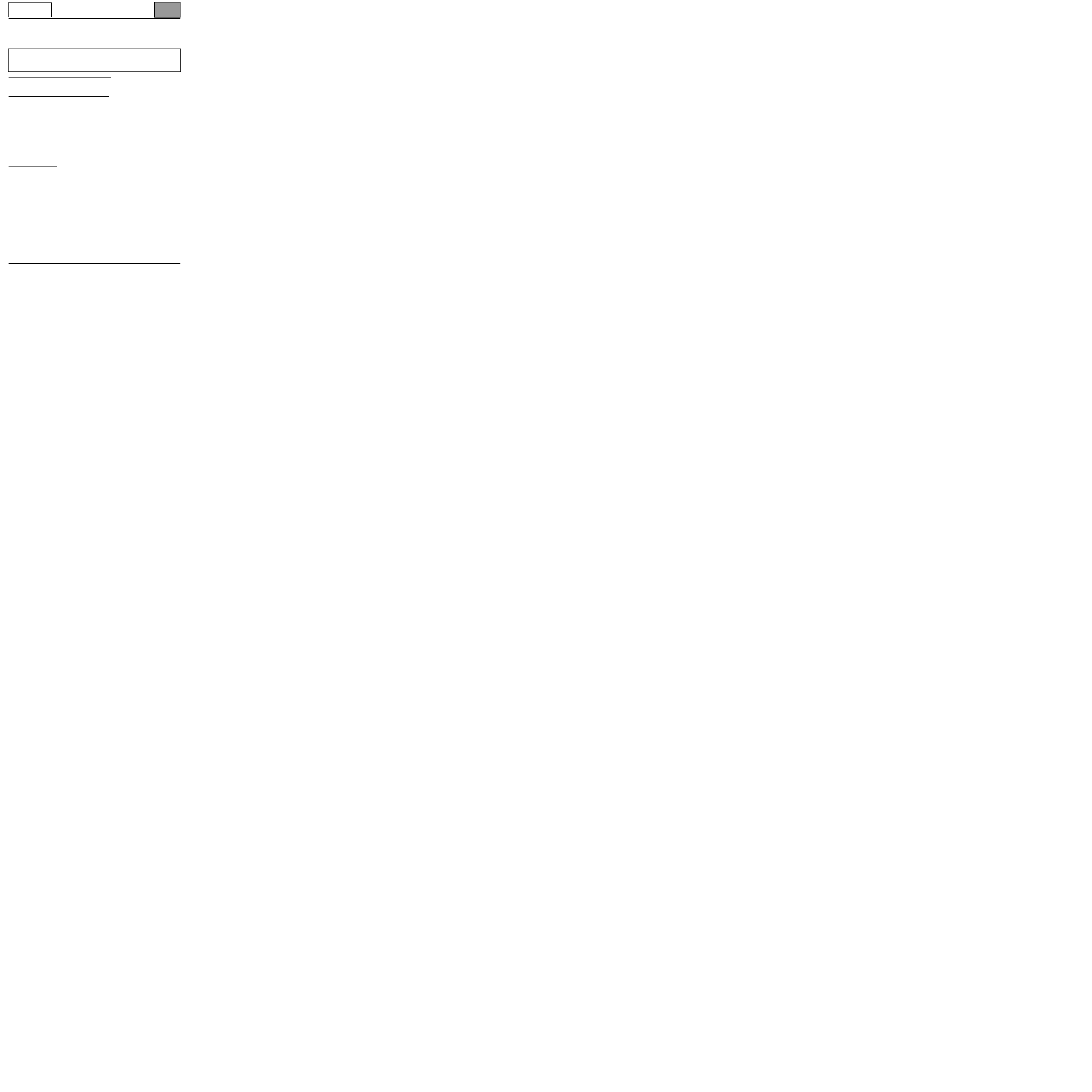

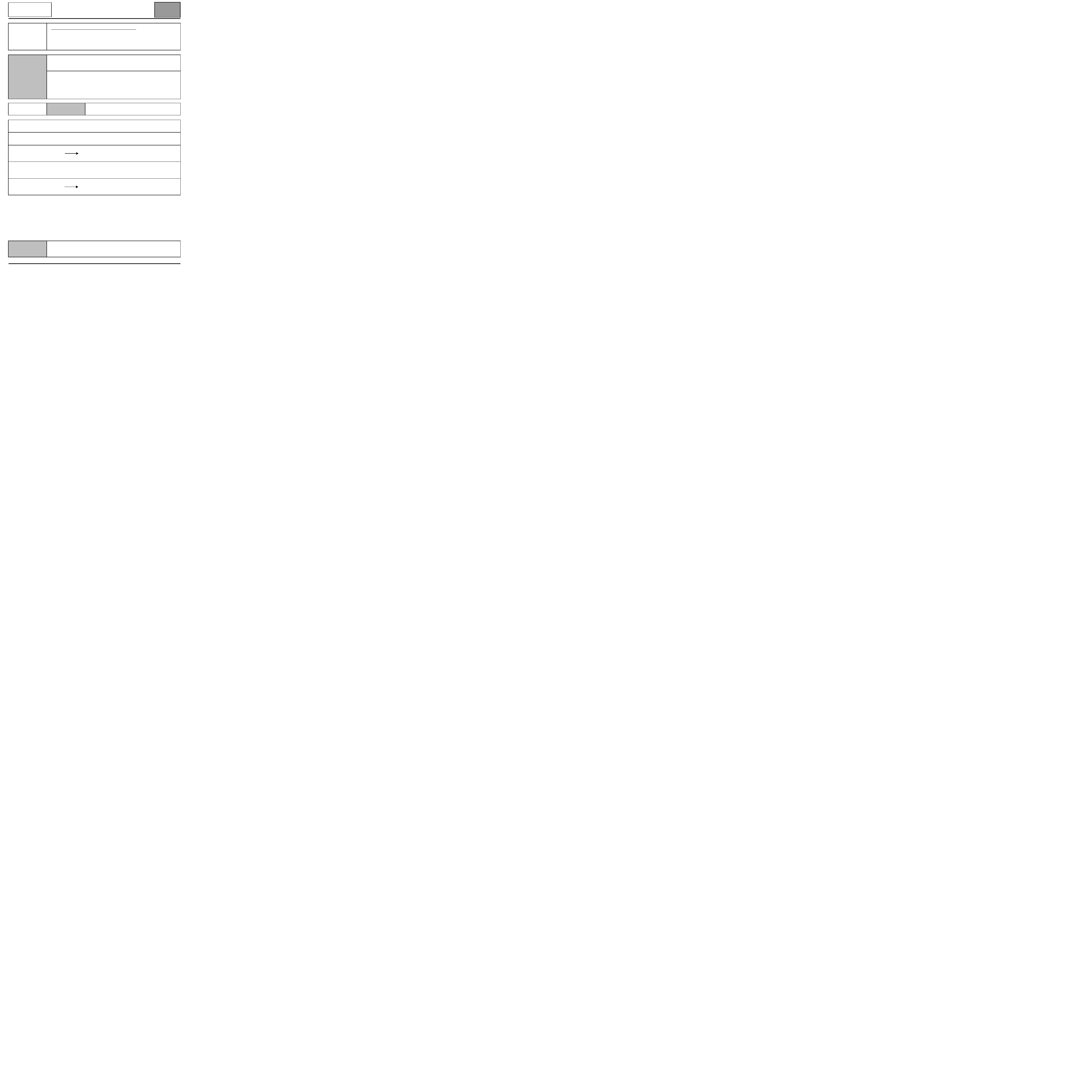

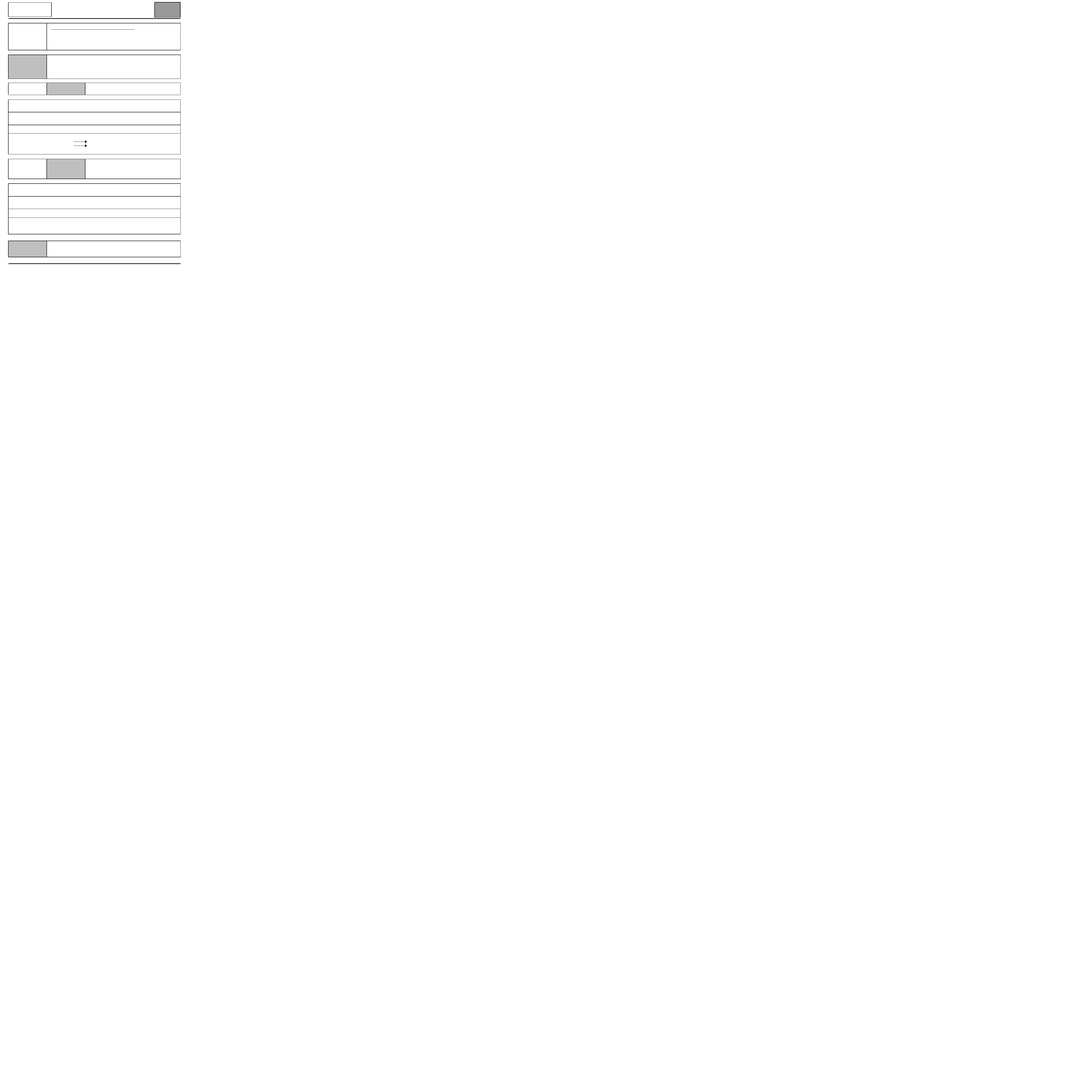

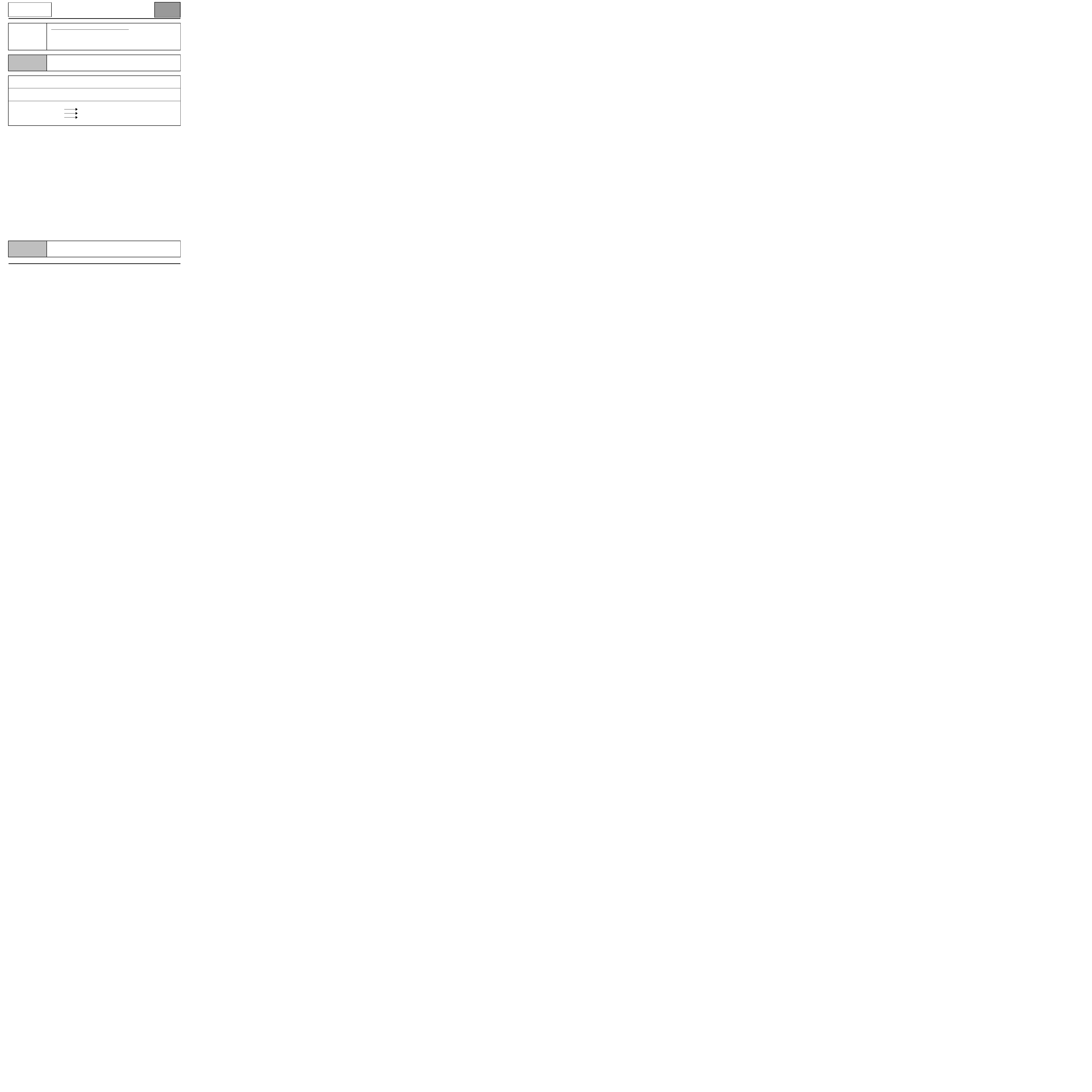

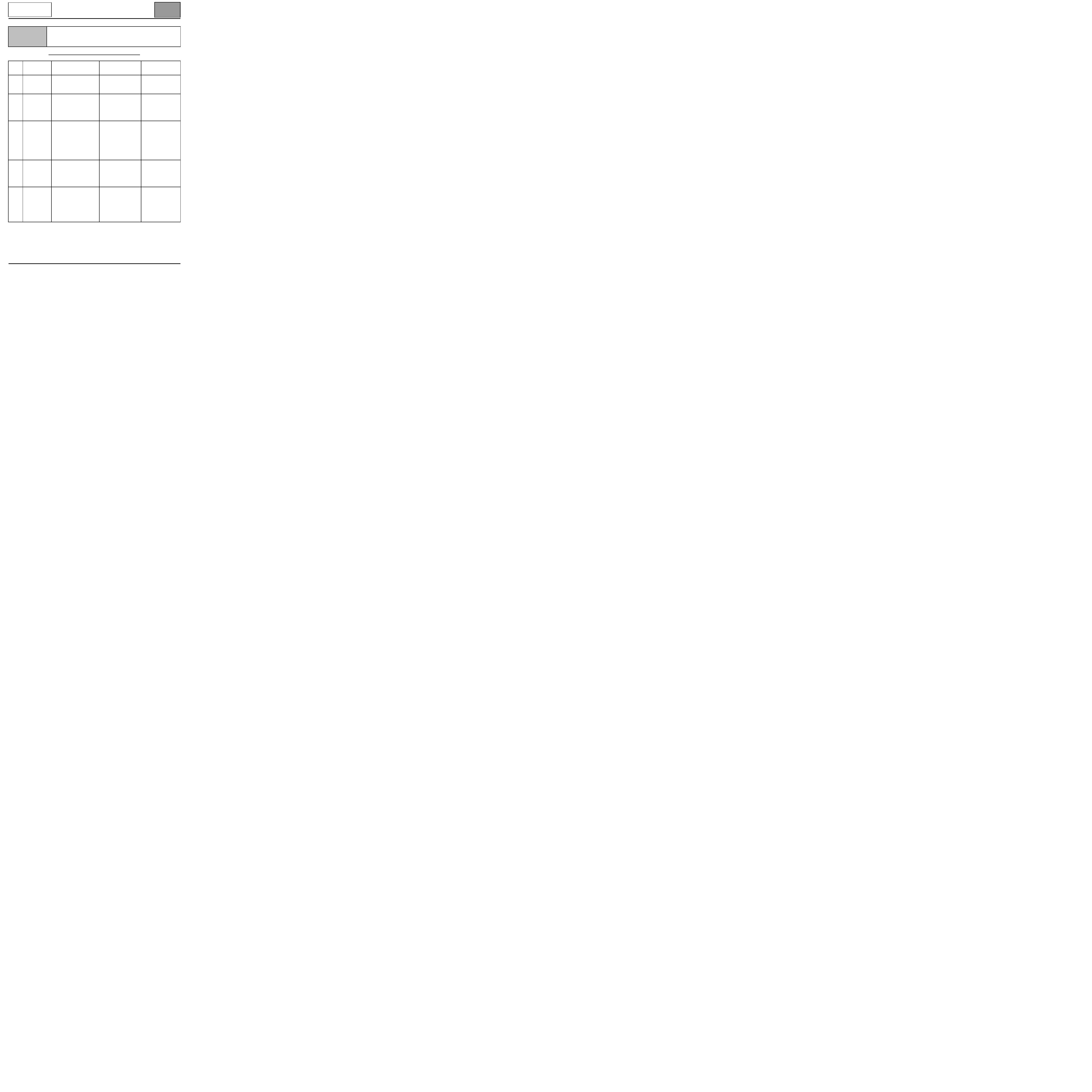

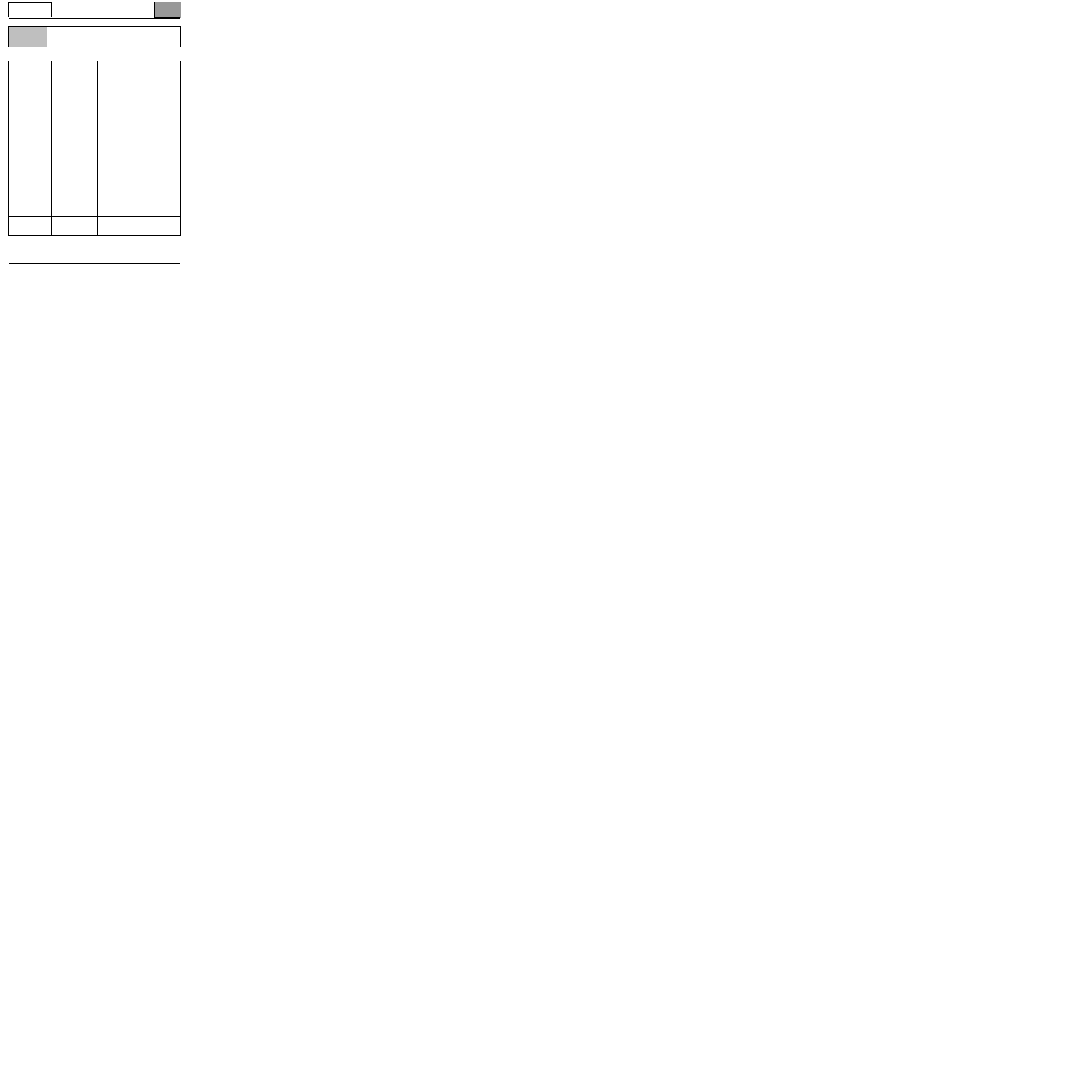

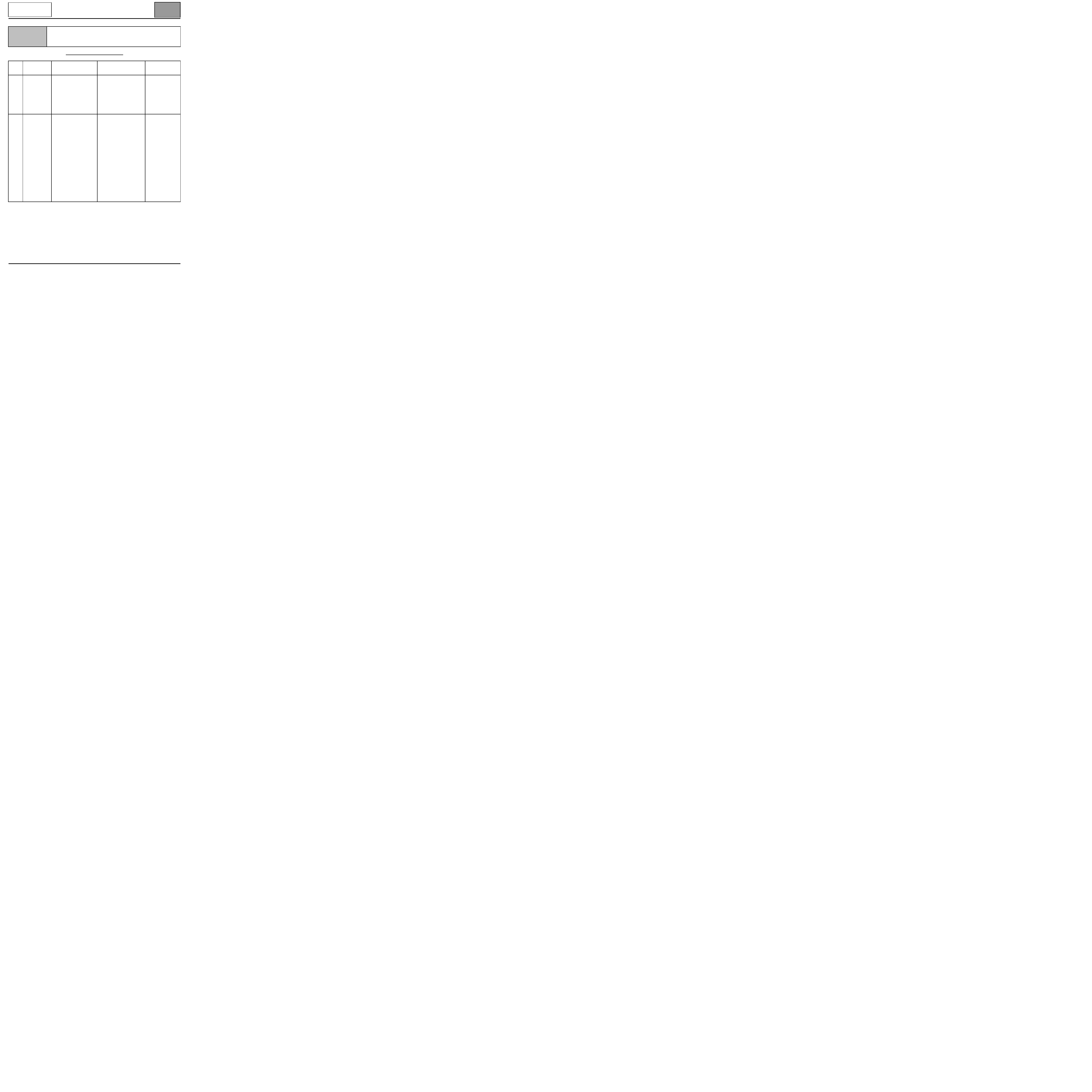

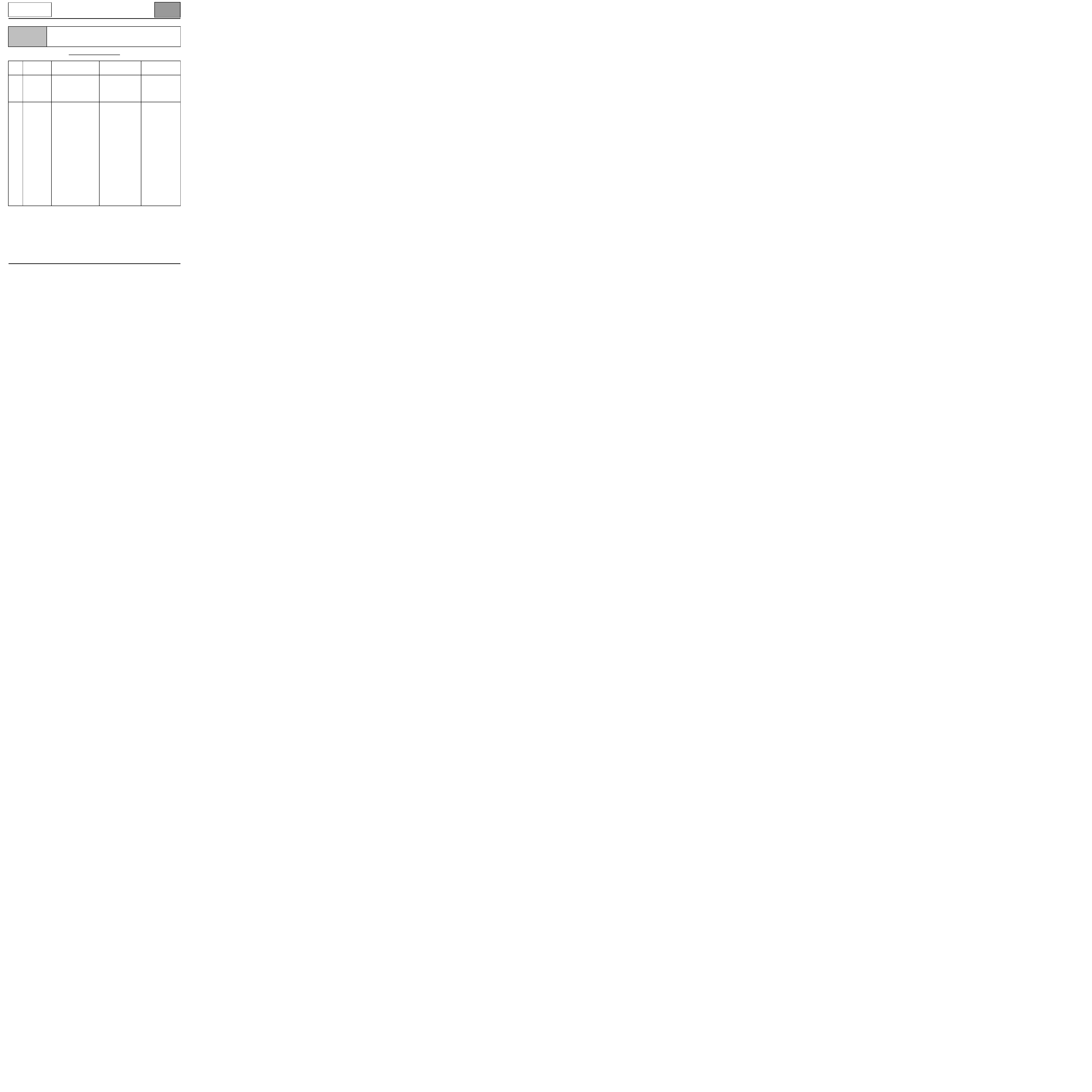

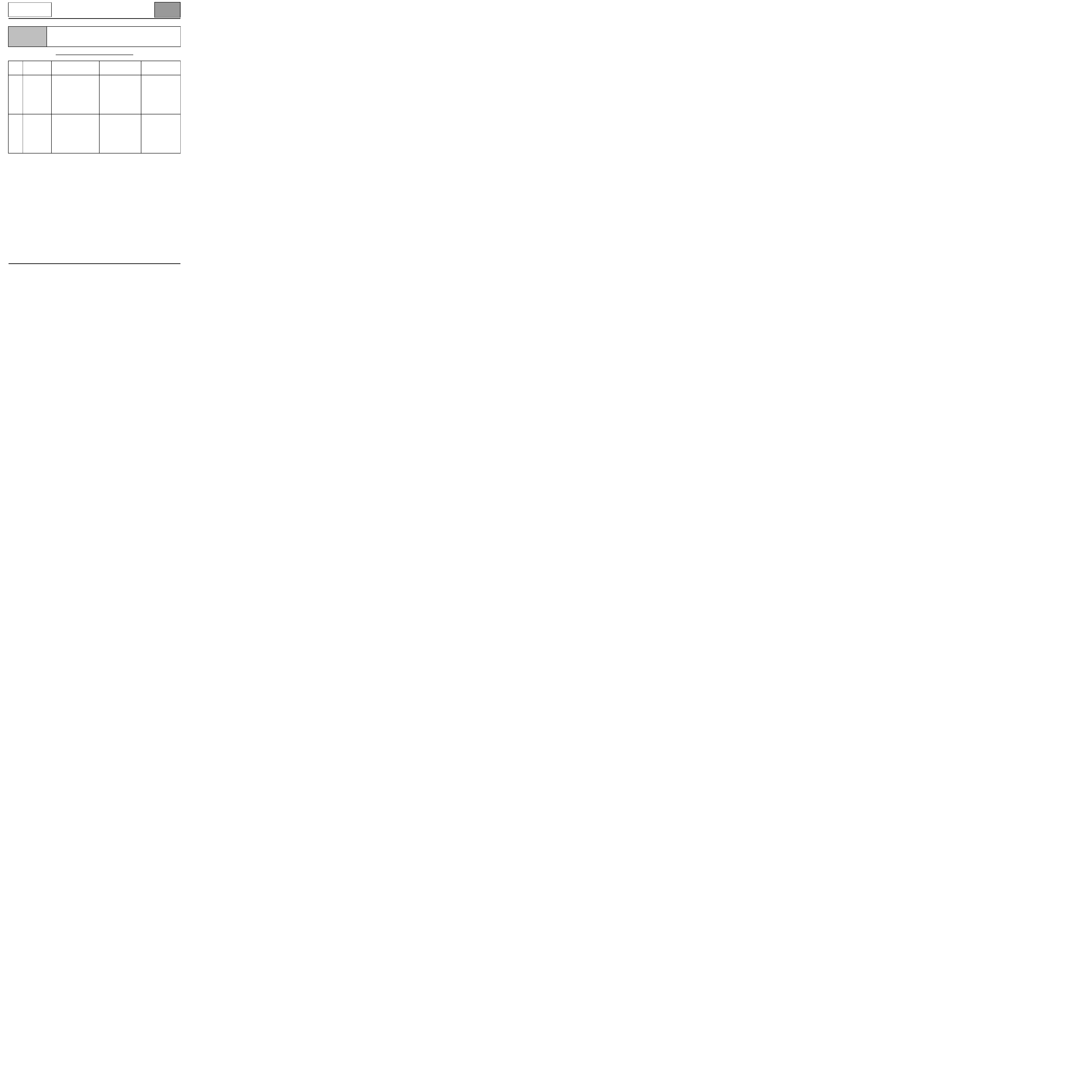

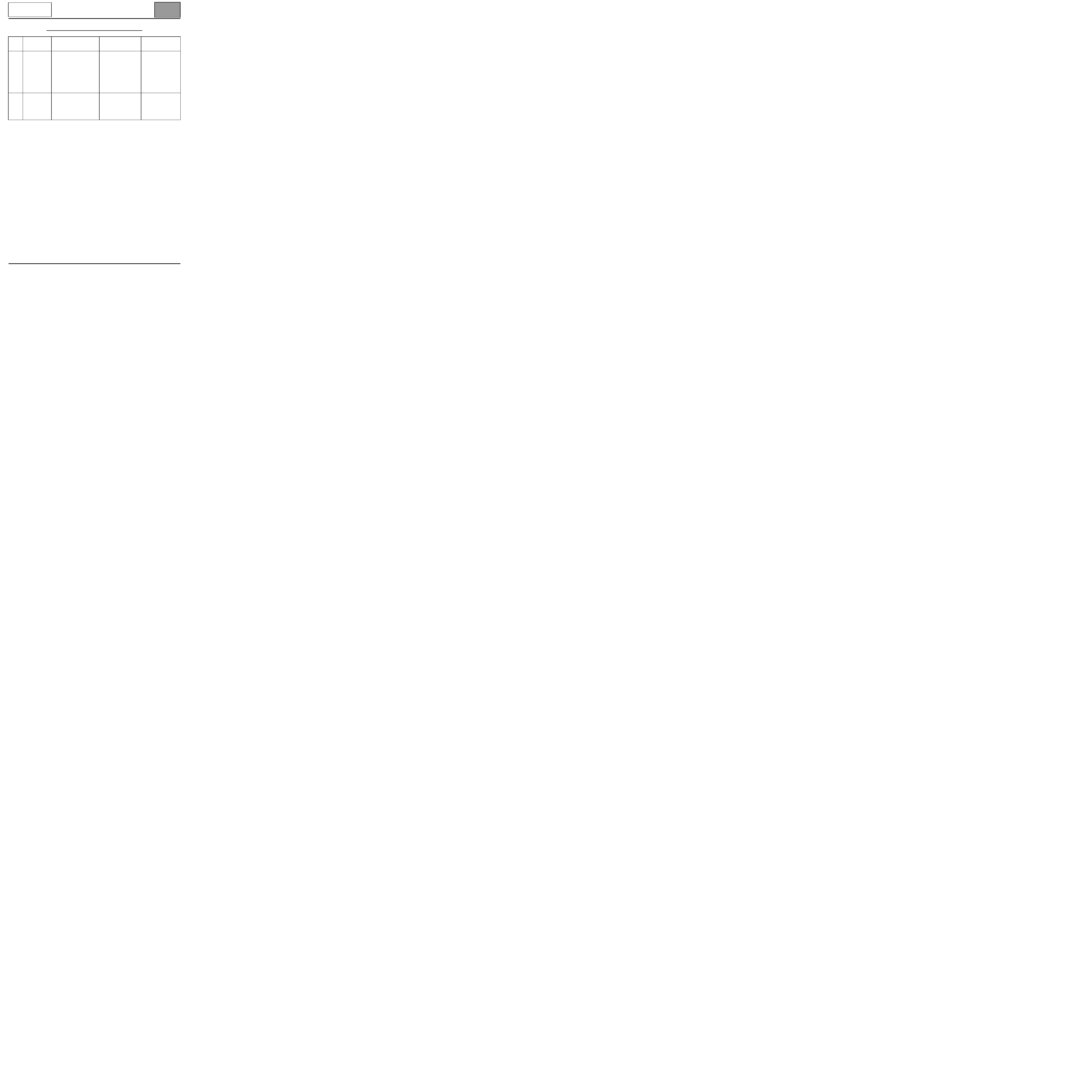

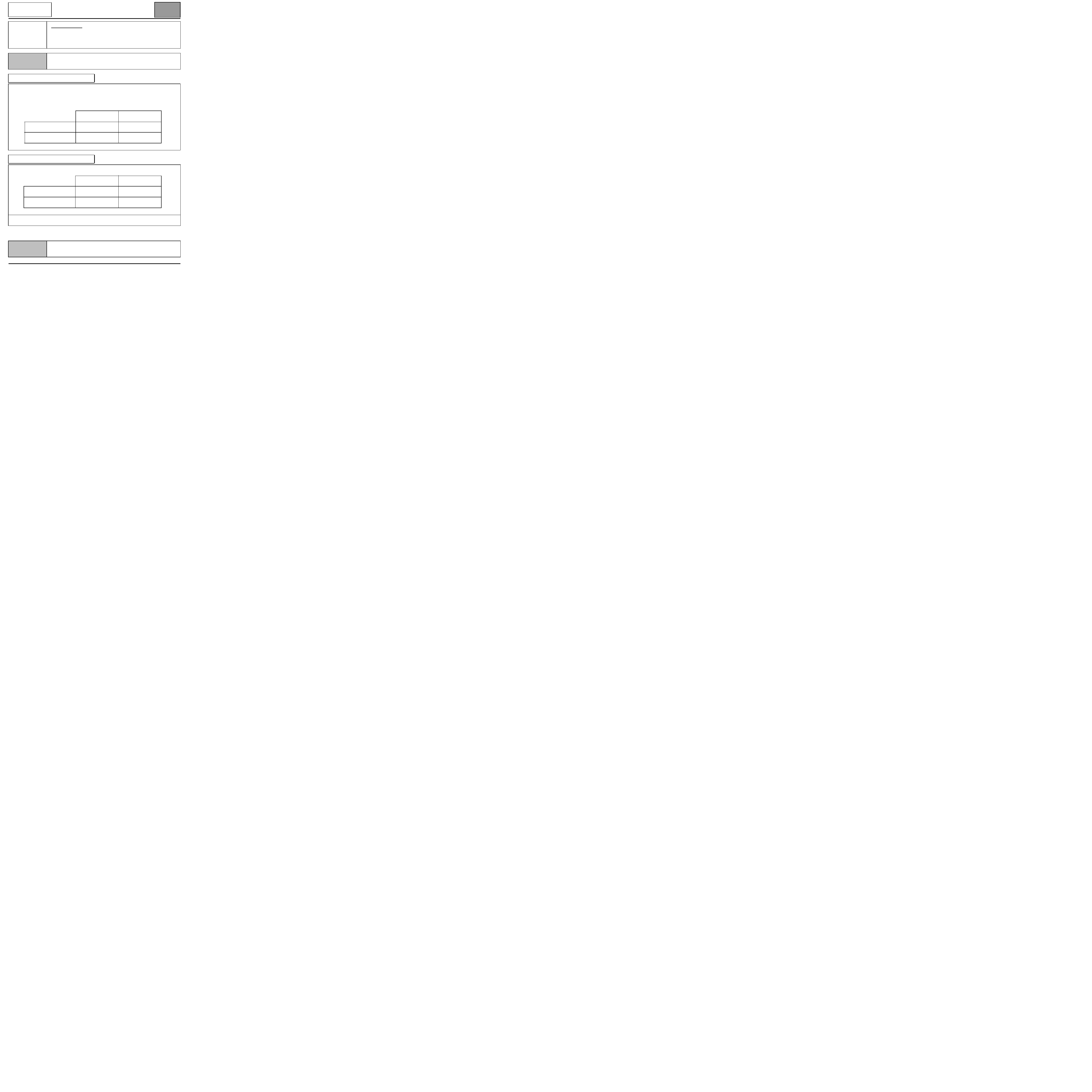

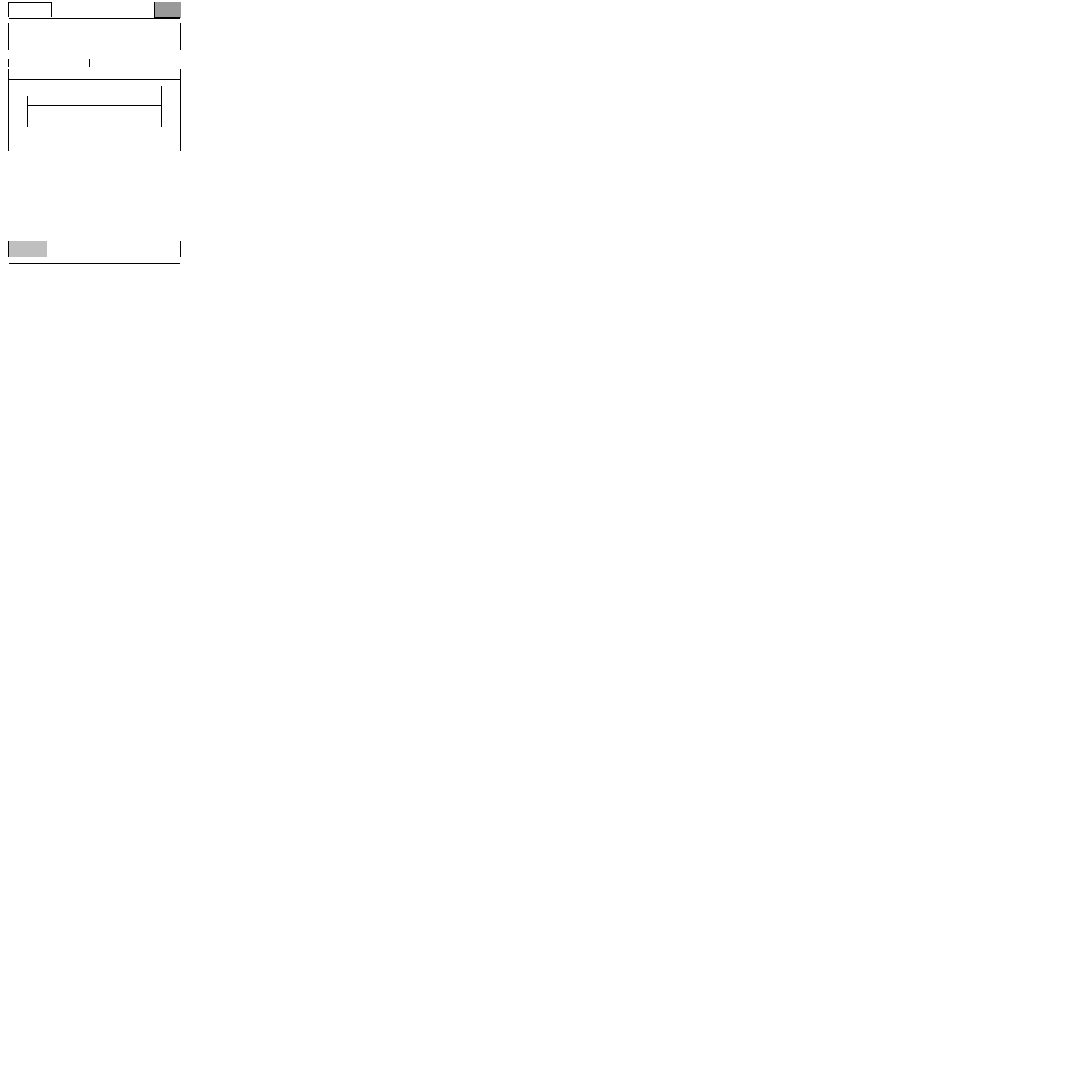

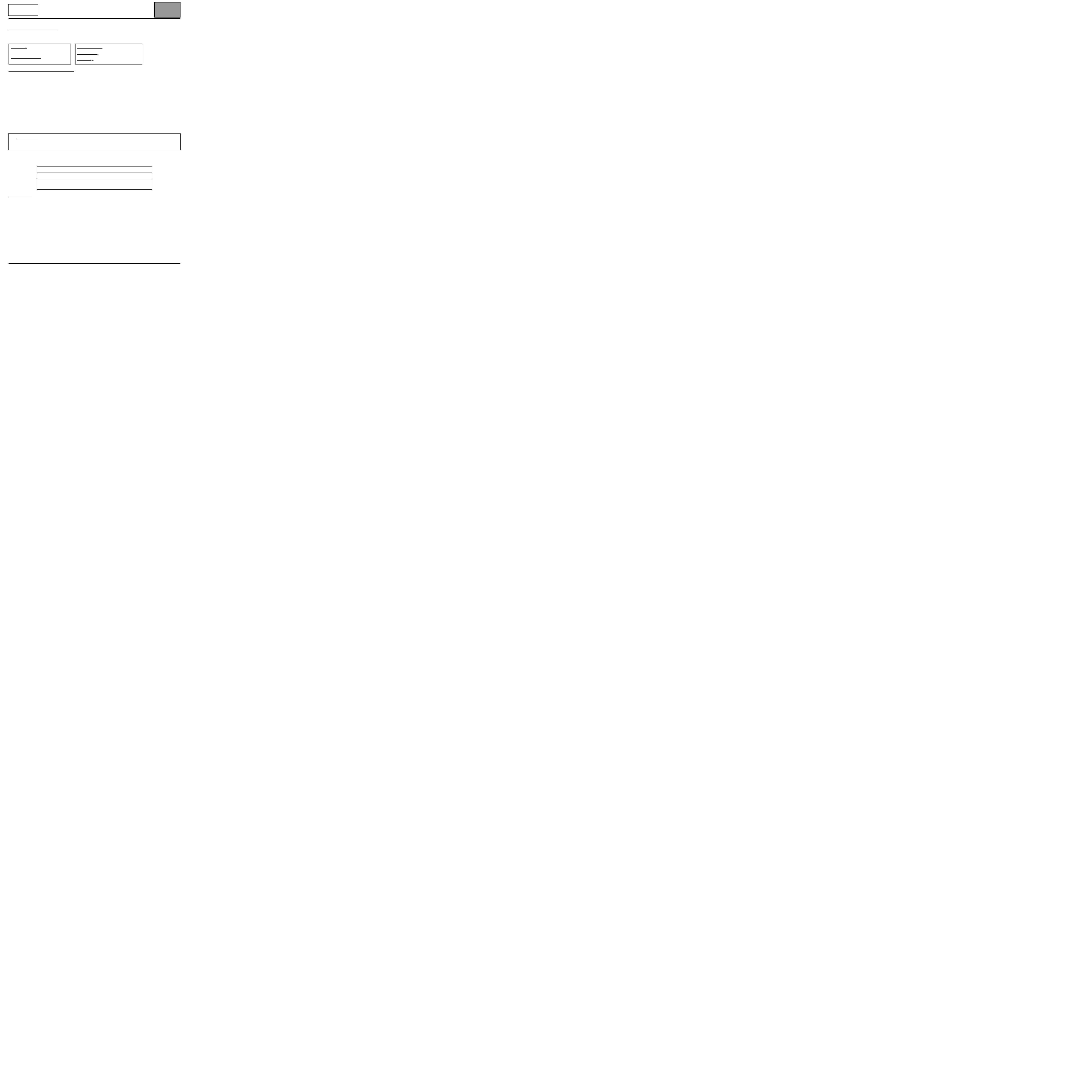

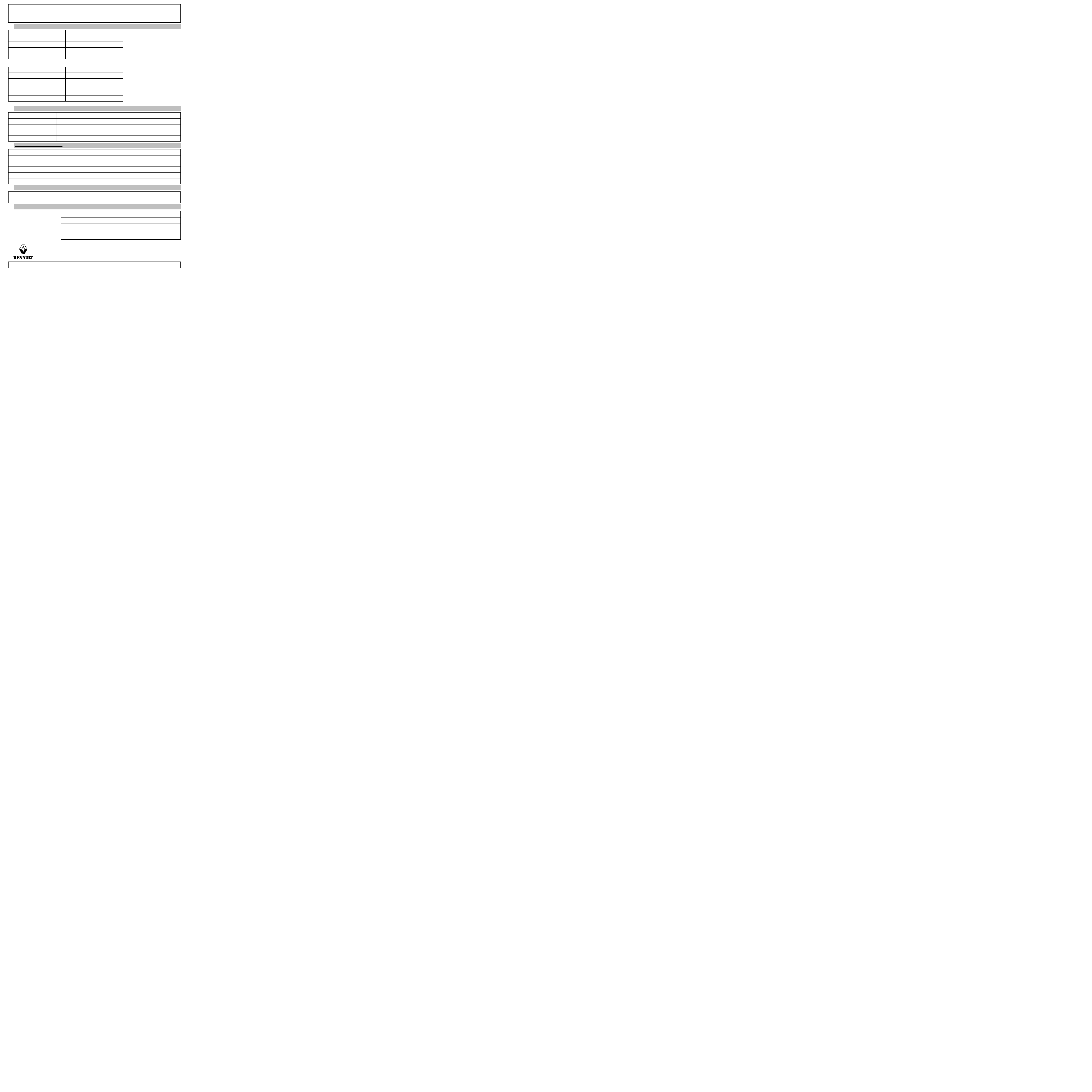

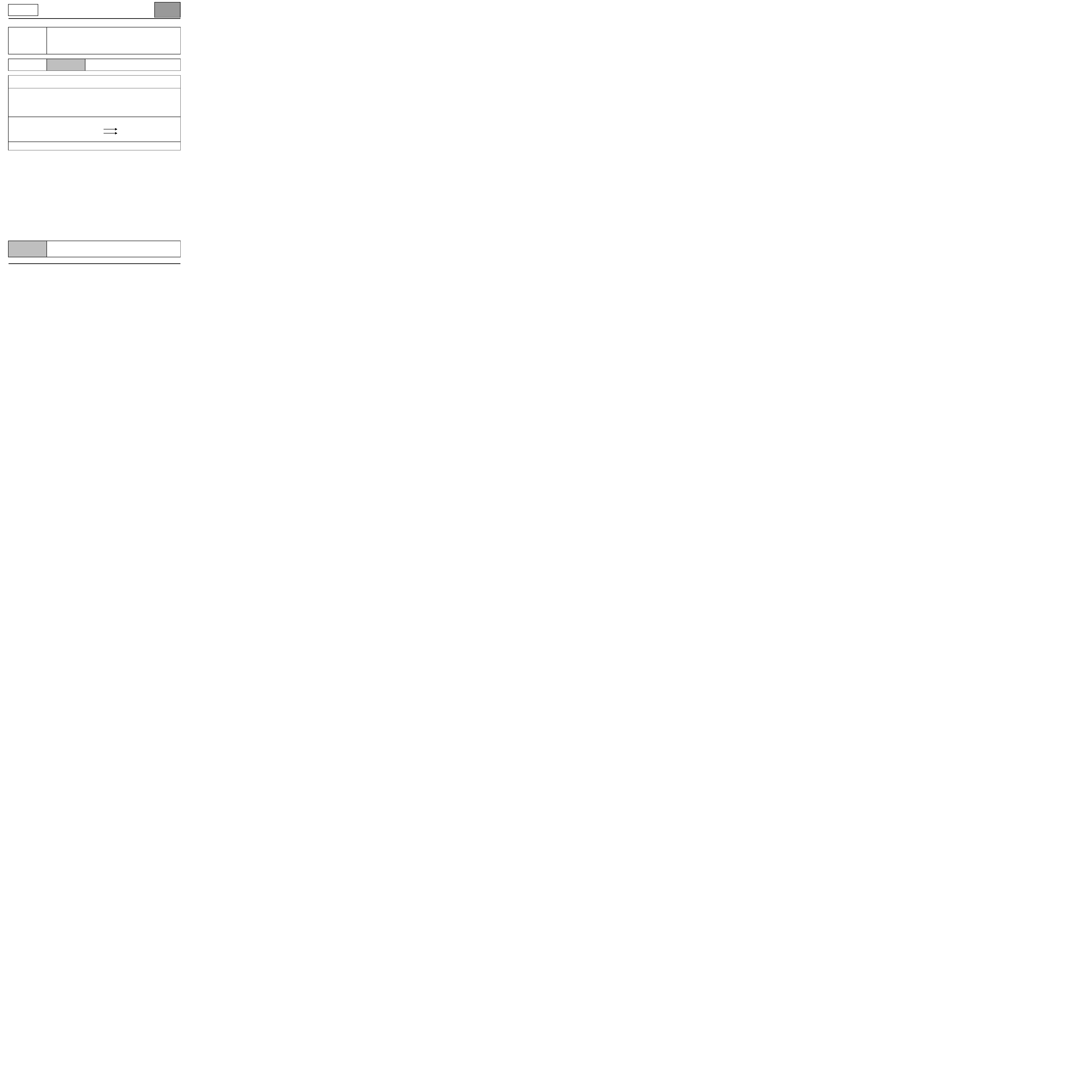

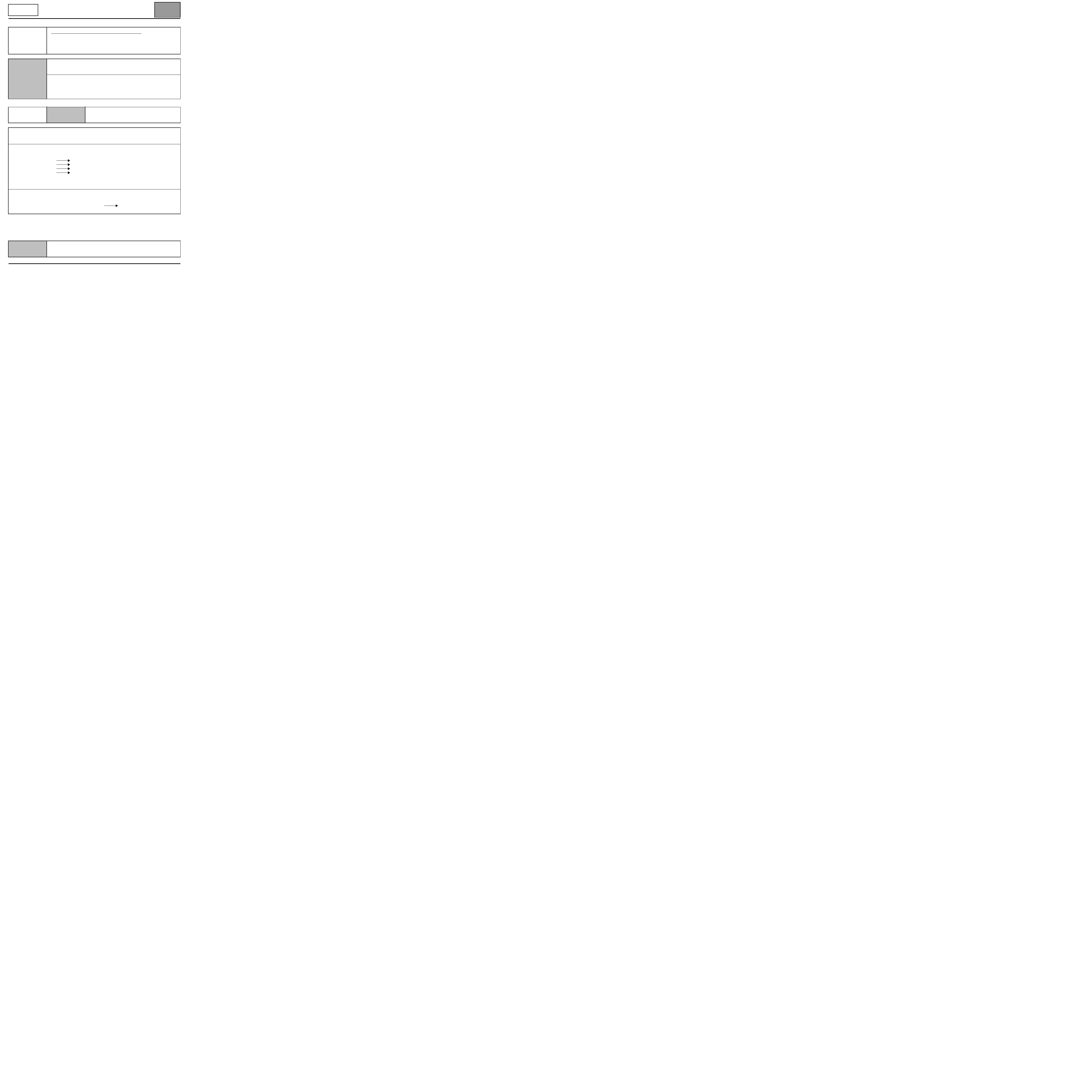

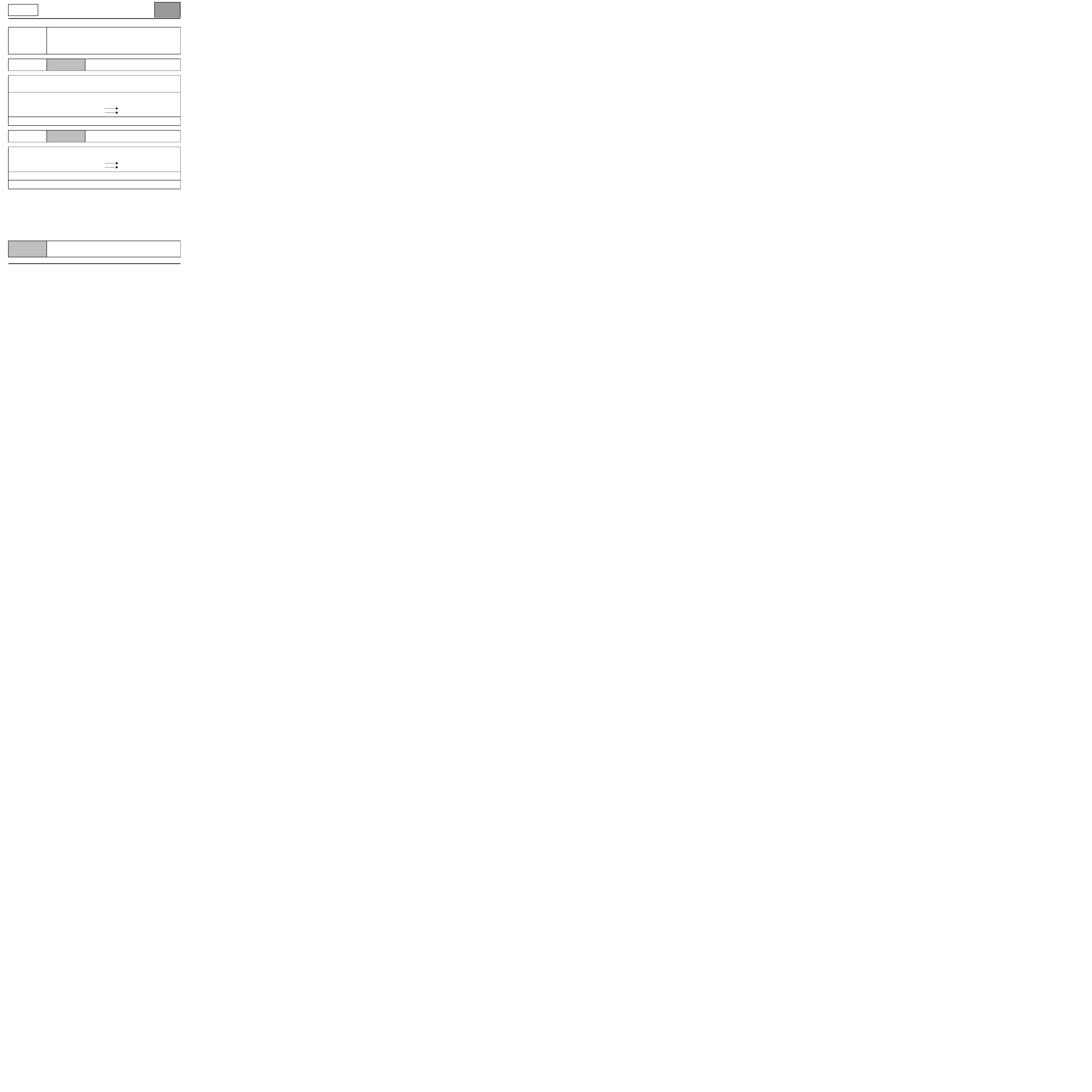

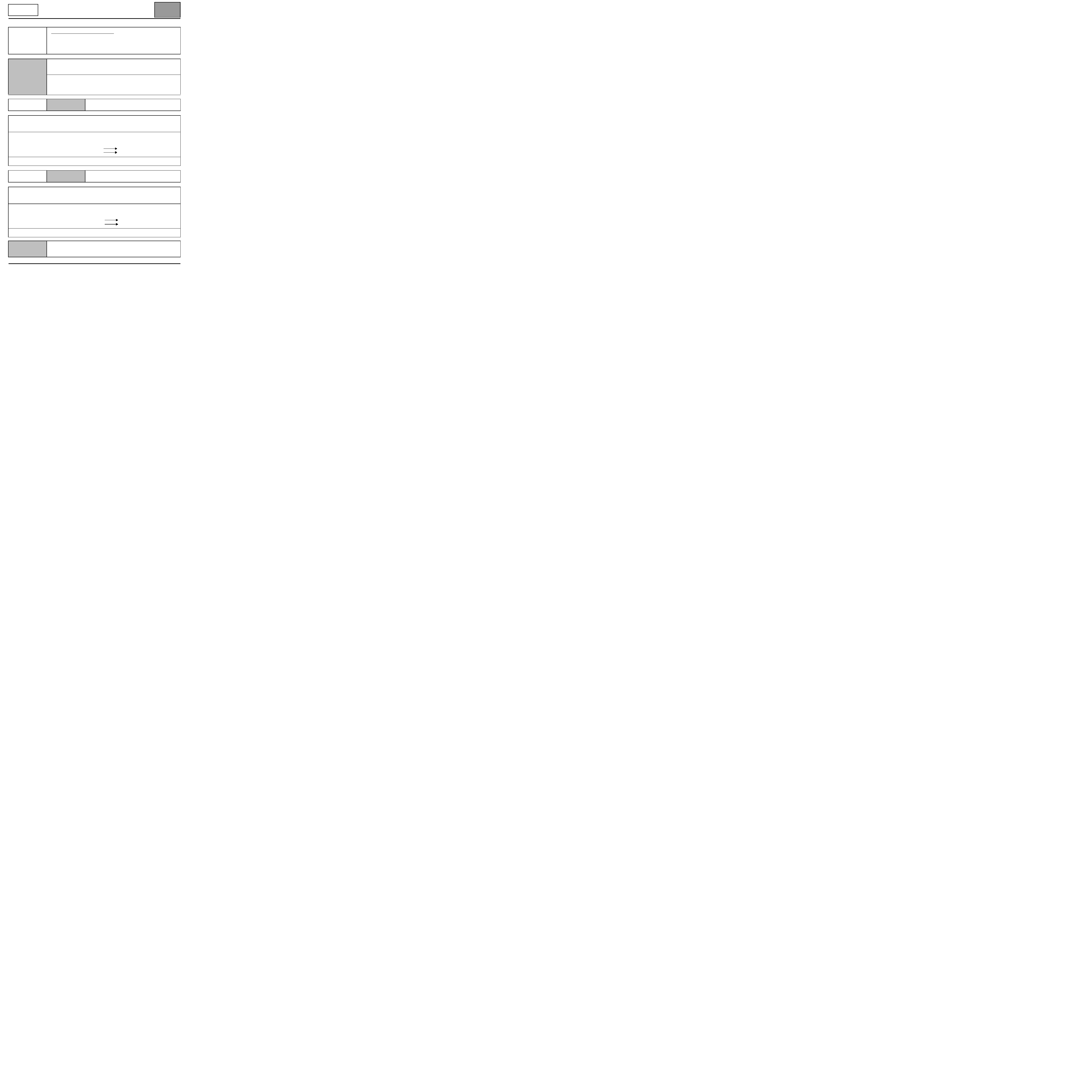

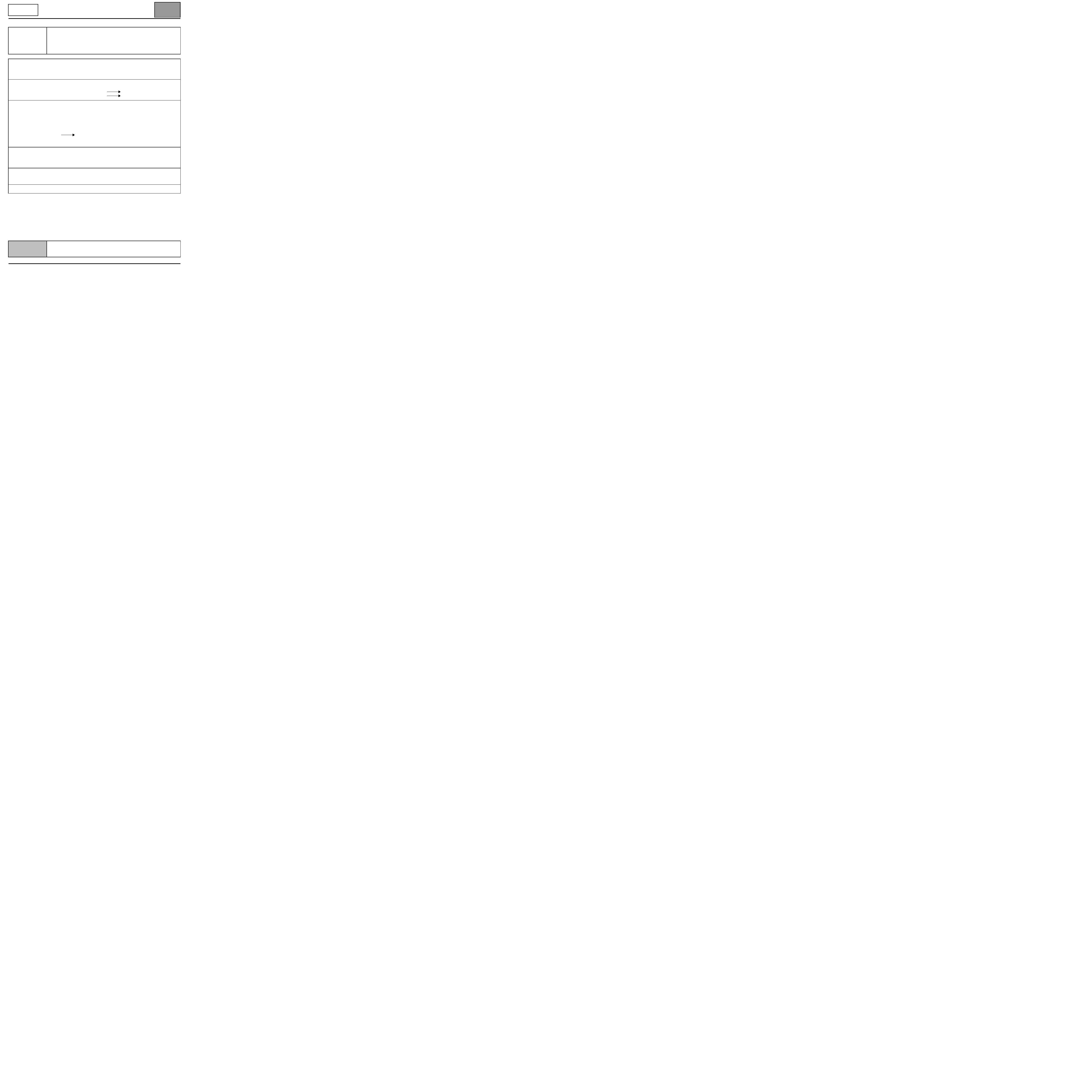

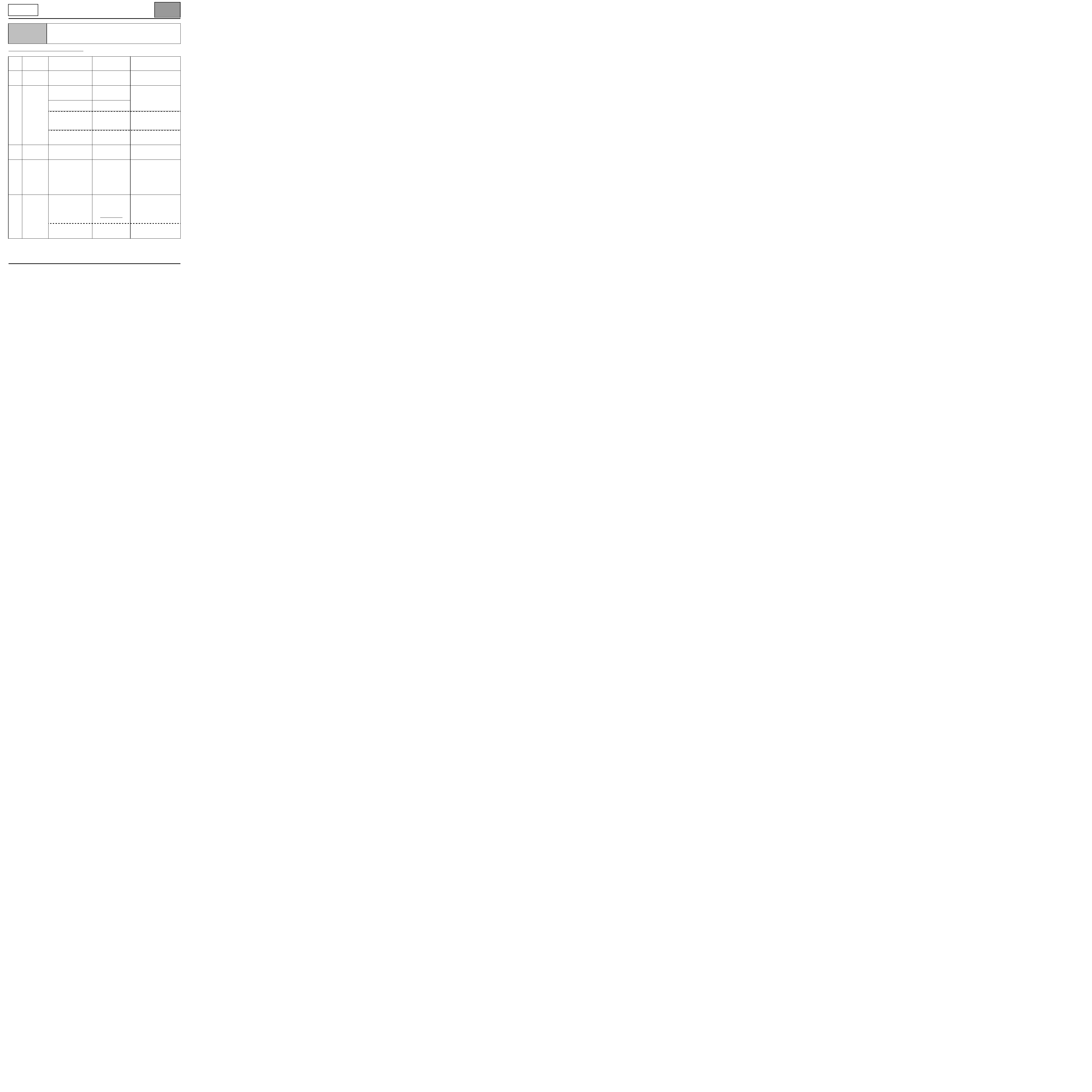

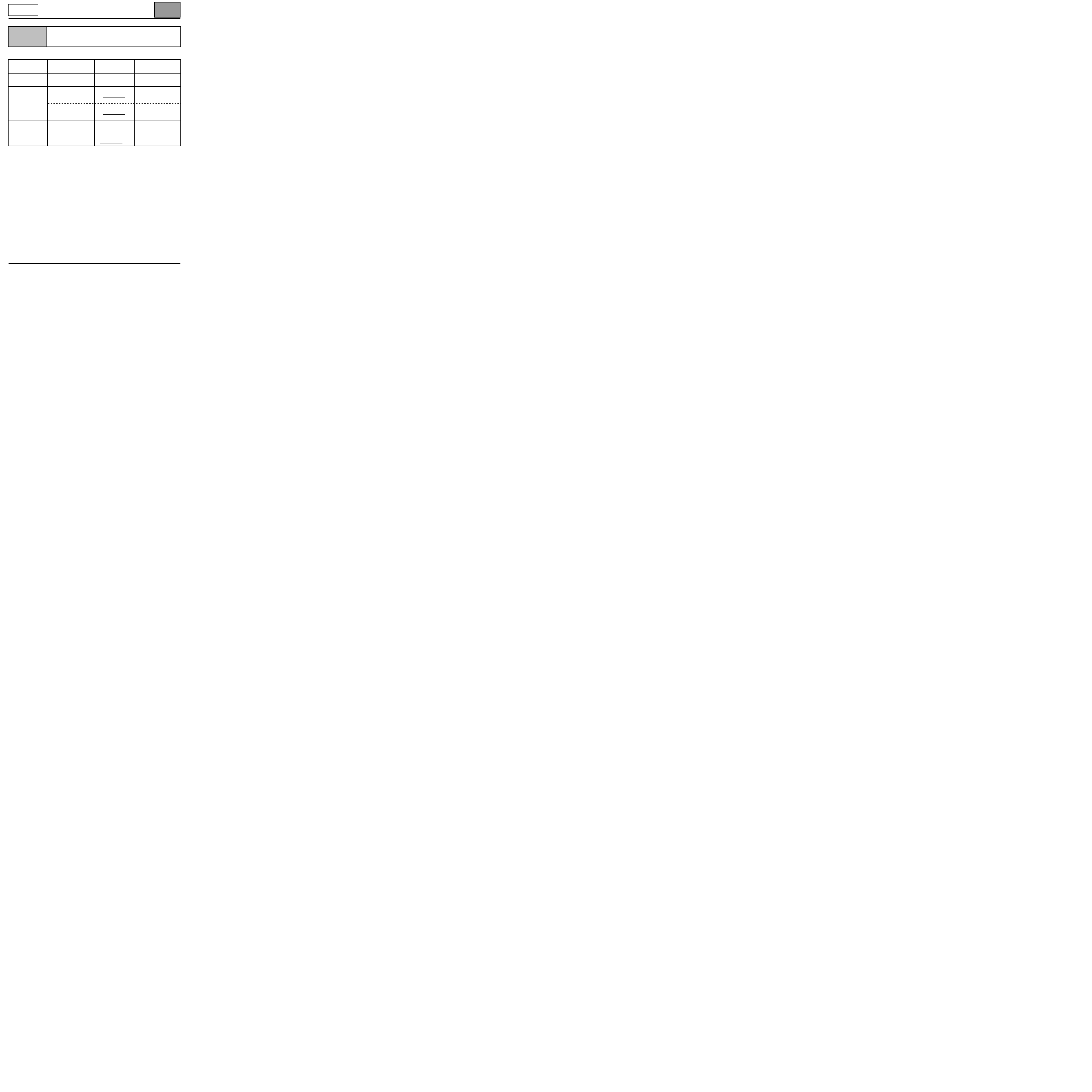

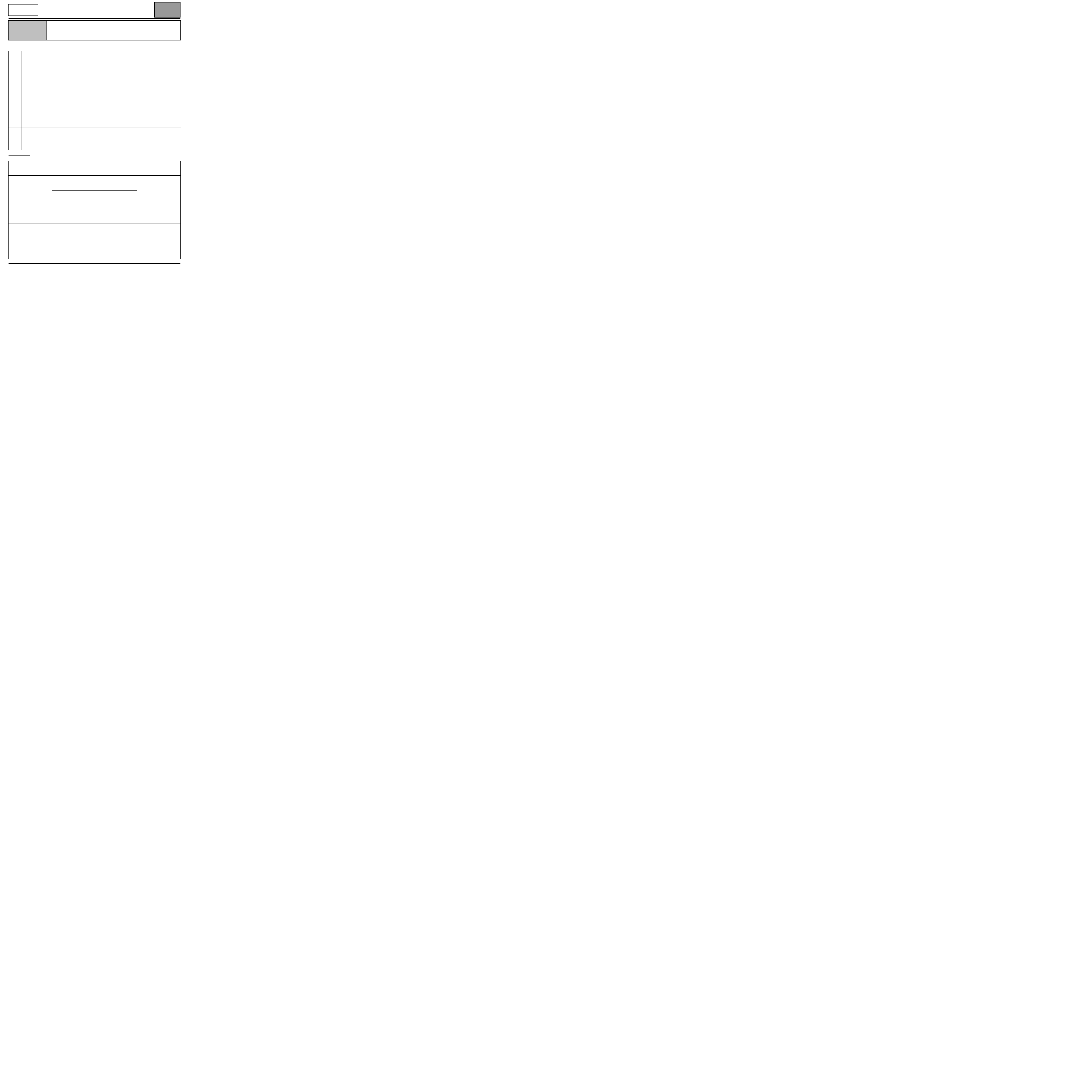

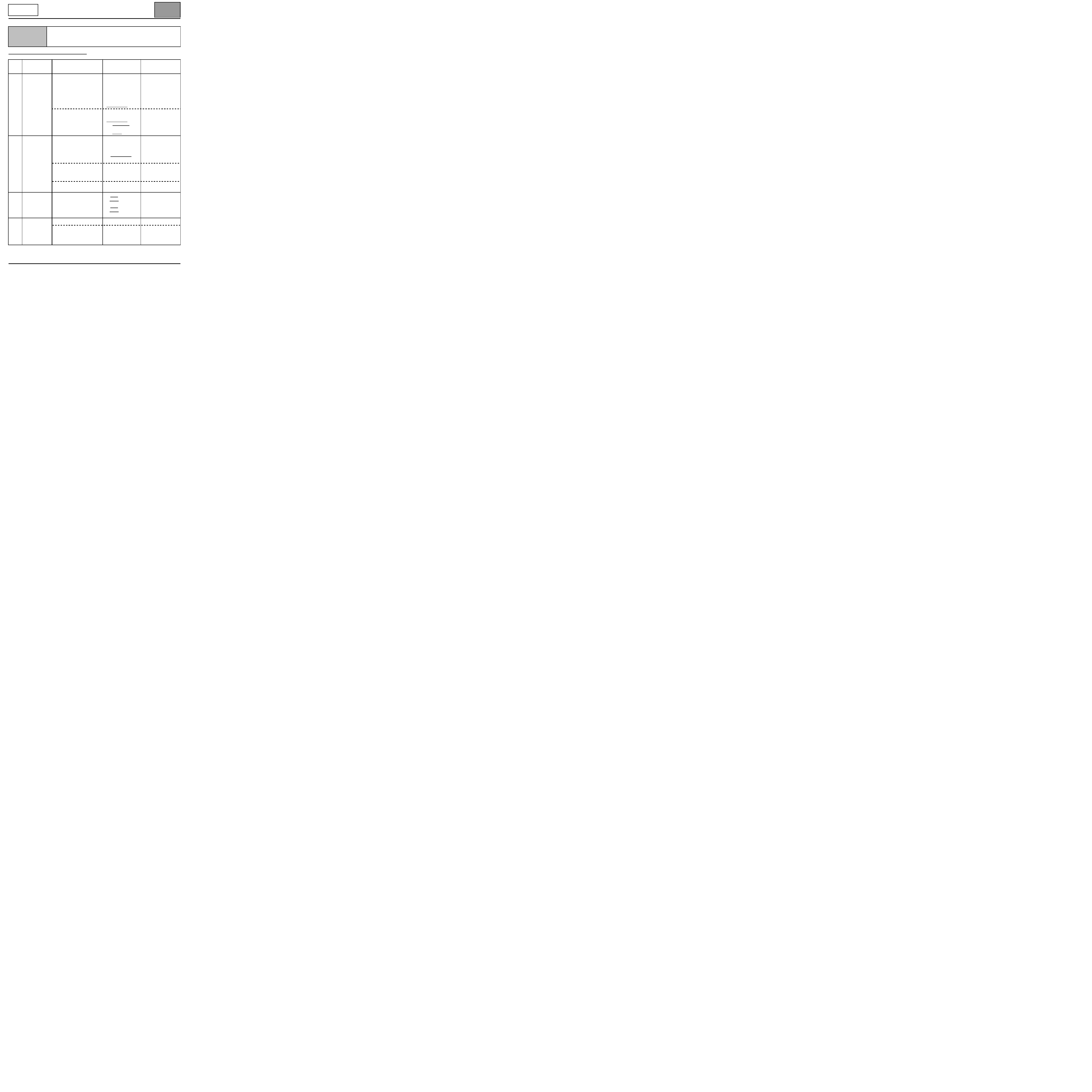

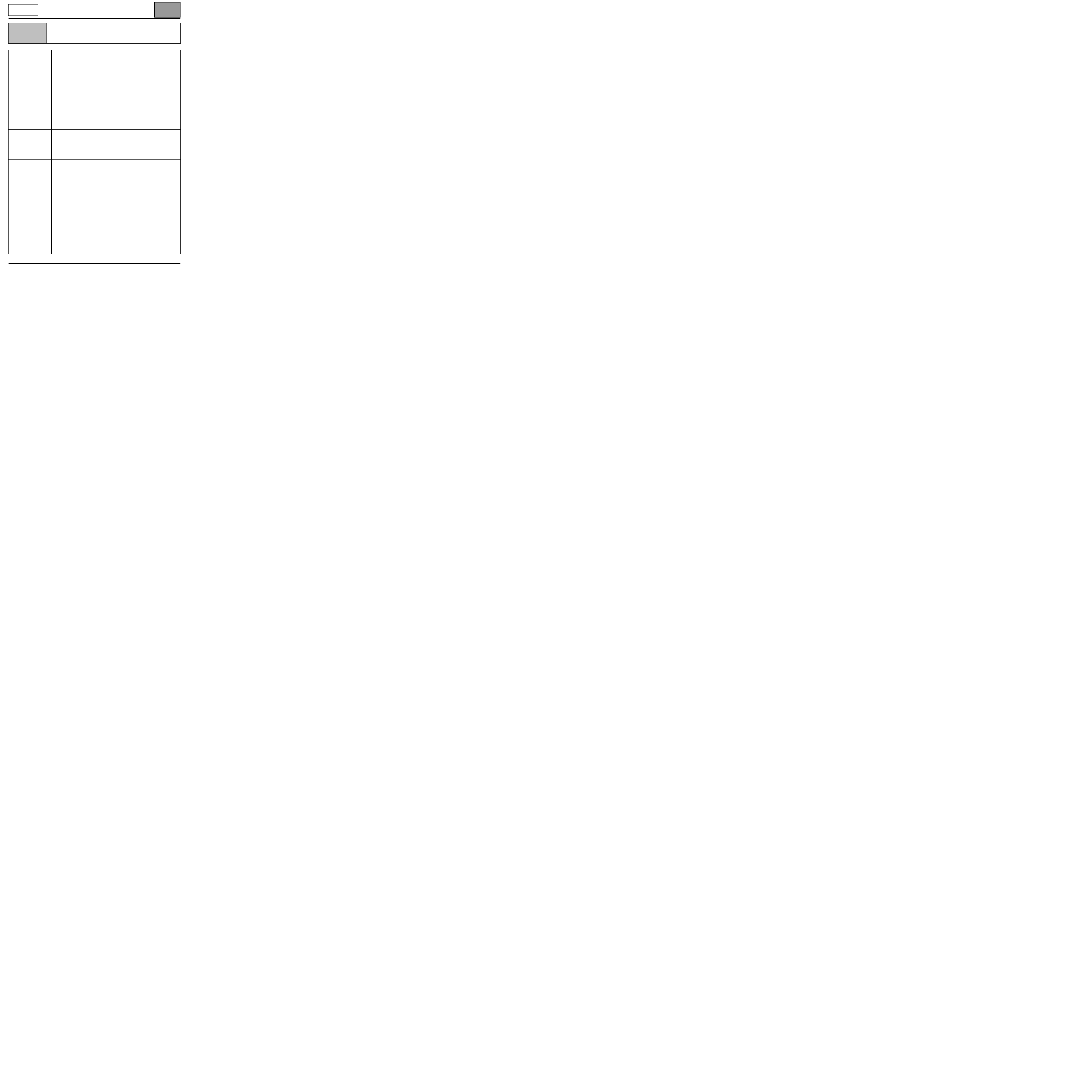

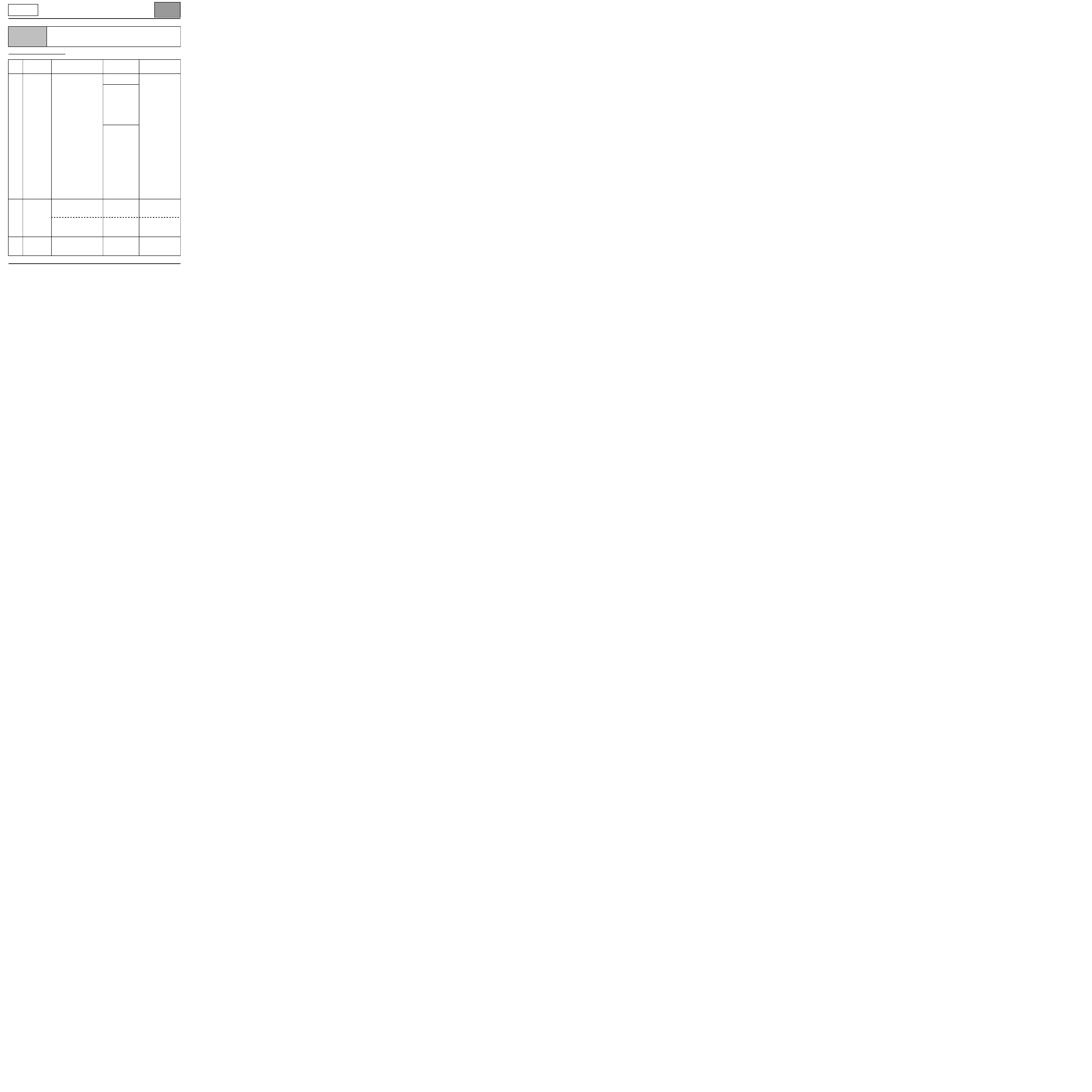

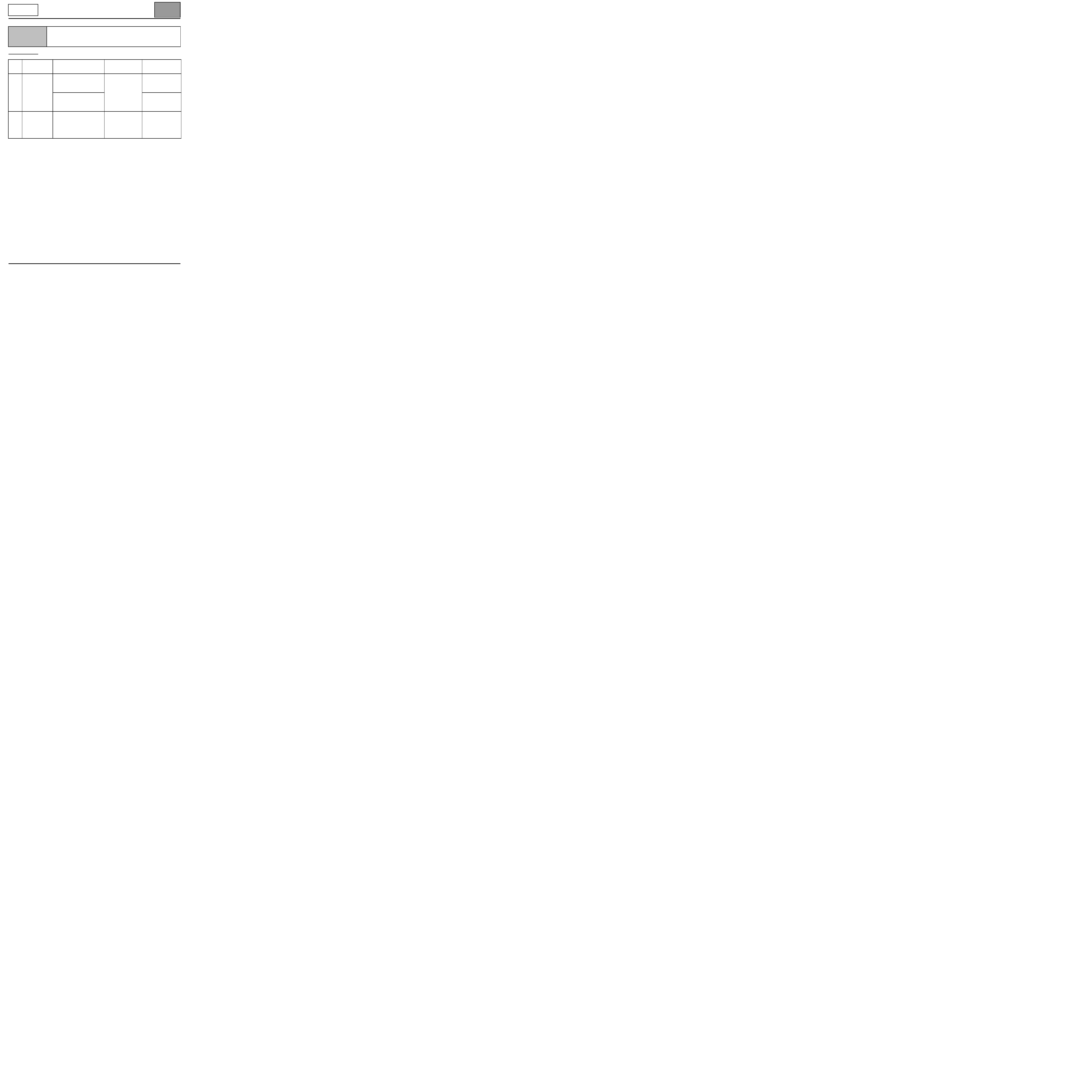

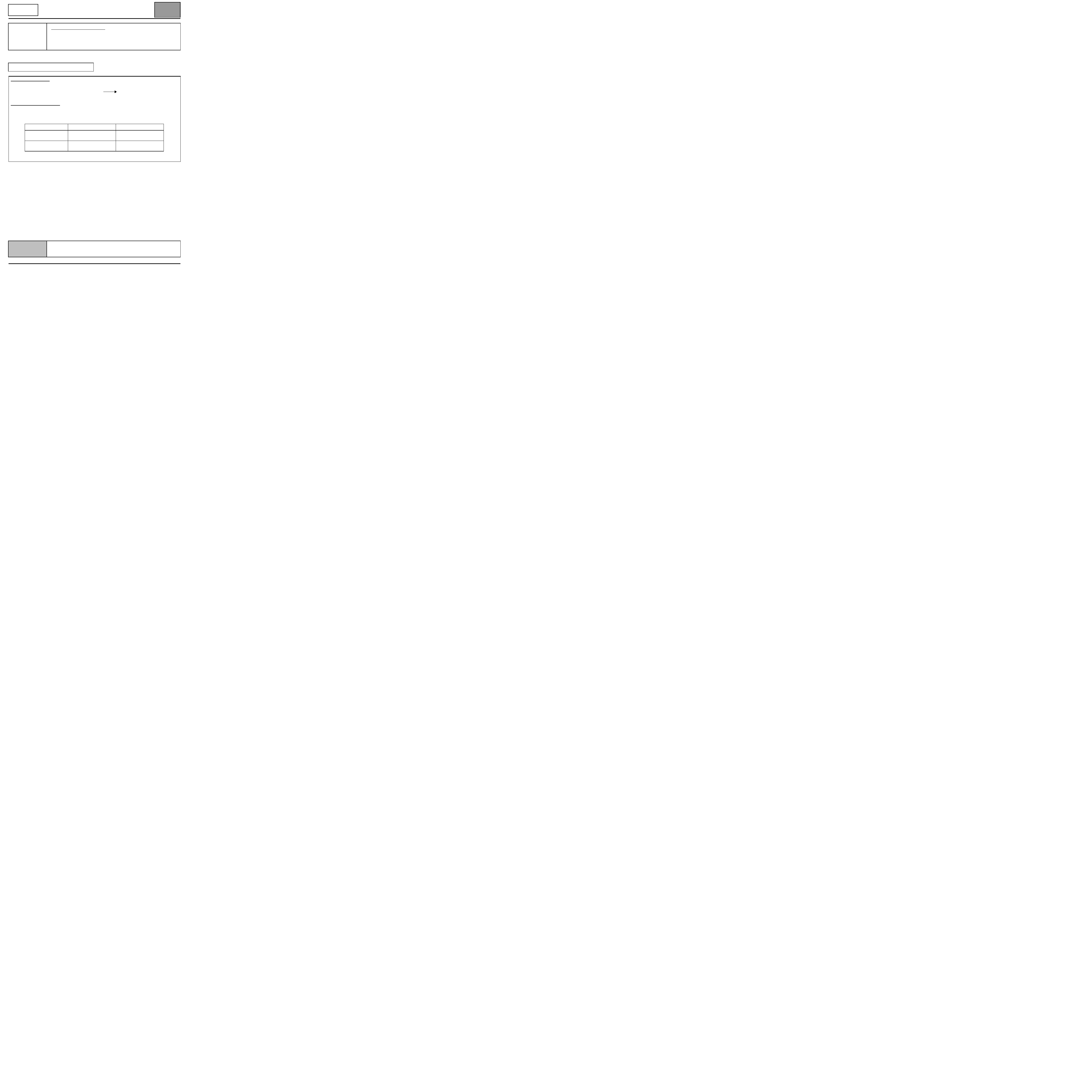

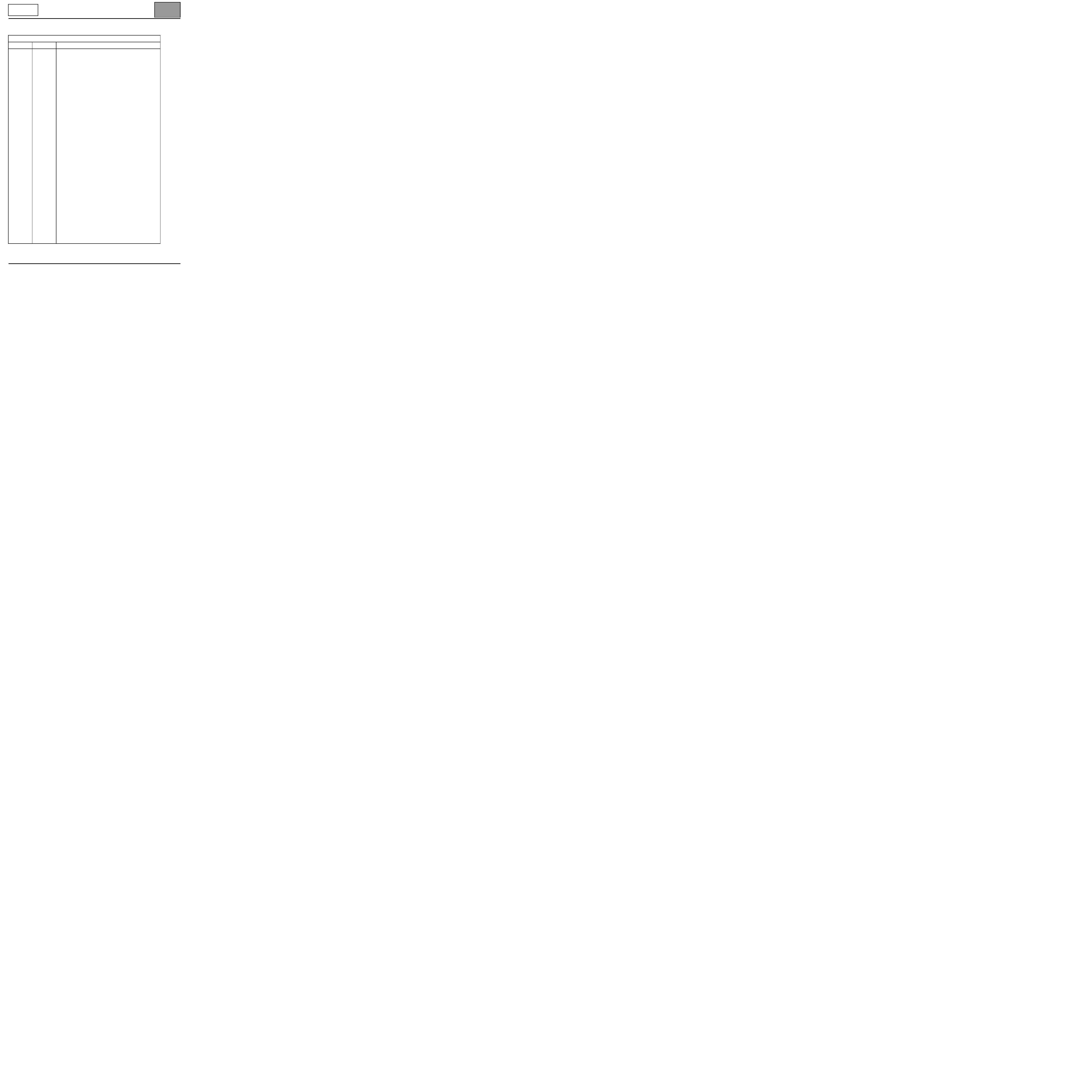

List of monitored parts: Computer

FAULT FINDING LOG

System: Injection

Page 1 / 2

●

Administrative identification

Date:

2

0

Sheet completed by:

VIN:

Engine

Diagnostic tool

CLIP

Version

●

Customer complaint

579

Does not start - fault

570

Stalls - difficult to start when

cold

571

Stalls - difficult to start when

warm

586

Difficult to start

572

Idle - engine speed unsteady

574

Jerking - flat spots

573

Lack of power

520

Abnormal noise, vibrations

576

Smoke - exhaust odours

569

Difficult to start

Other

Your comments

●

Conditions under which the customer complaint occurs

001

When cold

005

While driving

008

When decelerating

002

When warm

006

When changing gear

009

Sudden breakdown

003

When stationary

007

When accelerating

010

Gradual deterioration

004

Intermittently

Other

Your comments

●

Documentation used in fault finding

Fault finding procedure

Type of fault finding manual:

Workshop Repair Manual: Technical Note

Assisted fault finding

Fault Finding Manual No.:

Wiring diagram used

Wiring Diagram Technical Note No.:

Other documentation

Title and/or part no.:

FD 01

Fault finding log

page to print or photocopy - page to print or photocopy - page to print or photocopy

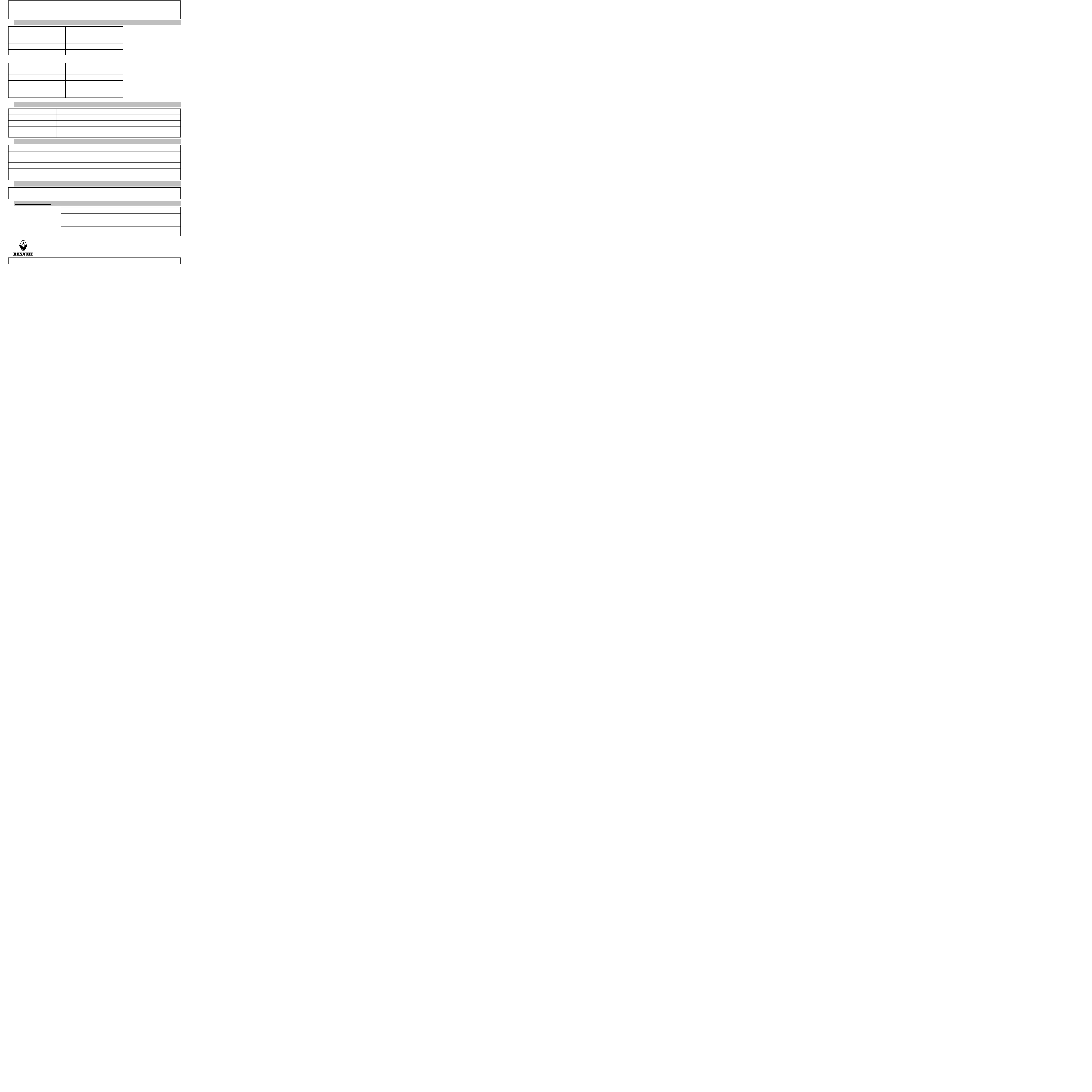

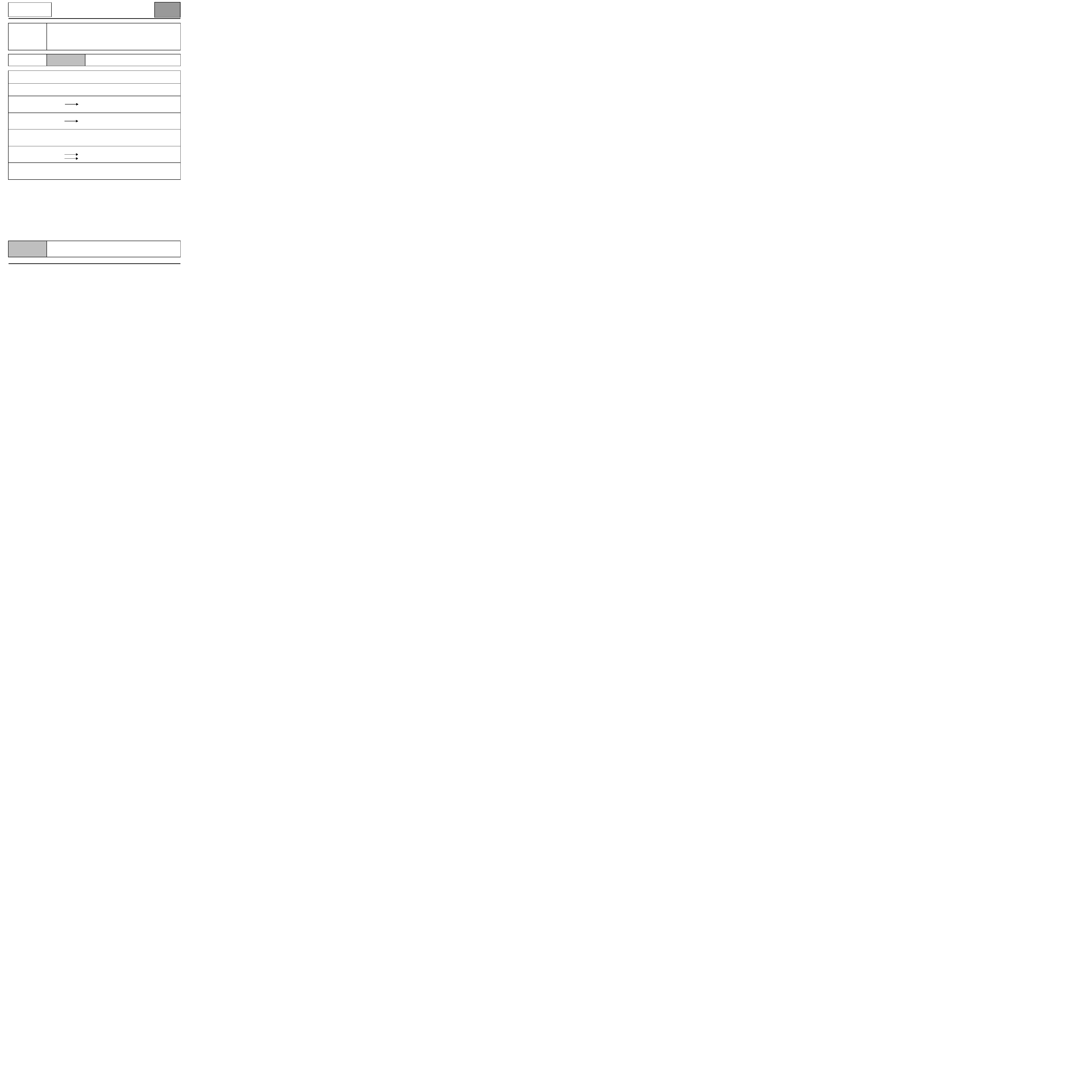

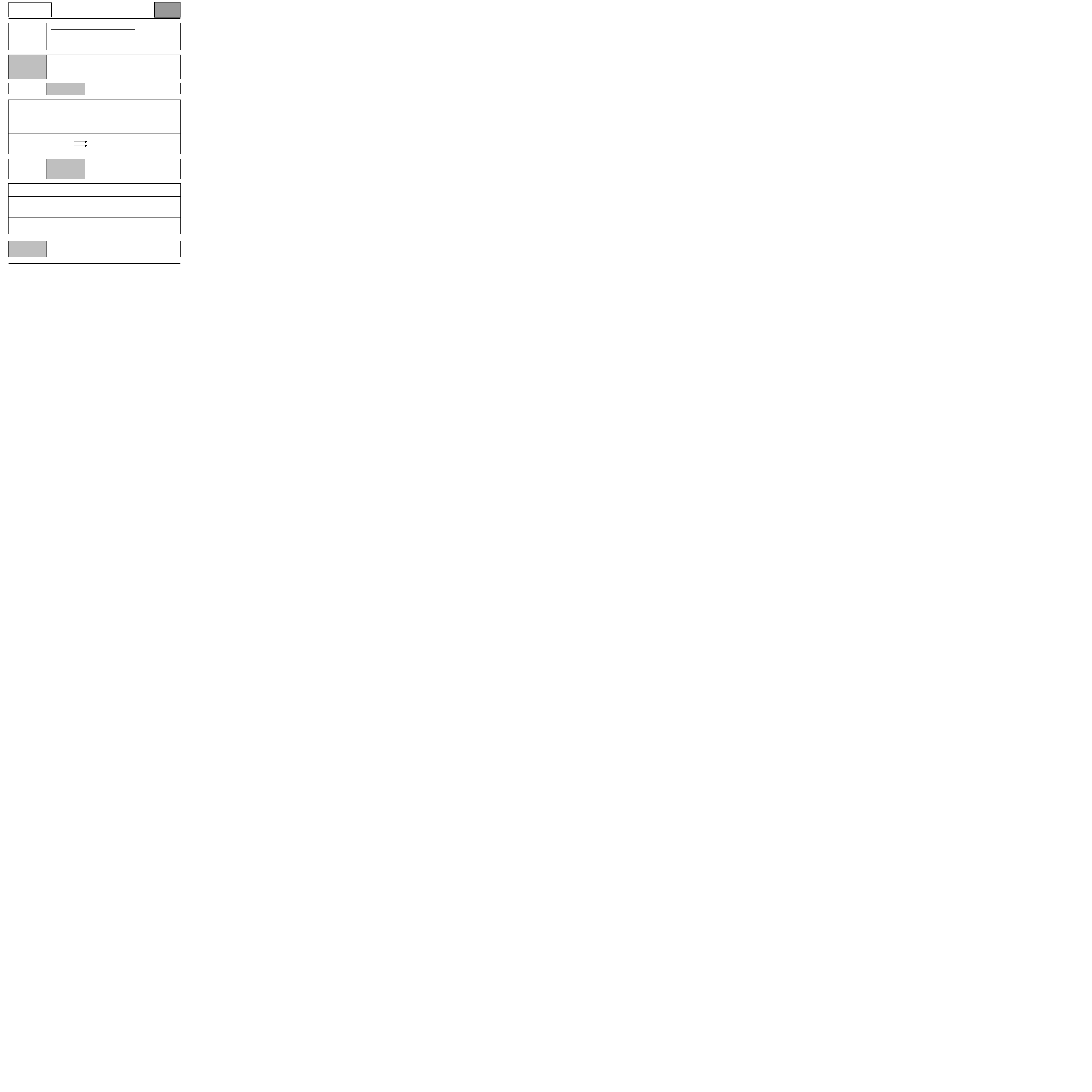

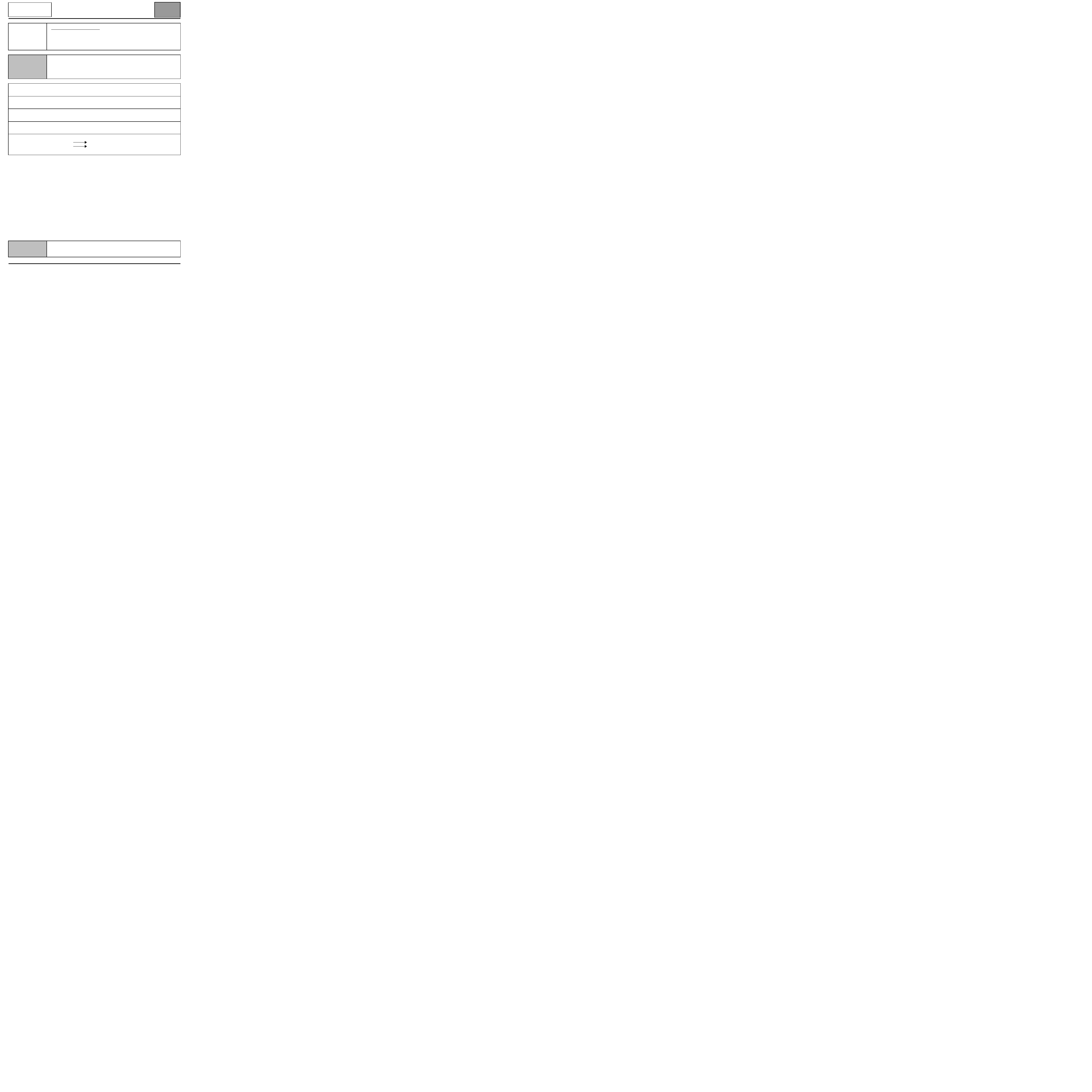

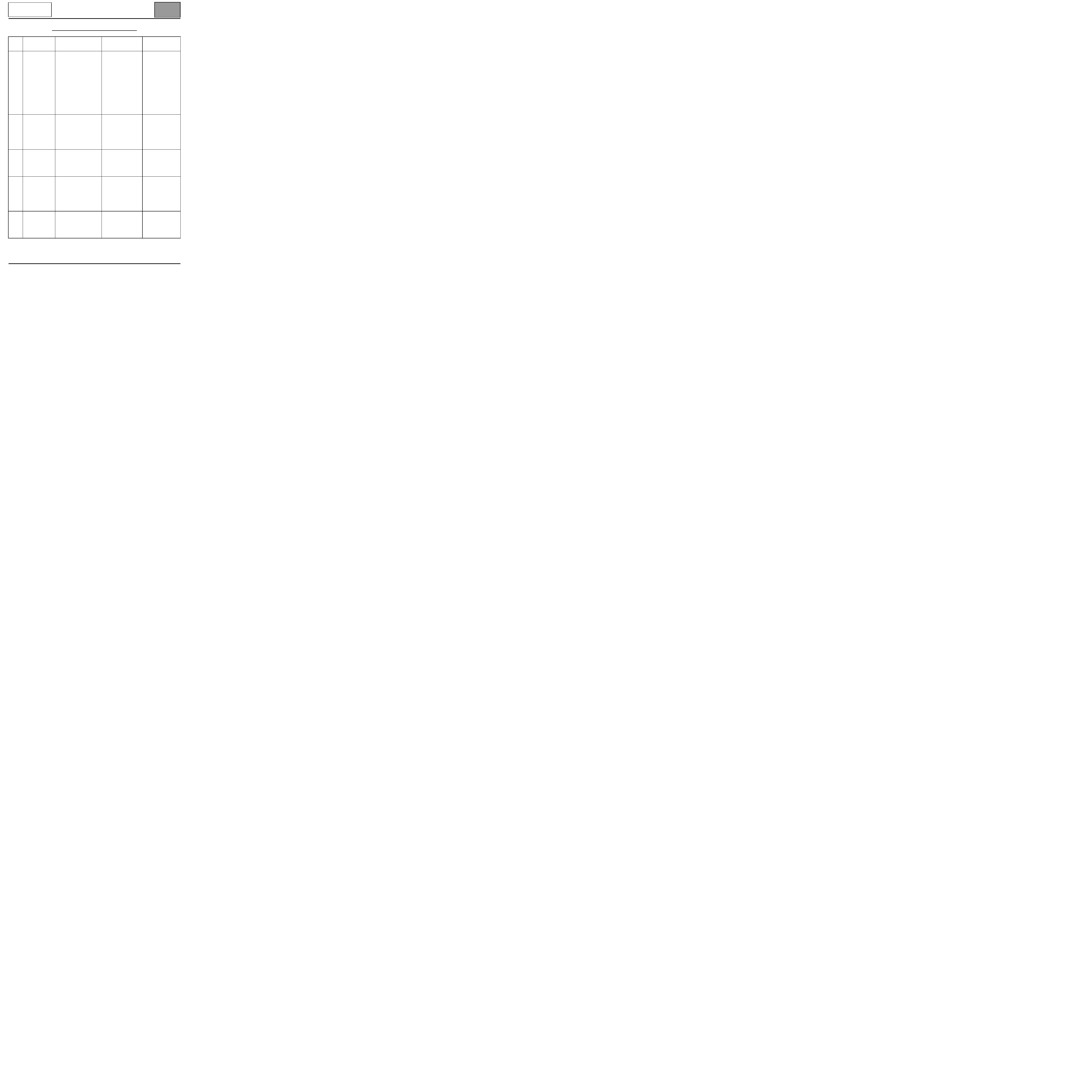

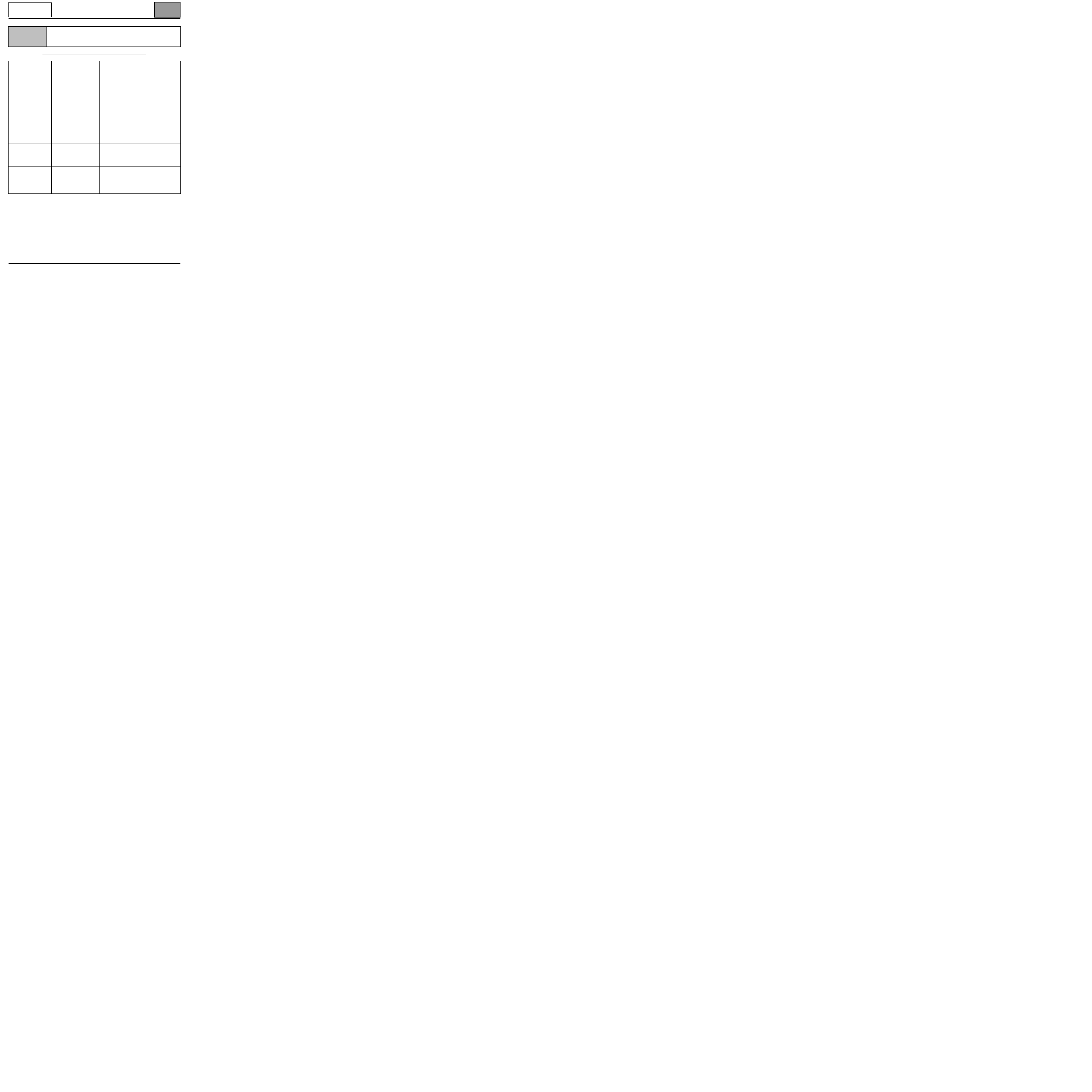

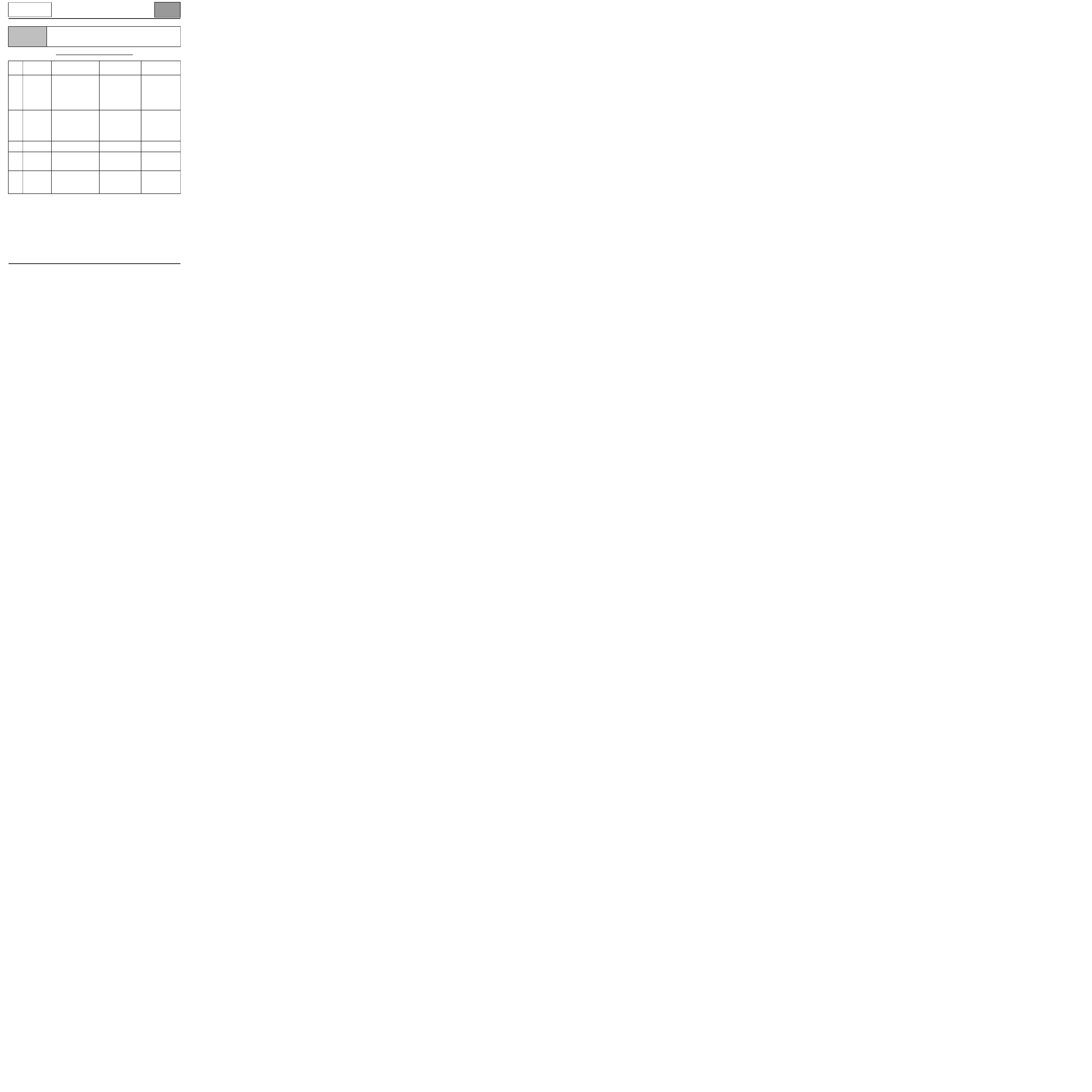

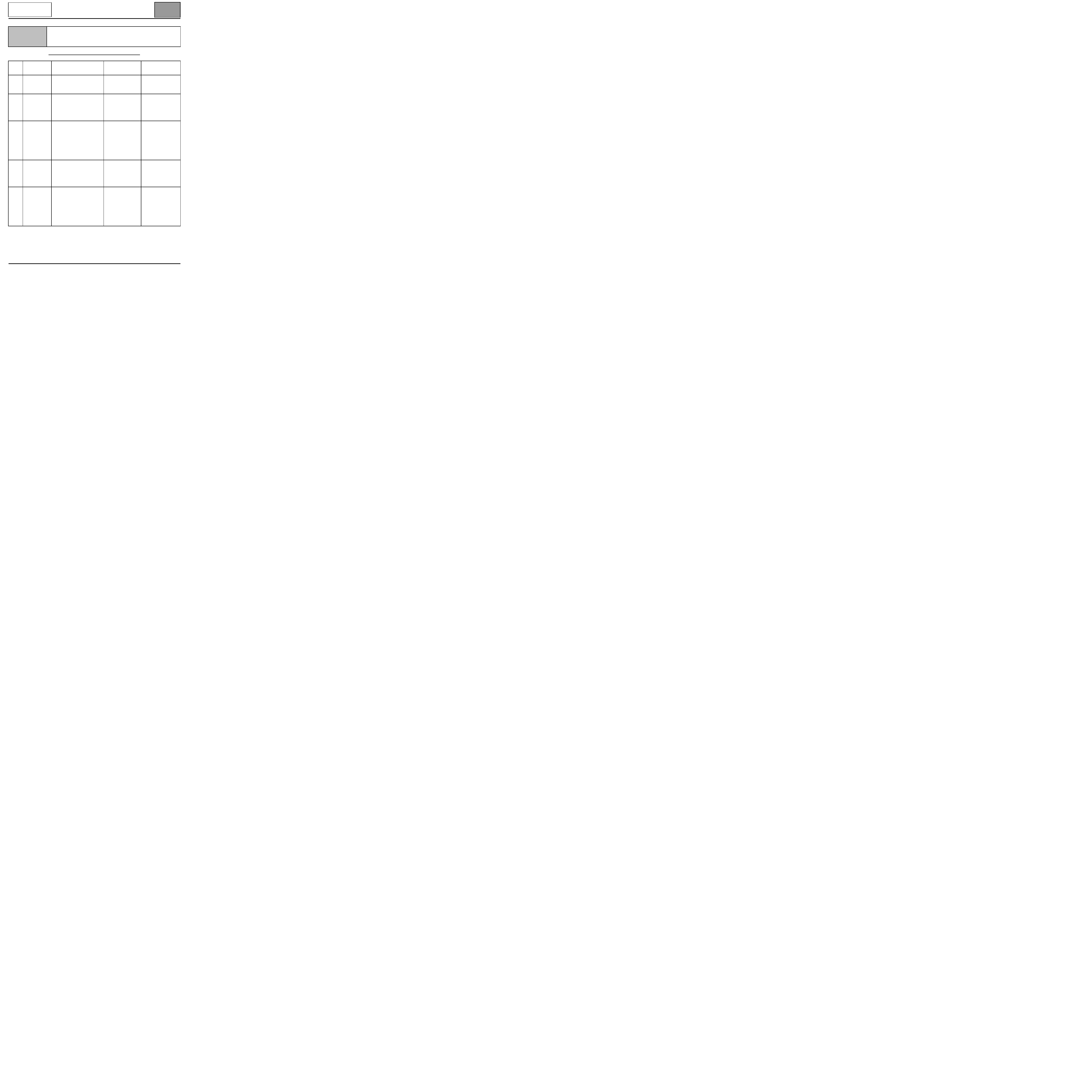

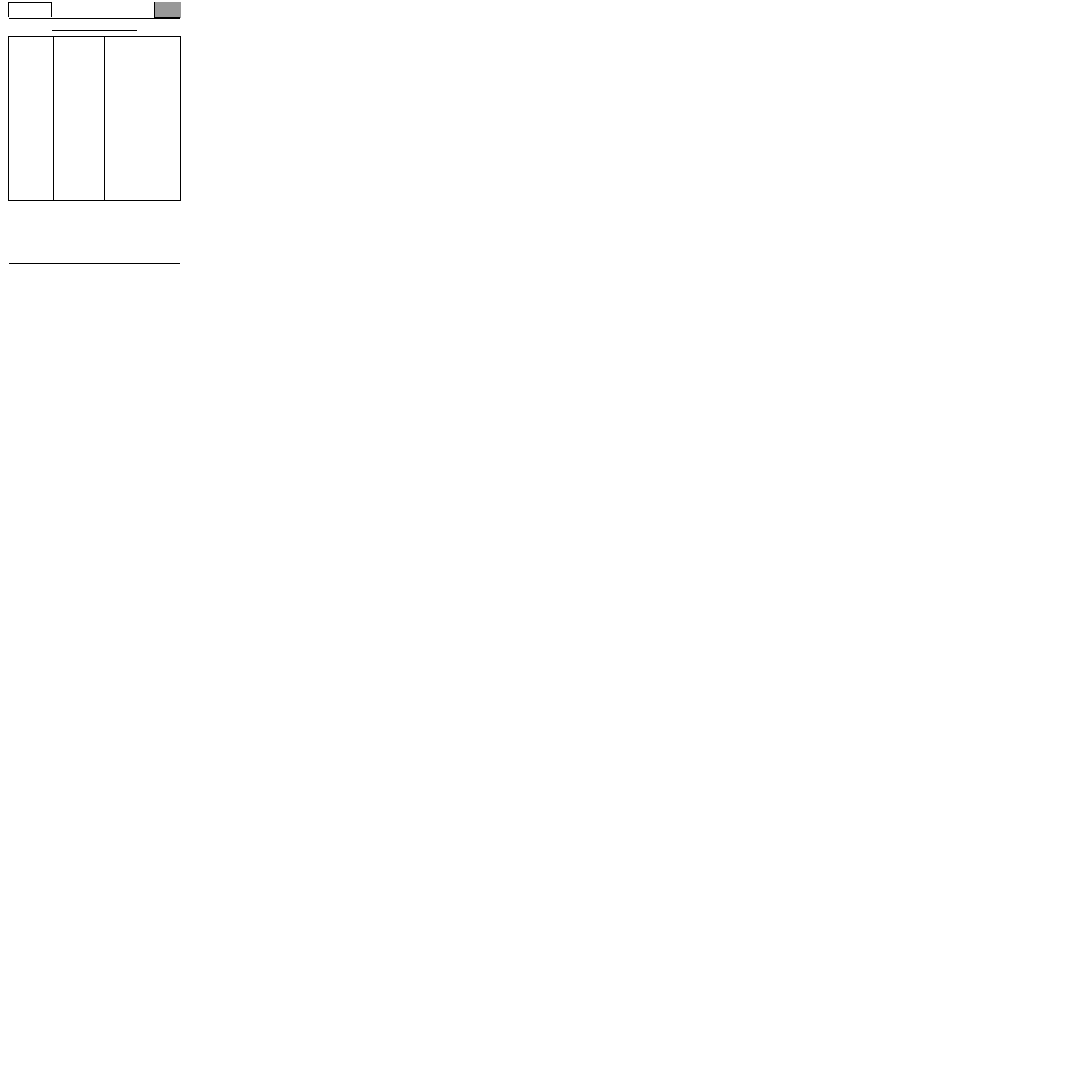

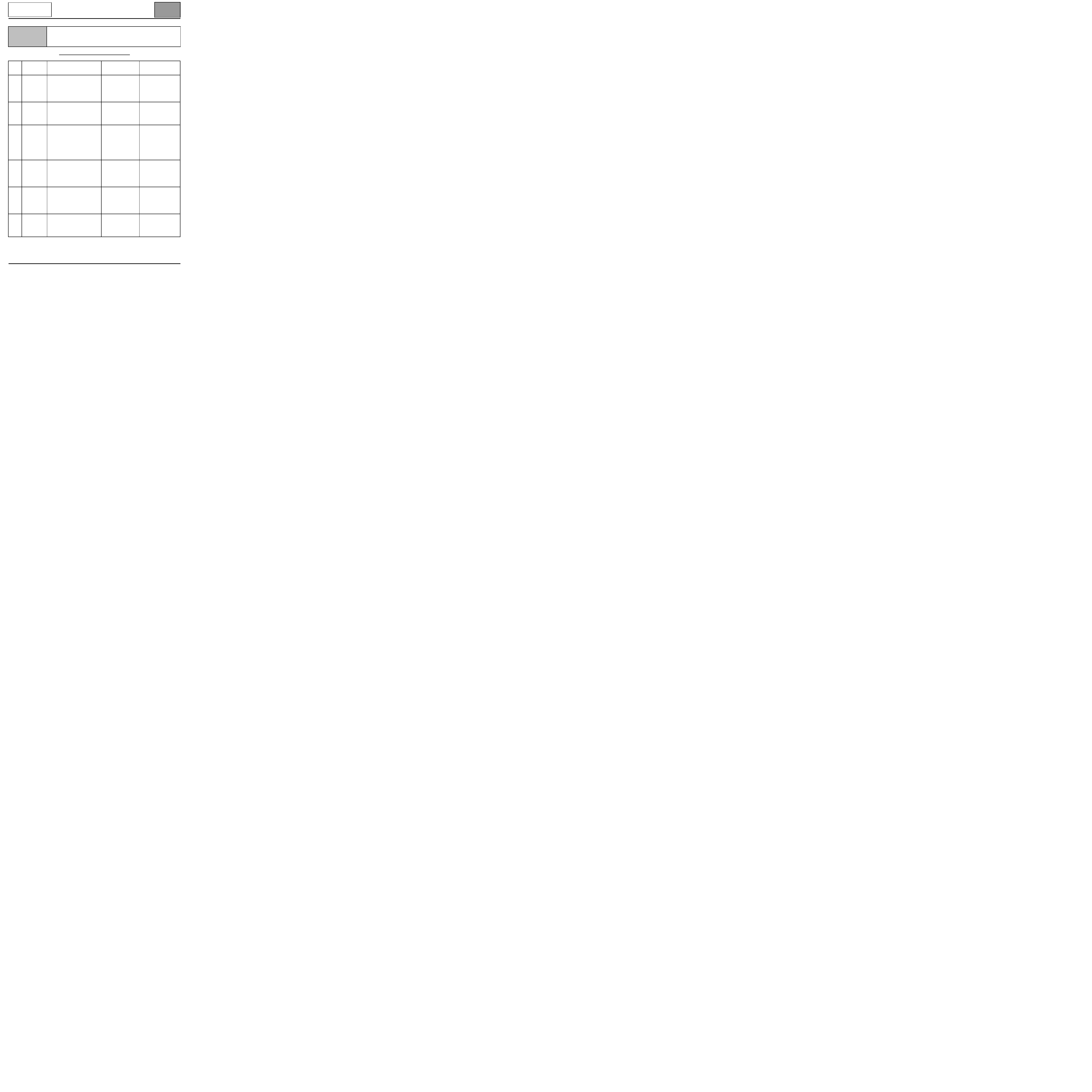

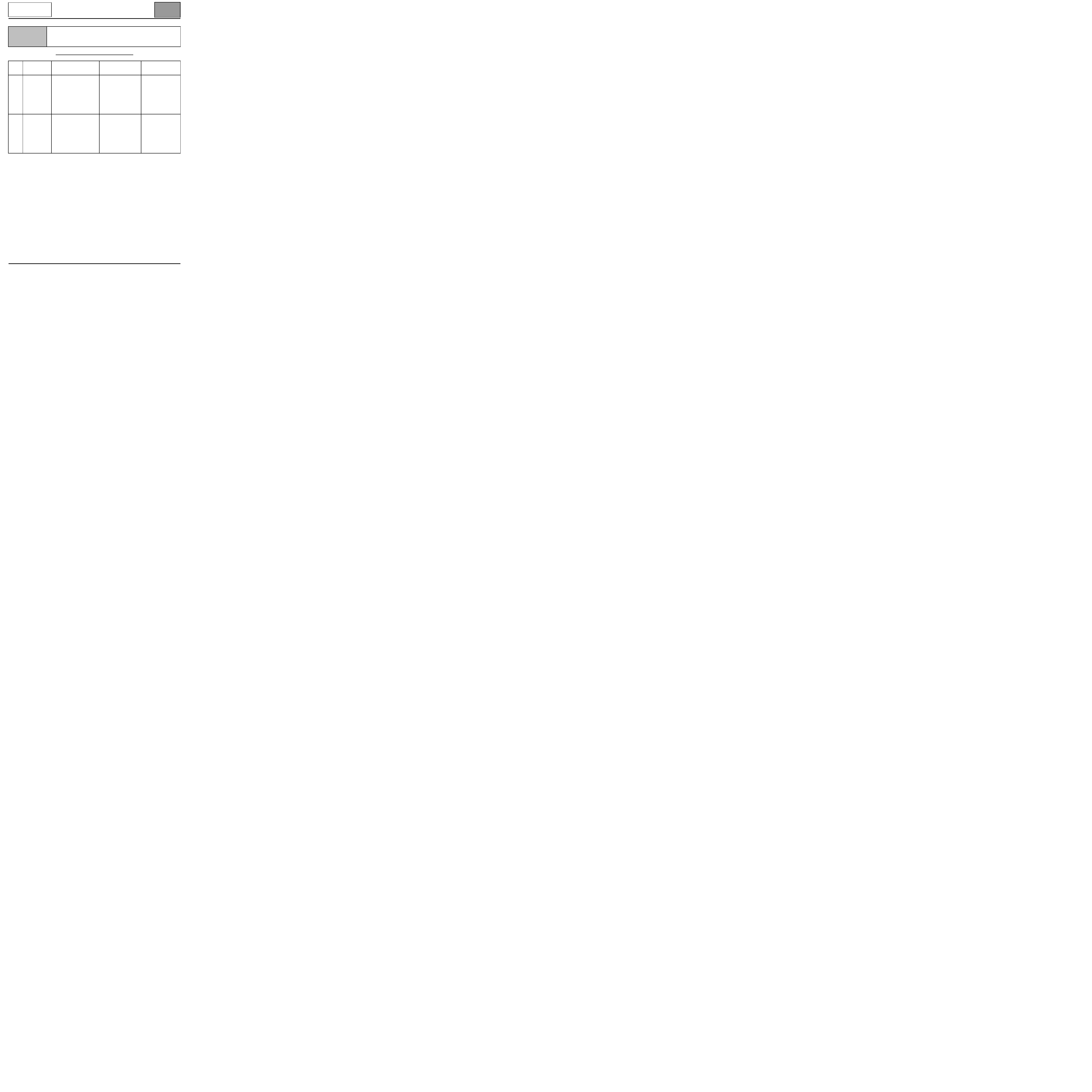

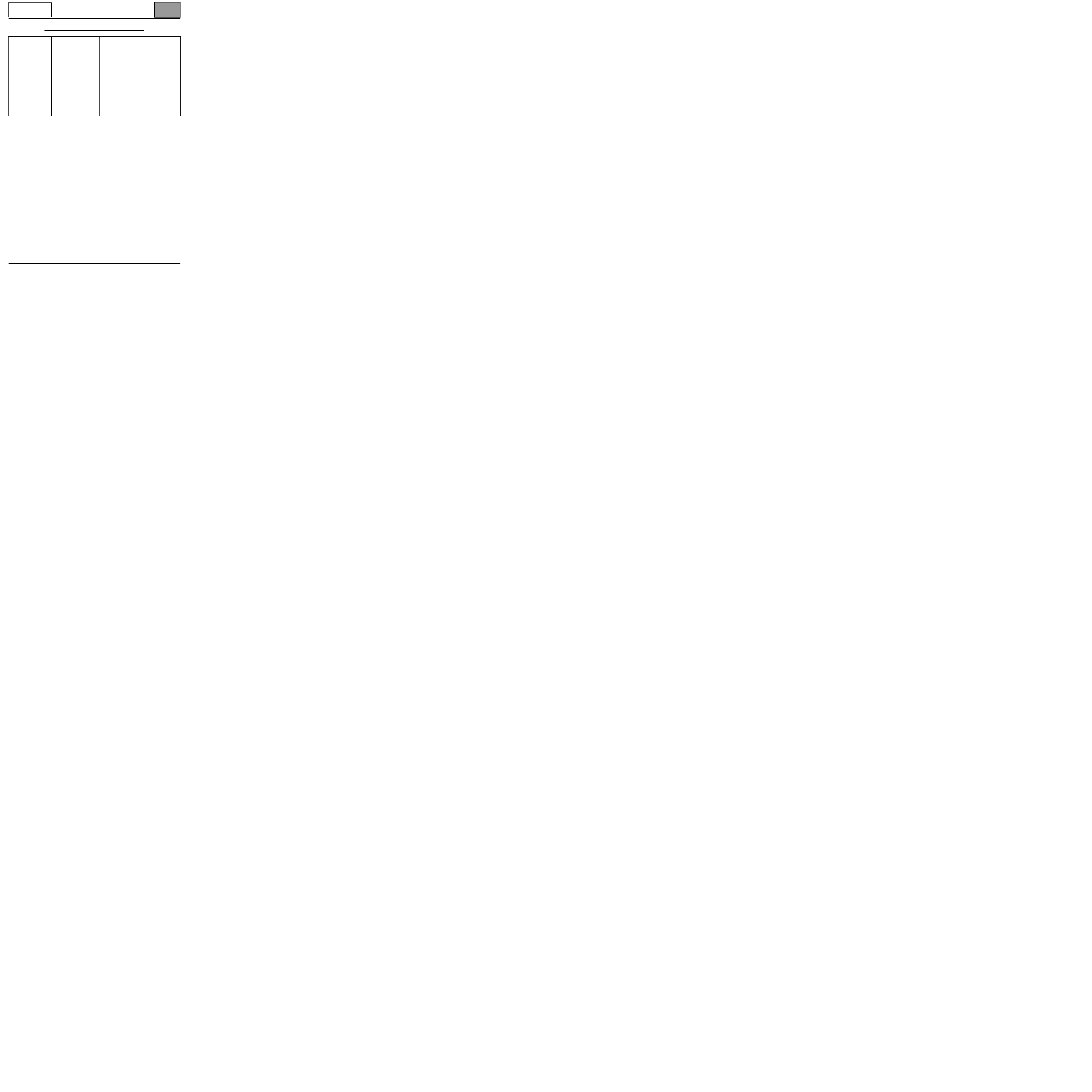

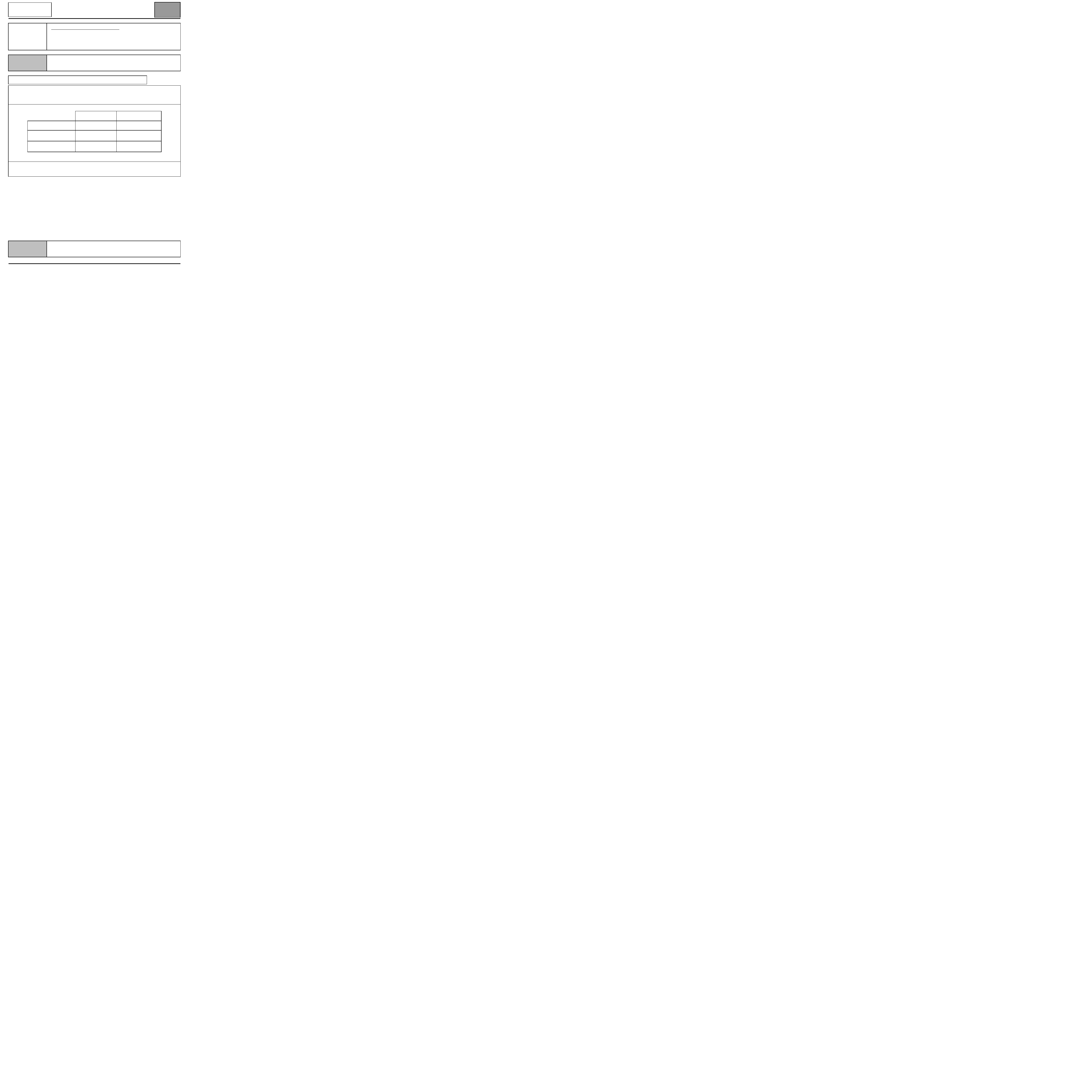

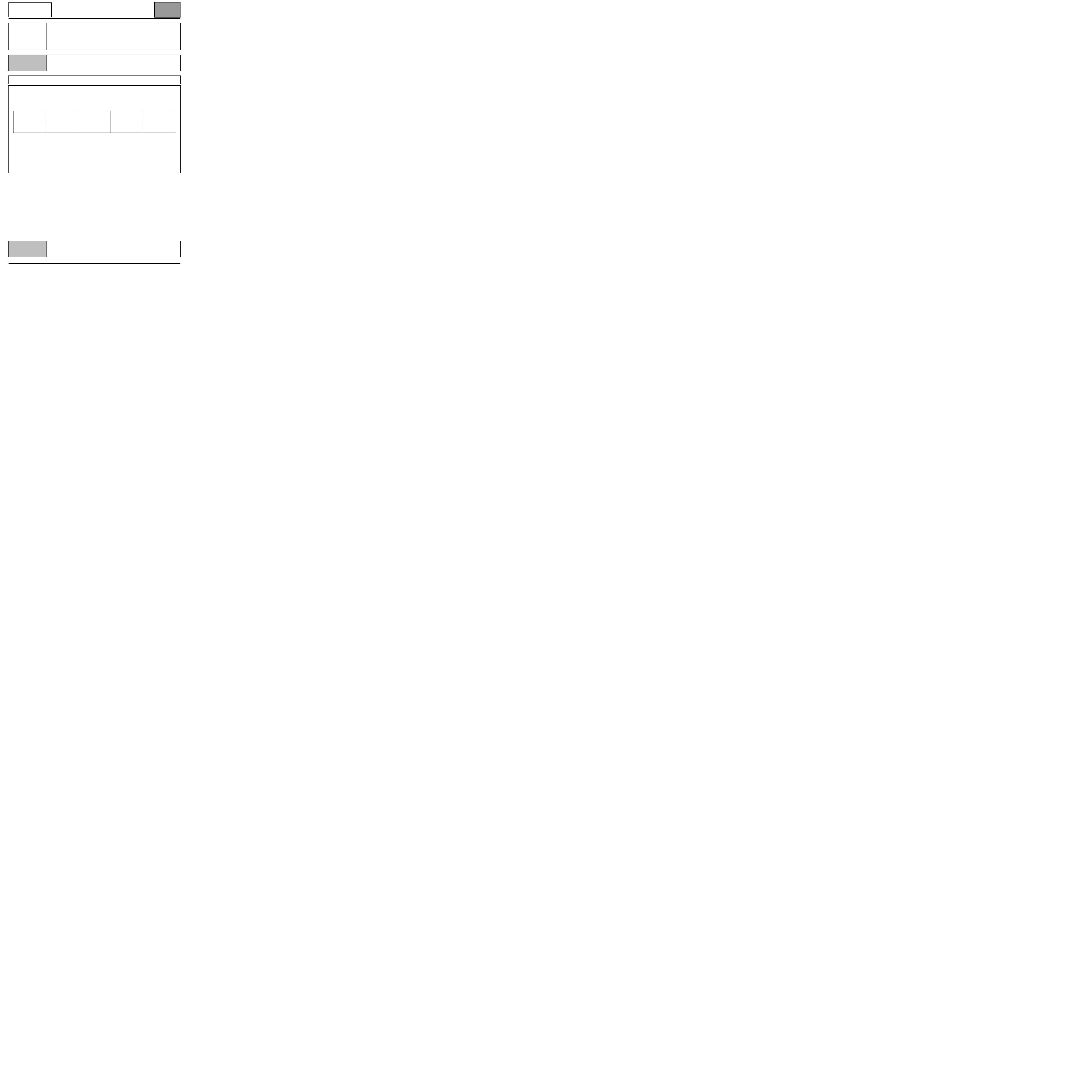

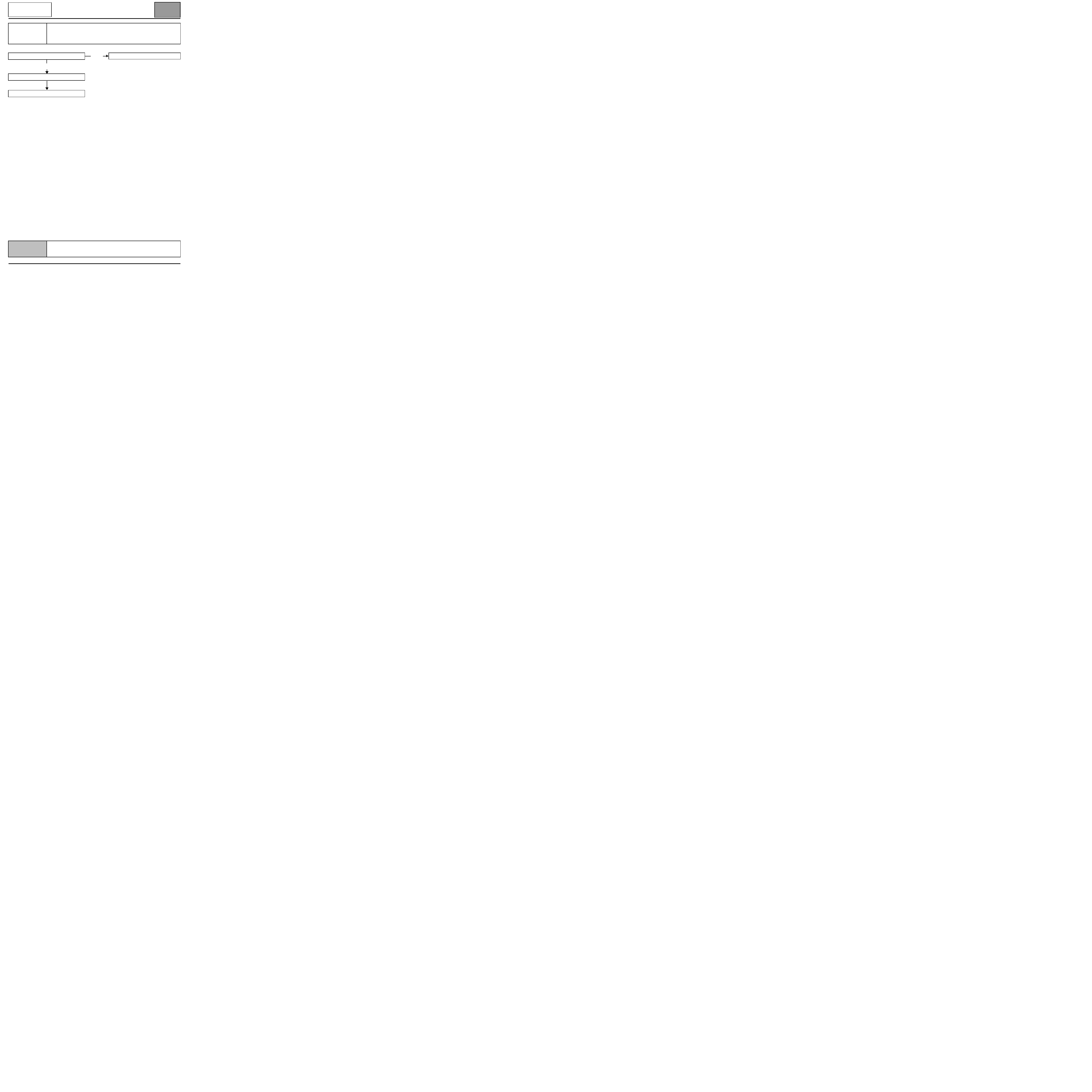

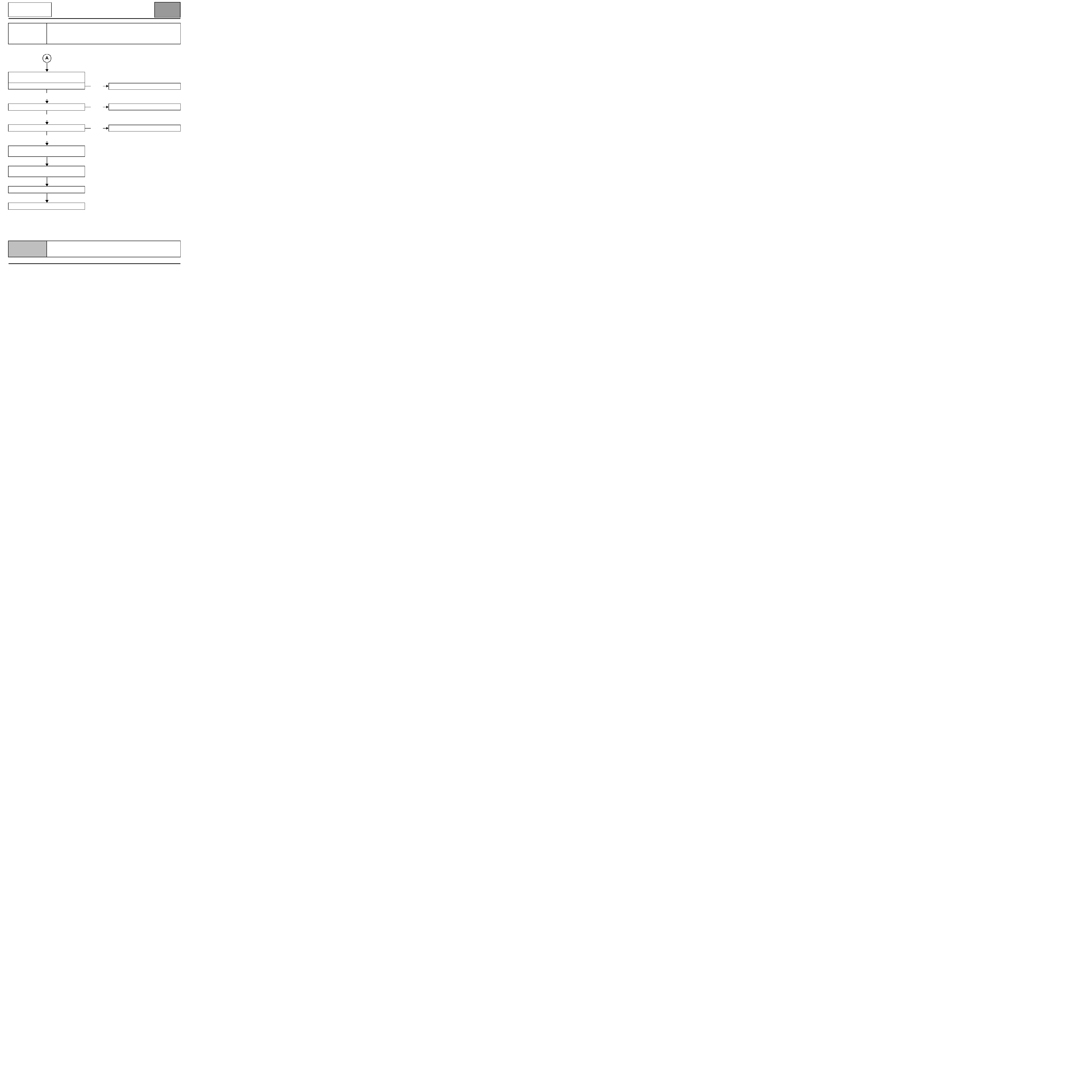

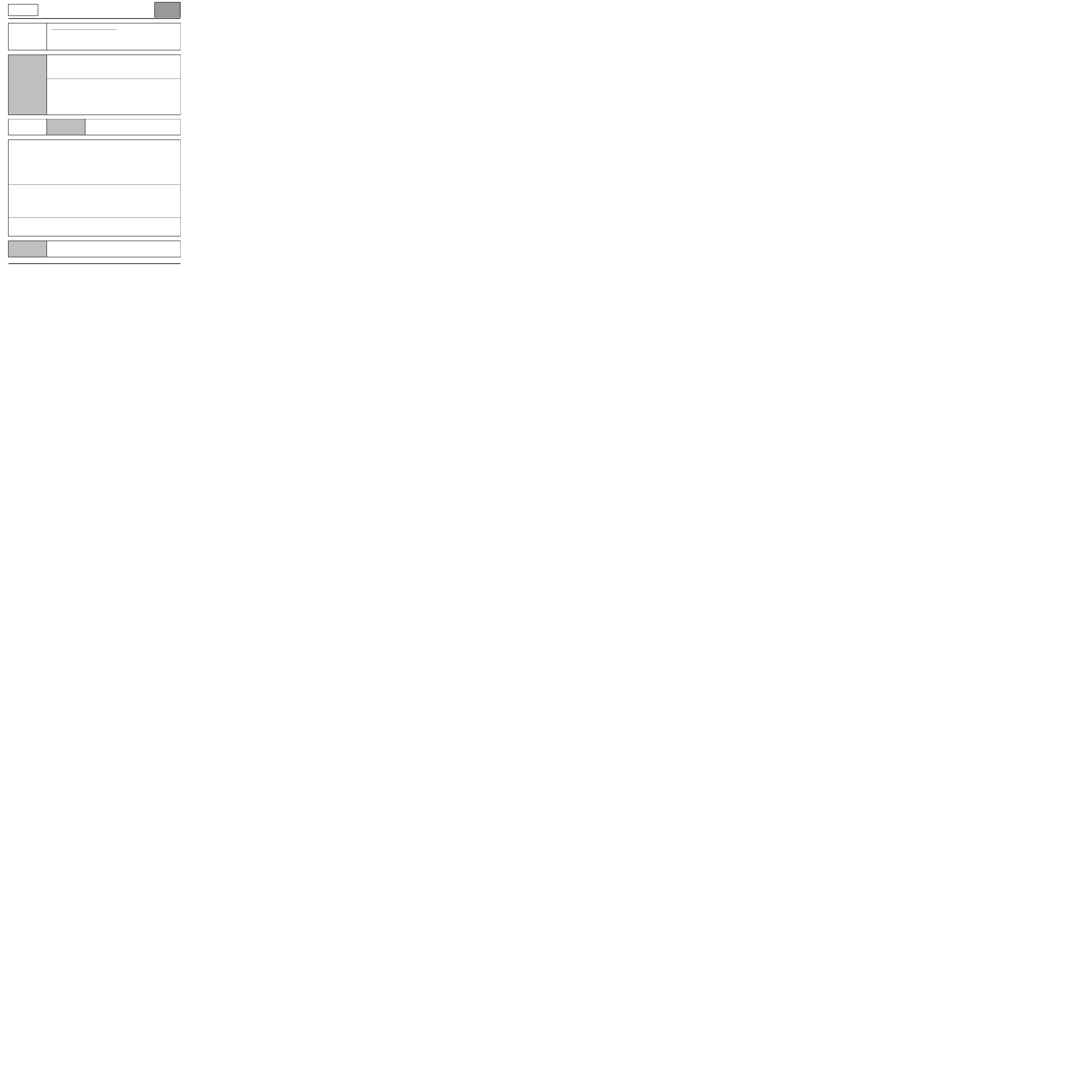

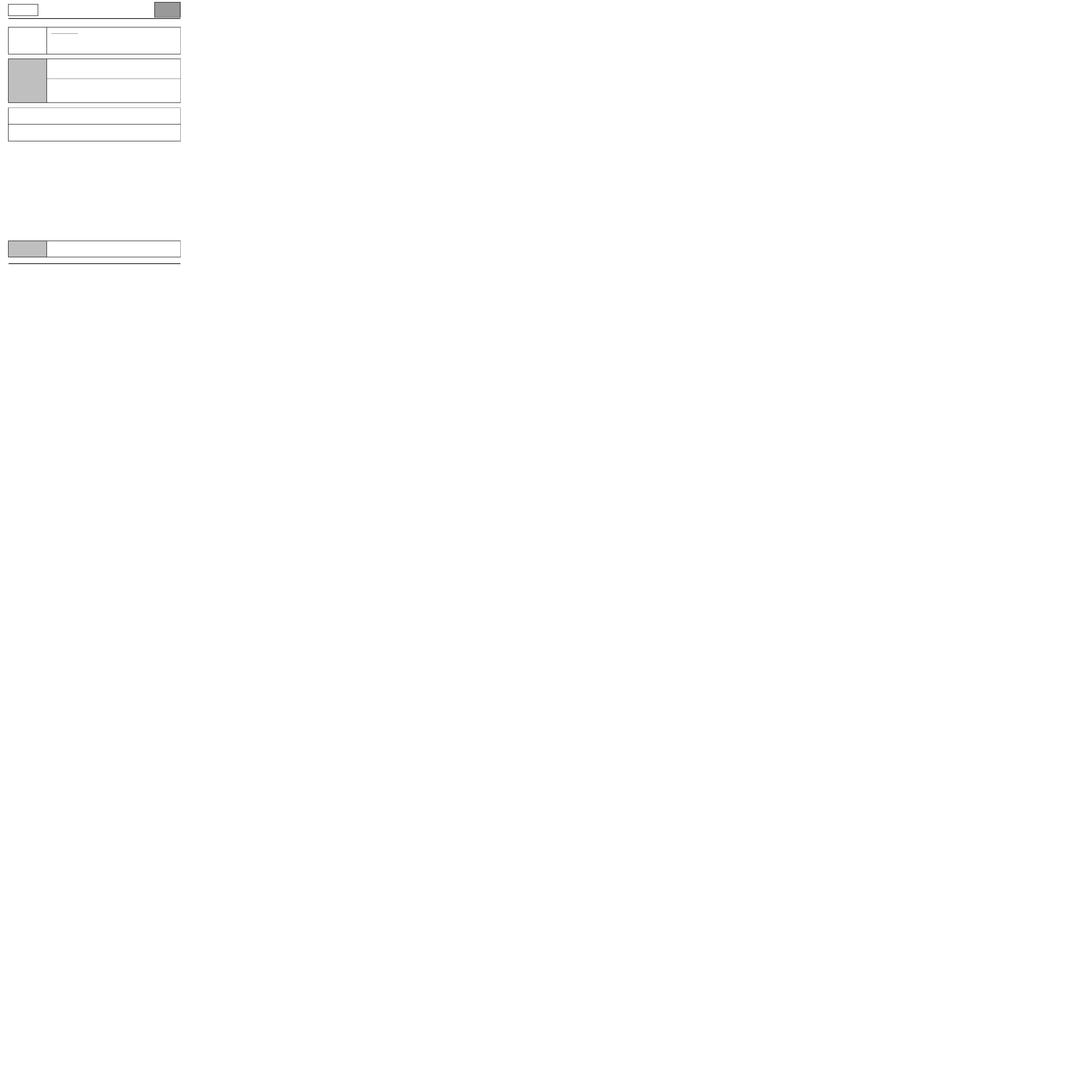

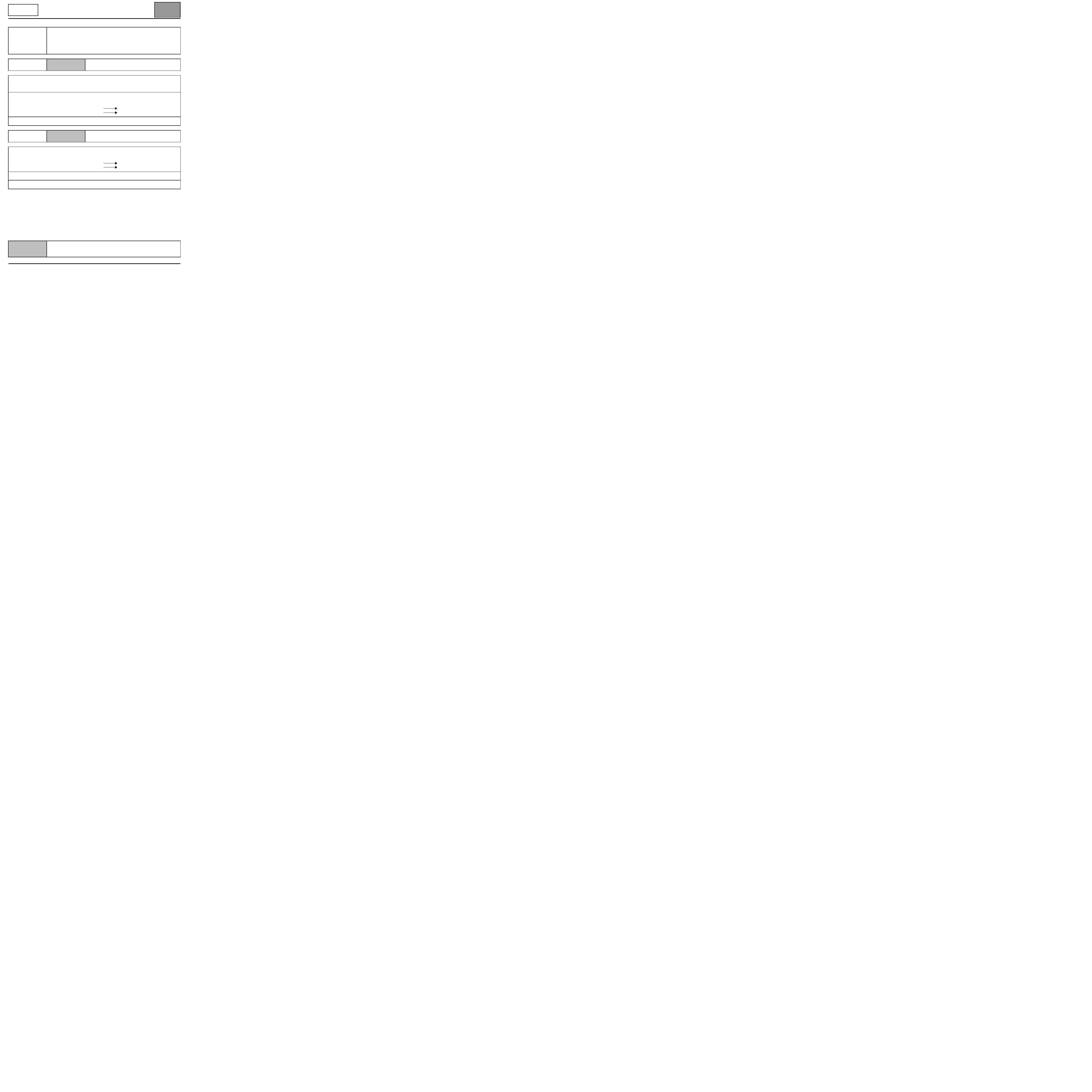

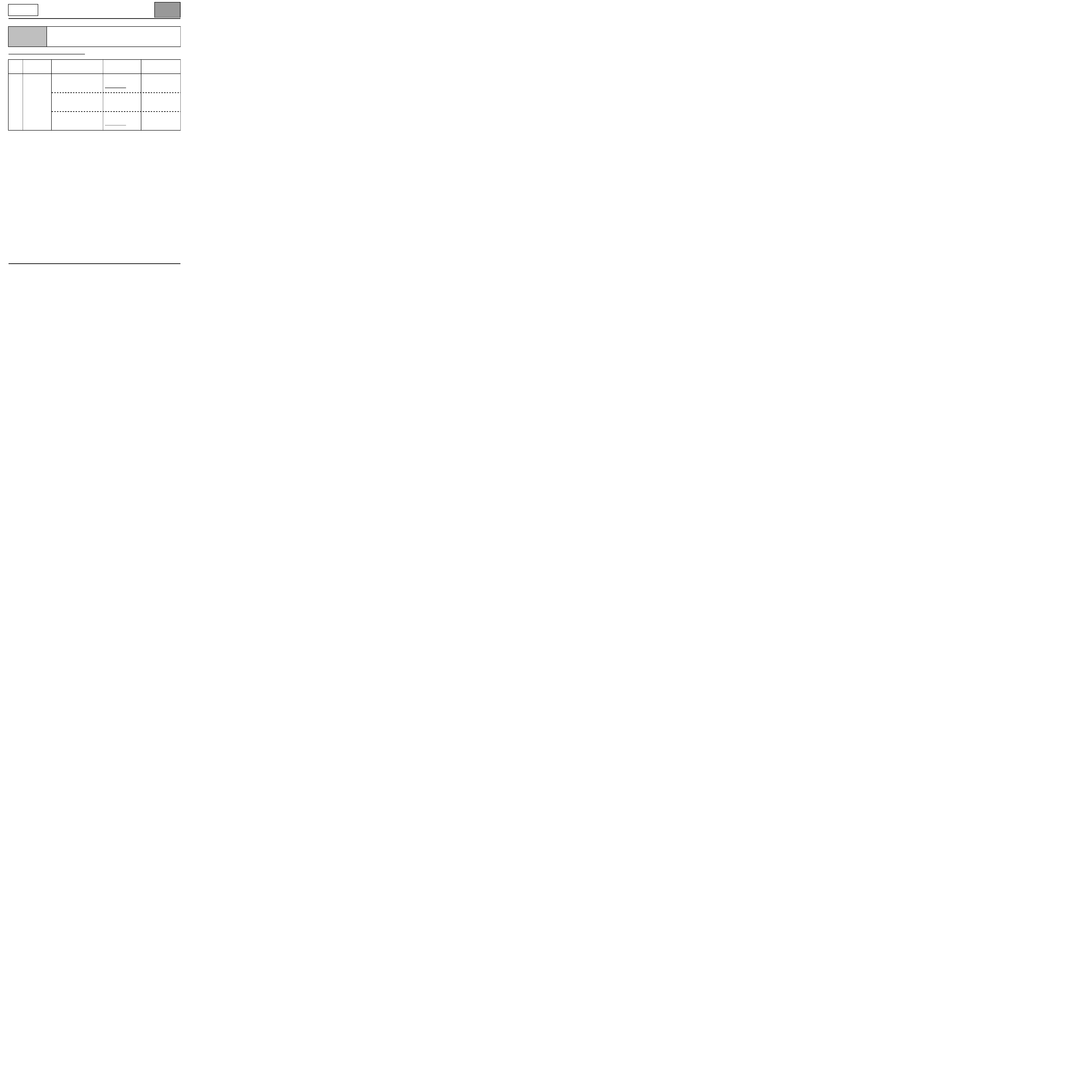

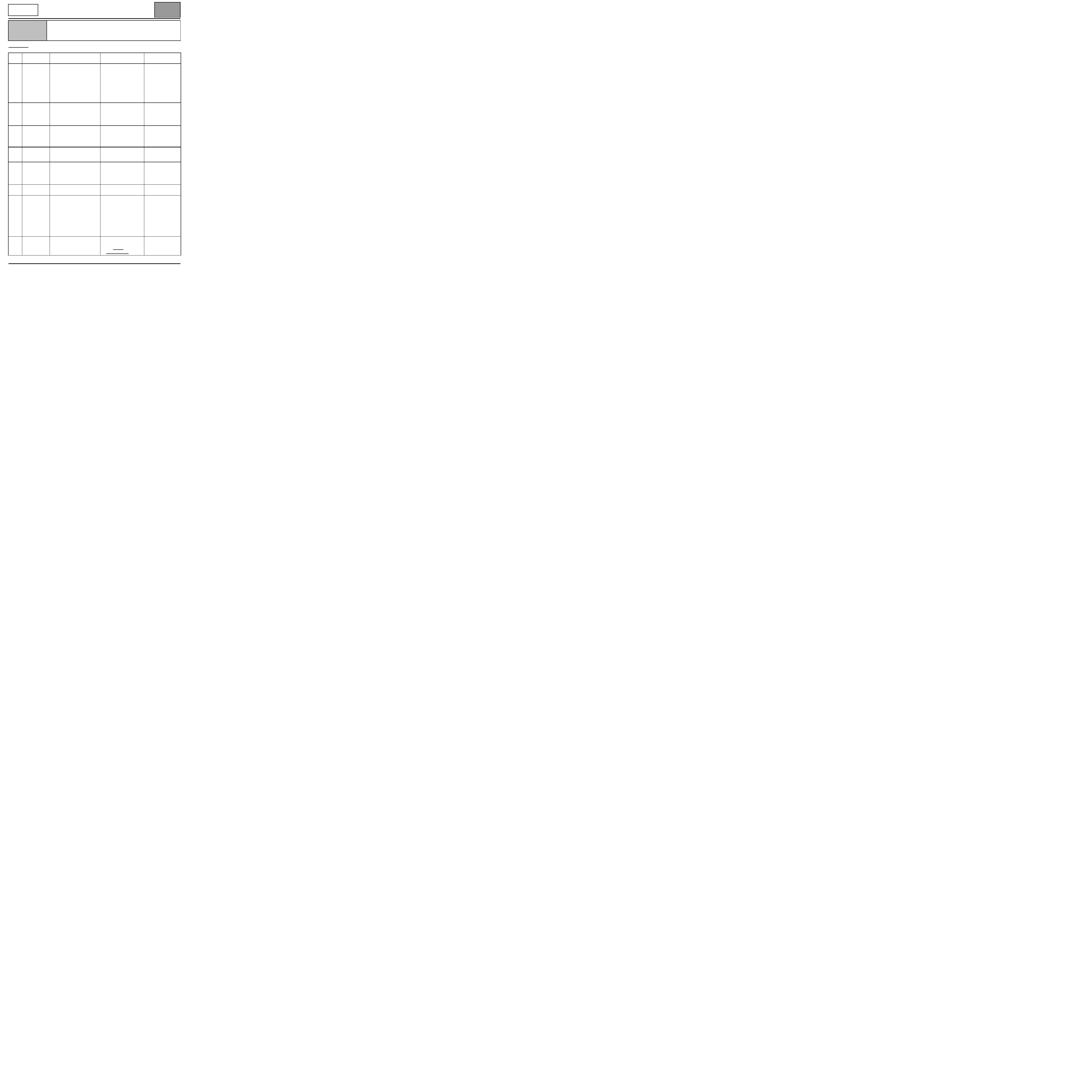

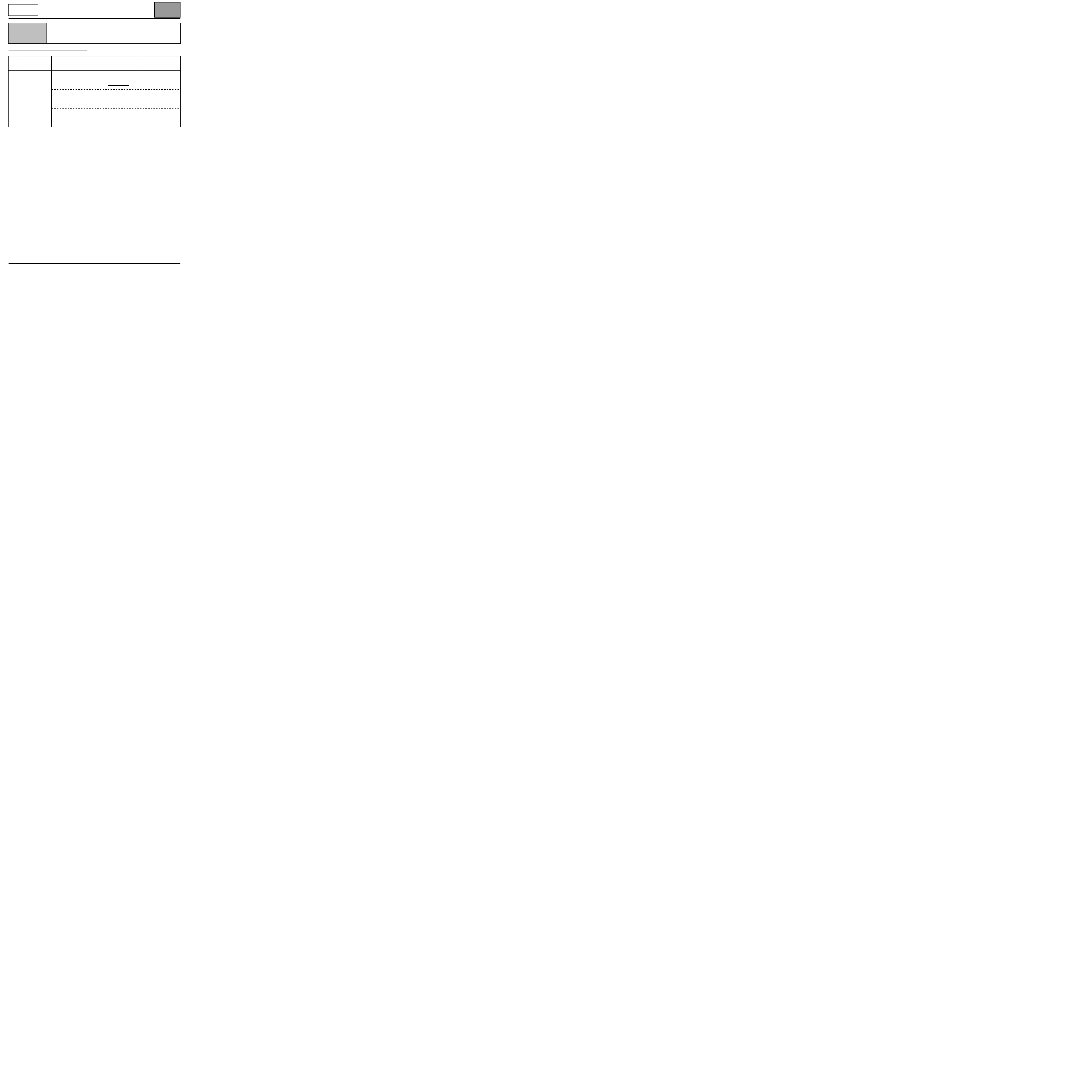

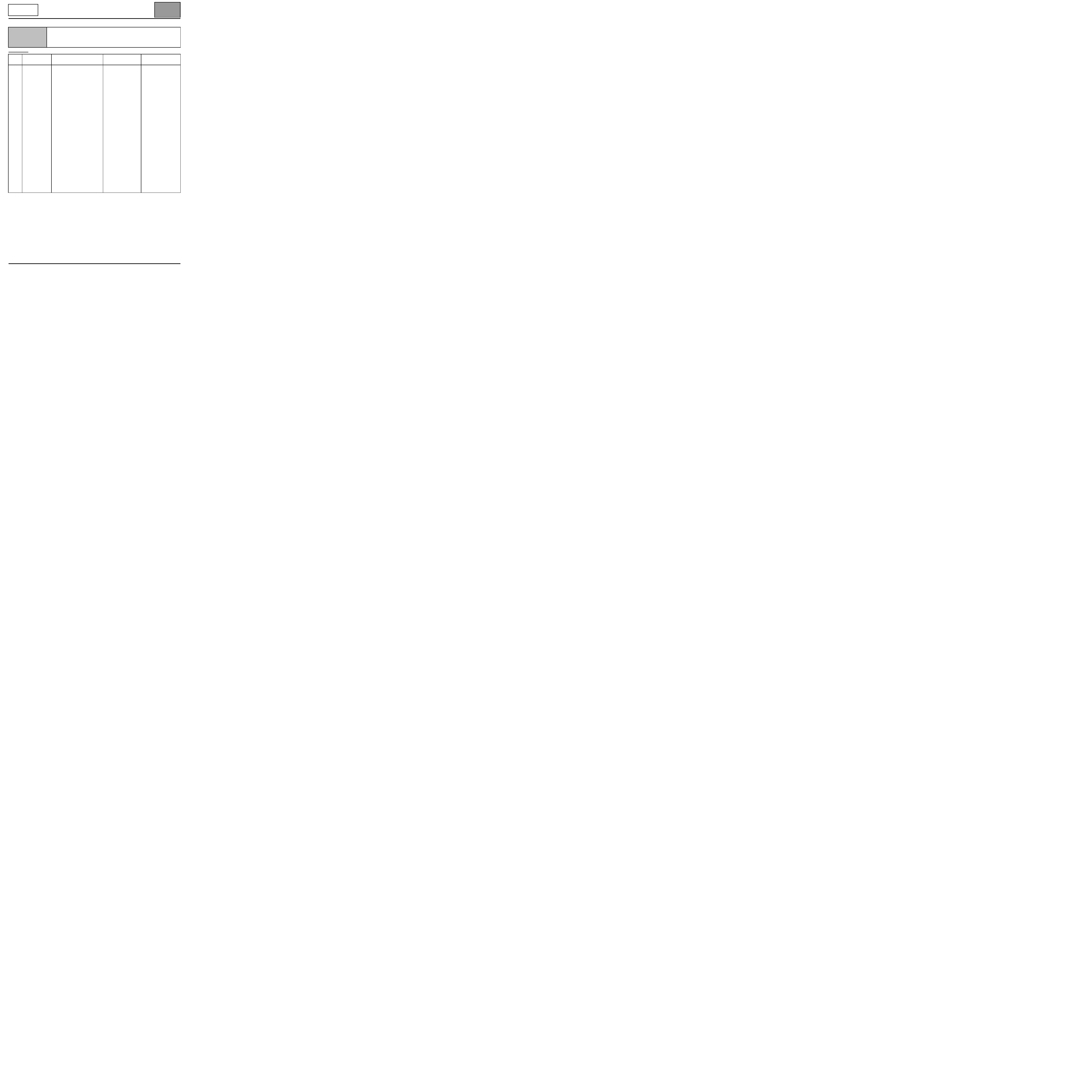

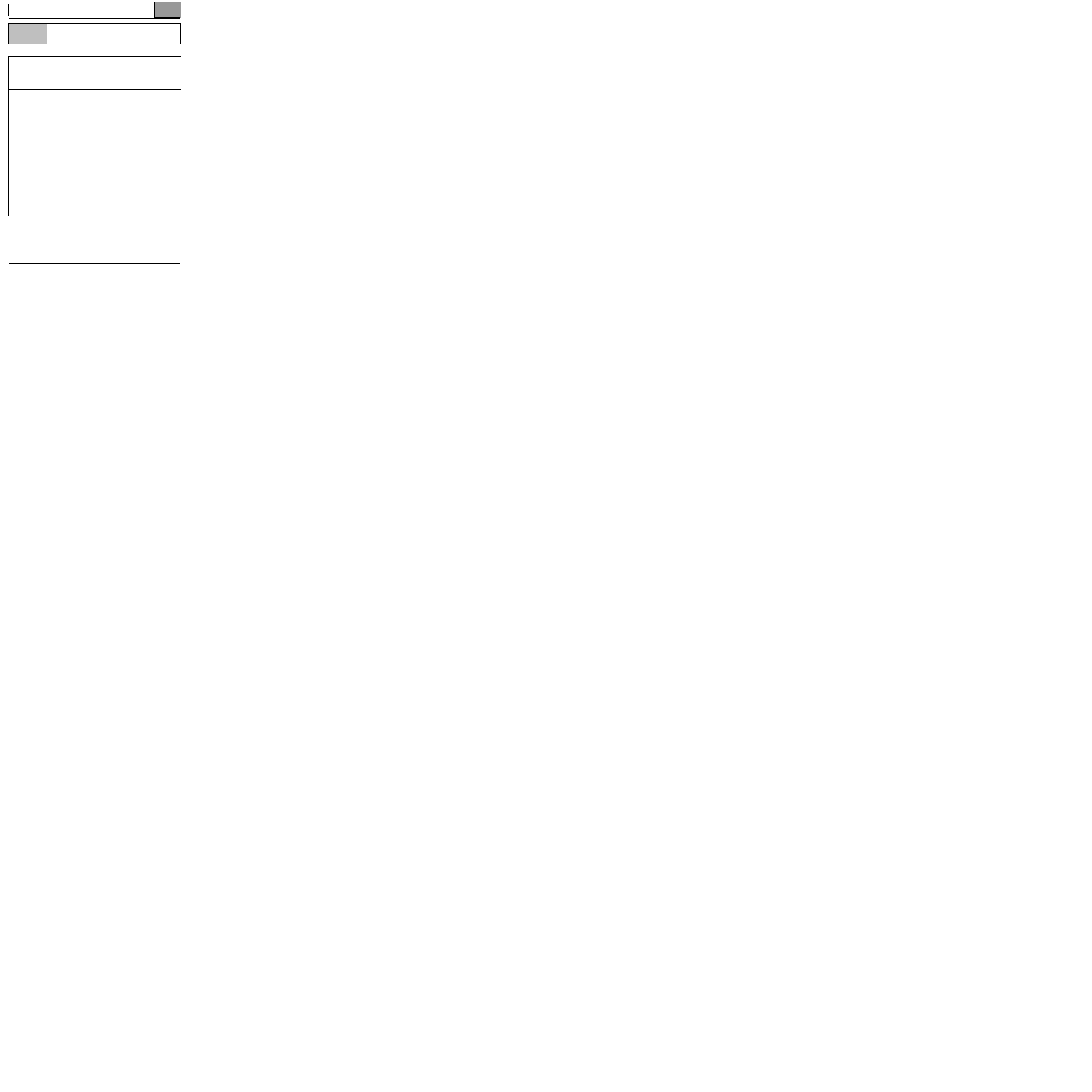

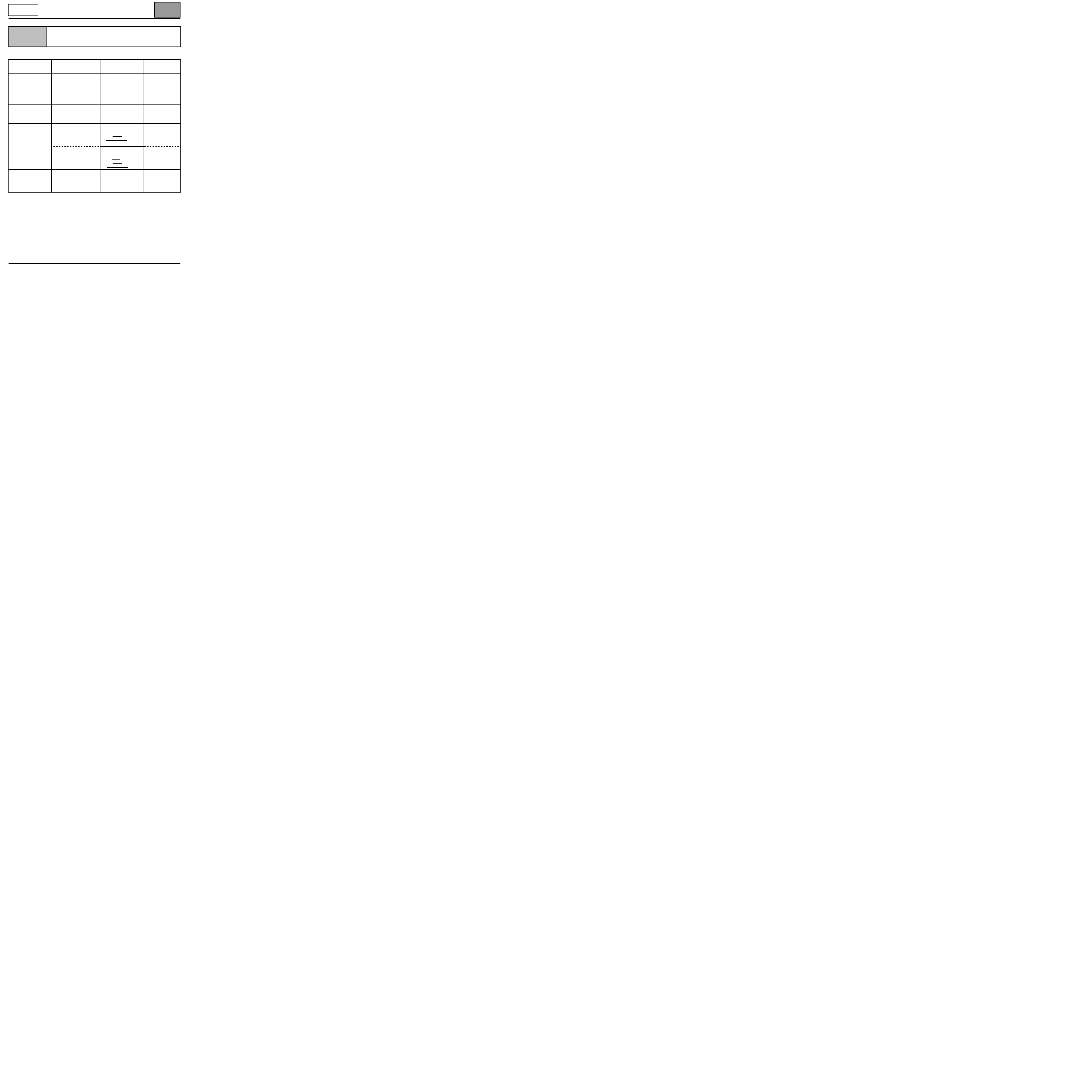

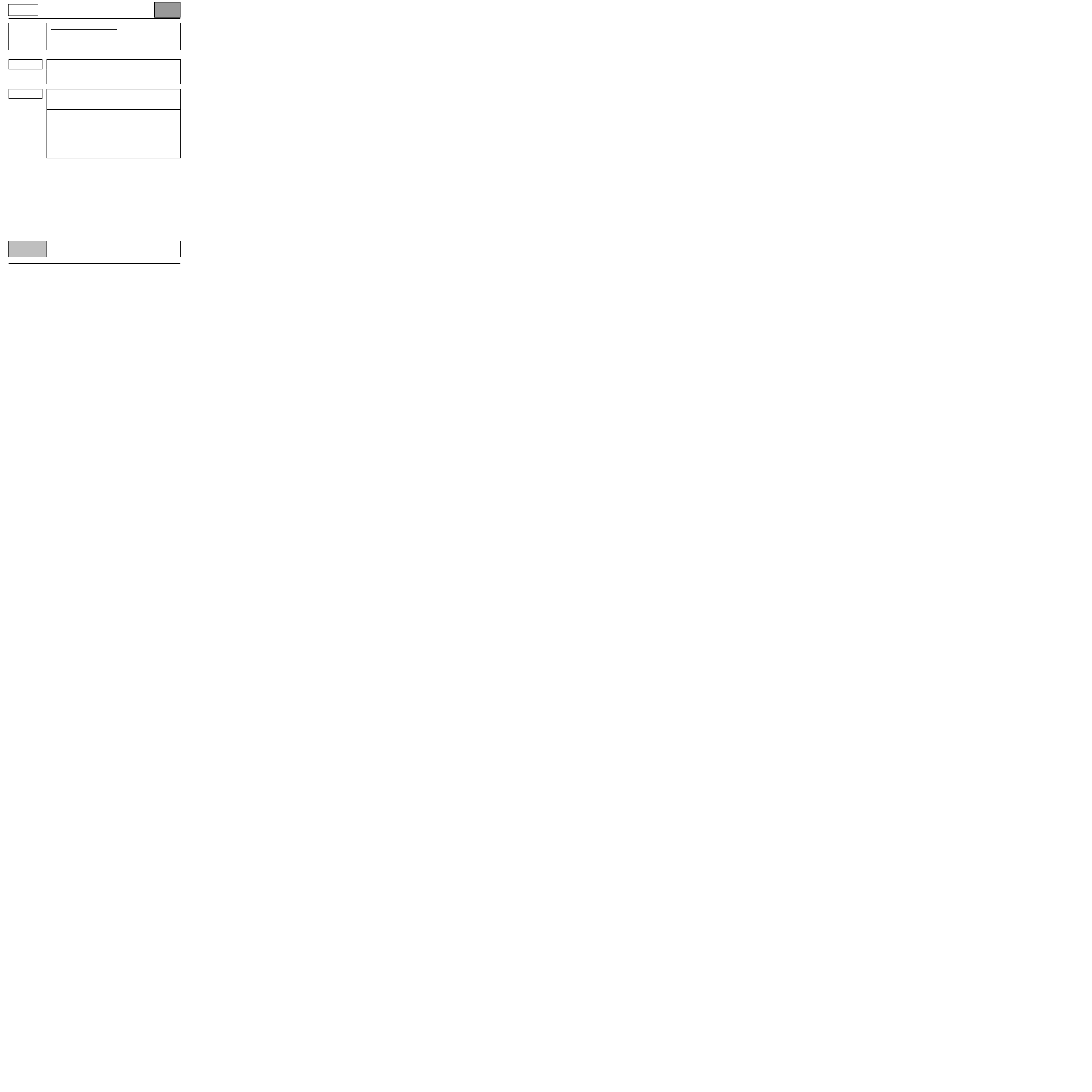

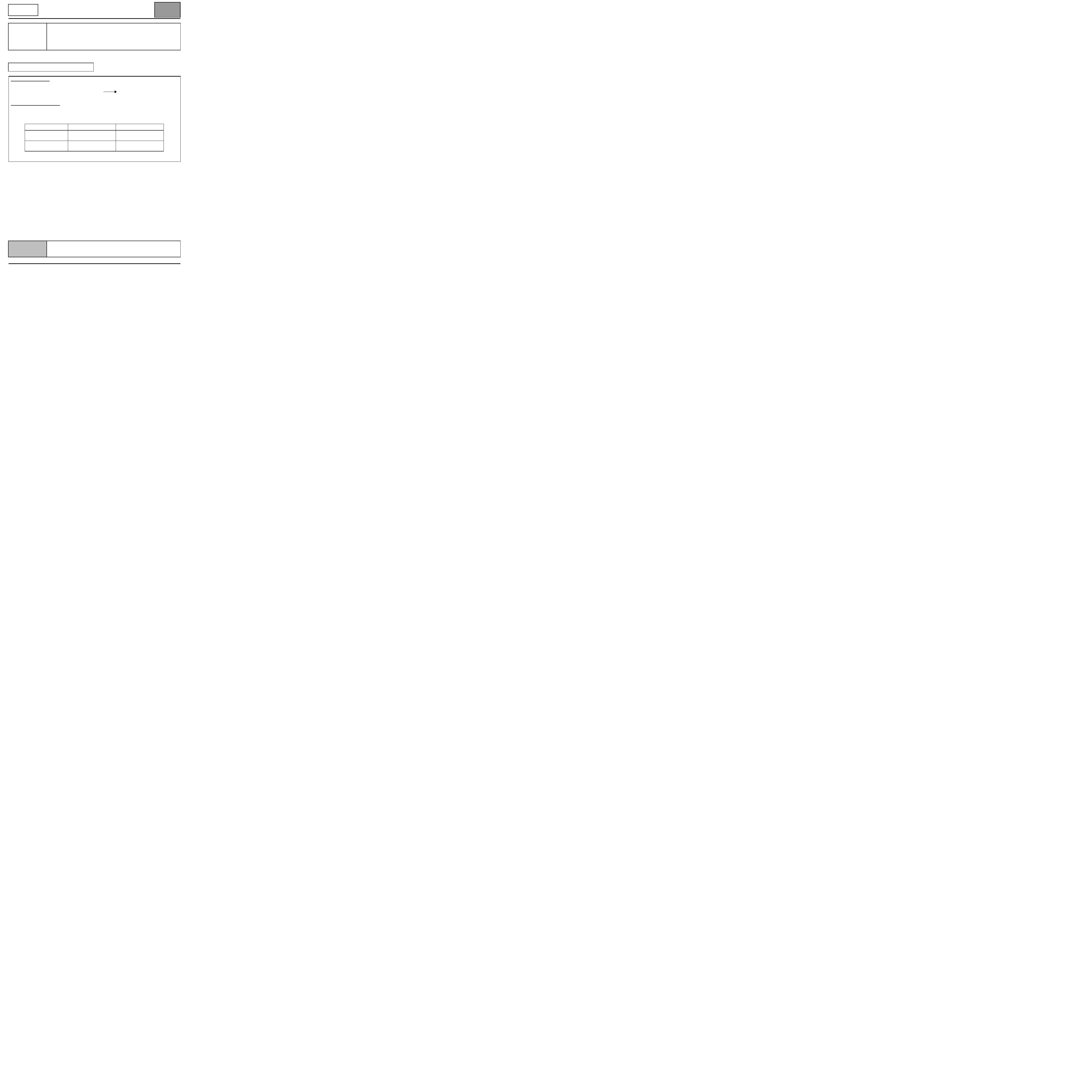

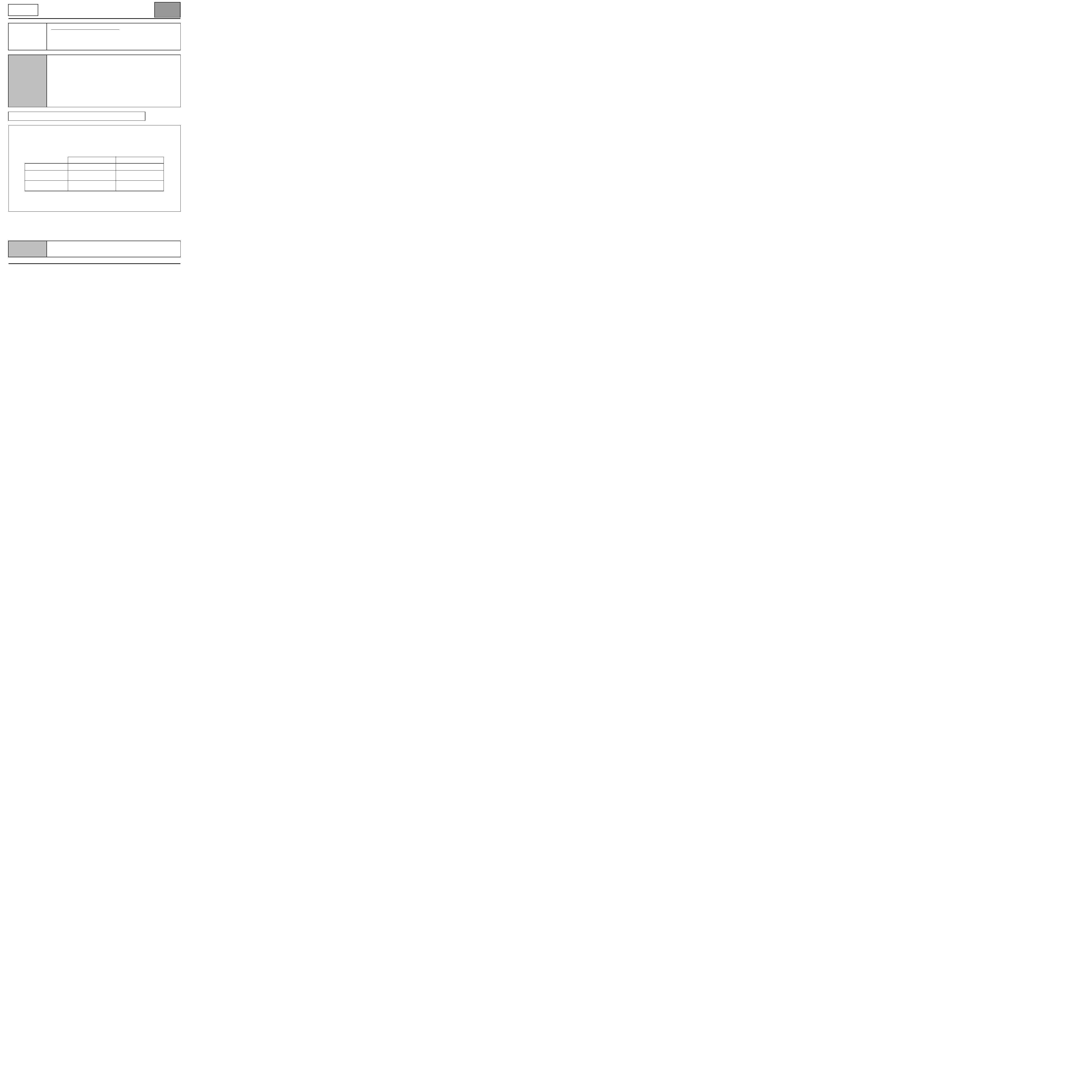

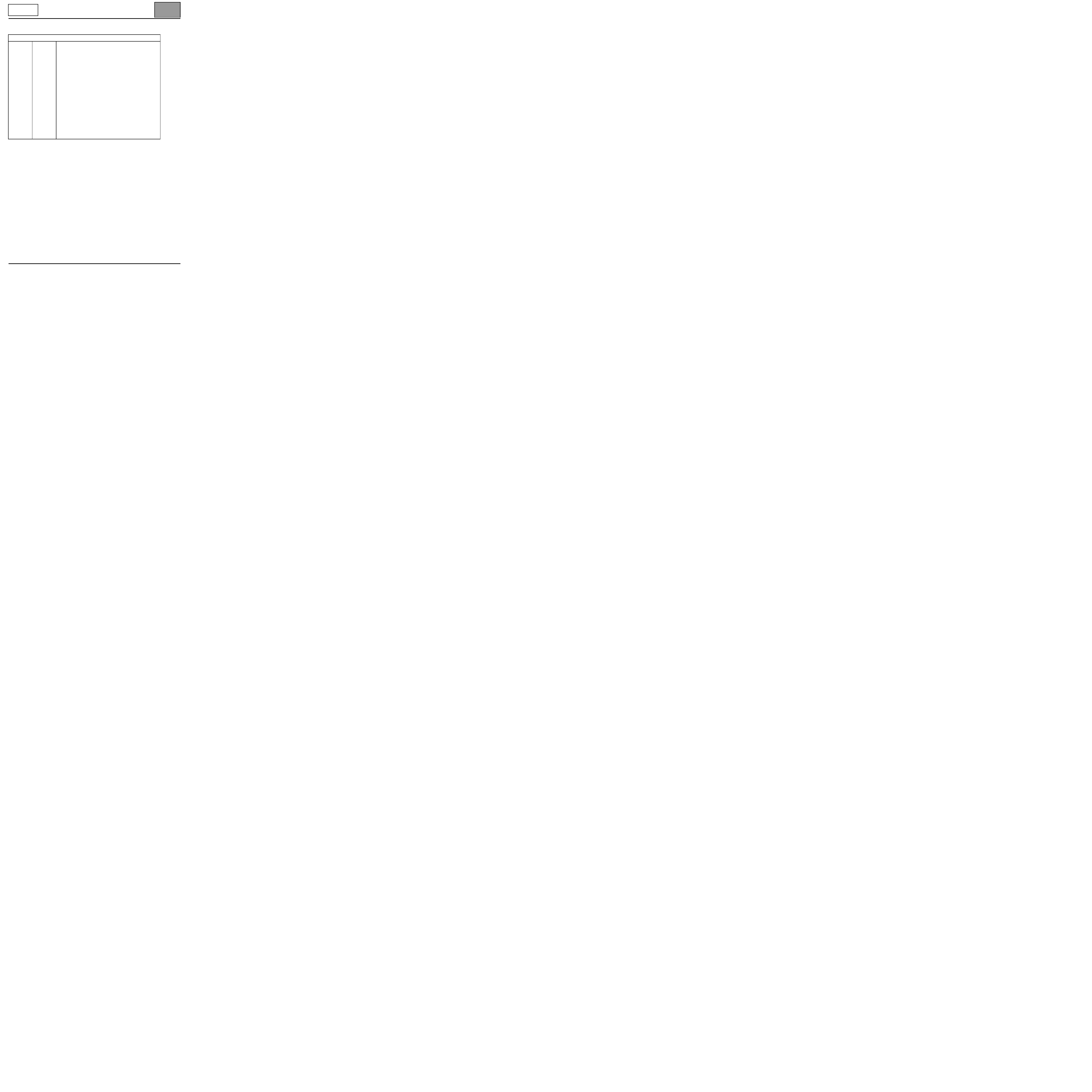

To be read with the diagnostic tool (Identification screen):

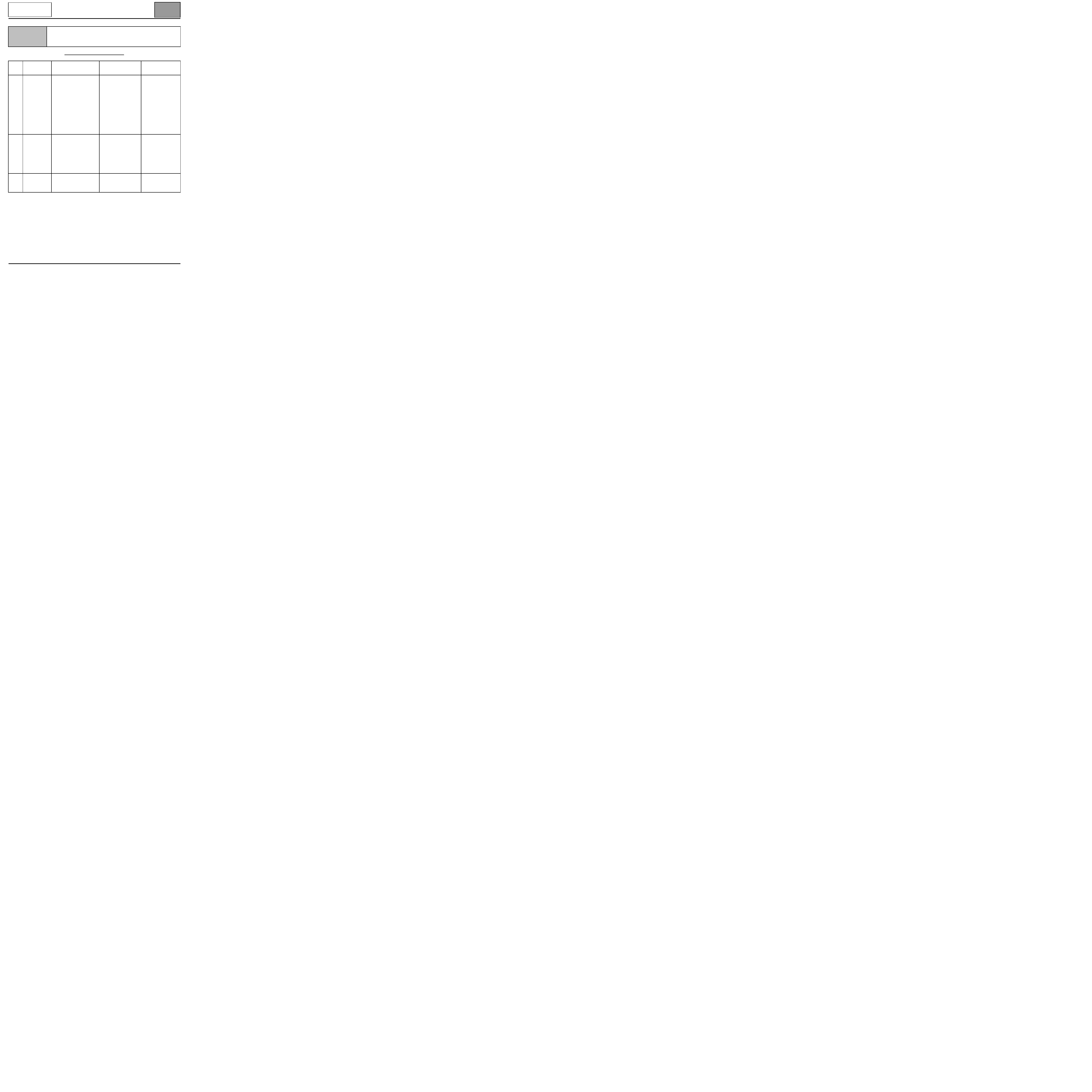

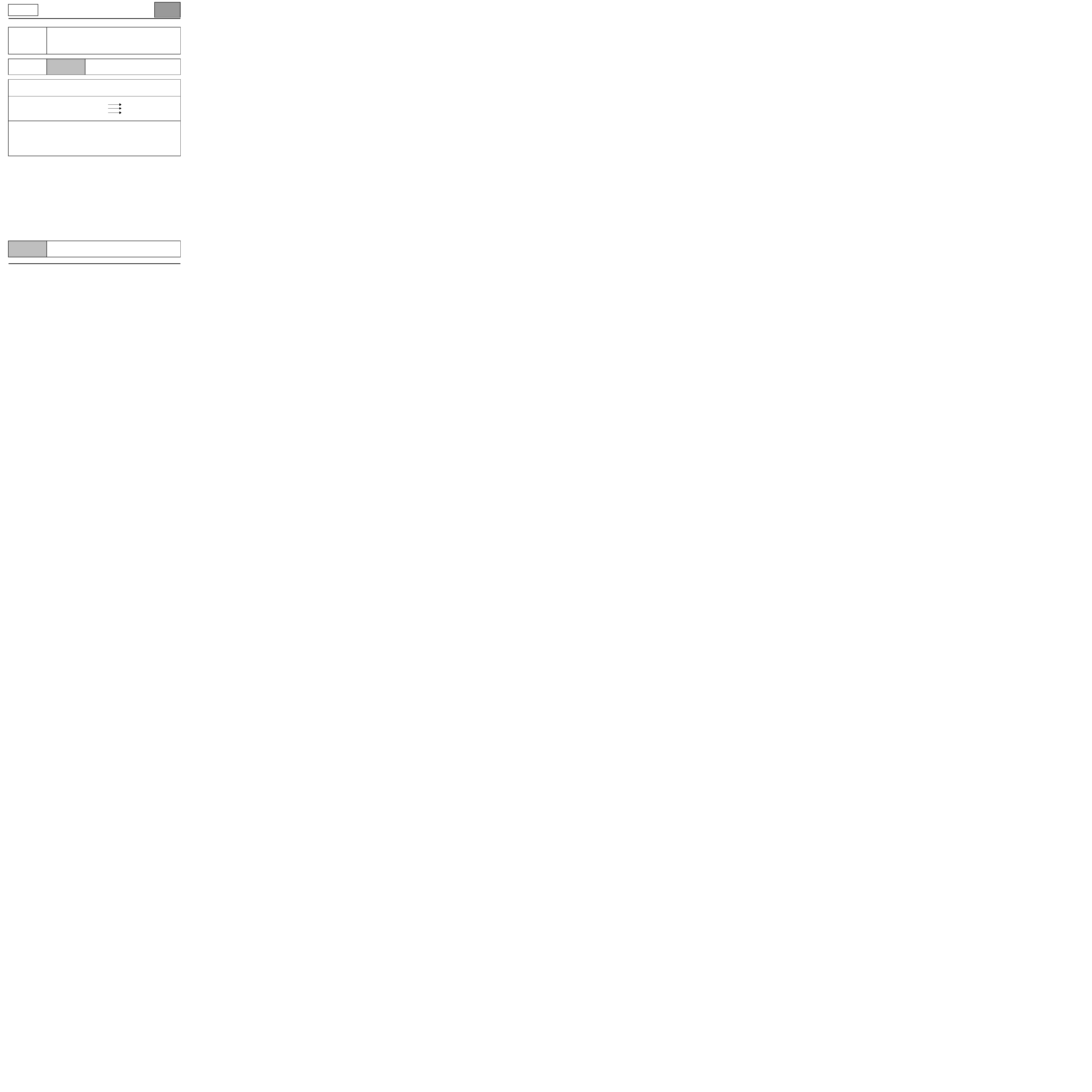

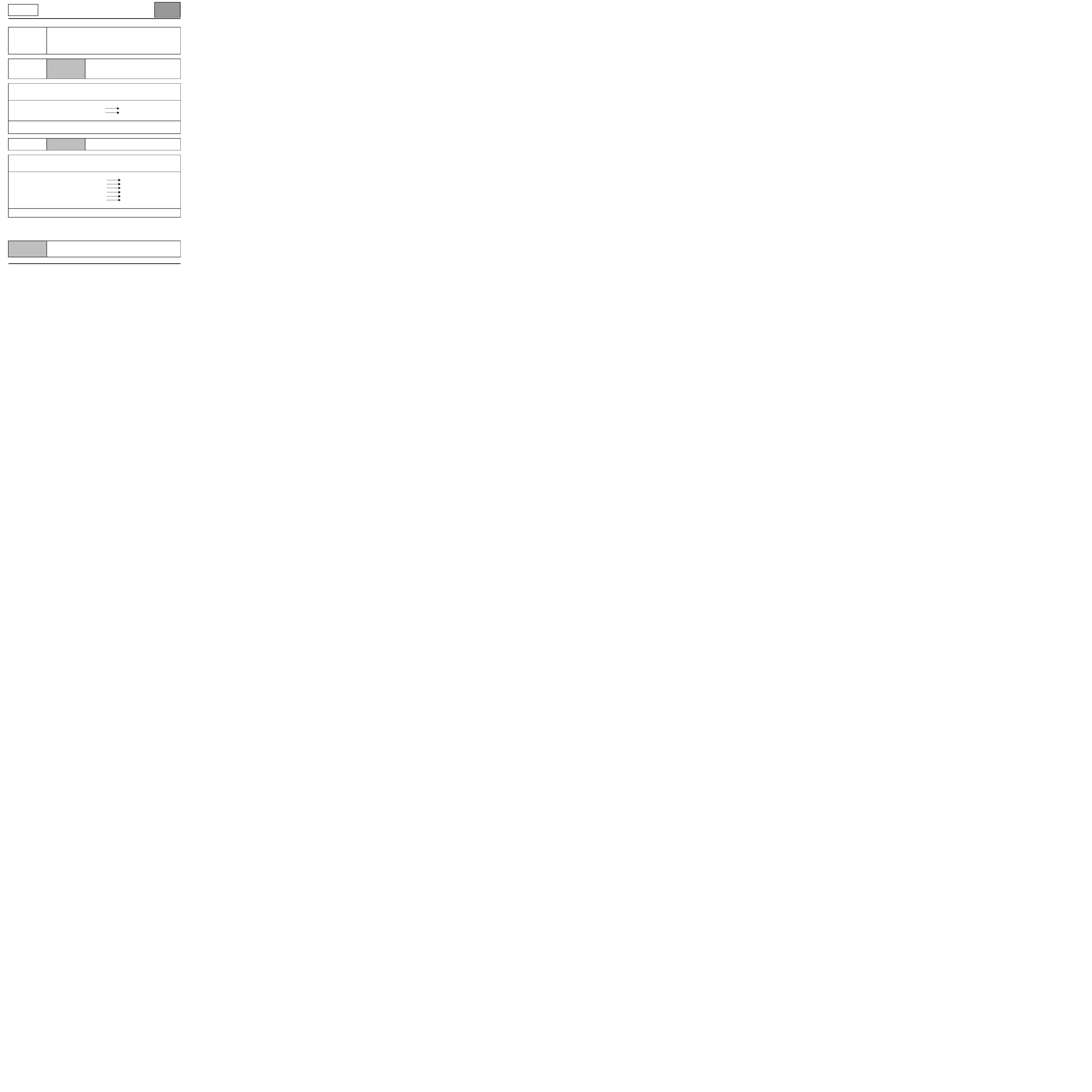

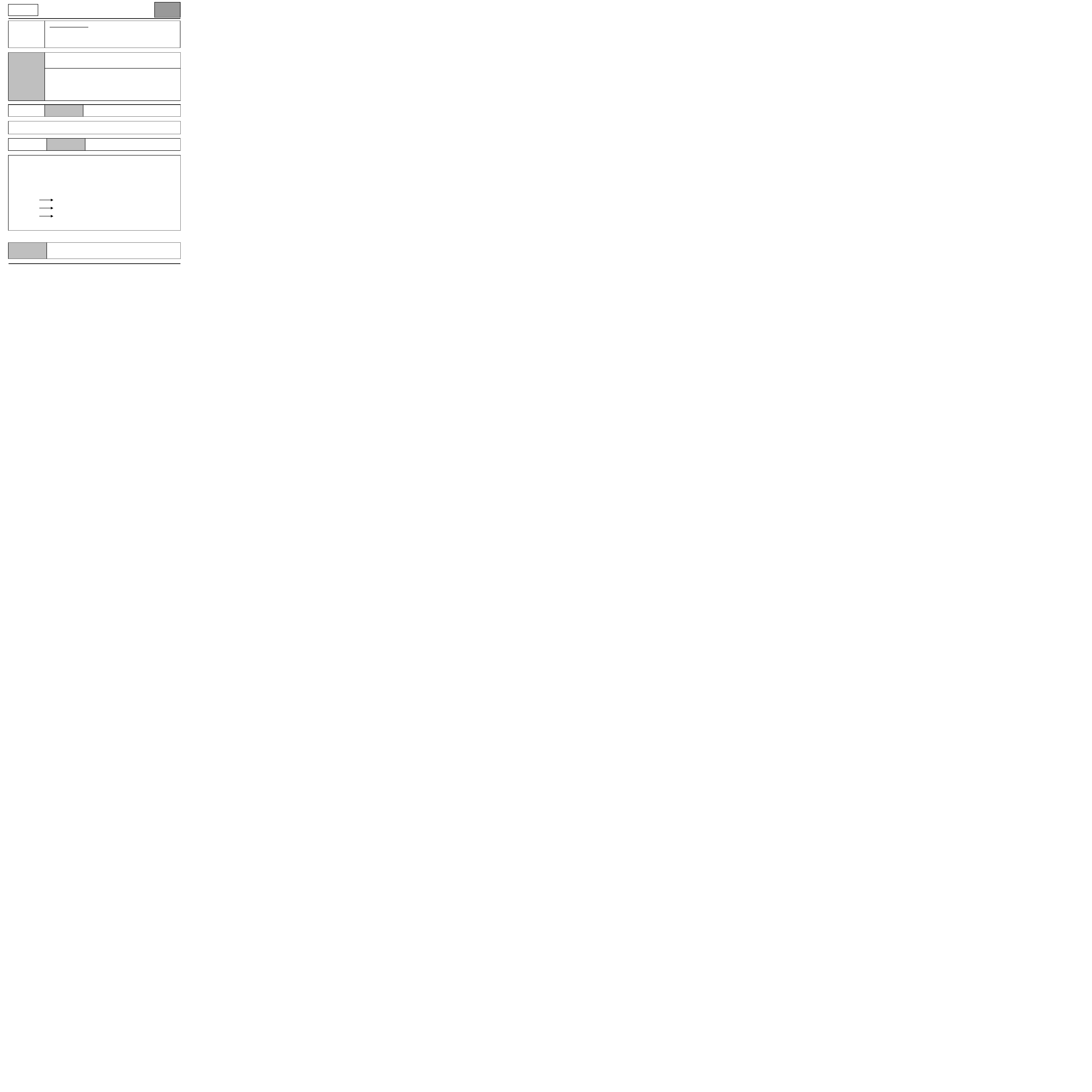

FAULT FINDING LOG

System: Injection

Page 2 / 2

●

Identification of computer and system parts exchanged

Part 1 part no.

Part 2 part no.

Part 3 part no.

Part 4 part no.

Part 5 part no.

Computer part no.

Supplier no.

Program no.

Software version

Calibration no.:

VDIAG

●

Faults found with the diagnostic tool

Fault no.

Present

Stored

Fault title

Specification

●

Conditions when fault occurs

State or parameter no.

Name of parameter

Value

Unit

●

System-specific information

Description:

●

Additional information

What factors led you to replace the

computer?

What other parts were replaced?

Other faulty functions?

Your comments

FD 01

Fault finding log

page to print or photocopy - page to print or photocopy - page to print or photocopy

DIESEL INJECTION

Fault finding - System operation

13B

13B-11

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

Fault finding - System operation

The high-pressure direct injection system is intended to deliver a precise quantity of diesel to the engine at a specific

time.

DESCRIPTION

DELPHI "DDCR" type 112-track computer.

The system consists of:

– a priming bulb on the low-pressure circuit,

– a diesel filter,

– a high-pressure pump combined with a booster pump (transfer pump),

– a pressure regulator mounted on the pump,

– an injector rail,

– a pressure sensor located in the rail,

– four solenoid injectors,

– a diesel temperature sensor,

– a coolant temperature sensor,

– a cylinder reference sensor,

– an engine speed sensor,

– an accelerometer,

– an exhaust gas recirculation solenoid valve,

– an accelerator pedal potentiometer,

– an atmospheric pressure sensor,

– and a computer.

The common rail direct high-pressure injection system works sequentially (based on the operation of multipoint

injection for petrol engines).

This new injection system reduces operating noise, reduces the volume of pollutant gases and particles and

produces high engine torque at low engine speeds thanks to a pre-injection procedure.

The high-pressure pump generates the high-pressure sent to the injector rail. The actuator located on the pump

controls the quantity of diesel supplied, according to the demand determined by the computer. The rail supplies each

injector through a steel pipe.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - System operation

13B

13B-12

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

The computer:

– determines the value of injection pressure necessary for the engine to operate correctly and then controls the

pressure regulator. It checks that the pressure value is correct by analysing the value transmitted by the pressure

sensor located on the rail,

– determines the injection time necessary to deliver the right quantity of diesel and the moment when injection should

start,

– controls each injector electrically and individually after determining these two values.

The injected flow to the engine is determined by:

– the duration of injector control,

– the injector opening and closing speed,

– the needle travel (determined by a constant for the type of injector),

– the nominal hydraulic flow of the injector (specific to each injector),

– the high-pressure rail pressure controlled by the computer.

The computer controls:

– idle speed regulation,

– exhaust gas flow reinjection into the inlet,

– fuel supply monitoring (advance, flow and rail pressure),

– the fan unit (centralised coolant temperature management function),

– the air conditioning (cold loop function),

– the cruise control/speed limiter function,

– the pre/post heating function.

The high-pressure pump is supplied at low-pressure by an integrated low-pressure pump (transfer pump).

It supplies the rail the pressure in which is controlled for charging by the flow actuator and for discharging by the

injector valves. Drops in pressure may also be compensated for. The flow actuator allows the high-pressure pump to

supply the exact quantity of diesel fuel required to maintain the pressure in the rail. This feature allows heat

generation to be minimised and engine output to be improved.

In order to discharge the rail using the injector valves, the valves are controlled by brief electrical pulses which are:

– which are short enough not to open the injector (passing through the return circuit from the injectors),

– long enough to open the valves and discharge the rail.

The fan assembly and coolant temperature warning light on the instrument panel are controlled by the injection

computer (centralised coolant temperature management function).

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - System operation

13B

13B-13

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

The connections between the vehicle's various computers are multiplexed. The fault warning lights on the

instrument panel are therefore activated via the multiplex network.

There is no vehicle speed sensor in the gearbox. The vehicle speed signal on the instrument panel is transmitted by

the ABS computer or the wheel speed computer via a wire connection and is then transmitted on the multiplex

network by the instrument panel. The vehicle speed information is used mainly by the injection computer and the

airbag computer.

Some vehicles have a sensor for detecting water in the diesel, located in the filter. If there is water present in the

diesel, the orange injection and pre/postheating warning light comes on.

The system injects diesel into the engine at a pressure of up to 1400 bar. Before carrying out any work, check that

the injector rail is not pressurised and that the fuel temperature is not too high.

You must respect the cleaning and safety advice specified in this document for any work on the high-pressure

injection system.

Removal of the internal parts of the pump and injectors is prohibited. Only the flow actuator, the diesel temperature

sensor and the venturi can be replaced.

For safety reasons, it is strictly forbidden to undo a high-pressure pipe union when the engine is running.

It is not possible to remove the pressure sensor from the fuel rail because this may cause circuit contamination

problems. If the pressure sensor fails, the pressure sensor, the rail and the five high-pressure pipes must be

replaced.

It is strictly forbidden to remove any injection pump pulley marked number 070 575. If the pump is being replaced,

the pulley must be replaced.

Applying 12 volts directly to any component in the system is prohibited.

Ultrasonic decoking and cleaning are prohibited.

Never start the engine unless the battery is connected correctly.

Disconnect the injection system computer when carrying out any welding work on the vehicle.

It is essential to replace all the disconnected air inlet plastic pipes.

IMPORTANT

The engine must not operate with:

– diesel fuel containing more than 10%

diester,

– petrol, even in tiny quantities.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - System operation

13B

13B-14

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

HOSTED FUNCTIONS

Air conditioning management assistance:

For vehicles with air conditioning, the DDCR system can switch off the air conditioning in certain engine operating

conditions:

– When requested by the driver.

– When starting the engine.

– If the engine overheats (in order to reduce the power the engine has to supply).

– When the engine speed is very high (to protect the compressor).

– During transition phases (e.g. during high acceleration demands when overtaking, anti-stalling and moving

off strategies). These conditions are only taken into account when they occur repeatedly, so as to prevent

system instabilities (incorrect deactivation).

– When certain faults appear.

Cold loop air conditioning management:

The air conditioning is managed in a cold loop and this function is managed by several computers. The injection

computer is responsible for:

– Managing the request for cold air according to passenger compartment controls and pressure level.

– Ascertaining the power absorbed by the compressor from the pressure.

– Ascertaining the fan assembly controls according to vehicle speed and pressure.

The driver asks for the air conditioning to be switched on using the air conditioning switch. This request for cold air is

either authorised or not, depending on the measured pressure. If this pressure is outside the operating limits, the

cold loop strategy is not activated.

Thermal regulation of the passenger compartment heating circuit:

In a direct injection engine, fuel is injected directly into the combustion chamber. This leads to heat being lost

through the upper part of the engine and consequently, the cylinder head cooling circuit is smaller in size.

The effect of this is that the temperature of the coolant which flows through this circuit rises more slowly. However,

this coolant is used by the passenger compartment heating system. In very cold conditions, it is therefore difficult to

reach a comfortable passenger compartment temperature quickly.

Note:

Requests to operate the fan assembly can be made by the injection computer but these are sent on the CAN.

These requests depend on the air conditioning but also on the coolant temperature and vehicle speed.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - System operation

13B

13B-15

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

To limit the time taken to warm up the system, air heating resistors, called passenger compartment heating resistors

are fitted into the passenger compartment heating circuit. The UCH decides whether or not the passenger

compartment heating resistors are required, the Protection and Switching Unit physically controls the passenger

compartment heating resistors and the injection computer determines whether to limit the power supplied to the

passenger compartment heating resistors depending on alternator load and also whether to prohibit the operation of

the passenger compartment heating resistors according to engine speed, load and vehicle speed.

Cruise control - speed limit management:

When activated, the cruise control function maintains the vehicle at a preselected speed, regardless of the driving

conditions encountered. Using the control buttons, the driver can increase or decrease the vehicle speed.

The cruise control function can be deactivated either by using the control buttons, or by switching off the cruise

control function selection switch or when system events are detected such as depression of the brake or clutch

pedals, or when system errors are detected such as an incorrect vehicle speed or a deceleration level which is too

high.

The cruise control function can also be temporarily suspended when the driver wants to resume control of the

vehicle and exceed the selected cruising speed by pressing the accelerator pedal which then exceeds the selected

fuel flow. The cruising speed is returned to when the driver releases the accelerator pedal.

The cruise control function can be reactivated and the last cruising speed can be reselected after deactivating the

function for whatever reason until the ignition is switched off (i.e. for as long as power supply to the computer is not

switched off). The vehicle will then attempt to reach the cruising speed using a controlled vehicle acceleration rate.

When switched on using the selection switch, the vehicle speed limiter function limits the vehicle speed to a preset

value. The driver drives the vehicle in the normal way using the accelerator pedal until the preset speed is reached.

If an attempt is made to exceed this speed, the system will ignore the pedal demand and will control the vehicle

speed as it does with the cruise control function, provided that the driver continues to press the accelerator pedal.

Like for the cruise control function, the cruising speed can be altered using the control buttons by means of a quick

or a sustained press.

For safety reasons, the cruising speed can be exceeded by depressing the accelerator pedal beyond the pedal

position limiting value. Vehicle speed is then controlled using the accelerator pedal until the vehicle speed is

decreased to below the cruising speed, when the limiter function is activated again.

The driver uses the following controls to operate the speed limiter - cruise control function:

– Accelerator pedal.

– Brake pedal.

– Clutch pedal.

– Function selection switch which selects speed limiter or cruise control operating mode.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - System operation

13B

13B-16

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

Instrument panel display:

The computer displays certain information on the instrument panel relating to engine operation. This concerns five

functions: MIL (Malfunction Indicator Lamp) for the EOBD (European On Board Diagnostic), pre/post heating,

coolant temperature and engine faults: Severity 1 (non-critical fault) and Severity 2 (stop immediately). These five

functions are represented by 3 warning lights or messages displayed by the trip computer.

Pre/postheating warning light:

This warning light is used as an operating indicator light and as a system fault indicator light:

Permanently lit during + after ignition feed: indicates preheating of the plugs.

After preheating and an automatic 3 second off period, the warning light will come on if a level 1 problem occurs

(leading to reduced operation and reduced safety levels). The driver should carry out repairs as soon as possible.

Temperature/emergency stop warning light:

This warning light is used as an operating indicator light and as a system fault indicator light. It lights up for

3 seconds when the ignition is switched on (automatic test procedure managed by the instrument panel).

Permanently on: this indicates engine overheating or a level 2 fault.

If the fault reaches a critical level, the injection cuts off automatically after a few seconds. In the event of

overheating, it is up to the driver whether to stop the vehicle or continue driving.

PROGRAMMING OF WARNING LIGHTS ON THE INSTRUMENT PANEL:

Orange SERVICE warning light (level 1):

This warning light comes on and is accompanied by the injection faulty message.

The driver should carry out repairs as soon as possible.

Red STOP warning light (level 2):

This warning light comes on and is accompanied by the injection faulty message.

The driver should carry out repairs as soon as possible.

Excess pollution orange OBD warning light:

This warning light, in the form of an engine symbol, comes on for about 3 seconds when the ignition is switched on

then goes out. It never comes on when the engine is running.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Allocation of computer tracks

13B

13B-17

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

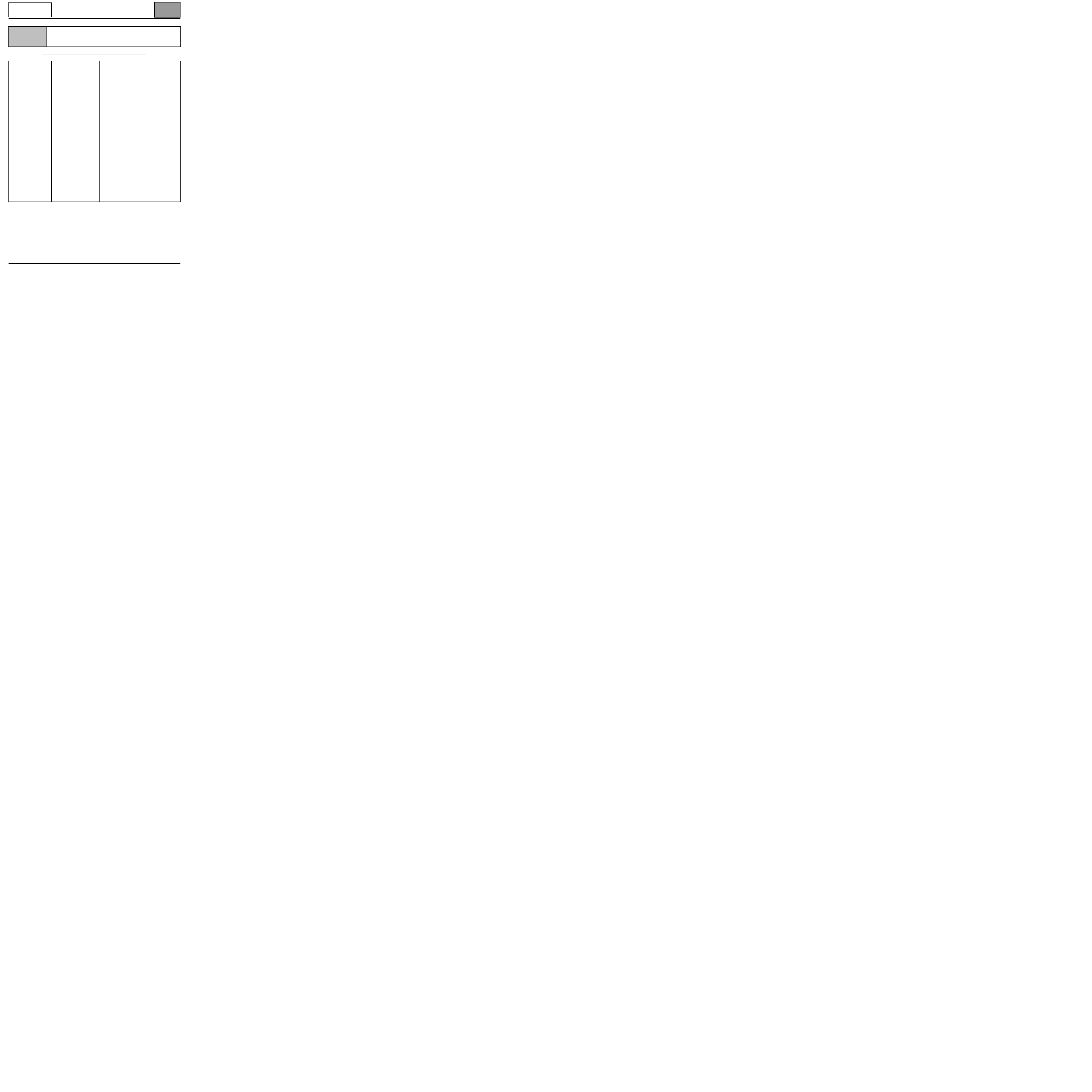

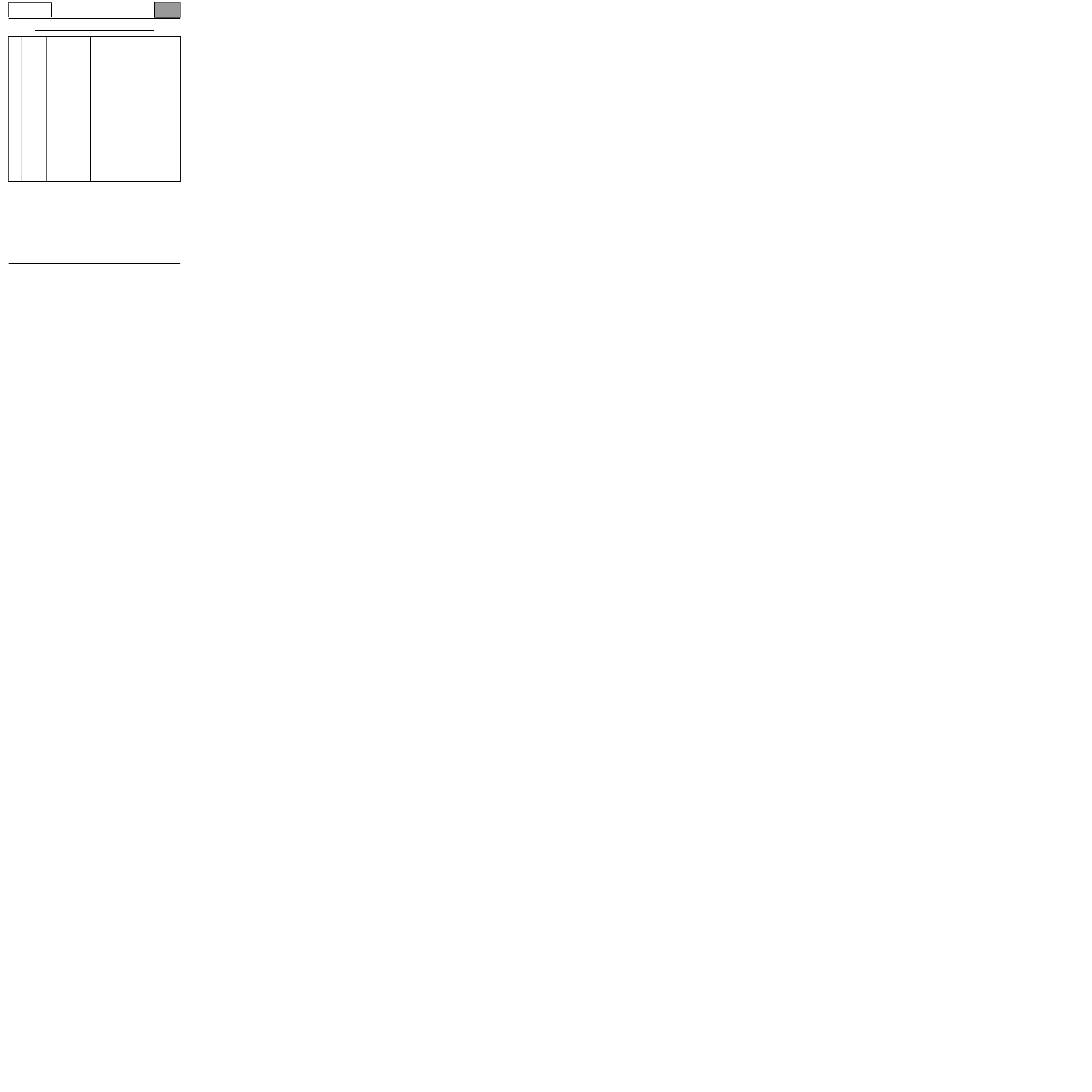

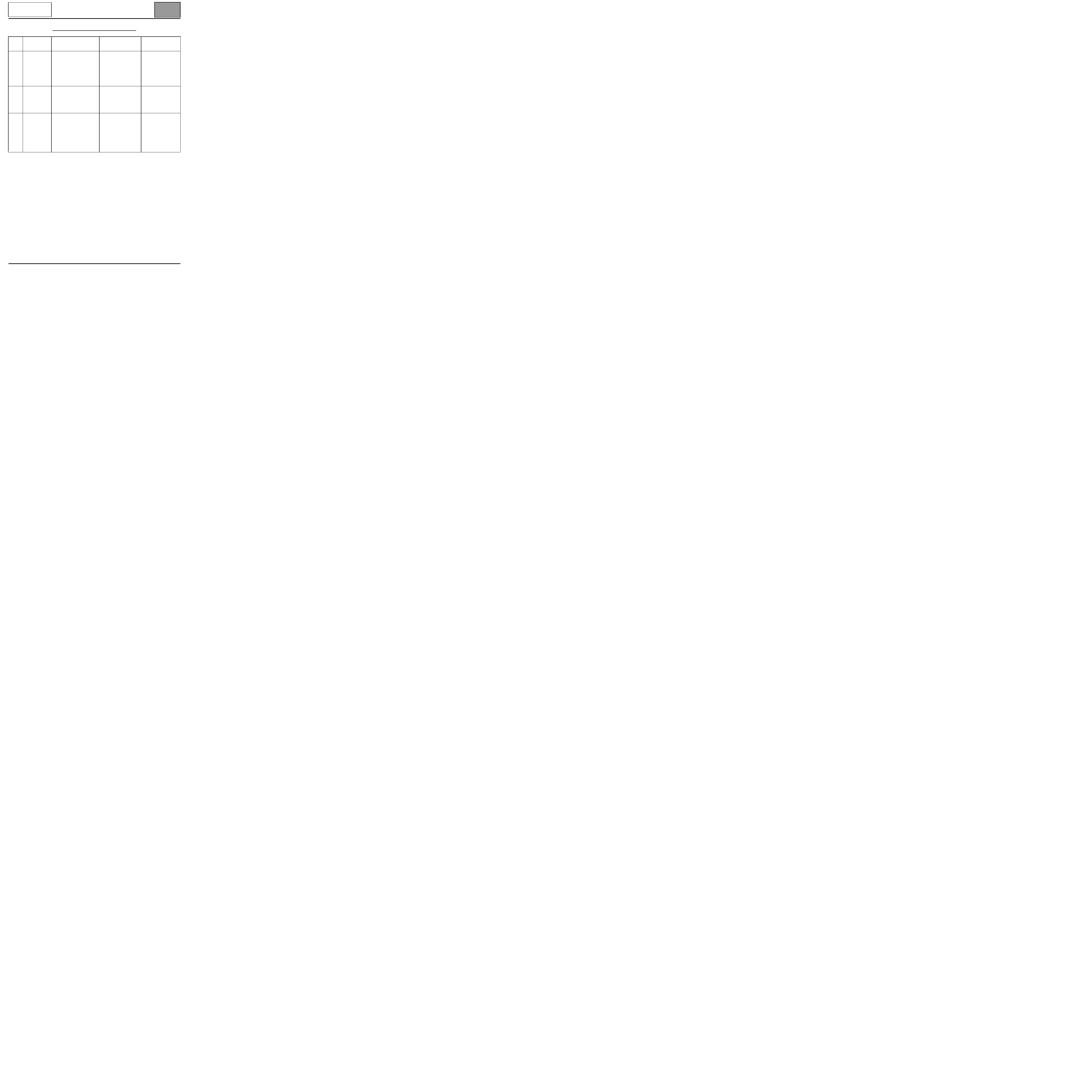

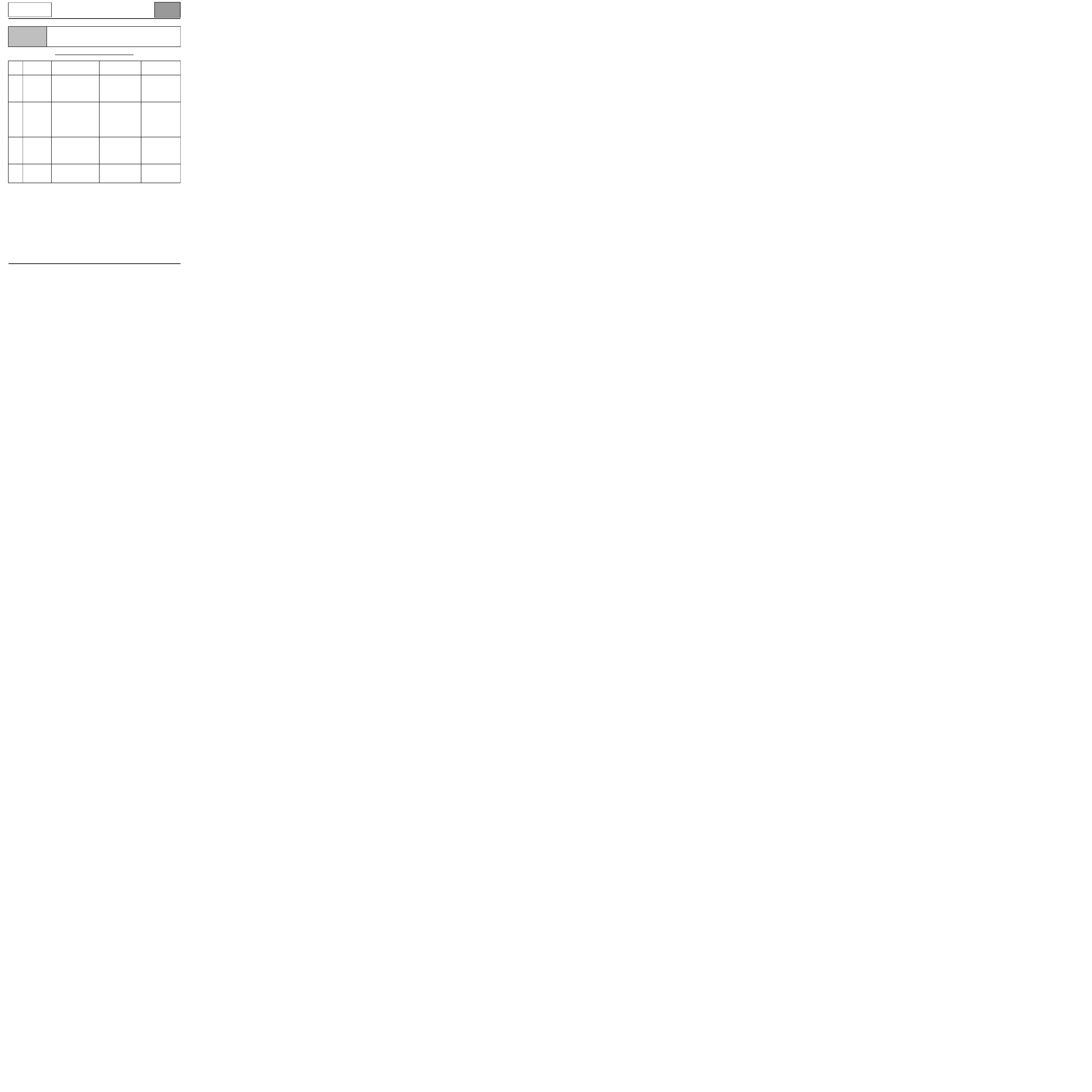

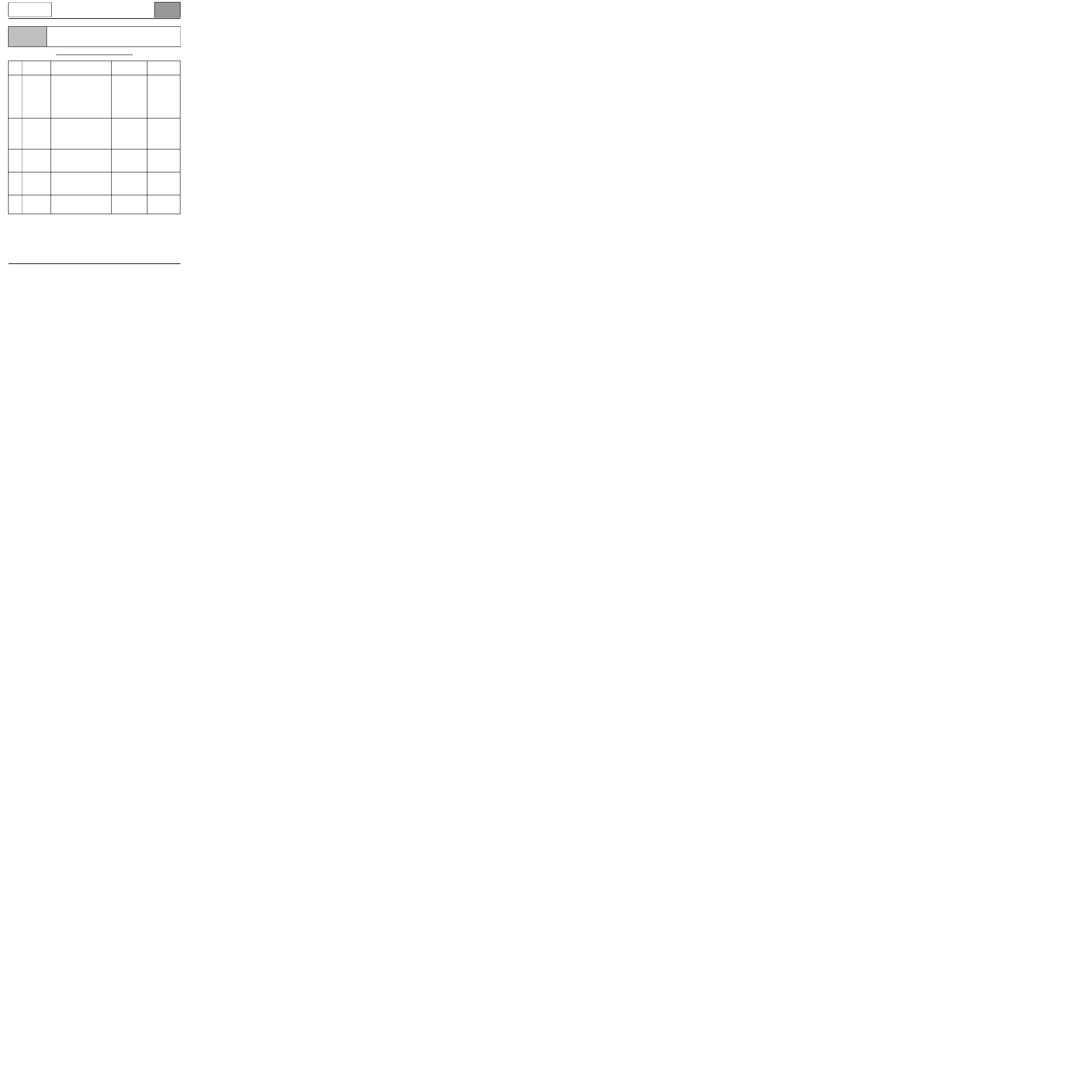

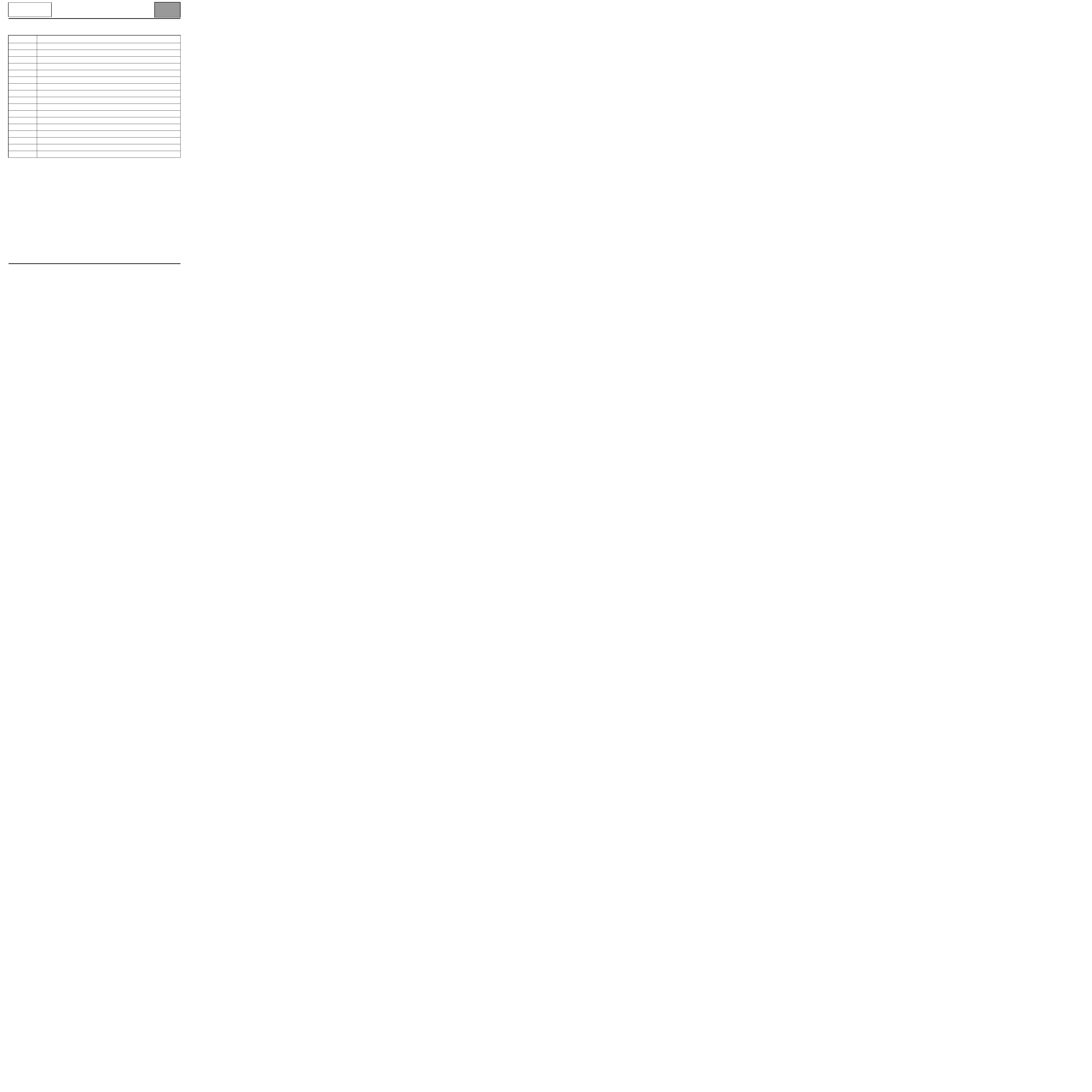

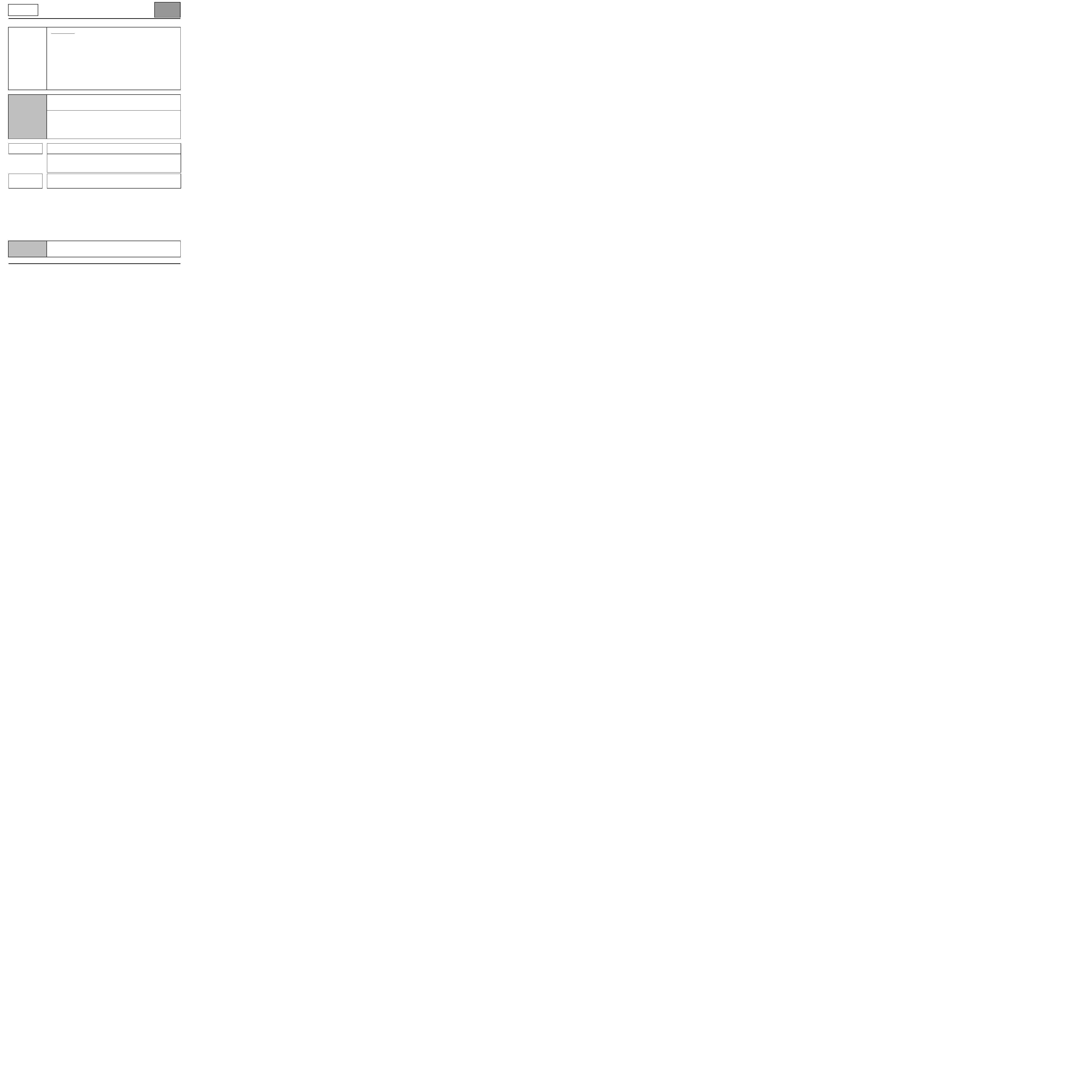

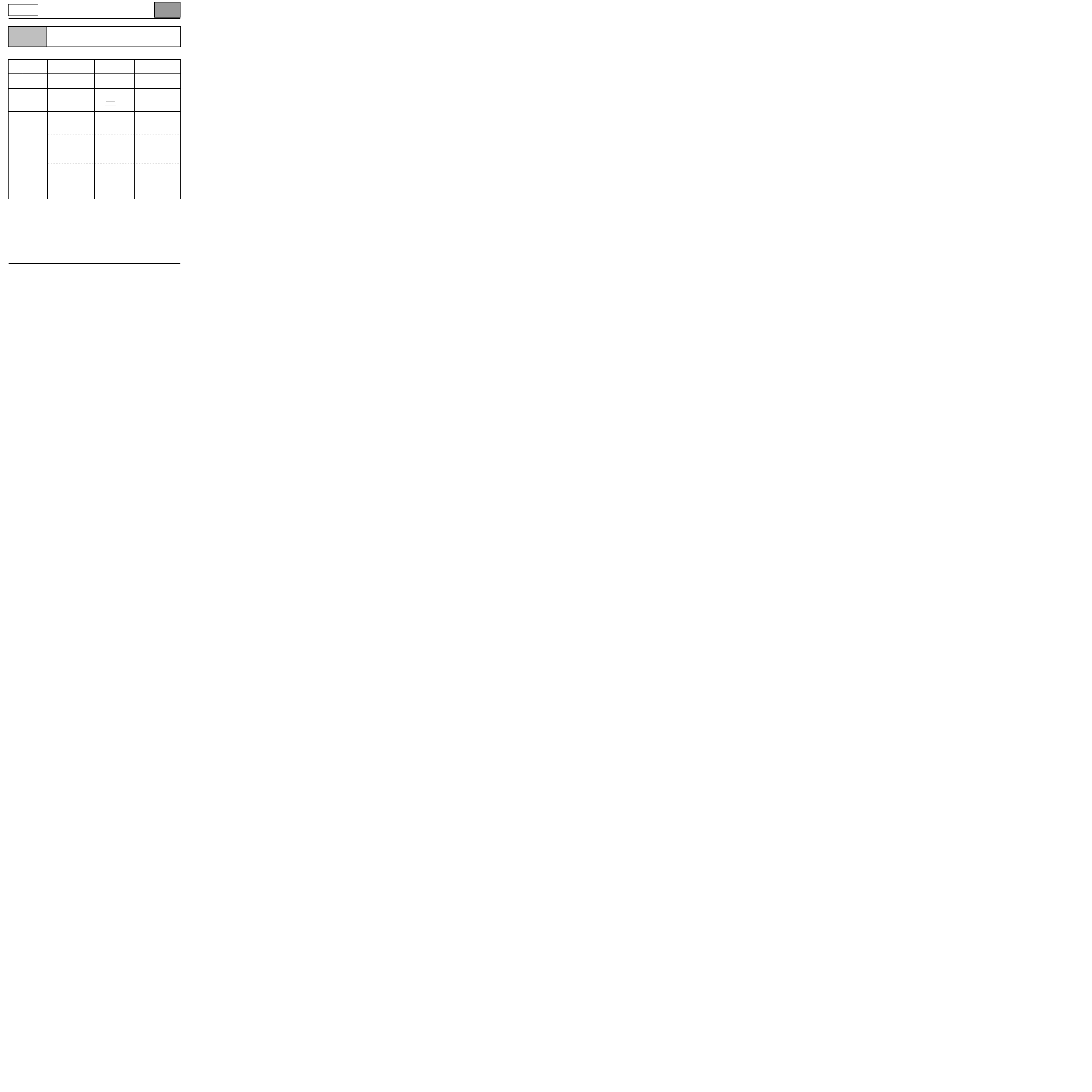

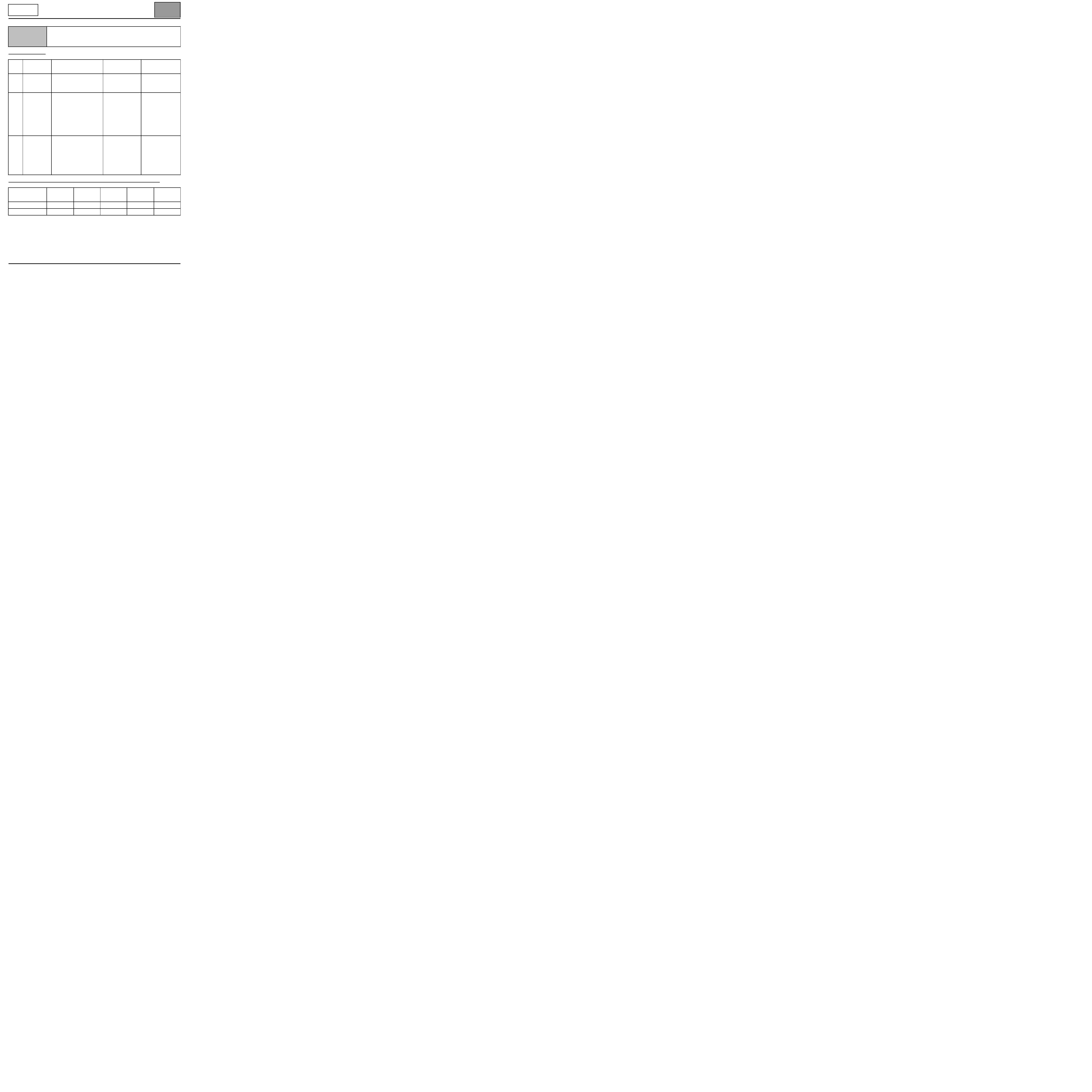

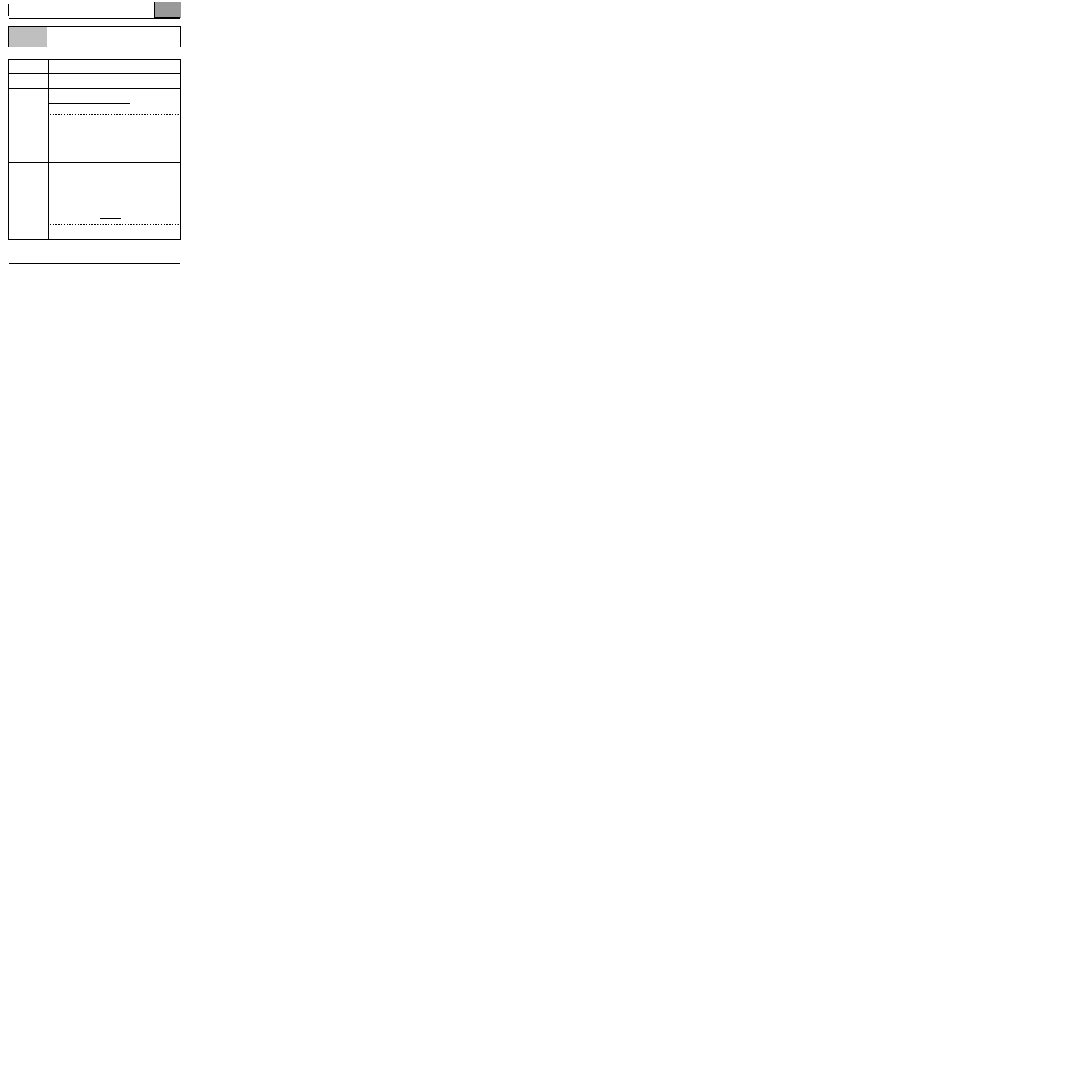

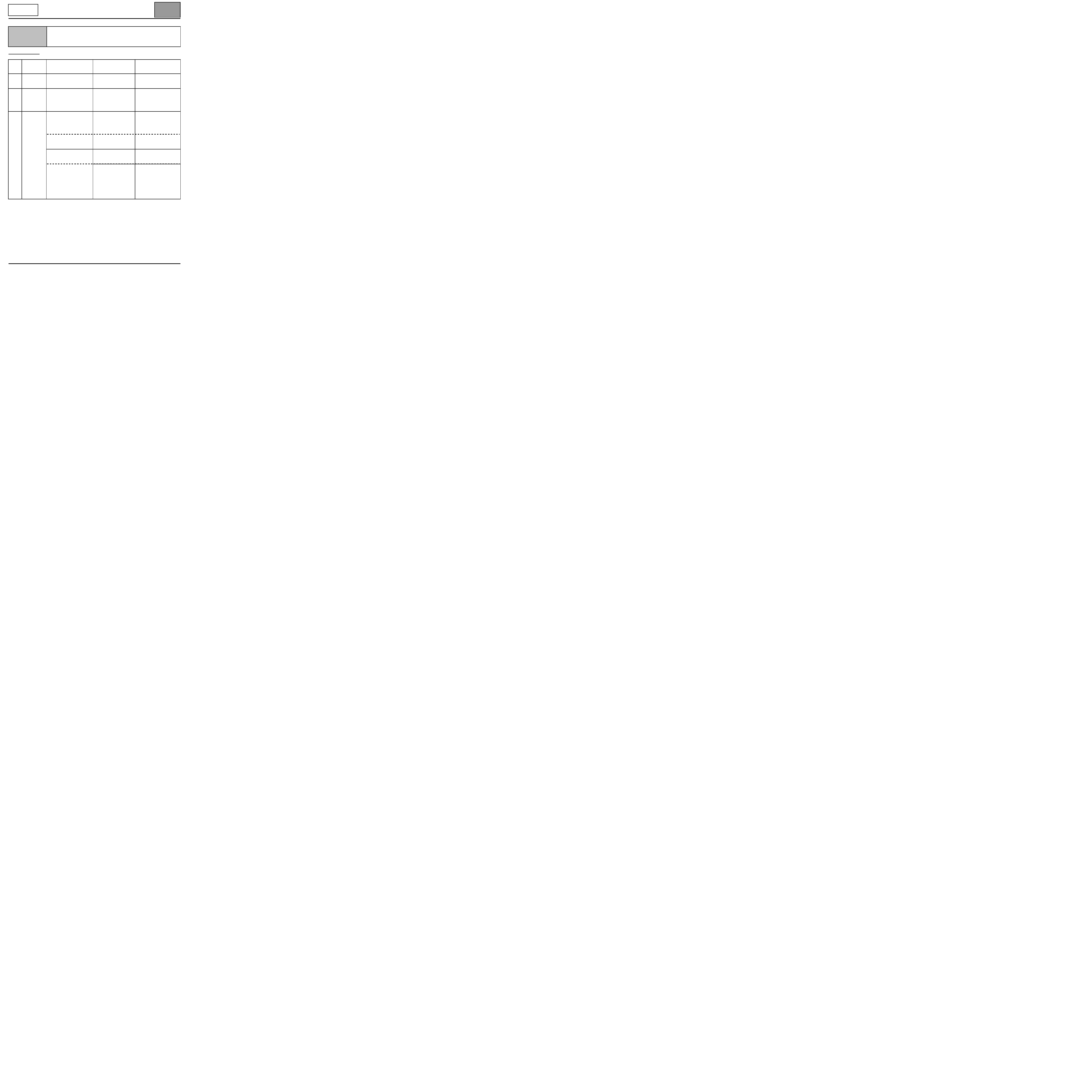

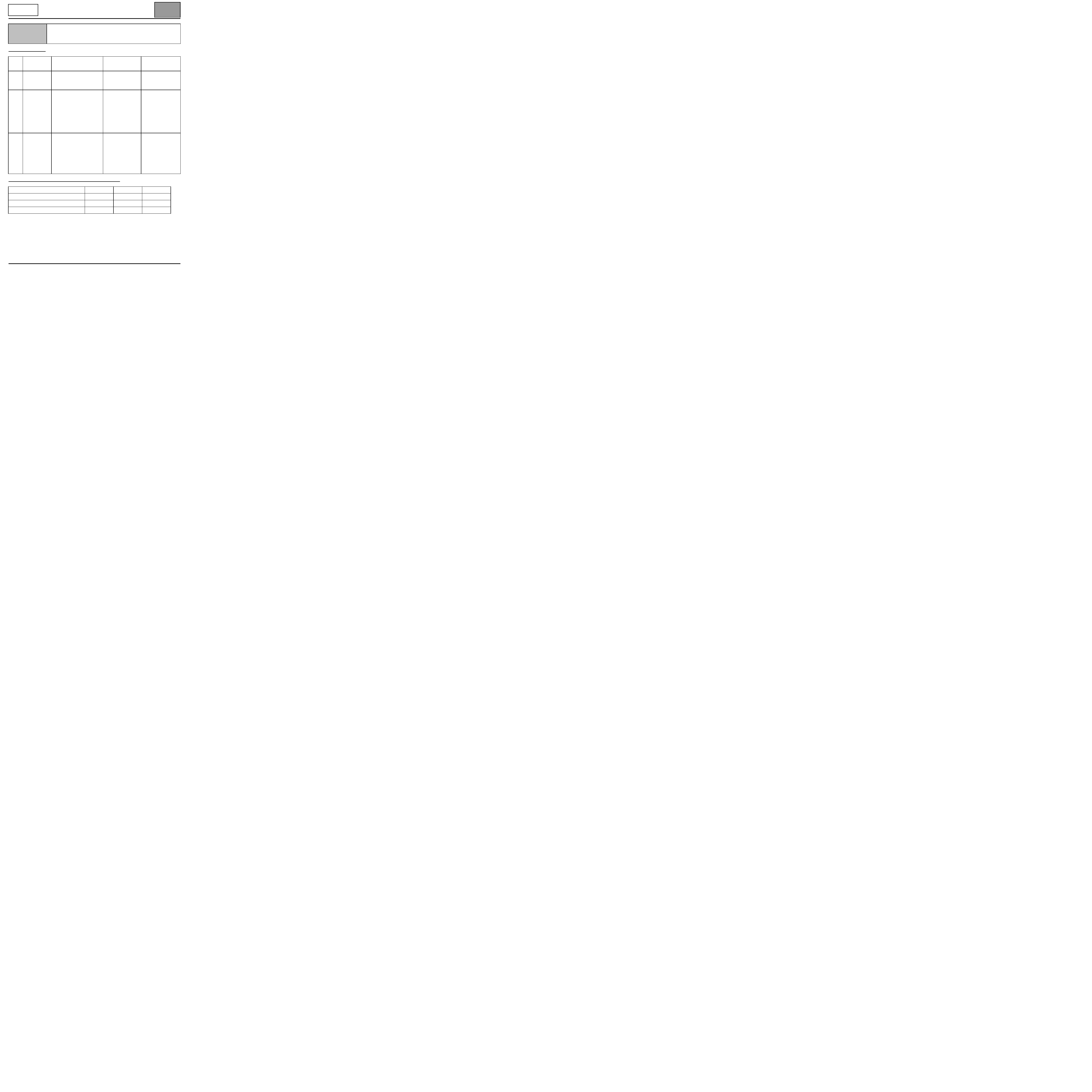

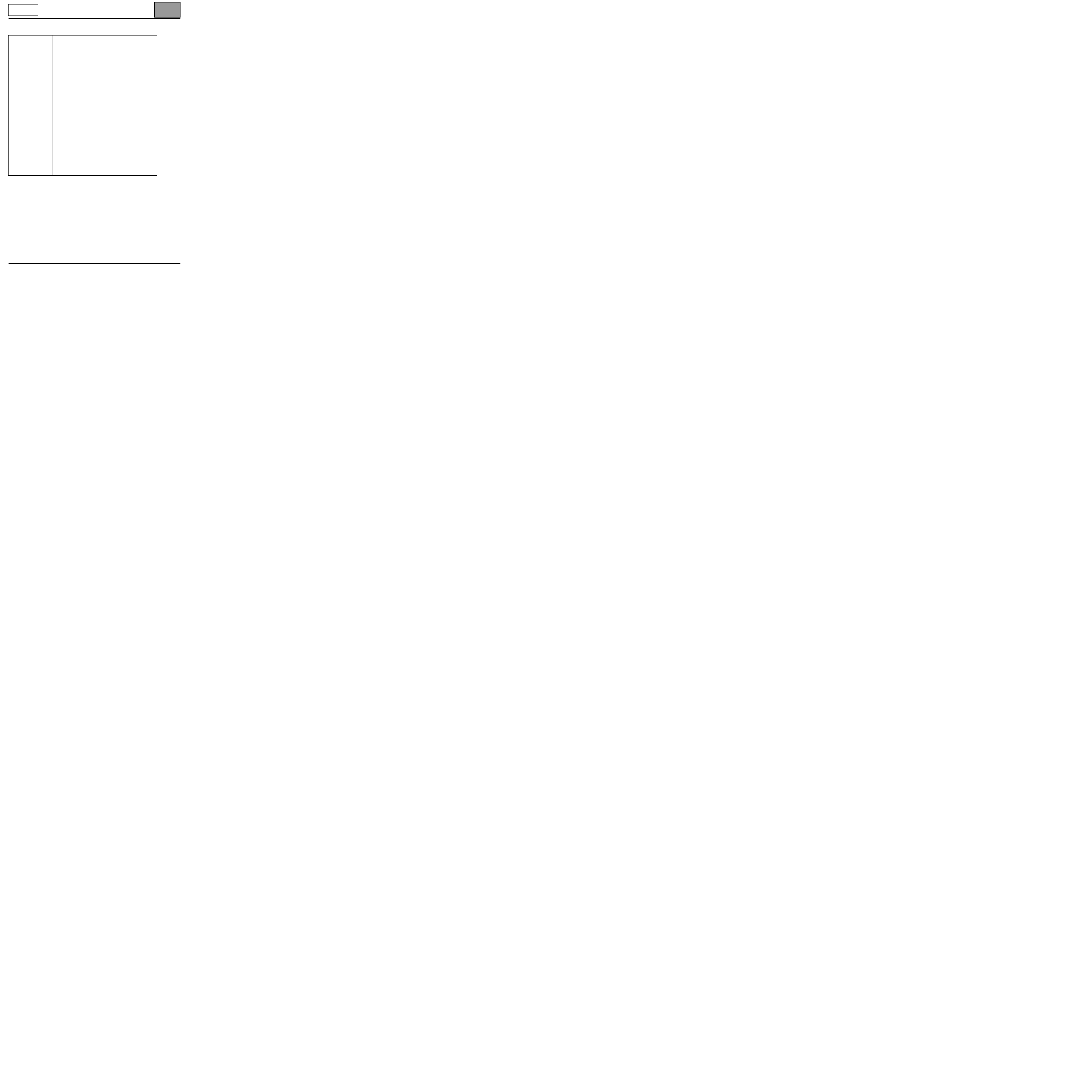

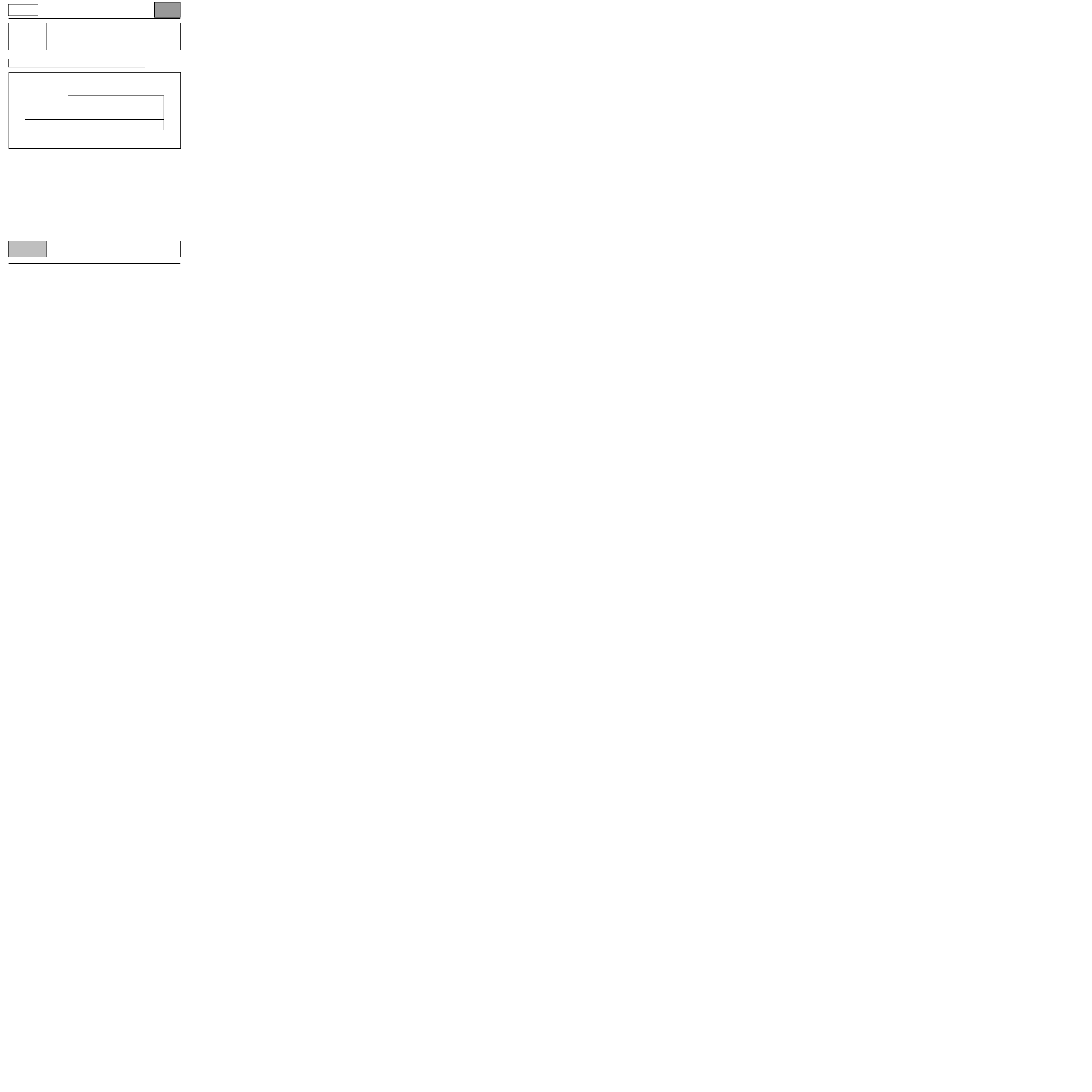

Fault finding - Allocation of computer tracks

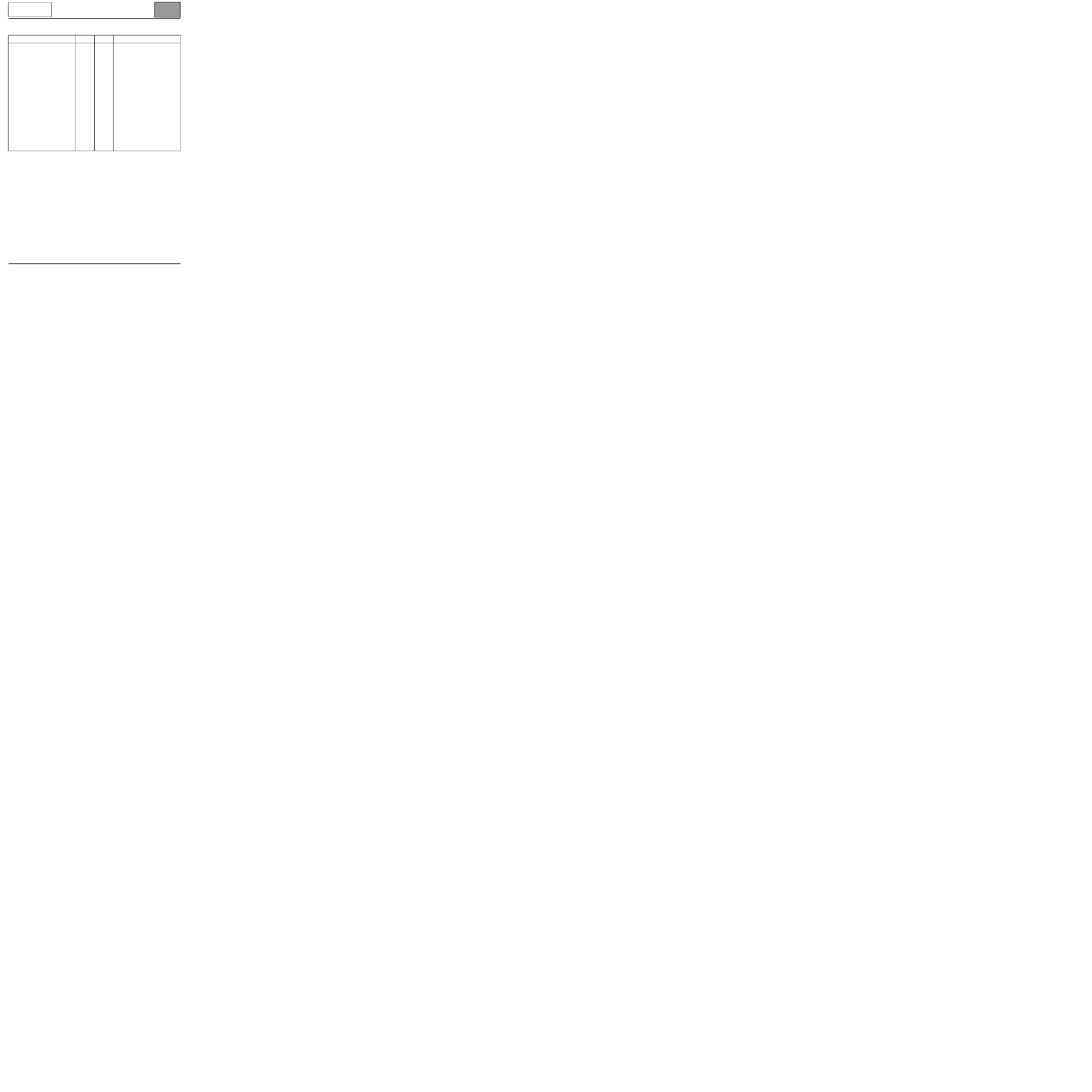

BLACK 32 TRACK CONNECTOR A

Description

Track

Track

Description

Not used

A1

E1

Not used

Cruise control on / off

A2

E2

Air conditioning inhibit request

CAN L1

A3

E3

Not used

CAN H1

A4

E4

Stop switch closing closed

Not used

B1

F1

Not used

Not used

B2

F2

Potentiometer track 2 supply

Not used

B3

F3

Potentiometer track 2 signal

Diagnostic line K

B4

F4

Potentiometer track 2 earth

Not used

C1

G1

Not used

Not used

C2

G2

Potentiometer track 1 supply

Speed limiter on/off

C3

G3

Not used

Clutch switch signal

C4

G4

Not used

+ After ignition supply

D1

H1

Not used

Cruise control stalk signal

D2

H2

Potentiometer track 1 signal

Cruise control stalk earth

D3

H3

Potentiometer track 1 earth

Not used

D4

H4

Not used

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Allocation of computer tracks

13B

13B-18

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

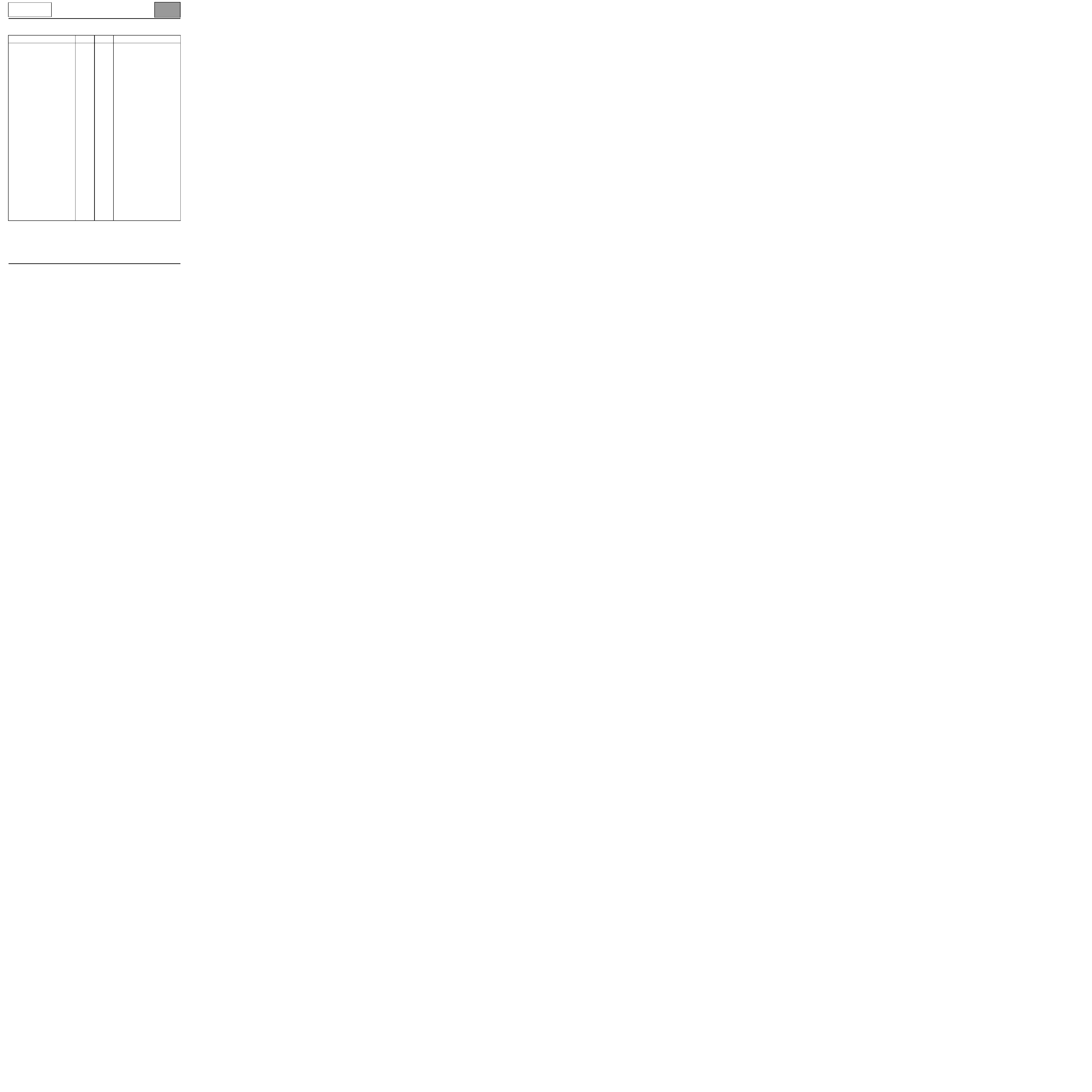

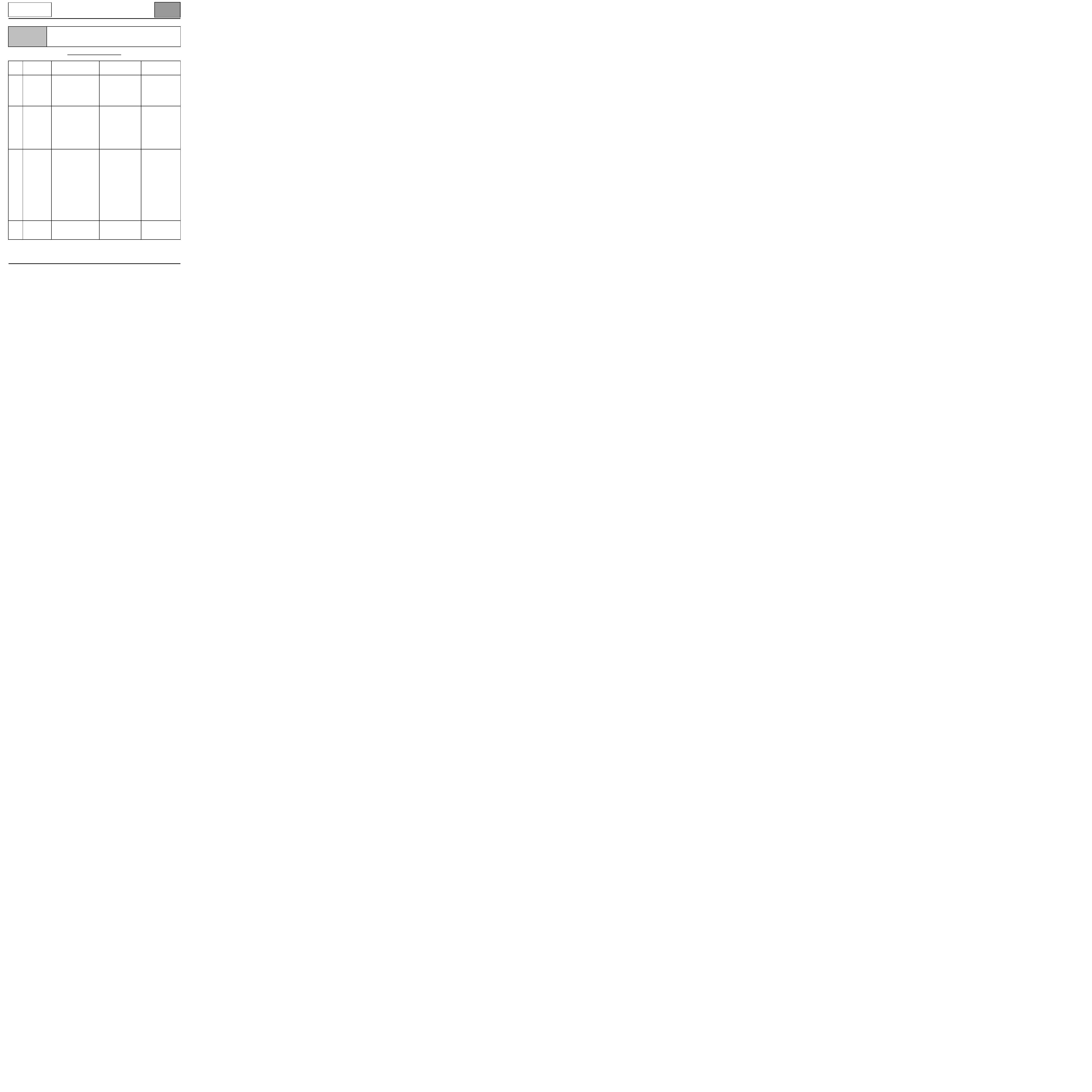

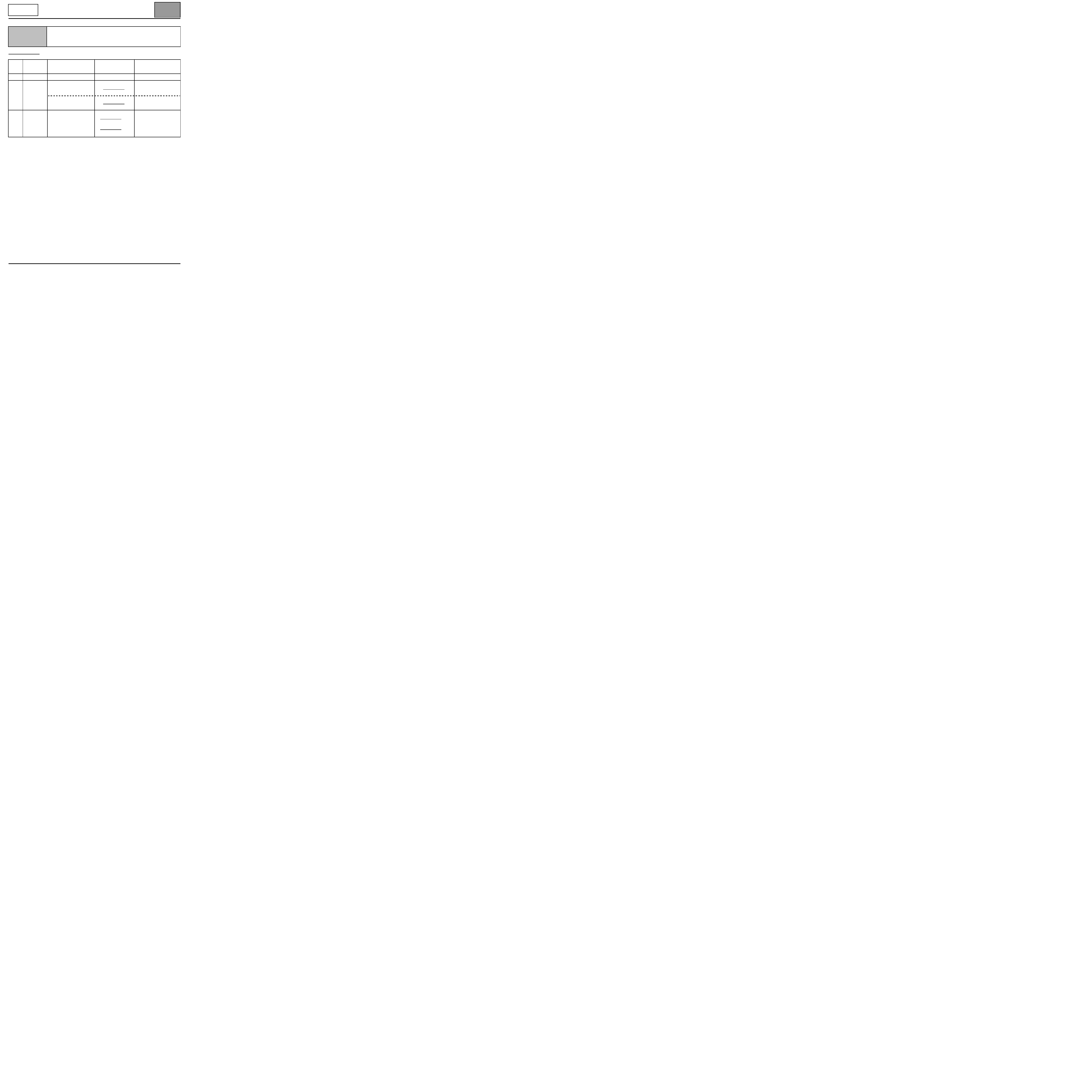

BROWN 48 TRACK CONNECTOR B

Description

Track

Track

Description

Not used

A1

G1

Accelerometer sensor earth (pinking)

Not used

A2

G2

Fuel temperature signal

Not used

A3

G3

Fuel temperature sensor earth

Cylinder 1 injector + control

A4

G4

Cylinder 4 injector control (+)

Exhaust gas recirculation feedback

potentiometer supply

B1

H1

Not used

Exhaust gas recirculation feedback

potentiometer signal

B2

H2

Coolant temperature signal

Exhaust gas recirculation feedback

potentiometer earth

B3

H3

Coolant temperature sensor earth

Cylinder 1 injector control (-)

B4

H4

Cylinder 4 injector control (-)

Turbocharging pressure sensor supply

C1

J1

Not used

Turbocharging pressure sensor signal

C2

J2

Inlet air temperature signal

Turbocharger pressure sensor earth

C3

J3

Inlet air temperature earth

Cylinder 2 injector control (+)

C4

J4

Not used

Rail pressure sensor supply

D1

K1

Accelerometer shielding (pinking)

Rail pressure sensor signal

D2

K2

Outside air temperature signal

Rail pressure sensor earth

D3

K3

Inside air temperature earth

Cylinder 2 injector control (-)

D4

K4

Not used

Phase sensor supply (cylinder)

E1

L1

Not used

Phase sensor signal (cylinder)

E2

L2

Not used

Phase sensor earth (cylinder)

E3

L3

Exhaust gas recirculation solenoid valve

control

Cylinder 3 injector control (+)

E4

L4

Not used

Accelerometer sensor signal (pinking)

F1

M1

Not used

Engine speed sensor (TDC) signal (+)

F2

M2

Not used

Engine speed sensor (TDC) earth

F3

M3

Not used

Cylinder 3 injector control (-)

F4

M4

Flow actuator control

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Allocation of computer tracks

13B

13B-19

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

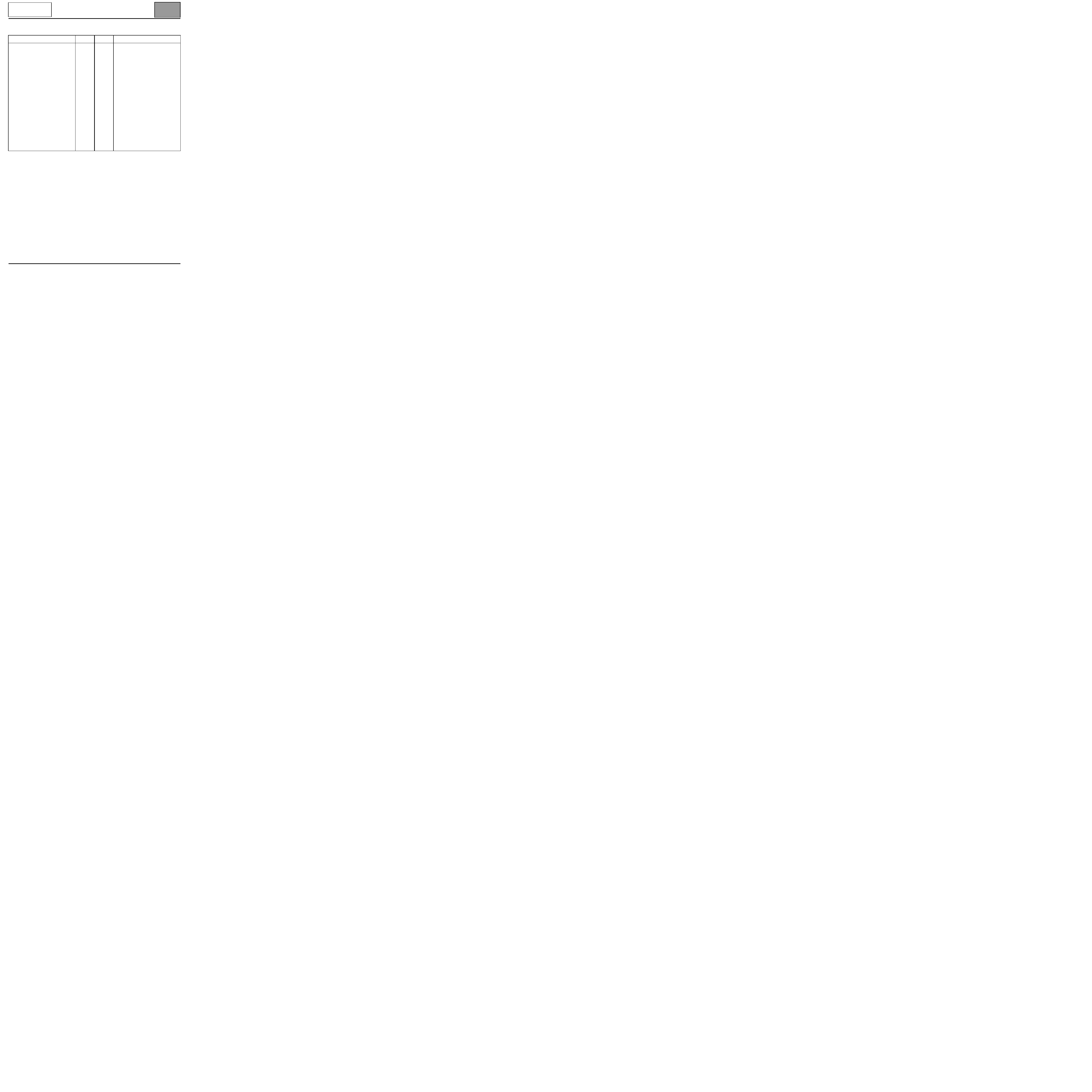

GREY 32-TRACK CONNECTOR C

Description

Track

Track

Description

Not used

A1

E1

Not used

Not used

A2

E2

Not used

Not used

A3

E3

Not used

Not used

A4

E4

Not used

Not used

B1

F1

Not used

Not used

B2

F2

Supply relay control

Not used

B3

F3

Preheating relay control

Not used

B4

F4

Not used

Not used

C1

G1

Body power 1 earth

Not used

C2

G2

+ Battery after relay 1

Not used

C3

G3

Not used

Not used

C4

G4

Not used

Not used

D1

H1

Body power earth 2

Not used

D2

H2

+ Battery after relay 2

Not used

D3

H3

Not used

Plug 1 diagnostic info

D4

H4

Not used

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Diagnostics - Replacing parts

13B

13B-20

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

Diagnostics - Replacing parts

COMPUTER REPLACEMENT, PROGRAMMING OR REPROGRAMMING OPERATIONS

The system can programmed and reprogrammed via the diagnostic socket with the RENAULT CLIP fault finding tool

(Refer to Technical Note 3585A or observe the instructions of the fault finding tool).

During the entire computer (re)programming procedure, the engine fan assemblies are triggered

automatically (check the battery condition, have a battery charger standing by).

Before programming, reprogramming or replacing the computer in After Sales save the following data in the

fault finding tool:

– the C2I parameters (individual injector correction) and the engine parameters using the SC003 "Save

computer data" command.

After programming, reprogramming or replacing the computer:

– Switch off the ignition.

– Start and stop the engine (to reinitialise the computer) and wait 30 seconds.

– Turn on the ignition and use the fault finding tool to carry out the following steps:

– Use command SC001 Write saved data to establish the C2I codes and the engine parameters.

– Use command VP010 Write the VIN.

– Deal with any faults detected by the diagnostic tool. Clear the computer memory.

– Perform a road test and then recheck with the diagnostic tool.

Note:

If the SC001 or SC003 commands have been forgotten or do not work, after replacing or reprogramming the

computer, enter each C2I injector code manually, by reading the C2I codes on each injector (see replacing

injectors).

IMPORTANT:

It is not possible to test an injection computer from the parts stores because it cannot be fitted to any other vehicle.

REPLACING THE INJECTORS:

NB.: the injectors are calibrated in the factory with C21 (individual injector correction), codes which allow the

flow of each injector to be precisely adjusted.

The correction values are written on a label affixed to each injector then entered in the computer which can then

control each injector by taking account of their manufacturing variations.

The system can be configured via the diagnostic socket using the RENAULT CLIP diagnostic tools.

The C2I parameters must be replaced after replacing an injector. To do this, reprogram C2I into the computer using

the following commands:

cylinder 1 injector: command VP001 (flywheel side cylinder)

cylinder 2 injector: command VP002

cylinder 3 injector: command VP003

cylinder injector 5: command VP004

It is also possible to enter the four C2I codes using command SC002 ENTER INJECTOR CODES.

The technician uses the appropriate command to reprogram the new C2I code for the replaced injector and clear

the old C2I code.

– Only after simultaneous replacement of at least 3 injectors, perform a reset of the injector parameters using the

RZ004 "Pressure regulation parameters" command.

WARNING:

– Turn on the fault-finding tool (electrical outlet or cigarette lighter).

– Connect a battery charger (during the entire computer (re)programming procedure, the engine fan

assemblies are triggered automatically).

– Observe the engine temperature instructions of the fault finding tool before (re)programming.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Configuration-programming

13B

13B-21

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

Fault finding - Configuration-programming

PARAMETER SETTINGS:

VP001: Cylinder 1 injector code.

VP002: Cylinder 2 injector code.

VP003: Cylinder 3 injector code.

VP004: Cylinder 4 injector code.

These commands enable you to manually write the calibration code inscribed on the injector. Use

these commands after replacing an injector, replacing or (re)programming a computer when the

SC001 command does not work.

VP010: Write VIN.

This command enables the vehicle VIN to be entered into the computer. This command must be

used each time the computer is replaced or (re)programmed.

SPECIFIC COMMANDS:

SC001: Write saved data.

Use this command after replacing or (re)programming a computer (if the information was saved

by the SC003 command.

SC002: Enter injector codes.

This command enables you to manually write the calibration code inscribed on the injectors. This

command must be used when replacing injectors.

SC003: Save computer data.

This command allows you to save the computer data, the C2I parameters (individual injector

correction) and the engine parameters. This command must be carried out before the computer

is replaced or (re)programmed.

OTHER COMMANDS:

LC005: Gearbox type.

This command enables you to determine the type of gearbox configured on the vehicle.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Summary table of faults

13B

13B-22

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

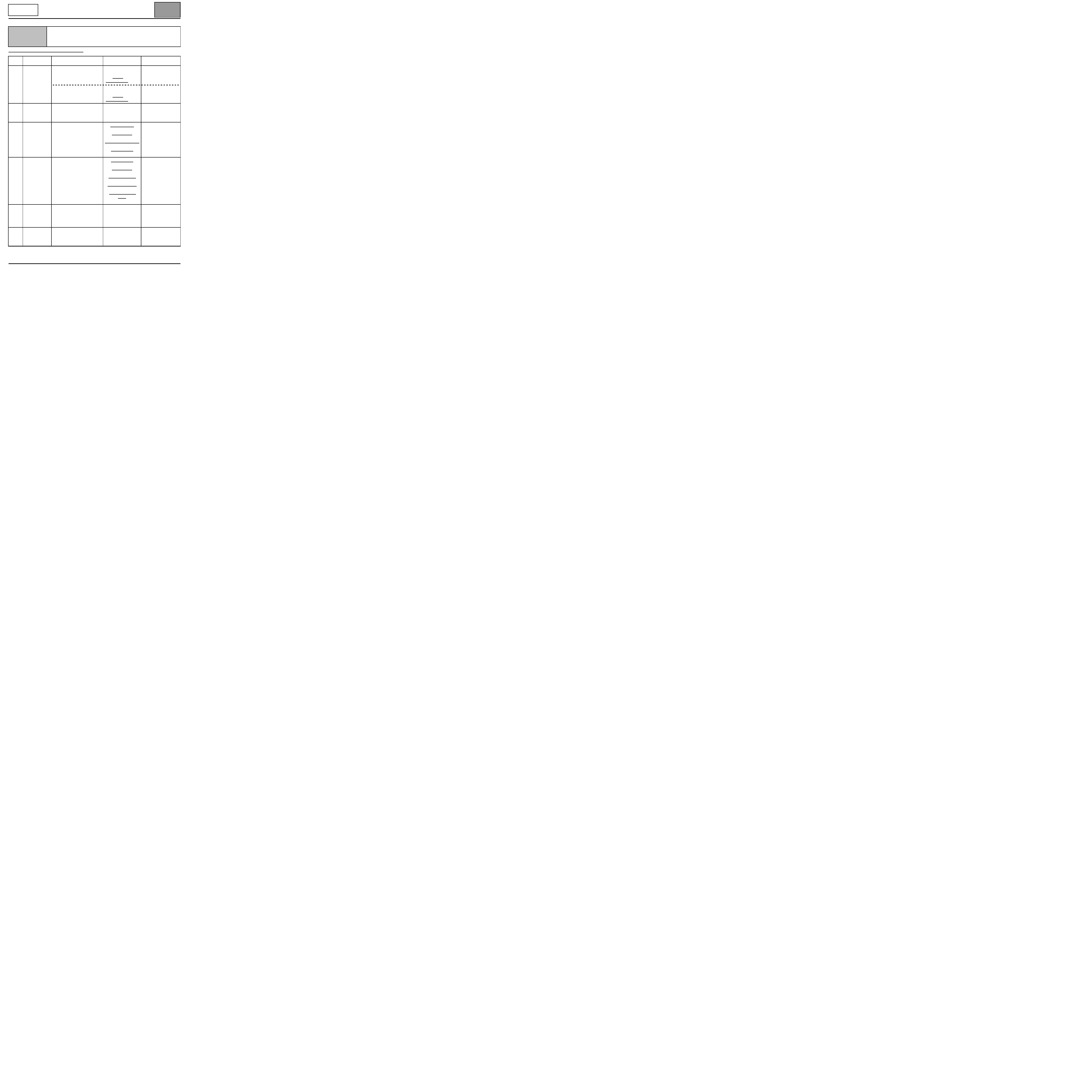

Fault finding - Summary table of faults

Tool faults

Related DTC

Diagnostic tool description

DF001

0115

Coolant temperature sensor circuit

DF003

2226

Atmospheric pressure sensor circuit

DF005

0335

Engine speed sensor circuit

DF007

0190

Rail pressure sensor circuit

DF008

0225

Pedal potentiometer track 1 circuit

DF009

2120

Pedal potentiometer track 2 circuit

DF010

0409

EGR position sensor circuit

DF014

0500

Vehicle speed information circuit

DF015

0685

Main relay control circuit

DF016

0403

EGR control circuit

DF017

0382

Preheater unit control circuit

DF024

0231

Low-pressure actuator control circuit

DF025

0380

Preheater unit diagnostic connection

DF026

0201

Injector cylinder 1 control circuit

DF027

0202

Injector cylinder 2 control circuit

DF028

0203

Injector cylinder 3 control circuit

DF029

0204

Injector cylinder 4 control circuit

DF037

0513

Immobiliser

DF038

0606

Computer

DF039

0110

Inlet air temperature sensor circuit

DF047

0560

Computer supply voltage

DF049

0530

Refrigerant sensor circuit

DF050

0571

Brake switch circuit

DF051

0575

Cruise control/speed limiter function

DF052

0200

Injector control circuit

DF053

0089

Rail pressure regulation function

DF057

2264

Water in diesel detector circuit

DF059

0301

Misfiring on cylinder 1

DF060

0302

Misfiring on cylinder 2

DF061

0303

Misfiring on cylinder 3

DF062

0304

Misfiring on cylinder 4

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Summary table of faults

13B

13B-23

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

Tool faults

Related DTC

Diagnostic tool description

DF089

0235

Inlet manifold pressure sensor circuit

DF098

0180

Fuel temperature sensor circuit

DF107

0604

Computer memory

DF112

0340

Cylinder sensor reference circuit

DF113

0608

Sensor supply voltage

DF114

0400

EGR solenoid valve circuit

DF116

C001

Multiplex network

DF121

0325

Accelerometer circuit

DF122

0609

Supply voltage pedal potentiometer track 2

DF130

0087

Flow capacity function

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-24

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

Fault finding - Interpretation of faults

DF001

PRESENT

COOLANT TEMPERATURE SENSOR CIRCUIT

CO.1 : Open circuit or short circuit to + 12 volts

CC.0 : Short circuit to earth

NOTES

Special notes:

If fault DF001 Low speed fan assembly operation (Fan assembly 1) is present.

If fan assembly 1 is faulty, then fan assembly 2 is switched on for vehicles with air

conditioning.

Check the 4-track connector of the coolant temperature sensor.

Repair if necessary.

Check the condition of the 48-track computer connector B.

Repair if necessary.

Measure the resistance between tracks 2 and 3 of the coolant temperature sensor.

Replace the coolant temperature sensor if the resistance is not 2252

Ω

Ω

Ω

Ω

±

112.16

Ω

Ω

Ω

Ω

at 25

°°°°

C.

Check the insulation, continuity and absence of interference resistance of the connections:

Sensor connector track 2

Track H3 computer connector B

Sensor connector track 3

Track H2 computer connector B

Sensor connector track 1

Instrument panel

Sensor connector track 4

Instrument panel

Repair if necessary.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-25

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF003

PRESENT

ATMOSPHERIC PRESSURE SENSOR CIRCUIT

CO.0 : Open circuit or short circuit to earth

CC.1 : Short circuit to 12 volts

NOTES

Special notes: None.

Contact your Techline.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-26

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF005

PRESENT

OR

STORED

ENGINE SPEED SENSOR CIRCUIT

1.DEF : Inconsistency

2.DEF : No signal

3.DEF : Too many additional teeth

4.DEF : Teeth missing

5.DEF : Additional teeth

6.DEF : Too many teeth missing

NOTES

Special notes: If faults 1.DEF, 2.DEF, 3.DEF, 6.DEF are present: the engine stops

and level 1 warning light comes on along with the message "injection failure".

If faults 4.DEF or 5.DEF are present engine performance is limited to 75% but the

warning light does not come on.

Conditions for applying fault finding procedure to a stored fault: the fault is

declared present when the starter motor is activated or at idle speed (600 rpm)

Check the connection and condition of the 2-track connector of the engine speed sensor. Repair if

necessary. Ensure the sensor is correctly mounted on the engine.

Check the condition of the 48-track computer connector B.

Repair if necessary.

Measure the resistance at the engine speed sensor terminals.

Replace the engine speed sensor if the resistance is not approximately 760

Ω

Ω

Ω

Ω

.

Check the insulation, continuity and absence of interference resistance of the connections:

Sensor connector track A

Track F2 computer connector B

Sensor connector track B

Track F3 computer connector B

Repair if necessary.

Check that the flywheel ring gear is not faulty (missing teeth).

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-27

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF007

STORED

RAIL PRESSURE SENSOR CIRCUIT

CC.0 : Short circuit to earth

CO.1 : Open circuit or short circuit to + 12 volts

1.DEF : Inconsistency

2.DEF : Below minimum threshold

3.DEF : Above maximum threshold

NOTES

Priorities when dealing with a number of faults: if dealing with faults DF007 and

DF113 treat voltage feed sensor DF113 as a priority.

Condition for applying the fault finding procedure to stored faults: The fault is

declared present after the engine has been started.

Special notes: in the case of DF007 engine stopped and starting impossible the

level 1 warning light comes on along with the message "injection failure".

Check the connection and condition of the 3-track connector of the rail pressure sensor.

Repair if necessary.

Check the condition of the 48-track computer connector B.

Repair if necessary.

Check the insulation, continuity and absence of interference resistance of the connections:

Sensor connector track 2

Track D3 computer connector B

Sensor connector track 1

Track D2 computer connector B

Sensor connector track 3

Track D1 computer connector B

Repair if necessary.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-28

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF008

PRESENT

PEDAL POTENTIOMETER TRACK 1 CIRCUIT

CO.0 : Open circuit or short circuit to earth

CC.1 : Short circuit to 12 volts

1.DEF : Inconsistency between pedal track 1 and track 2

2.DEF : No signal

3.DEF : Blocked component

NOTES

Priorities when dealing with a number of faults: if dealing with faults DF008 and

DF113 treat voltage feed sensor DF113 as a priority.

Special notes: if fault DF008 is present: the engine speed is maintained above

1000 rpm and the level 1 warning light comes on along with the message

"injection failure".

If dealing with faults DF008 and DF009: I the engine speed is fixed at 1300 rpm and

the level 1 warning light comes on along with the message "injection failure".

1.DEF - 3.DEF

NOTES

Special notes: None.

Disconnect computer connector A and the pedal potentiometer connector.

Check the insulation between track H2 and track F3 on computer connector A.

Repair if necessary.

Replace the pedal potentiometer if the fault persists.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-29

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF008

CONTINUED

CC.0

CC.1

2.DEF

NOTES

Special notes: None.

Check the condition of the 6-track connector of the pedal potentiometer.

Repair if necessary.

Check the condition of the 32-track computer connector A.

Repair if necessary.

Measure the resistance at the pedal potentiometer terminals:

Track 5 (earth)

Track 3 (+ 5 volts)

Replace the potentiometer pedal if the resistance is not 1.7 k

Ω

Ω

Ω

Ω

±±±±

0.9 k

Ω

Ω

Ω

Ω

.

Check the insulation, continuity and absence of interference resistance of the connections:

Sensor connector track 3

Track G2 computer connector A

Sensor connector track 4

Track H2 computer connector A

Sensor connector track 5

Track H3 computer connector A

Repair if necessary.

Disconnect computer connector A and the pedal potentiometer connector.

Check the insulation between track H2 and track F3 on computer connector A.

Repair if necessary.

Replace the pedal potentiometer if the fault persists.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-30

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF009

PRESENT

PEDAL POTENTIOMETER CIRCUIT TRACK 2

CO.0 : Open circuit or short circuit to earth

CC.1 : short circuit to 12 volts

NOTES

Priorities when dealing with a number of faults: if dealing with faults DF009 and

DF113 treat voltage feed sensor DF113 as a priority.

Special notes: if fault DF009 is present: the engine speed is maintained above

1000 rpm and the level 1 warning light comes on along with the message

"injection failure".

If faults DF009 and DF008 are present: I the engine speed is fixed at 1300 rpm and

the level 1 warning light comes on along with the message "injection failure".

CO.0

NOTES

Special notes: None.

Check the condition of the 6-track connector of the pedal potentiometer.

Repair if necessary.

Check the condition of the 32-track computer connector A.

Repair if necessary.

Measure the resistance at the pedal potentiometer terminals:

Track 6 (earth)

Track 2 (+ 5 V)

Replace the potentiometer pedal if the resistance is not 2.85 k

Ω

Ω

Ω

Ω

±±±±

2.05 k

Ω

Ω

Ω

Ω

.

Disconnect computer connector A and the pedal potentiometer connector.

Check the insulation to earth on track F3 of computer connector A.

Repair if necessary.

Check the continuity of the connection between:

Sensor connector track 1

Track F3 computer connector A

Repair if necessary.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-31

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF009

CONTINUED

CC.1

NOTES

Special notes: None.

Check the condition of the 6-track connector of the pedal potentiometer.

Repair if necessary.

Check the condition of the 32-track computer connector A.

Repair if necessary.

Measure the resistance at the pedal potentiometer terminals:

Track 6 (earth)

Track 2 (+ 5 V)

Replace the potentiometer pedal if the resistance is not 1.7 k

Ω

Ω

Ω

Ω

±±±±

0.7 k

Ω

Ω

Ω

Ω

.

Check the insulation, continuity and absence of interference resistance of the connection:

Sensor connector track 2

Track F2 computer connector A

Repair if necessary.

Disconnect computer connector A and the pedal potentiometer connector.

Check the insulation in relation to 12 volts of tracks F2 and F3 on computer connector A

Repair if necessary.

Check the continuity of the connections:

Sensor connector track 2

Track F2 computer connector A

Sensor connector track 6

Track F4 computer connector A

Disconnect computer connector A and the pedal potentiometer connector.

Check the insulation between track F2 and track F3 on computer connector A.

Repair if necessary.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-32

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF010

STORED

EGR POSITION SENSOR CIRCUIT

CO.0 : Open circuit or short circuit to earth

CC.1 : Short circuit to 12 volts

1.DEF : Above maximum threshold

2.DEF : Below minimum threshold

NOTES

Priorities when dealing with a number of faults: if dealing with faults DF010 and

DF113 treat voltage feed sensor DF113 as a priority.

Condition for applying the fault finding procedure to stored faults: the fault is

declared present after starting the engine.

Check the condition and the connection of the 6-track connector of the exhaust gas recirculation solenoid

valve.

Repair if necessary.

Check the condition of the 48-track computer connector B.

Repair if necessary.

Measure the resistance at the the exhaust gas recirculation solenoid valve terminals.

Replace the solenoid valve if the resistance is not 4 k

Ω

Ω

Ω

Ω

±±±±

1.6 k

Ω

Ω

Ω

Ω

at 20

°°°°

C between tracks 2 and 4 and

approximately 1 k

Ω

Ω

Ω

Ω

±±±±

0.5 k

Ω

Ω

Ω

Ω

at 20

°°°°

C between tracks 4 and 6.

Check the insulation, continuity and absence of interference resistance of the connections:

Sensor connector track 2

Track B1 computer connector B

Sensor connector track 6

Track B2 computer connector B

Sensor connector track 4

Track B3 computer connector B

Repair if necessary.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-33

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF014

PRESENT

VEHICLE SPEED SIGNAL CIRCUIT

NOTES

Special notes: None.

For this type of vehicle, the ABS computer or an additional unit (if the vehicle does not have ABS) transmits

the vehicle speed on the CAN.

Test the multiplex network to be able to work on the CAN (fault on the CAN H and CAN L lines between the

injection and the ABS). Also check there are no faults in the ABS part or in the system which supplies the

vehicle speed.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-34

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF015

PRESENT

MAIN RELAY CONTROL CIRCUIT

1.DEF : Permanent low signal

2.DEF : Permanent high signal

NOTES

Special notes: The main relay is incorporated in the UPC.

Test the main relay supply fuse in the engine compartment: (30 A fuse) on the UPC.

Replace the fuse if necessary.

Check the condition and connection of the PEM D 12-track brown and PPM1 4-track black connectors on

the UPC.

Repair if necessary.

Check the condition of the 32-track computer connector C.

Repair if necessary.

Check the insulation, continuity and absence of interference resistance of the connections:

Computer connector C track F1

Track 2 12 track brown PEM D UPC connector

Computer connector C track G1

Vehicle earth

Computer connector C track H2

Track 1 4 track black PPM1 UPC connector

Computer connector C track G2

Track 1 4 track black PPM1 UPC connector

Repair if necessary.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-35

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF016

STORED

EGR VALVE CONTROL CIRCUIT

CO.0 : Open circuit or short circuit to earth

CC.1 : Short circuit to +12 volts

NOTES

Condition for applying the fault finding procedure to stored faults: The fault is

declared present when the engine is running at idle speed

Special notes: If fault DF016 is present, the engine speed will be unsteady and may

even stall.

Difficult to start engine or even impossible when cold. Level 1 warning light comes

on and is accompanied by the "injection faulty" message.

Check the condition and the connection of the 6-track connector of the exhaust gas recirculation solenoid

valve.

Repair if necessary.

Check the condition of the 48-track computer connector B.

Repair if necessary.

Measure the resistance at the the exhaust gas recirculation solenoid valve terminal.

Replace the solenoid valve if the resistance is not 4 k

Ω

Ω

Ω

Ω

±±±±

1.6 k

Ω

Ω

Ω

Ω

at 20

°°°°

C between tracks 2 and 4 and

approximately 1 k

Ω

Ω

Ω

Ω

±±±±

0.5 k

Ω

Ω

Ω

Ω

at 20

°°°°

C between tracks 4 and 6.

Ensure the presence of 12 Volts after ignition on the connector side on track 1 of the EGR valve connector.

Check the insulation, continuity and absence of interference resistance of the connections:

+ after ignition PPM1 G black UPC connector track 3

Track 1 EGR solenoid valve

Computer connector B track L3

Track 5 EGR solenoid valve

Repair if necessary.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-36

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF017

PRESENT

PREHEATER UNIT CONTROL CIRCUIT

CO.0 : Open circuit or short circuit to earth

CC.1 : Short circuit to 12 volts

NOTES

Special notes: If DF017 is present starting is difficult (or impossible when cold).

If CC.1: plugs permanently controlled with risk of being damaged and risk of damaging

the engine.

Check the condition and connection of the preheating unit connector.

Repair if necessary.

Check the condition of the 32-track computer connector C.

Repair if necessary.

Check the insulation, continuity and absence of interference resistance of the connections:

12 Volts after ignition

Track 3 preheater unit

Computer connector C track D3

Track 9 preheater unit

Computer connector C track F2

Track 8 preheater unit

Repair if necessary.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-37

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF024

PRESENT

LOW-PRESSURE ACTUATOR CONTROL CIRCUIT

CO.0 : Open circuit or short circuit to earth

CC.1 : Short circuit to 12 volts

NOTES

Special notes: If fault DF024 is present with CO.0 or CC.1 level 1 warning light comes

on along with the message "injection failure".

The fuel flow actuator is fully opened and the engine is stopped to prevent it from

racing.

Check the connection and condition of the 'fuel flow actuator connector.

Repair if necessary.

Check the condition of the 48-track computer connector B.

Repair if necessary.

Measure the resistance across tracks 1 and 2 of the fuel flow actuator.

Replace the flow actuator if the resistance is not 5.3

Ω

Ω

Ω

Ω

±±±±

0.5

Ω

Ω

Ω

Ω

at 20

°°°°

C.

Check the insulation, continuity and absence of unwanted resistance on the following connection:

Computer connector B track M4

Track 1 fuel flow actuator

Repair if necessary.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-38

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF025

PRESENT

PREHEATER UNIT DIAGNOSTIC CONNECTION

CO : open circuit

NOTES

Special notes: None.

Check the condition and connection of the preheating unit connector.

Repair if necessary.

Check the condition and connection of the heater plug connectors.

Repair if necessary.

Check the condition of the 32-track computer connector C.

Repair or replace the passenger compartment fan if necessary.

Measure the resistance of each heater plug. The resistance must be less than 1

Ω

Ω

Ω

Ω

.

Replace the faulty plugs.

Check the insulation, continuity and absence of unwanted resistance on the following connection:

Computer connector C track F2

Track 8 preheating unit

Repair if necessary.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-39

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF026

PRESENT

OR

STORED

INJECTOR CYLINDER 1 CONTROL CIRCUIT

CO

: Open circuit

CC

: Short circuit

1.DEF : At minimum stop

NOTES

Condition for applying the fault finding procedure to stored faults: The fault is

declared present when the engine is running at idle speed

Level 1 warning light comes on along with the message "injection failure".

CO

NOTES

Special notes: None.

Switch off the ignition, and wait 15 seconds.

Check the connection and condition of the injector connector. Repair if necessary.

Check the continuity between the two injector terminals using a multimeter.

Replace the injector if necessary.

Check the condition of the 48-track computer connector B. Repair if necessary.

Check the insulation, continuity and absence of unwanted resistance on the following connections:

Computer connector B track A4

Track 1 injector 1

Computer connector B track B4

Track 2 injector 1

Repair if necessary.

CC - 1.DEF

NOTES

Condition for applying the fault finding procedure to the

stored fault: The fault is declared present when driving

Levels 1 and 2 warning lights light up.

Switch off the ignition, and wait 15 seconds.

Check the connection and condition of the injector connector. Repair if necessary.

Switch off the ignition, disconnect the injector and switch the ignition back on.

Replace the injector if the fault becomes stored or present in open circuit.

Check the condition of the 48-track computer connector B. Repair if necessary.

Disconnect computer connector B and the connector from injector 1.

Check the insulation between track A4 and track B4 on computer connector B.

Repair if necessary.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-40

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF027

PRESENT

OR

STORED

INJECTOR CYLINDER 2 CONTROL CIRCUIT

CO

: Open circuit

CC

: Short circuit

1.DEF : At minimum stop

NOTES

Condition for applying the fault finding procedure to stored faults: The fault is

declared present when the engine is running at idle speed.

Level 1 warning light comes on and is accompanied by the "injection faulty"

message.

CO

NOTES

Special notes: None.

Switch off the ignition, and wait 15 seconds.

Check the connection and condition of the injector connector. Repair if necessary.

Check the continuity between the two injector terminals using a multimeter.

Replace the injector if necessary.

Check the condition of the 48-track computer connector B. Repair if necessary.

Check the insulation, continuity and absence of unwanted resistance on the following connections:

Computer connector B track G4

Track 1 injector 2

Computer connector B track H4

Track 2 injector 2

Repair if necessary.

CC - 1.DEF

NOTES

Condition for applying the fault finding procedure to the

stored fault: The fault is declared present when driving

Levels 1 and 2 warning lights light up.

Switch off the ignition, and wait 15 seconds.

Check the connection and condition of the injector connector. Repair if necessary.

Switch off the ignition, disconnect the injector and switch the ignition back on.

Replace the injector if the fault becomes stored or present in open circuit.

Check the condition of the 48-track computer connector B. Repair if necessary.

Disconnect computer connector B and the connector from injector 2.

Check the insulation between track H4 and track G4 on computer connector B.

Repair if necessary.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-41

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF028

PRESENT

OR

STORED

INJECTOR CYLINDER 3 CONTROL CIRCUIT

CO

: Open circuit

CC

: Short circuit

1.DEF : At minimum stop

NOTES

Condition for applying the fault finding procedure to stored faults: The fault is

declared present when the engine is running at idle speed.

Level 1 warning light comes on and is accompanied by the "injection faulty"

message.

CO

NOTES

Special notes: None.

Switch off the ignition, and wait 15 seconds.

Check the connection and condition of the injector connector. Repair if necessary.

Check the continuity between the two injector terminals using a multimeter.

Replace the injector if necessary.

Check the condition of the 48-track computer connector B. Repair if necessary.

Check the insulation, continuity and absence of unwanted resistance on the following connections:

Computer connector B track C4

Track 1 injector 3

Computer connector B track D4

Track 2 injector 3

Repair if necessary.

CC - 1.DEF

NOTES

Condition for applying the fault finding procedure to the

stored fault: The fault is declared present when driving

Levels 1 and 2 warning lights light up.

Switch off the ignition, and wait 15 seconds.

Check the connection and condition of the injector connector. Repair if necessary.

Switch off the ignition, disconnect the injector and switch the ignition back on.

Replace the injector if the fault becomes stored or present in open circuit.

Check the condition of the 48-track computer connector B. Repair if necessary.

Disconnect computer connector B and the connector from injector 3.

Check the insulation between track C4 and track D4 on computer connector B.

Repair if necessary.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-42

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF029

STORED

INJECTOR CYLINDER 4 CONTROL CIRCUIT

CO

: Open circuit

CC

: Short circuit

1.DEF : At minimum stop

NOTES

Condition for applying the fault finding procedure to stored faults: The fault is

declared present when the engine is running at idle speed.

Level 1 warning light comes on and is accompanied by the "injection faulty"

message.

CO

NOTES

Special notes: None.

Switch off the ignition, and wait 15 seconds.

Check the connection and condition of the injector connector. Repair if necessary.

Check the continuity between the two injector terminals using a multimeter.

Replace the injector if necessary.

Check the condition of the 48-track computer connector B. Repair if necessary.

Check the insulation, continuity and absence of unwanted resistance on the following connections:

Computer connector B track E4

Track 1 injector 4

Computer connector B track F4

Track 2 injector 4

Repair if necessary.

CC - 1.DEF

NOTES

Condition for applying the fault finding procedure to the

stored fault: The fault is declared present when driving

Levels 1 and 2 warning lights light up.

Switch off the ignition, and wait 15 seconds.

Check the connection and condition of the injector connector. Repair if necessary.

Switch off the ignition, disconnect the injector and switch the ignition back on.

Replace the injector if the fault becomes stored or present in open circuit.

Check the condition of the 48-track computer connector B. Repair if necessary.

Disconnect computer connector B and the connector from injector 4.

Check the insulation between track E4 and track F4 on computer connector B.

Repair if necessary.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-43

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF037

PRESENT

IMMOBILISER

NOTES

Special notes: None.

Carry out a fault finding procedure on the multiplex network.

Refer to the fault finding procedure for the keyless vehicle function.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-44

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF038

PRESENT

COMPUTER

1.DEF : Analogue/digital converter

2.DEF : Write EEPROM memory

3.DEF : Read EEPROM memory

4.DEF : Enter injector codes

5.DEF : Memory self-test

6.DEF : Non refreshed watchdog

7.DEF : Interference on the injector control line

8.DEF : Watchdog activation

NOTES

Special notes: None.

7.DEF

NOTES

Special notes: None.

Check the condition of the 48-track computer connector B. Repair if necessary.

Check the insulation, continuity and absence of interference resistance of the connections:

Computer connector B track A4

Track 1 injector 1

Computer connector B track B4

Track 2 injector 1

Computer connector B track G4

Track 1 injector 2

Computer connector B track H4

Track 2 injector 2

Computer connector B track C4

Track 1 injector 3

Computer connector B track D4

Track 2 injector 3

Computer connector B track E4

Track 1 injector 4

Computer connector B track F4

Track 2 injector 4

Repair if necessary.

If the fault persists, contact your techline.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-45

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF038

CONTINUED

4.DEF

NOTES

Special notes: None.

Check the condition of the 48-track computer connector B.

Repair if necessary.

Check that the individual injector correction (C2I) matches the injectors, if not write the C2I codes

(see "configurations/programming").

If the C2I does match the injectors, contact your Techline.

1.DEF

2.DEF

3.DEF

5.DEF

6.DEF

8.DEF

NOTES

Special notes: Contact your Techline.

Contact your Techline.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

13B-46

DDCR INJECTION

PROGRAM no.: BE88

VDIAG No.: 44

DF039

PRESENT

INLET AIR TEMPERATURE SENSOR CIRCUIT

CO.1 : Open circuit or short circuit to + 12 volts

CC.0 : Short circuit to earth

NOTES

Special notes: None.

Check the condition of the air temperature sensor 4-track connector.

Repair if necessary.

Check the condition of the 48-track computer connector B.

Repair if necessary.

Measure the resistance of the air temperature sensor between tracks 1 and 2.

Replace the air temperature sensor if the resistance is not 2051 k

Ω

Ω

Ω

Ω

±±±±

120 k

Ω

Ω

Ω

Ω

at 25

°°°°

C.

Check the insulation, continuity and absence of interference resistance of the connections:

Sensor connector track 1

Track C3 computer connector B

Sensor connector track 2

Track J2 computer connector B

Sensor connector track 3

Track C1 computer connector B

Sensor connector track 4

Track C2 computer connector B

Repair if necessary.

AFTER REPAIR

Deal with any faults detected by the diagnostic tool. Clear the computer memory.

Perform a road test and then recheck with the diagnostic tool.

K9K044 X 84 1.0

Edition 2