Fenoxycarb

Materials to be

analyzed

Air, water, soil, and plant (pasture grass hay, forage, cu-

curbits, citrus, pome fruit, tree nuts, fruiting vegetables,

and cotton) and animal materials (tissues, milk, blood,

and eggs)

Instrumentation

Liquid

chromatography/ultraviolet

detection,

three-

column switching liquid chromatography with fluo-

rescence detection, two-column switching liquid chro-

matography/ultraviolet detection, gas chromatography/

thermionic specific detection, gas chromatography/mass

spectrometry, and liquid chromatography/atmospheric

pressure ionization/mass spectrometry.

1

Introduction

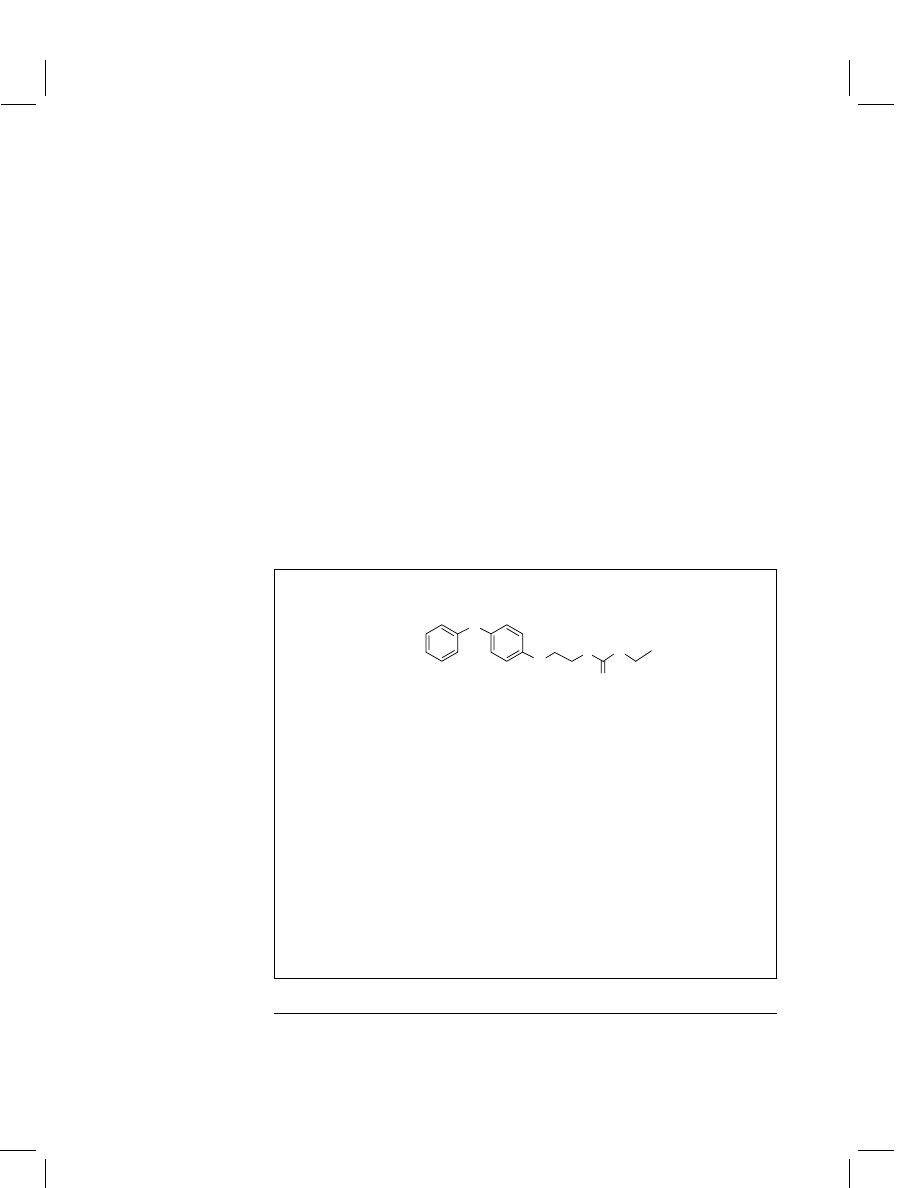

Chemical name

(IUPAC )

Carbamic acid, [2-(4-phenoxyphenoxy)ethyl]-, ethyl

ester

Structural formula

O

O

O

O

H

N

Empirical formula

C

17

H

19

NO

4

Molar mass

301.34

Melting point

53.6

◦

C

Vapor pressure

6.5

× 10

−9

mbar at 25

◦

C

Solubility (25

◦

C)

Soluble in water: 5.66 mg L

−1

Readily soluble in organic solvents: ethanol 51, acetone

77, toluene 63, n-octanol 13, n-hexane 0.53 g per 100 mL

Other properties

Colorless to white solidified melt, no dissociation con-

stant in an accessible pH range, octanol/water partition

coefficient (log K

ow

) 4.07 at 25

◦

C.

Use pattern

An insect growth regulator, used to control early instar

larvae of Homoptera, Lepidoptera, and Coleoptera in

citrus, cotton, and vines and fruiting vegetables

Regulatory position

The residue of concern is for the parent, fenoxycarb,

only

Handbook of Residue Analytical Methods for Agrochemicals.

C

2003 John Wiley & Sons Ltd.

Fenoxycarb

1295

2

Outline of methods

1

Air was sampled for a specific rate and time and the analyte collected on XAD-2

resin. The analyte was eluted from the resin using methanol followed by concen-

tration of the eluate and analysis using gas chromatography/nitrogen–phosphorus

detection (GC/NPD). Water was extracted by passing the sample through XAD-2

resin followed by elution of the analyte using ethyl acetate. Further purification of the

extract was obtained using Florisil chromatography and final analysis was obtained

using liquid chromatography/ultraviolet detection (LC/UV). Pond water was parti-

tioned into hexane followed by evaporation of the solvent and analysis using LC/UV.

Soil was extracted with acetone, acetonitrile was added, and the mixture partitioned

with hexane. After discarding the hexane, the acetone–acetonitrile was adjusted to

basic pH and re-partitioned with hexane. The hexane fraction was reduced and sub-

jected to analysis using gas chromatography (GC)/thermionic specific detection. Plant

and animal samples were extracted with acetone, filtered, and partitioned with hex-

ane. After discarding the hexane, the acetone–acetonitrile fraction was adjusted to

basic pH and re-partitioned with hexane followed by further purification using silica

and Florisil SPE cartridges. Final analysis was accomplished using gas chromatog-

raphy/mass spectrometry (GC/MS). Certain citrus samples were blended with C

8

or

C

18

SPE packing material and the mixture was loaded into a glass column. The an-

alyte was eluted using dichloromethane–acetonitrile for final analysis using liquid

chromatography/atmospheric pressure ionization/mass spectrometry (LC/API/MS).

3

Apparatus

3.1

Air

Air sampler, Alpha-1 (Messgerate-Werk Lauda, RMT 20, Germany)

Circulation cooler

Mini-Buck calibrator, Model M-5 (A.P. Buck, Inc.)

OSHA versatile sampler (OVS) sorbent tubes (SKC, Inc., Cat. No. 226-30-16)

Teflon vacuum pump (Analytichem International, N726.3FT.18)

Ultrasonic bath (Branson, Model 2200)

3.2

Water

Carbon filter tube (Fisher 08-261B)

Chromatography columns: 100

× 15-mm i.d. with Teflon stopcock

Glass-fiber filter (Whatman GF/D, 11-cm)

Rotary evaporator (B¨uchii) with water-bath temperature 50

◦

C

3.3

Soil

Buchner funnels, 7-cm

Evaporation flasks, 250- and 500-mL

1296

Individual compounds

Glass-microfiber filters, 7-mm (Whatman GF/D)

Reciprocating shaker

Separatory funnels, 125- and 250-mL

Side-arm flask, 500-mL

Wide-mouthed bottles with Teflon-lined lids, 250-mL

3.4

Pasture grass hay, forage, cucurbits, citrus, pome fruit, tree nuts,

fruiting vegetables, and cotton substrates

Bottles, 8-oz

Round-bottom flasks, 50-, 100-, 250- and 1000-mL

Side-arm flasks, 500-mL

Florisil, 1000-g/6-cm

3

(J.T. Baker, 7213-07)

Homogenizer, Polytron (or equivalent)

PrepSep Florisil (Fisher Scientific, Cat. No. P476)

PrepSep Silica (Fisher Scientific, Cat. No. P478)

Silica, 100-g/6-cm

3

(J.T. Baker, 7086-07)

Sep-Pak, C

18

(Waters, 43365)

3.5

Animal tissues, milk, blood, and eggs

Acrodisc filter, liquid chromatography (LC), poly(vinylidene fluoride) (PVDF),

0.2-µm, 13-mm

Bottles, 32-oz, wide-mouthed

Side-arm flasks, 500-mL

Flat-bottom boiling flasks, 250-mL

Glass-wool (Fisher, 11-390)

Silica gel solid-phase-extraction (SPE) cartridge, 1-g/6-cm

3

(J.T. Baker, 7086-07)

Other items as in Soil and Plant material lists

4

Reagents

Acetone, glass distilled

Acetonitrile, LC grade

Ammonium hydroxide, ACS reagent grade

Anhydrous sodium sulfate, ACS reagent grade

Dichloromethane, HPLC grade

Ethyl acetate, glass distilled

Florisil (Fluka), 60–100-mesh

Hexane, glass distilled and residue analysis grade

Methanol, glass distilled and analytical grade

Phosphoric acid, ACS grade

Potassium dihydrogenphosphate, analytical grade

Potassium phosphate, monobasic, ACS grade

Fenoxycarb

1297

Sea sand, purified with acid and calcined

Sodium carbonate, ACS grade

Sodium sulfate, ACS grade

Toluene, high-purity

Water, glass distilled and LC grade

XAD-2 resin (0.15–0.20-mm particle size), research grade

5

Sample preparation

5.1

Air

Air was sampled by passing air at 0.5 L min

−1

for 4 h (via vacuum) through an OVS

tube containing a glass-fiber filter (to trap aerosols and particulates) and XAD-2 resin

(to trap vapors). A second XAD-2 section in the sampling tube provided a means of

checking for overloading of the first XAD-2 section. After sampling, the glass-fiber

filter and first section of XAD-2 resin were transferred to a 10-mL round-bottom

flask. The second portion of XAD-2 resin was transferred to a second 10-mL

round-bottom flask. A volume of 5 mL of methanol was added to each flask followed

by ultrasonication for 5 min. The solids were allowed to settle and the methanol was

transferred by pipet to respective 25-mL round-bottom flasks. The extraction process

using another 5-mL portion of methanol was repeated for each sample. The pooled

methanol fractions for each sample were evaporated to dryness via rotary evaporation

and the residues were reconstituted in 12 mL of hexane for analysis by GC/NPD.

5.2

Water

Water was extracted for fenoxycarb by passing 1 kg of water sample through a glass-

microfiber filter into a 1-L dropping funnel. A chromatography column containing 5 g

of XAD resin supported by 5 g of sea sand was successively conditioned with 80 mL

of methanol and then 80 mL of acetone. Drying was accomplished by passing dry

nitrogen through the column. The filtered water sample was passed through the XAD

resin at a rate of 10 mL min

−1

. After passage of the water sample through the resin,

the remaining water was forced out of the column using dry nitrogen. The analyte was

eluted from the column using 100 mL of ethyl acetate at 1 mL min

−1

and collected

in a 250-mL flask. The eluate was reduced to dryness using a rotary evaporator

and reconstituted in 2 mL of ethyl acetate. Another column was prepared by adding

10 mL of hexane–ethyl acetate (23 : 2, v/v) in a chromatography column plugged with

glass-wool. Next, 10 g of Florisil in a solvent slurry mixture were slowly added to the

column by gently tapping the sides and the solvent level was allowed to drain to the

top of the Florisil. A 2-mL fraction from the previous column step was quantitatively

transferred to the Florisil column and the column was washed with 100 mL of ethyl

acetate. The analyte was eluted using 100 mL of hexane–ethyl acetate (17 : 3, v/v)

and collected in a 250-mL flask. This fraction was reduced to dryness and the residue

was reconstituted using 0.5 mL of mobile phase for analysis using LC/UV.

Pond water was analyzed for fenoxycarb by partitioning 1 L of filtered (Whatman

No. 2 filter) water sample with 75 mL of hexane. The partitioning step was repeated

1298

Individual compounds

twice and the pooled hexane fraction was dried through a bed of anhydrous sodium

sulfate. The dried hexane was reduced to about 1 mL using rotary evaporation and

quantitatively transferred to a concentration tube. This fraction was again reduced to

about 1 mL and the sides of the concentration tube were rinsed with 2 mL of methanol.

This fraction was then reduced to dryness and reconstituted in an appropriate volume

of mobile phase for analysis using three-column switching LC/UV.

5.3

Soil

Soil was extracted for fenoxycarb by placing 20 g of sample in a 250-mL extraction jar

with a Teflon-lined lid containing 20 mL of 1% phosphoric acid. The jar was allowed

to stand for 20 min before adding 200 mL of acetone followed by mechanical shaking

for 30 min. The extract was filtered through glass-fiber filters into a 500-mL side-arm

filtering flask using 2

× 15 mL of acetone to rinse the extraction jar. This fraction

was quantitatively transferred to a 500-mL evaporation flask and reduced in volume

to 20–25 mL at a water-bath temperature of

<35

◦

C to remove all traces of acetone.

Acetonitrile (30 mL) was added to the flask and swirled to mix before transfer to a

250-mL separatory funnel. A volume of 2

× 10 mL of acetonitrile–water (3 : 2, v/v)

was used to rinse the evaporation flask. The acetonitrile–water mixture was partitioned

with 50 mL of hexane (1 min). The hexane phase was separated from the aqueous

phase and partitioned twice (for 1 min each time) with 10 mL of acetonitrile–water

(3 : 2, v/v). The two acetonitrile–water solvent extracts were returned to the original

acetonitrile–water extract and the hexane was discarded. The acetonitrile–water frac-

tion was reduced to about 40 mL via rotary evaporation at a water-bath temperature

of

<35

◦

C to remove the acetonitrile. To the remaining aqueous fraction was added

2 mL of concentrated ammonia solution and 20 mL of deionized water followed by

transfer to a 125-mL separatory funnel. A volume of 50 mL of hexane was added to

the evaporation flask for rinsing purposes before transfer to the separatory funnel. Af-

ter phase separation, the hexane phase was dried through a bed of anhydrous sodium

sulfate and collected in a clean 250-mL evaporation flask. The aqueous fraction was

partitioned twice more, each time with 50 mL of hexane. The pooled and dried hexane

fraction was reduced to dryness using rotary evaporation prior to reconstitution in an

appropriate volume of hexane for GC analysis.

5.4

Plant material

5.4.1

Pasture grass hay, forage, and cucurbits

Fenoxycarb was extracted from pasture grass hay, forage, and cucurbits (cucum-

bers, squash, and cantalope) by weighing a 25-g representative sample into a 16-oz

wide-mouthed jar followed by the addition of 20 mL of 1% phosphoric acid. After

waiting for 20 min, 200 mL of acetone were added. After waiting for 1 min, the sample

was homogenized using a Polytron at a rate of 17 000–20 000 rpm for 2 min. The sam-

ple was then filtered using a 500-mL side-arm flask equipped with a Buchner funnel

containing a glass-microfiber filter. The sample bottle was rinsed with 50 mL of ace-

tone and the solvent was filtered. The extract was transferred to a 1-L round-bottom

Fenoxycarb

1299

flask and the acetone volume was reduced to about 18 mL using rotary evaporation

at a water-bath temperature of

<35

◦

C. The volume of the remaining aqueous frac-

tion was measured and enough acetonitrile was added to obtain an acetonitrile : water

ratio of 3 : 2 (v/v). This fraction was transferred to a 250-mL separatory funnel using

2

× 10 mL of acetonitrile–water (3 : 2, v/v) solvent mixture for rinsing purposes. The

1-L round-bottom flask was rinsed with 50 mL of hexane and the rinsate was added

to the separatory funnel, which was then shaken for 1 min. The hexane fraction was

removed and back-partitioned with 2

× 10 mL of acetonitrile–water (3 : 2, v/v) and

these two portions were returned to the original aqueous acetonitrile fraction. The

hexane layer was discarded. Acetonitrile was removed via rotary evaporation until

the first drops of water were observed in the condenser (the aqueous volume should be

similar to that previously, about 18 mL). Concentrated ammonia solution (2 mL) and

water (20 mL) were added and the mixture was transferred to a 125-mL separatory

funnel. The flask was rinsed with 50 mL of hexane and the rinsings were also added to

the separatory funnel. After shaking for 1 min, the hexane phase was removed and

transferred to a 250-mL round-bottom flask. The aqueous portion was partitioned

twice more with 50 mL of hexane. The aqueous phase was discarded and the pooled

hexane fraction was reduced to dryness using rotary evaporation. This fraction was

reconstituted in 2 mL of hexane and analyzed by LV/UV for crop samples. Pasture

grass and forage samples were subjected to further purification by preconditioning a

silica gel SPE cartridge with 2–3 mL of hexane. The sample was loaded on to the SPE

cartridge and the 250-mL round-bottom flask was rinsed with 2

× 2-mL portions of

hexane, the rinsings also being added to the cartridge. The column was first eluted with

7 mL of dichloromethane–hexane–tetrahydrofuran (49 : 50 : 1, v/v/v) solvent mixture,

which was discarded after passage through the cartridge. The analyte was eluted using

an appropriate volume of the same elution solvent (typically 15–25 mL) and collected

in a 50-mL round-bottom flask. Note that the fenoxycarb elution volume on each lot

of silica gel SPE cartridges was profiled due to lot-to-lot variability. The eluate was

reduced to dryness followed by reconstitution in 2 mL of hexane. A 5-mm deep layer

of sodium sulfate was added to the top of a Florisil PrepSep cartridge and was then

preconditioned using 2–3 mL of hexane–ethyl acetate (23 : 2, v/v). The 2-mL hexane

fraction was loaded on to the Florisil PrepSep cartridge using 2

× 2-mL portions of

hexane for rinsing purposes. The analyte was eluted with 50 mL of hexane–ethyl

acetate (23 : 2, v/v) and collected in a 100-mL round-bottom flask. This fraction was

reduced to dryness and reconstituted in an appropriate volume of mobile phase for

LC analysis or in an appropriate volume of acetonitrile for GC/MS analysis.

5.4.2

Citrus, pome fruit, tree nut, fruiting vegetables, and cotton substrates

A 10-g representative sample (5-g sample for citrus oil or cotton substrates) was

extracted by adding 150 mL of acetonitrile–water (4 : 1, v/v) to the sample in an 8-oz

bottle and homogenized with a Polytron at high speed for 2 min. The extract was

filtered through a Whatman No. 1 filter-paper into a 500-mL side-arm flask. The

extraction bottle was rinsed with 50 mL of acetonitrile–water (4 : 1, v/v) for citrus

and cottonseed oil (for molasses use 10 mL of water followed by 40 mL of acetoni-

trile for rinsing). The extract was transferred to a 500-mL separatory funnel and

partitioned twice, each time with 50 mL of hexane for 1 min. The hexane fractions

1300

Individual compounds

were discarded. The extract was transferred to a 500-mL boiling flask and the acetoni-

trile was removed using rotary evaporation at a water-bath temperature of 35–40

◦

C

(removal of all the acetonitrile is critical). For tree nut samples only, a Waters C

18

Sep-Pak cartridge was conditioned with 10 mL of acetonitrile–water (3 : 2, v/v) and

10 mL of water at a flow rate of 1–3 drops per second (avoiding column dryness).

The sample was loaded followed by washing with 25 mL of acetonitrile–water (1 : 4,

v/v) and then 10 mL of acetonitrile–water (3 : 2, v/v). The analyte was eluted using

40 mL of acetonitrile–water (3 : 2, v/v). For all other samples (excluding tree nuts),

the remaining aqueous portion after removing the acetonitrile was transferred to a

250-mL separatory funnel to which 50 mL of 0.5% sodium carbonate and 25 mL of

water saturated with sodium chloride were added. For tree nuts, the eluate from the

Waters Sep-Pak cleanup step was transferred to a 250-mL separatory funnel, and

30 mL of 0.5% sodium carbonate and 10 mL of water saturated with sodium chloride

were added. All the samples were partitioned twice, each time with 50 mL of hexane.

The pooled hexane fraction was dried through anhydrous sodium sulfate. The re-

maining aqueous portion was discarded. For tree nuts only, the dried hexane fraction

was reduced to dryness and reconstituted in 2 mL of hexane for Florisil purification.

The dried hexane fraction for all other samples was reduced to 5–15 mL using rotary

evaporation for silica gel purification. A silica gel SPE cartridge was conditioned

with 6 mL of ethyl acetate–hexane (1 : 4, v/v) and 6 mL of hexane at a flow rate of 1–

2 drops per second. The hexane fraction was loaded on the column followed by ad-

dition of 6 mL of ethyl acetate–hexane (1 : 4, v/v) for washing purposes. The analyte

was eluted using 12 mL of ethyl acetate–hexane (1 : 4, v/v) and collected in a 50-mL

concentration tube. This fraction was reduced to dryness and reconstituted in 2 mL of

hexane for Florisil cleanup, except for cucurbit and fruiting vegetable samples, which

were reconstituted in acetonitrile–0.05 M potassium dihydrogenphosphate (1 : 1, v/v)

for LC analysis. All other samples (including tree nuts) were further purified by con-

ditioning a Florisil SPE cartridge with 3–5 mL of ethyl acetate–hexane (2 : 23, v/v) at

a rate of 1–2 drops per second (avoiding column dryness). The hexane fraction was

loaded on to the column and the concentration tube was rinsed in 2

× 2 mL of hexane,

the rinsings being added to the column. The analyte was eluted with 50 mL of ethyl

acetate–hexane (2 : 23, v/v) and collected in a 125-mL boiling flask. This fraction

was reduced to dryness and reconstituted in 1 mL of acetonitrile–0.05 M potassium

dihydrogenphosphate (1 : 1, v/v) for LC analysis.

5.4.3

Oranges, onions, grapes, and tomatoes

A 0.5-g portion of sample was weighed into a mortar and gently blended with 0.5 g

of silica-based sorbent containing C

8

or C

18

functional groups (45–55-µm particle

diameter range) to obtain a homogeneous mixture. The mixture was introduced into

a 100

× 9-mm i.d. glass column. A 10-mL volume of dichloromethane–acetonitrile

(3 : 2, v/v) was added to the column and allowed to elute dropwise under slight

vacuum into a 15-mL conical-shaped graduated cylinder. This fraction was reduced

to 0.5 mL using a gentle stream of nitrogen prior to analysis using LC/MS [with

atmospheric pressure chemical ionization (APCI) and electrospray ionization (ESI)].

This method was applicable to the analysis of 13 carbamate residues, including

fenoxycarb.

Fenoxycarb

1301

5.5

Animal material

5.5.1

Meat, milk, blood, and eggs

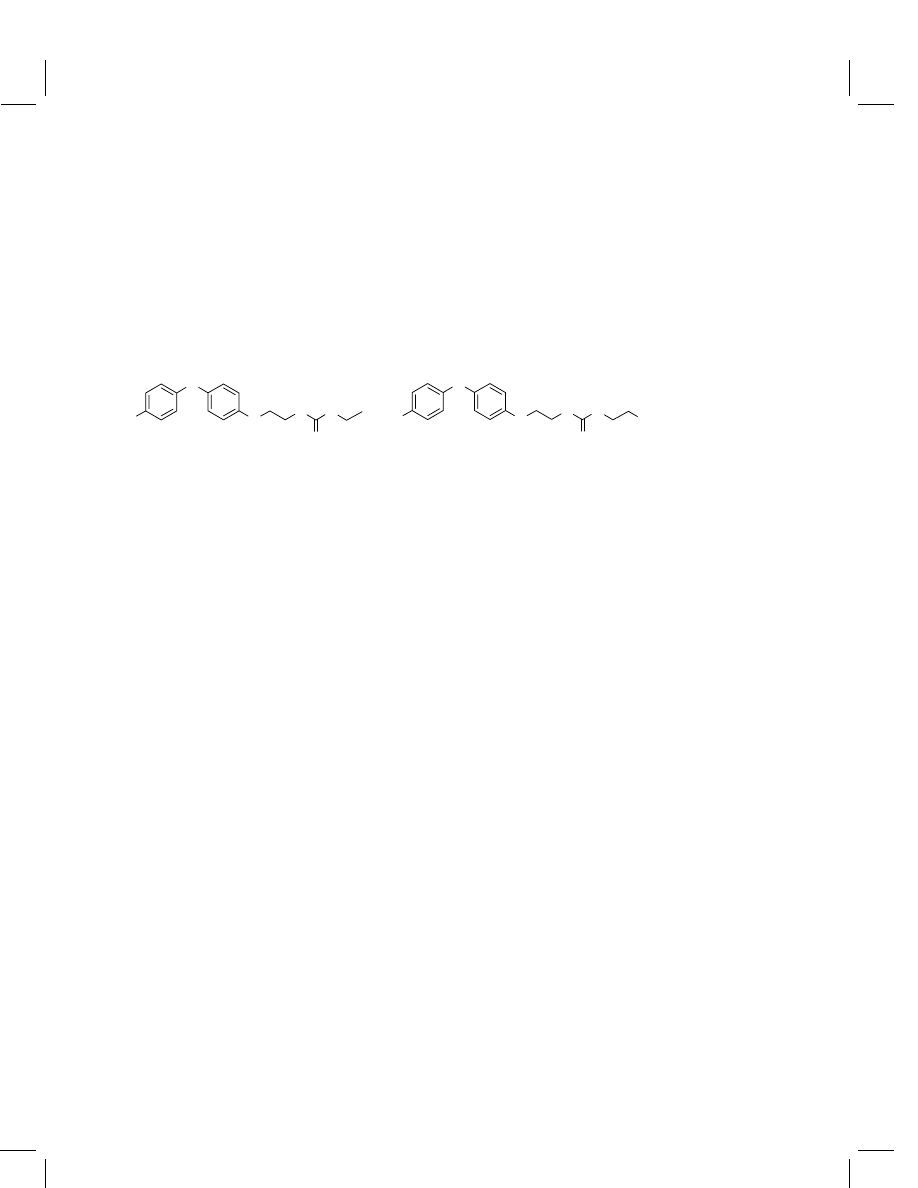

In addition to the parent fenoxycarb, residue methods for the two major

metabolic products Ro-16-8797

{CGA-294850, ethyl N-2-[4-(4-hydroxyphenoxy)

phenoxyethyl]carbamate, MW

= 317.3} and Ro-17-3192 {CGA-294851, (2-

hydroxyethyl)-N -2-[4-(4-hydroxyphenoxy)phenoxyethyl]carbamate, MW

= 333.3}

in animal by-products were also developed.

O

O

N

H

O

O

HO

Ro-16-8797

O

O

N

H

O

O

HO

OH

Ro-17-3192

Fat, muscle, and blood samples (or liver, kidney, well-mixed milk, and egg ho-

mogenate) were extracted for fenoxycarb and its hydroxylated metabolites Ro-16-

8797 and Ro-17-3192 by homogenizing 10 g of tissue or whole blood in 200 mL of

acetonitrile [or 200 mL of water–acetonitrile (1 : 4, v/v)] for 2 min using a Polytron

at high speed. The extract was then filtered through Whatman No. 1 filter-paper into

a 500-mL side-arm flask. A volume of 50 mL of acetonitrile [or 50 mL of water–

acetonitrile (1 : 4, v/v)] was used to rinse the extraction bottle and filter pad. This

fraction was transferred to a 500-mL separatory funnel and partitioned twice using

50 mL of hexane each time. The hexane was discarded. For fat, muscle, and blood, the

acetonitrile was removed using rotary evaporation at a water-bath temperature of 35–

40

◦

C. For liver, kidney, milk, and eggs, 25 mL of water saturated with sodium chloride

and 50 mL of toluene were added to the remaining portion of water–acetonitrile (1 : 4,

v/v). The mixture was shaken for 1 min. The aqueous phase was discarded and the

toluene phase was transferred to a 500-mL flat-bottom flask. This fraction was re-

duced to dryness. For all samples, 25 mL of 0.5% sodium carbonate were added and

this fraction was swirled and sonicated to ensure complete dissolution and mixing

prior to transfer to a 125-mL separatory funnel. A second 25-mL portion of 0.5%

sodium carbonate was used for rinsing purposes. A volume of 2

× 25 mL of ethyl

acetate–hexane (1 : 1, v/v) was used for rinsing purposes and also as partitioning sol-

vent by shaking the separatory funnel for 1 min. After phase separation, the organic

solvent was dried through a bed of prerinsed [using 25 mL of ethyl acetate–hexane

(1 : 1, v/v)] sodium sulfate and collected in a 250-mL flat-bottom boiling flask. The

aqueous portion was partitioned a second time using 50 mL of ethyl acetate–hexane

(1 : 1, v/v) and dried through the same bed of sodium sulfate. The pooled and dried

ethyl acetate–hexane fraction was reduced just to dryness using rotary evaporation

and a water-bath temperature of 35–40

◦

C. A silica gel SPE cartridge was conditioned

using 15 mL of ethyl acetate and 10 mL of dichloromethane (avoiding column drying)

at a rate of 1–2 drops per second via gravity (a vacuum system was not used). To the

residue contained in the flat-bottom flask were added 5 mL of dichloromethane, which

was shaken vigorously and sonicated to ensure complete dissolution and mixing. This

fraction was loaded on to the preconditioned silica column. A second 5-mL portion

of dichloromethane was added to rinse the flask and also added to the silica gel SPE

1302

Individual compounds

cartridge. First, 10 mL of hexane and then 6 mL of ethyl acetate–hexane (1 : 4, v/v)

were added to the flask, followed by transfer to the silica column. These wash sol-

vents were discarded. Fenoxycarb and Ro-16-8797 were eluted with 8 mL of ethyl

acetate–hexane (1 : 1, v/v) and collected in a 50-mL concentration tube. Ethyl acetate

(15 mL) was then added to elute Ro-17-3192 and collected in a separate 50-mL con-

centration tube. The two fractions were reduced to dryness separately and each was

reconstituted in acetonitrile–0.02 M potassium dihydrogenphosphate (1 : 1, v/v) for

analysis using column switching LC.

6

Instrumentation

The following instrumental conditions have been shown to be suitable for the analysis

of fenoxycarb. Other operating parameters may be employed provided that fenoxycarb

is separated from sample interferences and the response is linear over the range of

interest.

Operating conditions for air

Gas chromatograph

Hewlett-Packard 5890A Series II with HP-7673A

autosampler and nitrogen–phosphorus detector.

Column

HP-17 fused silica, 10 m

× 0.53-mm i.d., 2.0-µm film

thickness

Temperatures

Injector 250

◦

C, detector 300

◦

C, oven 245

◦

C

Gas flow rates

Carrier gas, He, 11 mL min

−1

; make-up gas, N

2

, 22 mL

min

−1

; H

2

, 2.7 mL min

−1

; air, 108 mL min

−1

Volume injected

5 µL

Retention time for

3.4 min

fenoxycarb

Operating conditions for water

High-performance

Kontron 640

liquid chromatograph

Kontron Uvikon 735 LC/UV detector

Column

125

× 4.6-mm i.d., SS, Nucleosil C

18

, 5-µm particle

size

Mobile phase

Isocratic, acetonitrile–0.05 M potassium dihydrogen-

phosphate (1 : 1, v/v, pH 4.5)

Detector wavelength

228 nm

Flow rate

1 mL min

−1

Retention time for

10 min

fenoxycarb

Three-column switching

High-performance

Perkin-Elmer Series 410

liquid chromatograph

(pump 1)

Injector

Perkin-Elmer ISS-100 autosampler

Pumps 2 and 3

Waters M6000A

Switching valves

Valco Instruments, Model EL6W six-port with elec-

tronic actuator

Detector

Perkin-Elmer LS 40 fluorescence detector

Fenoxycarb

1303

Column 1

Phase-Sep S5 C1, 10 cm

× 4.6-mm i.d., 5-µm particle

size

Column 2

Phase-Sep S3 ODS-2, 10 cm

× 4.6-mm i.d., 3-µm par-

ticle size

Column 3

Hamilton PRP-1, 15 cm

× 4.1-mm i.d., 10-µm particle

size

Mobile phase 1

Acetonitrile–0.05 M phosphate buffer (2 : 3, v/v) at

1 mL min

−1

Mobile phase 2

Acetonitrile–0.05 M phosphate buffer (1 : 1, v/v) at

1 mL min

−1

Mobile phase 3

Acetonitrile–0.05 M phosphate buffer (13 : 7, v/v) at

1 mL min

−1

Injection volume

200 µL

Excitation/emission

230

/300 nm

wavelengths

Retention time for

fenoxycarb

Column 1, 8.9 min; column 2, 17.3 min; column 3,

23.6 min

Operating conditions for soil

Gas chromatograph

Varian 3400 with thermionic specific detector

Column

Restek Rtx-5, 30-m

× 0.53-mm i.d., 1.5-µm film thick-

ness

Temperatures

Injector: initial 50

◦

C (held 0 min), increased at

200

◦

C min

−1

to 250

◦

C (held 17.5 min)

Detector: 300

◦

C

Oven: initial 50

◦

C, increased at 25

◦

C min

−1

to 250

◦

C

Gas flow rates

Air, 180 mL min

−1

; He, 30 mL min

−1

; H

2

, 4.5 mL

min

−1

Volume injected

4–5 µL

Retention time for

1.25 min

fenoxycarb

Operating parameters for pasture grass hay, forage, cucumbers, squash, and

cantalope

High-performance

liquid chromatograph

Perkin-Elmer Model ISS-200 automatic HPLC sam-

pler

Kratos Spectroflow 400 LC pumps

ABI Model 783 variable-wavelength ultraviolet (UV)

detector

Valco Instruments, six-port switching valve

Column 1

Spherisorb C1, 100

× 4.6-mm i.d., 5-µm particle size

(Fisher, Cat. No. 05-692-547)

Column 2

Spherisorb ODS2, 150

× 4.6-mm i.d., 3-µm particle

size (Fisher, Cat. No. 05-692-536)

Mobile phase 1

Acetonitrile–0.05 M potassium dihydrogenphosphate

(2 : 3, v/v), 1 mL min

−1

Mobile phase 2

Acetonitrile–0.05 M potassium dihydrogenphosphate

(2 : 3, v/v), 1 mL min

−1

1304

Individual compounds

Detector wavelength

228 nm

Injection volume

40 µL

Retention time for

Column 1, 7 min; column 2, 12 min

fenoxycarb

Gas chromatograph/

mass spectrometer

Hewlett-Packard 6890 Series gas chromatograph with

Model 5973 mass-selective detector

Column

DB-1701, 30 m

× 0.25-mm i.d., 0.15-mm film thick-

ness (J&W Scientific, Cat. No. 1220731)

Temperatures

Injector : 200

◦

C

Detector : 280

◦

C

Oven : initial 50

◦

C (held 1 min), ramp A 50

◦

C min

−1

to 250

◦

C (held 0 min), ramp B 10

◦

C min

−1

to 300

◦

C

(held 5 min)

Gas flows rates

Pressure 10 psi, EPP mode, column (He) 1.2 mL min

−1

;

purge 60 mL min

−1

, purge time 0.6 min

Volume injected

2 µL

Retention time for

1.25 min

fenoxycarb

Selected ion monitoring

Target ion m

/z 116, qualifier ions m/z 186 and 301

Citrus, pome fruit, tree nuts, fruiting vegetables, and cotton substrates

High-performance

liquid chromatograph

Two Waters Model 501 pumps

Perkin-Elmer Model ISS-100 automatic sampler

Kratos ABI Spectroflow Model 783 ultraviolet/visible

(UV/VIS) detector

Column 1

Phase Separation Spherisorb C1, 100

× 4.6-mm i.d.,

S5

Column 2

Phase Separation Spherisorb ODS2, 150

× 4.6-mm

i.d., S3

Mobile phase 1

Acetonitrile–0.05 M potassium dihydrogenphosphate

(2 : 3, v/v)

Mobile phase 2

Acetonitrile–0.05 M potassium dihydrogenphosphate

(1 : 1, v/v)

For tree nuts: acetonitrile–methanol–0.05 M potassium

dihydrogenphosphate (8 : 5 : 7, v/v/v)

Detector wavelength

225 nm

Flow rate

1 mL min

−1

Injection volume

50 µL

Retention time of

fenoxycarb

About 13 min for tree nut substrates and 20 min for all

other substrates

Operating parameters for oranges, onions, grapes, and tomatoes

High-performance

liquid chromatograph

Hewlett-Packard 1100 Series LC-MSD equipped with

an atmospheric pressure ionization (API) source (APcI

or ESI)

Column

Spherisorb C

8

, SS, 150

× 4.6-mm i.d., 3-µm particle

size (and a LiChrosorb RP-8 guard column)

Fenoxycarb

1305

Mobile phase (APCI)

Methano–water (1 : 1, v/v), isocratic for 5 min, linear

to 60% methanol for 5 min, held for 5 min, then to 90%

methanol in 5 min, held for 7 min, 1 mL min

−1

(other

conditions may be more appropriate if analyzing solely

for fenoxycarb)

Mobile phase (ESI)

Methanol–water, (1 : 1, v/v), isocratic for 15 min, to

70% methanol in 5 min, held for 5 min, then to 90%

methanol in 5 min, held for 5 min

APcI (

+ mode)

302 [M

+ H]

+

, 230 [M

+ H − (CH

3

)

2

NCO]

+

Vaporizer temperature, 325

◦

C; nebulizer gas, N

2

, at

4.1 bar; drying gas, N

2

, at 4 L min

−1

and temperature

350

◦

C; capillary voltage, 4000 V; corona current, 4 µA

ESI (

+ mode)

302 [M

+ H]

+

Gas temperature, 350

◦

C at 13 L min

−1

; nebulizer gas

pressure, 30 psi; capillary voltage, 4000 V

Injection volume

5 µL

Retention time for

26–30 min

fenoxycarb

Operating parameters for meat, milk, blood, and eggs

High-performance

liquid chromatograph

Two Waters Model 501 pumps

Perkin-Elmer Model ISS-100 automatic sampler

Kratos ABI Spectroflow Model 783 UV/VIS detector,

VICI EQ60 LC switching valve

Column 1

Supelcosil LC-CN, 33

× 4.6-mm i.d., 5-µm particle

size

Column 2

Supelcosil LC-1, 250

×4.6-mm i.d., 5-µm particle size

Mobile phase 1

0.02 M potassium dihydrogenphosphate (adjusted to

pH 3 with phosphorous acid)–methanol (7 : 3, v/v)

Mobile phase 2

0.02 M potassium dihydrogenphosphate (adjusted to

pH 3 with phosphorous acid)–methanol–acetonitrile

(12 : 5 : 3, v/v/v)

Detector wavelength

235 nm

Flow rate

1.5 mL min

−1

Injection volume

50 µL

Retention time ranges

Fenoxycarb: 14–27 min

Ro16-8797: 10–16 min

Ro-17-3192: 5.6–8 min

7

Evaluation

7.1

Method

Quantification was performed in all cases using the external calibration method.

A series of standards were injected and the responses plotted against their known

concentrations. Peak responses in samples were compared with the calibration plots

1306

Individual compounds

to obtain the amount found (nanograms). A fresh calibration plot was generated with

each analytical set of samples.

7.2

Recoveries, limit of detection (LOD) and limit

of quantitation (LOQ)

The lower practical level of quantitation for fenoxycarb in air is 10 µg m

−3

using the

described sampling rates and times. The average recovery obtained from fortifying

and extracting the OVS tubes was 94%.

The recoveries of fenoxycarb (CGA-114597) from water ranged from 71 to 90%

at fortification levels from 0.05 to 1 µg L

−1

. The LOQ was 0.05 µg L

−1

.

The average recovery obtained for fenoxycarb when the analysis of pond water

was performed using three-column switching LC/fluorescence detection was 100%

at fortification levels ranging from 0.001 to 10 µg L

−1

. The LOQ and LOD were

0.001 µg L

−1

and 0.4 ng injected, respectively.

The average recoveries for fenoxycarb in soil were 89, 105, and 104% for soil

collected in California, Washington, and Georgia, respectively, at fortification levels

ranging from 0.01 mg kg

−1

to 1.0 mg kg

−1

. The LOQ and LOD were 0.01 mg kg

−1

and 0.2 ng injected, respectively.

The average recovery obtained for fenoxycarb in pasture grass at the method LOQ

was 82%. At all fortification levels, the average recovery for pasture grass was 81%.

For cucurbits (cucumbers, squash, cantalope) the average recovery at the method

LOQ were 102% and for all fortification levels is 99%. The LOQ and LOD were

0.01 mg kg

−1

and 2 ng injected, respectively, using LC. The average recovery for

the analysis of pasture grass forage and pasture grass hay using GC/MS were 97%

and 85%, respectively. The recovery data obtained using LC/UV and GC/MS were

comparable. However, confirmatory evidence was obtained using GC/MS.

The average recoveries and standard deviations for the many citrus, pome fruit,

tree nut, fruiting vegetables, and cotton substrate sample types were acceptable when

fortified at concentration levels ranging from 0.01 to 4 mg kg

−1

. The LOQ of the

method was 0.01 mg kg

−1

, except for citrus oil (0.02 mg kg

−1

), and the LOD was

1.25 ng injected.

The fenoxycarb recoveries for orange, onion, grape, and tomato samples ranged

from 63 to 70%. The LOQ and LOD were 0.01 mg kg

−1

and 0.005 mg kg

−1

, respec-

tively, when using liquid chromatography/electrospray ionization mass spectrometry

(LC/ESI/MS).

Average recoveries for fenoxycarb, Ro-16-8797, and Ro-17-3192 for all animal

sample substrates ranged from 80% (beef kidney) to 111% (goat kidney), 76% (goat

milk) to 93% (beef omental fat), and 56% (dairy milk) to 76% (beef perirenal fat),

respectively. The LOQ and LOD were 0.01 µg g

−1

and 2.5 ng injected, respectively.

7.3

Calculation of residues

Water

µ

g kg

−1

= AC100/B DR

Fenoxycarb

1307

where A

= ng found (from the calibration plot), B = injection volume, C = final

fraction volume, D

= weight of sample extracted, and R = percentage recovery (ex-

pressed as a decimal).

Pond water

ppb

= ng found/mL injected

where ng found is taken from the calibration plot,

g injected

= gV

i

/V

f

where g

= weight of sample (1.0 mL = 1.0 g), V

i

= volume of sample injected into

the LC system, and V

f

= final fraction volume.

Soil

ppm (µg g

−1

)

= (µg g

−1

equivalents from calibration plot) (V

f

/W

s

) (dilution

factor)

where V

f

= final fraction volume (mL) and W

s

= sample weight (g).

Plant and animal sample substrates

mg injected

= GV

a

V

i

/[(V

e

+ W(M/100)]V

f

where G

= mg sample extracted, V

a

= aliquot volume, V

e

= extraction volume,

V

i

= injection volume, M = sample moisture (%), and W = sample weight (g).

ppm

= ng found from calibration plot/mg sample injected

Reference

1. M. Fernandez, Y. Pico, and J. Manes, J. Chromatogr. A, 871, 43 (2000).

Robert A. Yokley

Syngenta Crop Protection, Inc., Greensboro, NC, USA

Document Outline

- Front Matter

- Table of Contents

- Volume I

- Volume II

- Recent Advances in Analytical Technology, Immunoassay and Other Nonchromatographic Methods

- Best Practices in the Generation and Analyses of Residues in Environmental Samples

- Compound Class

- Individual Compounds

- Azoxystrobin

- Famoxadone

- Fluthiacet-Methyl

- Flutolanil

- Hymexazol

- Imibenconazole

- Mepanipyrim

- Mepronil

- Tebuconazole

- Acetamiprid

- Alanycarb

- Azinphos-Methyl

- Benfuracarb

- Buprofezin

- Cyfluthrin

- Fenothiocarb

- Fenoxycarb

- Fenpyroximate

- Hexythiazox

- Imidacloprid

- Isoxathion

- Milbemectin

- Pyrimidifen

- Pyriproxyfen

- Index

Wyszukiwarka

Podobne podstrony:

91942 08w

91942 abb

91942 04m

91942 05d

91942 03d

91942 01e

91942 08j

91942 05b

91942 08p

91942 04b

91942 08u

91942 06c

91942 04i

91942 01c

91942 03c

91942 01a

91942 08x

91942 03f

91942 toc

więcej podobnych podstron