BOILING

AND

CONDENSATION

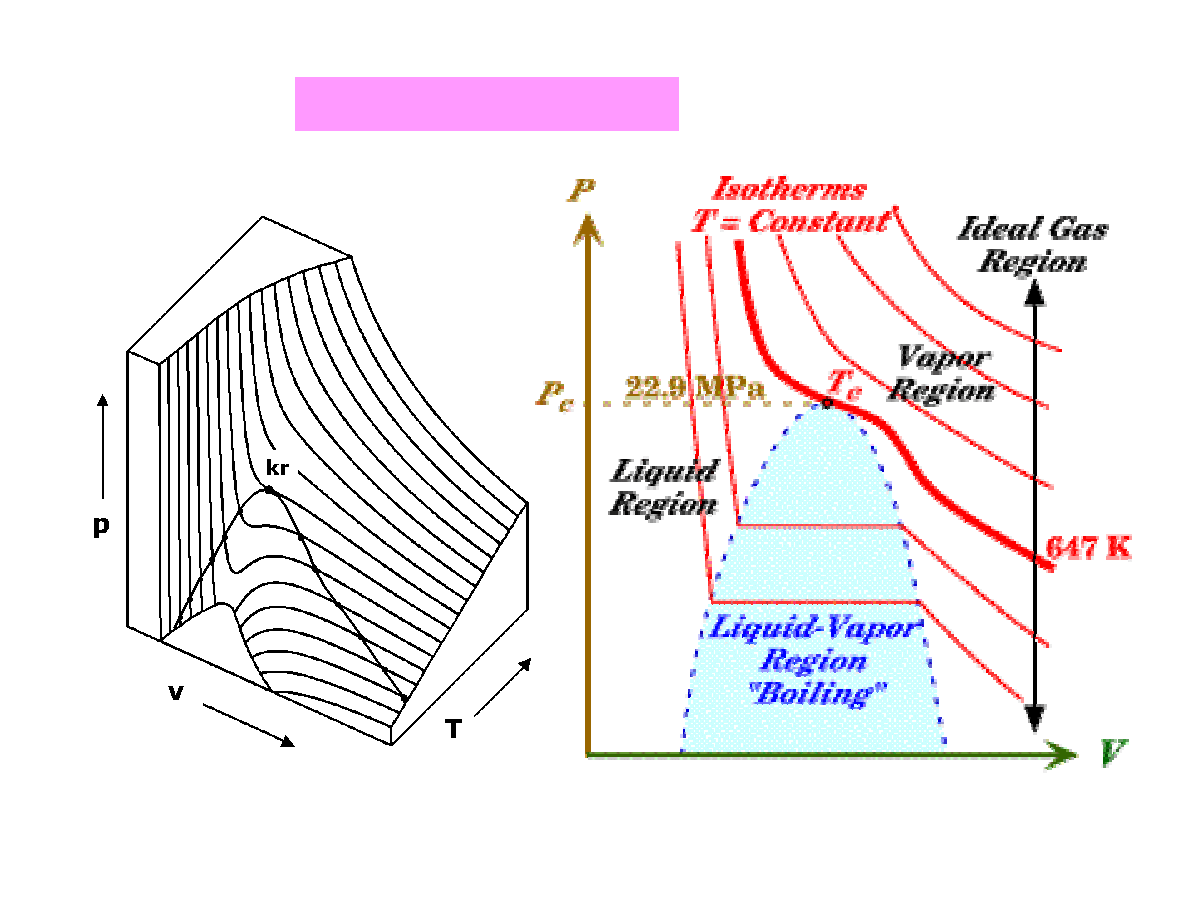

Isotherms of real gas

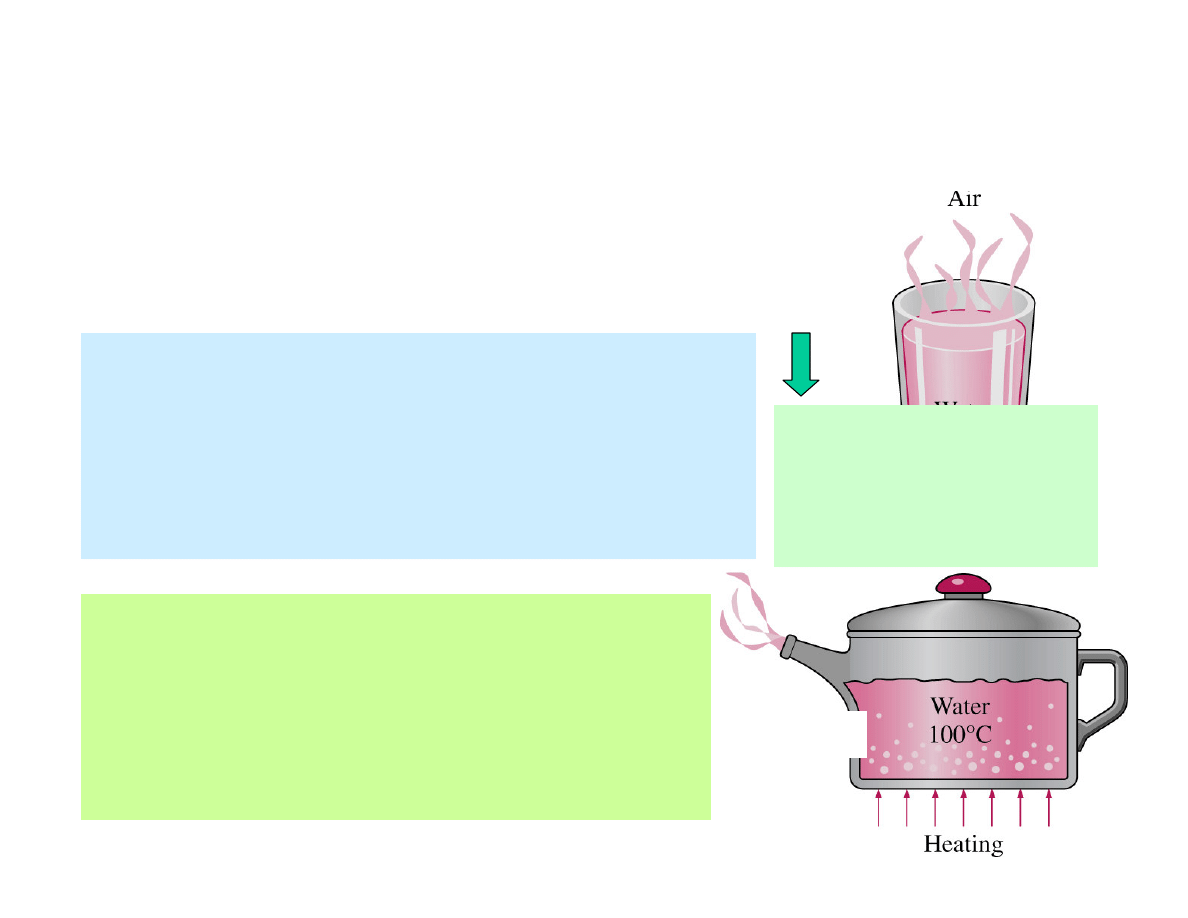

Evaporation

Boiling

Boiling

and

evaporation

- the liquid-to-vapour

phase change

processes that occur at a solid-

liquid interface when the surface is heated

above the

saturation temperature T

sat

of the

liquid →

→

→

→ convection heat transfer.

Evaporation

occurs when the vapour

pressure

is less than the saturation

pressure

of the liquid at a given

temperature, and it involves no

bubble formation or bubble motion.

Boiling

occurs when a liquid is

brought into contact with a surface

maintained at a temperature T

S

sufficiently above the saturation

temperature T

sat

of the liquid.

Refrigerators

Steam power plants

Electronic system

cooling

Water

20

0

C

Boiling →

→

→

→ convection heat transfer →

→

→

→ the boiling heat flux

from a solid surface to the fluid – Newton`s law of cooling:

excess

sat

S

boiling

T

h

T

T

h

q

∆

=

−

=

•

)

(

)

/

(

2

m

W

where ∆

∆

∆

∆T

excess

= T

S

– T

sat

is called the excess temperature,

which represents the excess of the surface above the

saturation temperature of the fluid

Two phases (liquid and vapour) involves:

- two sets of thermophysical properties (density

ρ

ρ

ρ

ρ

, dynamic

viscosity

µ

µ

µ

µ

, conductivity

Λ

Λ

Λ

Λ

, and the specific heat

C

p

)

- the latent heat of vaporisation

h

fg

- the surface tension

σ

σ

σ

σ

Parameter

h

fg

represents the energy absorbed as a unit mass of

liquid vaporizes at a specified temperature or pressure.

Surface tension

→

→

→

→ bubbles →

→

→

→ thermodynamic non-

equilibrium

conditions →

→

→

→ different temperature in the

bubble than in liquid.

The pressure difference between the liquid and the

vapour is balanced by the surface tension at the

interface →

→

→

→ the driving force for heat transfer between

two phases.

When the liquid is at a higher T than the bubble, heat will

be transferred from the liquid to the bubble →

→

→

→ the bubbles

grow and rise to the top under influence of buoyancy.

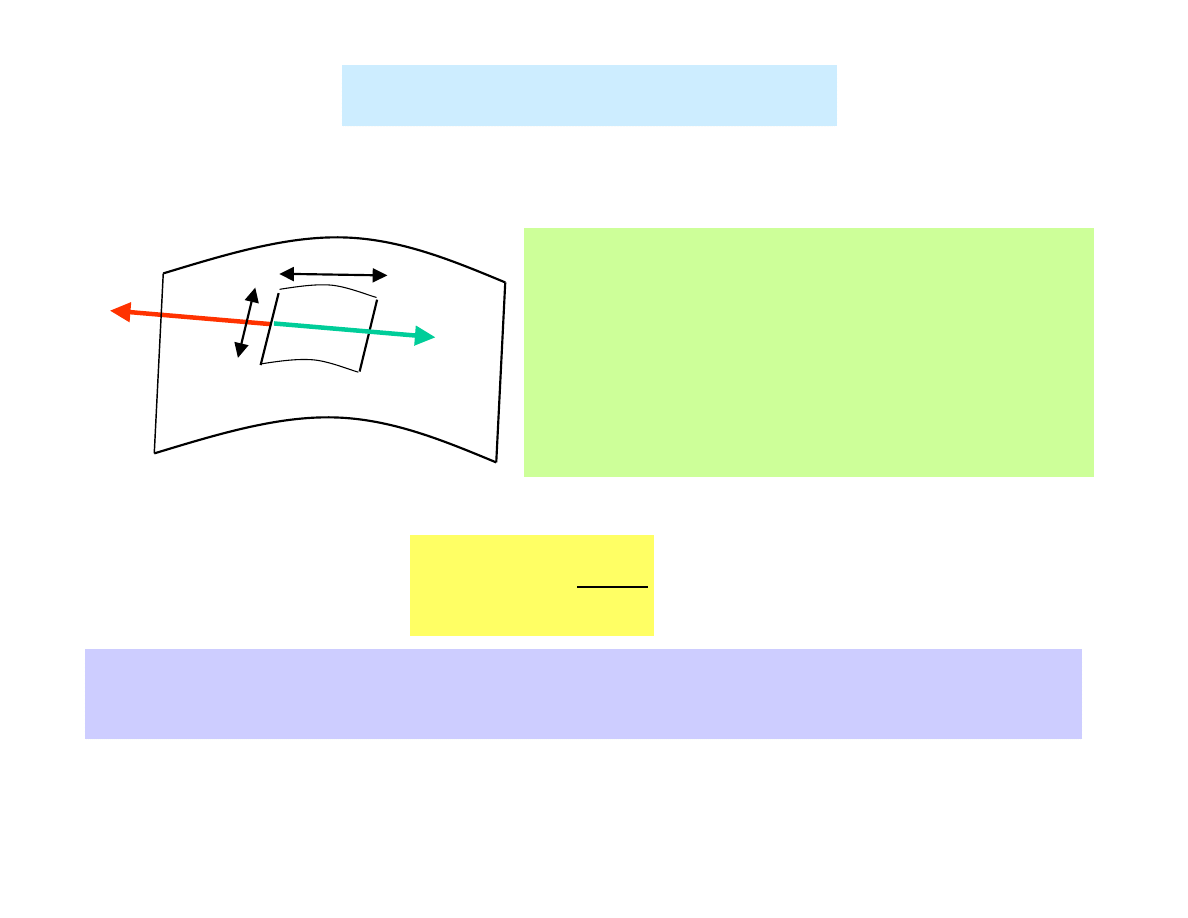

Surface tension

Surface tension in liquids →

→

→

→ in an elastic membrane (2D

effect) →

→

→

→ analogy to tension in an elastic spring (1D effect)

∆

∆

∆

∆l

∆

∆

∆

∆x

T

r

∆

T

r

∆

−

Any line element of the surface of

the „membrane” is in equilibrium

due to equal and opposite forces

exerted perpendicular to ∆

∆

∆

∆l by the

parts of the „membrane” on either

side.

The surface tension σ

σ

σ

σ →

→

→

→ the magnitude of the tensile force

per unit length:

l

|

T

|

limit

0

l

∆

∆

=

→

∆

r

σ

)

/

(

m

N

Note

: The surface tension in a liquid does not change as the

liquid surface is „stretched”.

Effects related to surface tension: liquid drop formation

(surface energy minimum condition) or soup bubbles.

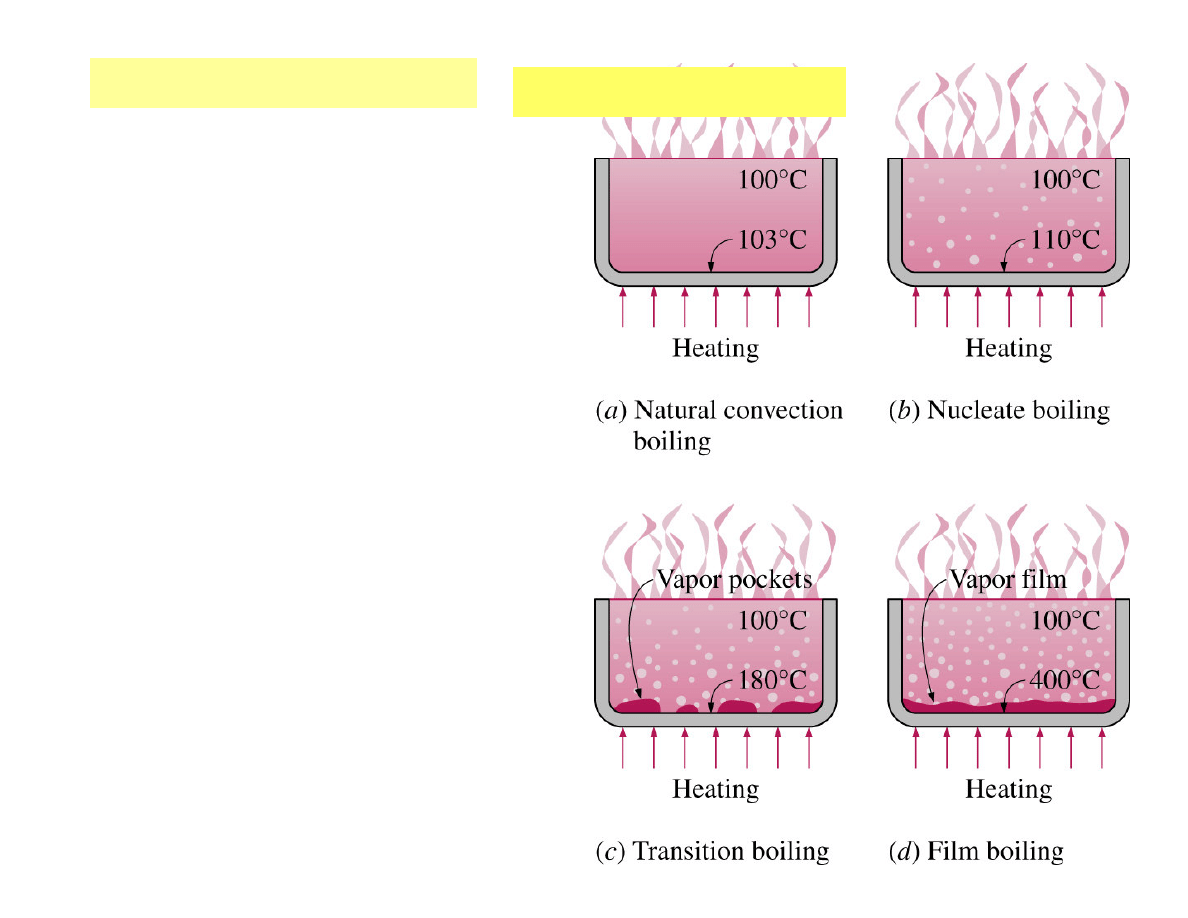

Natural convection boiling

regime

- the fluid motion is governed by

natural convection currents, and

heat transfer from the heating

surface to the fluid is by natural

convection.

Nucleate boiling

regime - bubbles

form at various preferential sites

on the heating surface, and rise

to the top.

Transition boiling

regime - part

of the surface is covered by a

vapor film.

Film boiling

regime - the heater

surface is completely covered by

a continuous stable vapor film,

and heat transfer is by combined

convection and radiation.

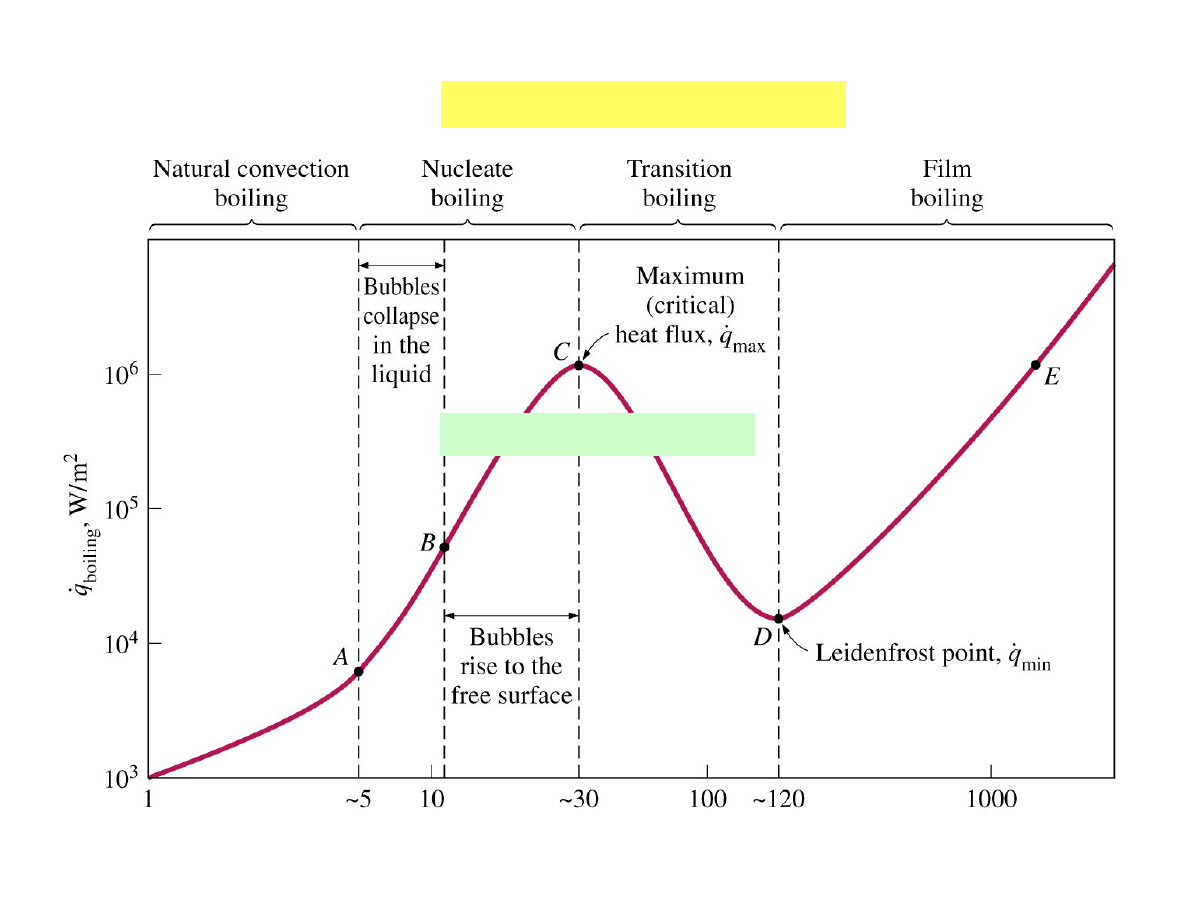

Mechanisms of boiling

→

→

→

→ pool boiling

Pioneering work by

S. Nukiyama (1934)

∆

∆

∆

∆T

excess

=T

S

-T

sat

,

0

C

The boiling curve

water

The burnout point C

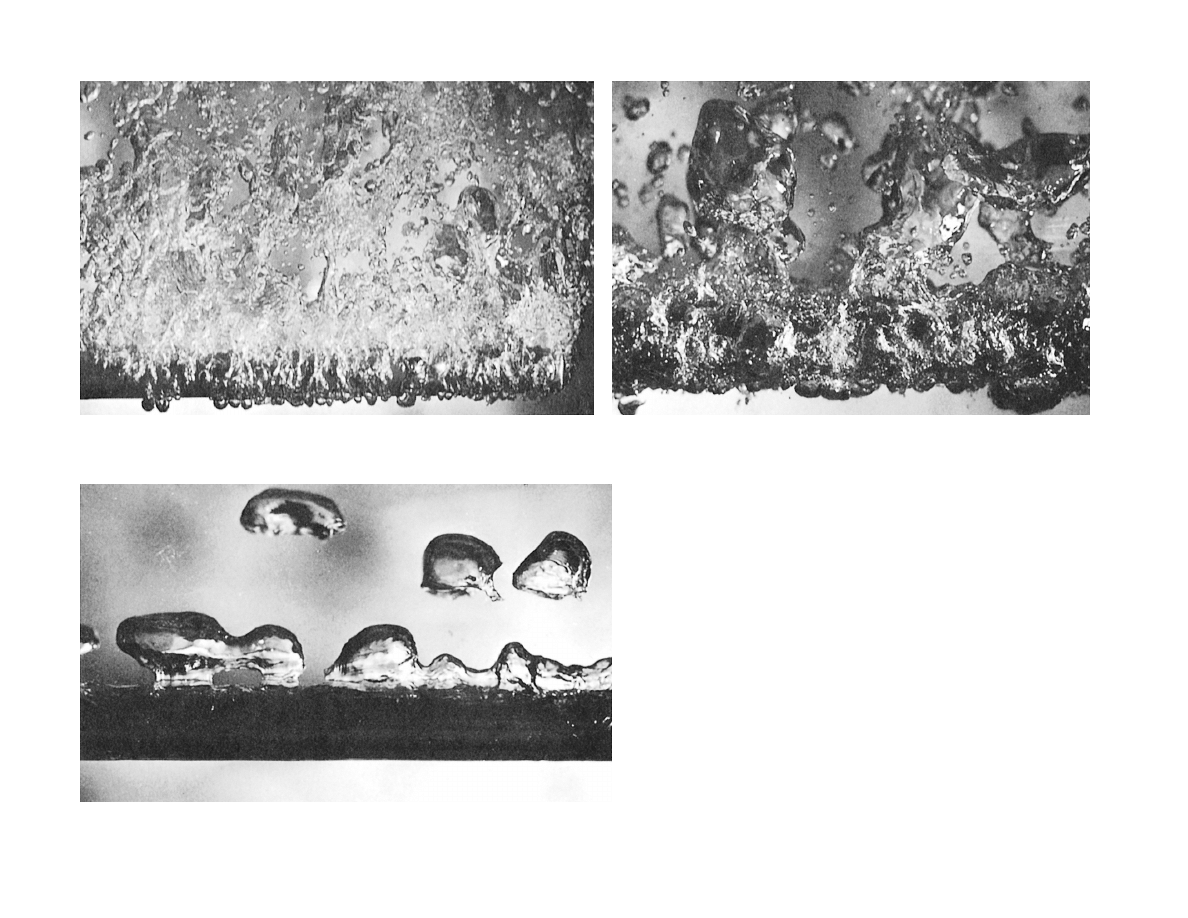

Boiling regimes (methanol)

on a horizontal 1 cm-diameter

steam-heated copper tube

(b) Transition boiling

(a) Nucleate boiling

(c) Film boiling

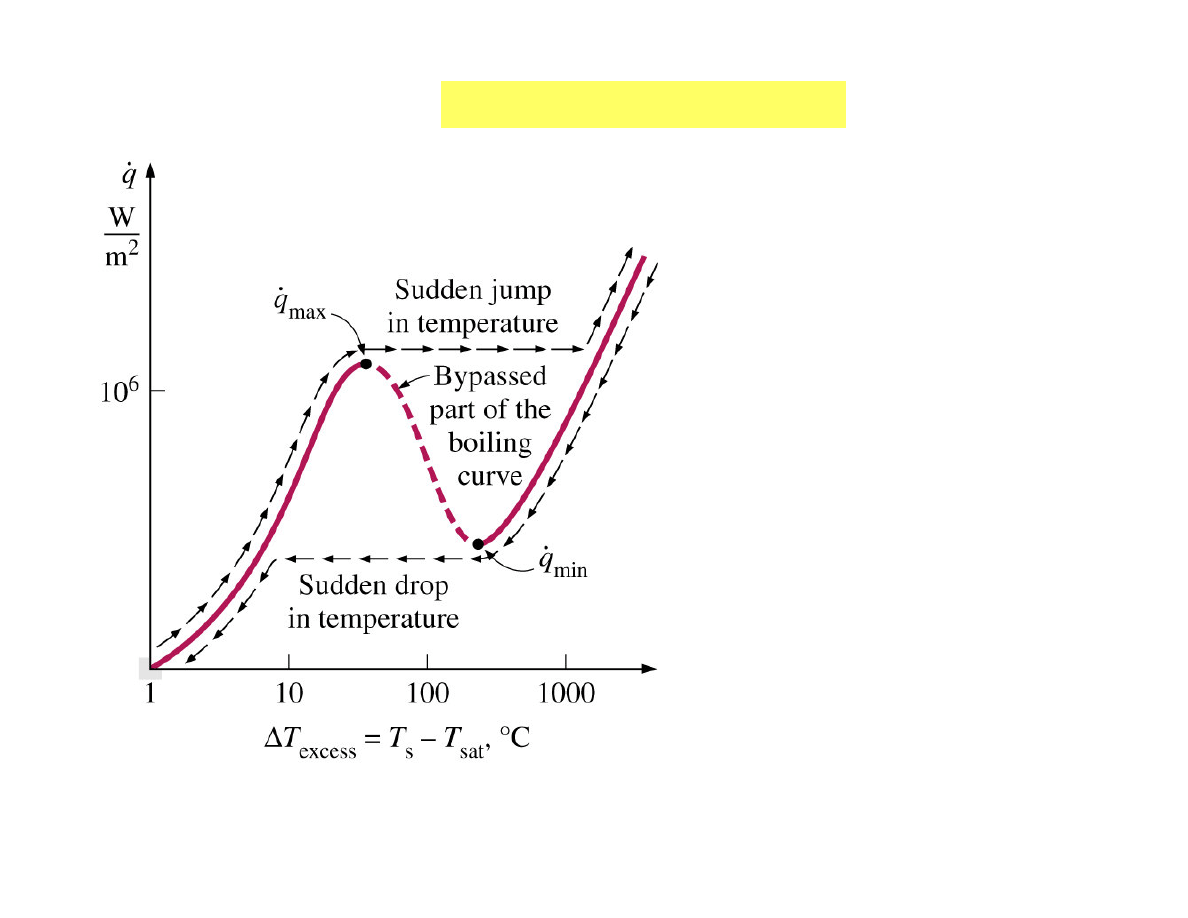

The actual boiling curve

obtained with platinum

wire in water as the heat

flux is increased and then

decreased.

The boiling curve

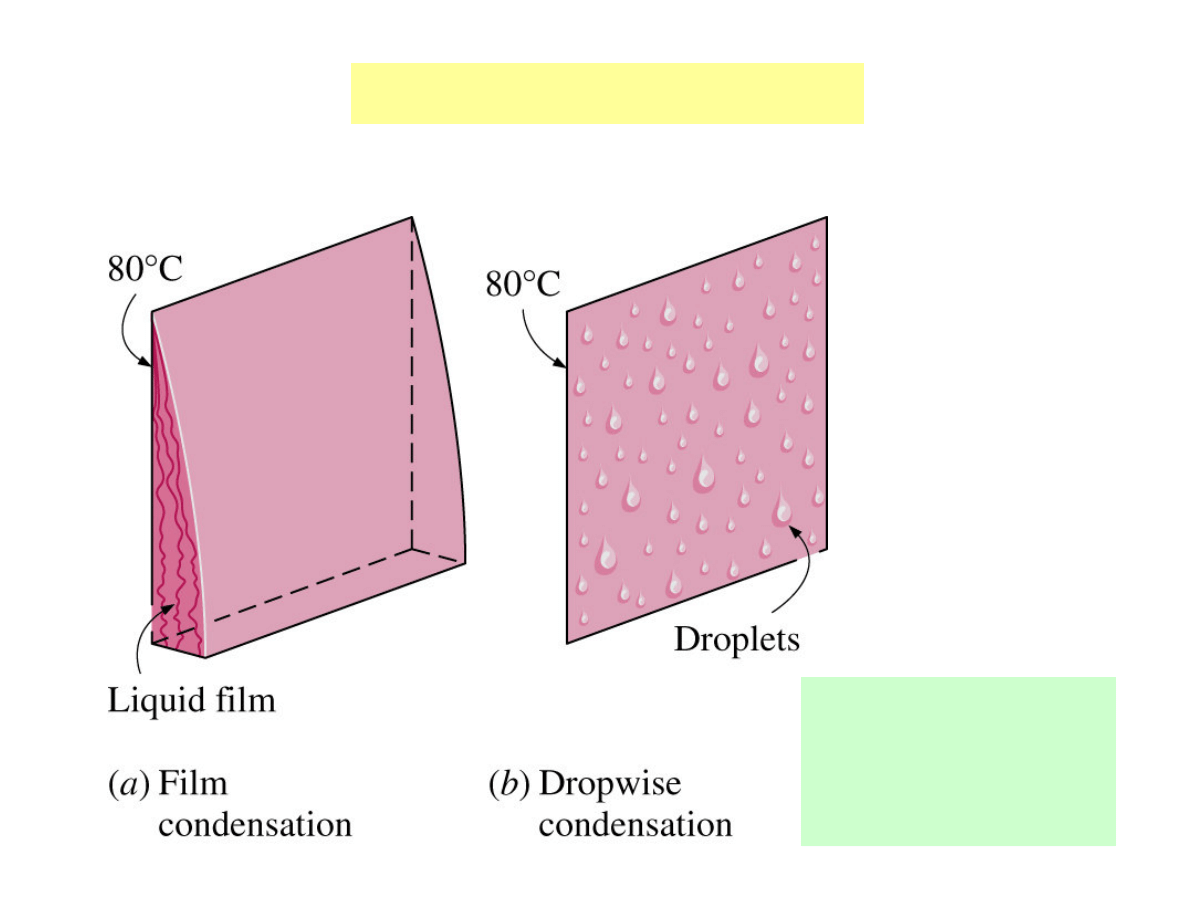

Condensation

Temperature of a vapour - reduced below T

sat

Larger values of

heat transfer rate

→

→

→

→ preferred mode

of condensation

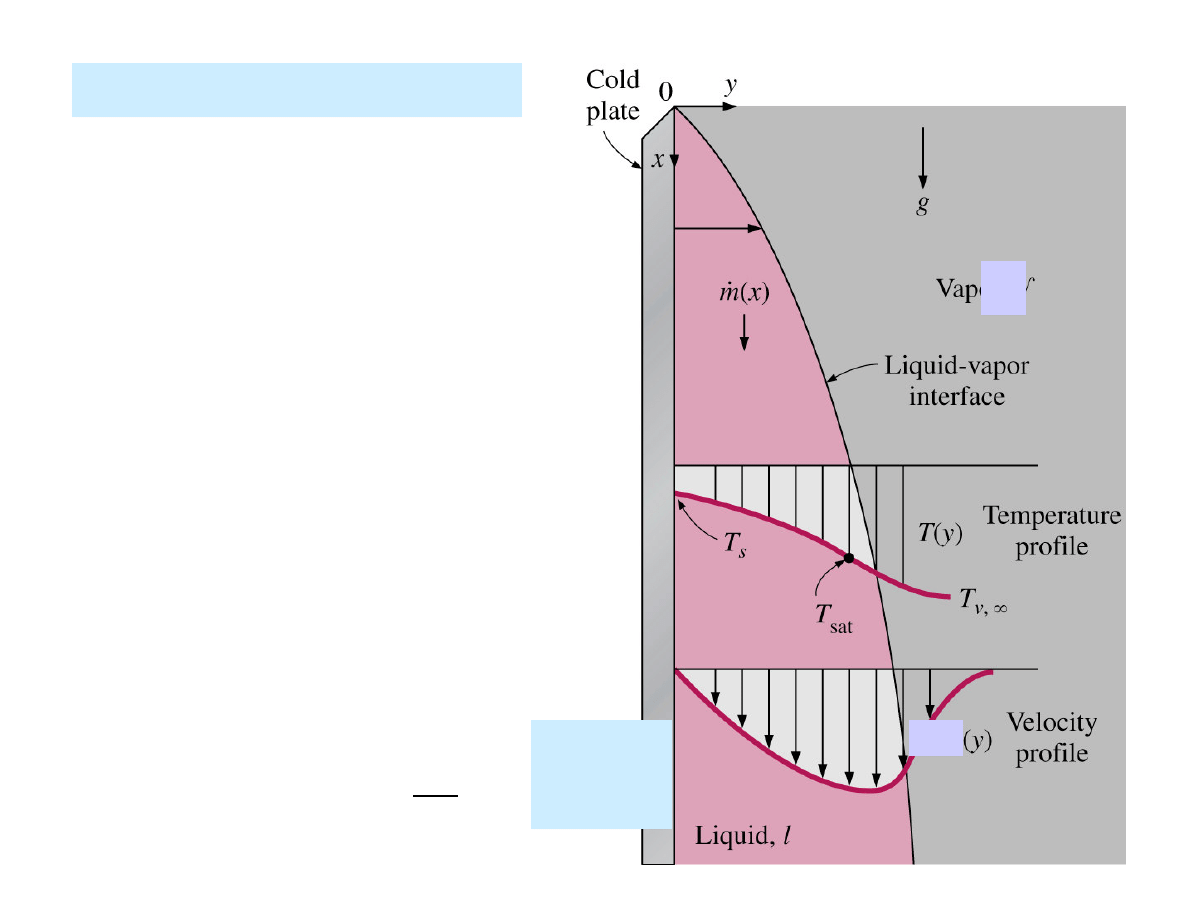

Condensation on a plate

• Influence of gravity.

• T

s

must be below T

sat

of the

vapour for condensation to occur.

• Temperature of the condensate is

T

sat

at the interface and decreases

gradually to T

s

at the wall.

• The velocity of the condensate at

the wall is zero because of the „no-

slip” condition.

• Velocity maximum at the liquid –

vapour interface.

v

v(y)

3

/

1

2

3

/

1

Re

47

.

1

Λ

≅

−

l

l

vert

v

g

h

Heat transfer coefficient:

l

v

ρ

ρ

〈〈

〈

〈

30

Re

0

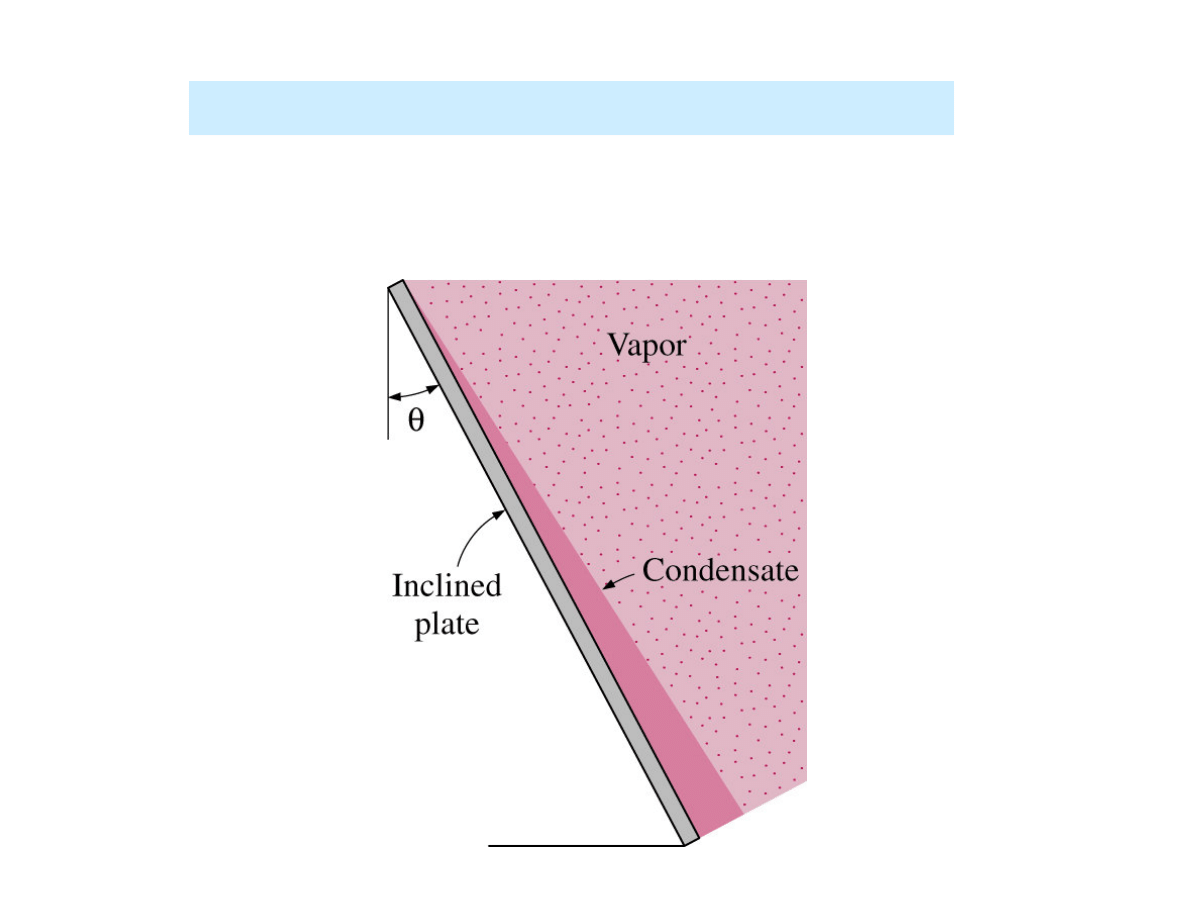

Film condensation on an inclined plate

4

/

1

)

(cos

θ

vert

inclined

h

h

=

for laminar flow of condensate

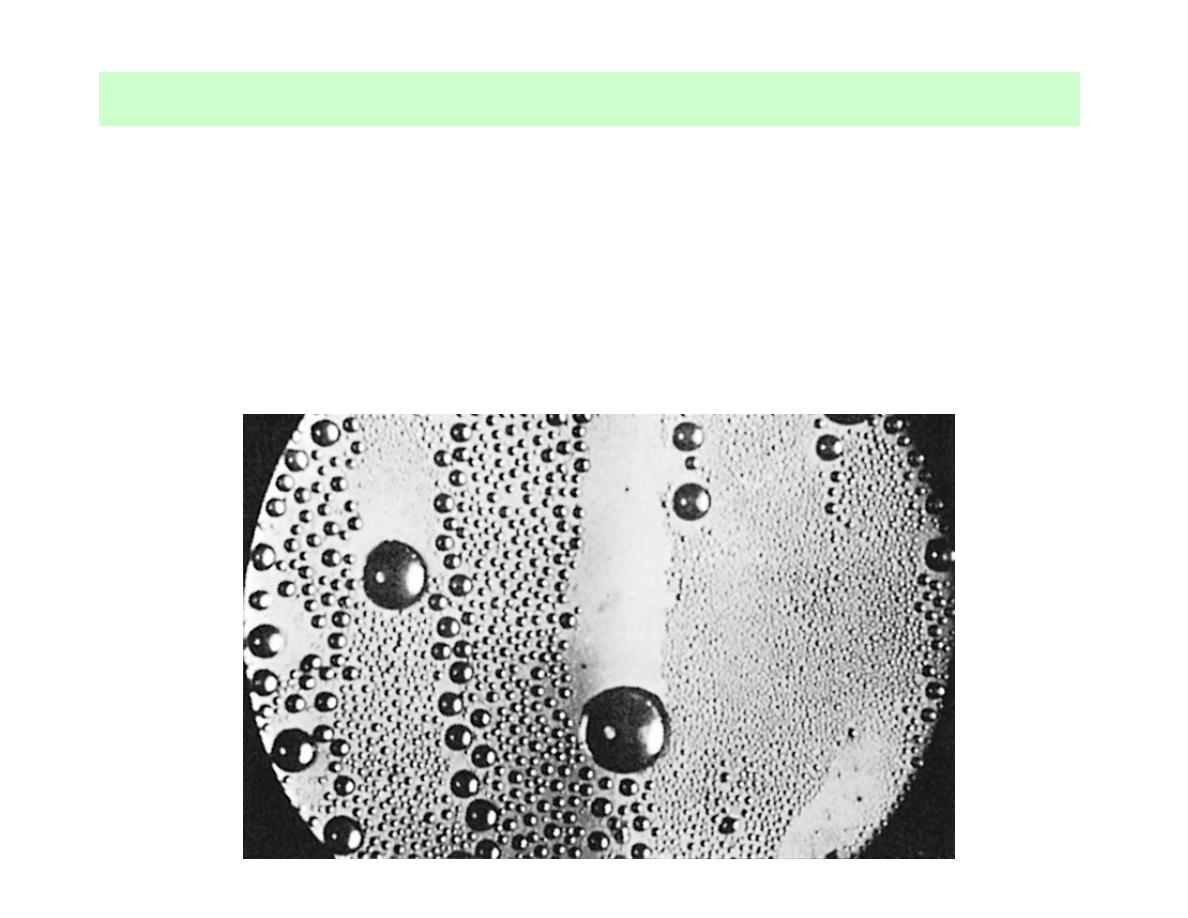

Dropwise condensation of steam on a vertical surface

One of the most effective mechanisms of heat transfer →

→

→

→

extremely large heat transfer coefficients (more than 10 times

larger than in case of film condensation) →

→

→

→ preferred mode of

condensation (efficient condensers) →

→

→

→ adding a promoting

chemical into the vapour, treating the surface with a promoter

chemical or coating the surface with a polymer (teflon) or a

noble metal (gold, platinum, silver)

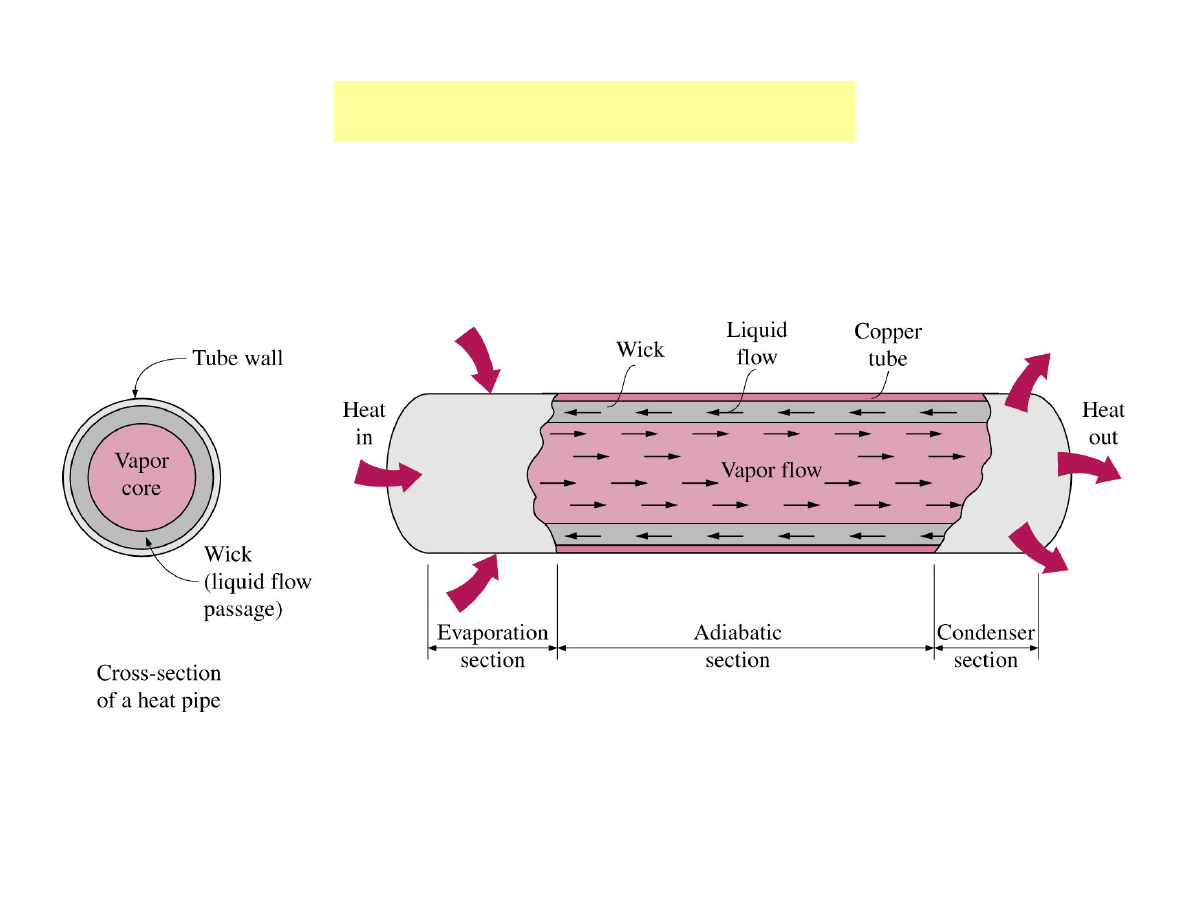

Heat exchangers

Wyszukiwarka

Podobne podstrony:

13 ZMIANY WSTECZNE (2)id 14517 ppt

13 zakrzepowo zatorowa

Zatrucia 13

pz wyklad 13

13 ALUid 14602 ppt

pz wyklad 13

ZARZ SRODOWISKIEM wyklad 13

Biotechnologia zamkniete użycie (2012 13)

Prezentacja 13 Dojrzewanie 2

SEM odcinek szyjny kregoslupa gr 13 pdg 1

w 13 III rok VI sem

Wykład 13 UKS

fundusze 7 13

13 ZACHOWANIA ZDROWOTNE gr wtorek 17;00

auksologia 13 02 2010

więcej podobnych podstron