Pyrimidifen

Materials to be

analyzed

Apple, pear, orange, peach, strawberry, cabbage, radish,

tea and soil

Instrumentation

High-performance liquid chromatographic determina-

tion for plant materials

1

Introduction

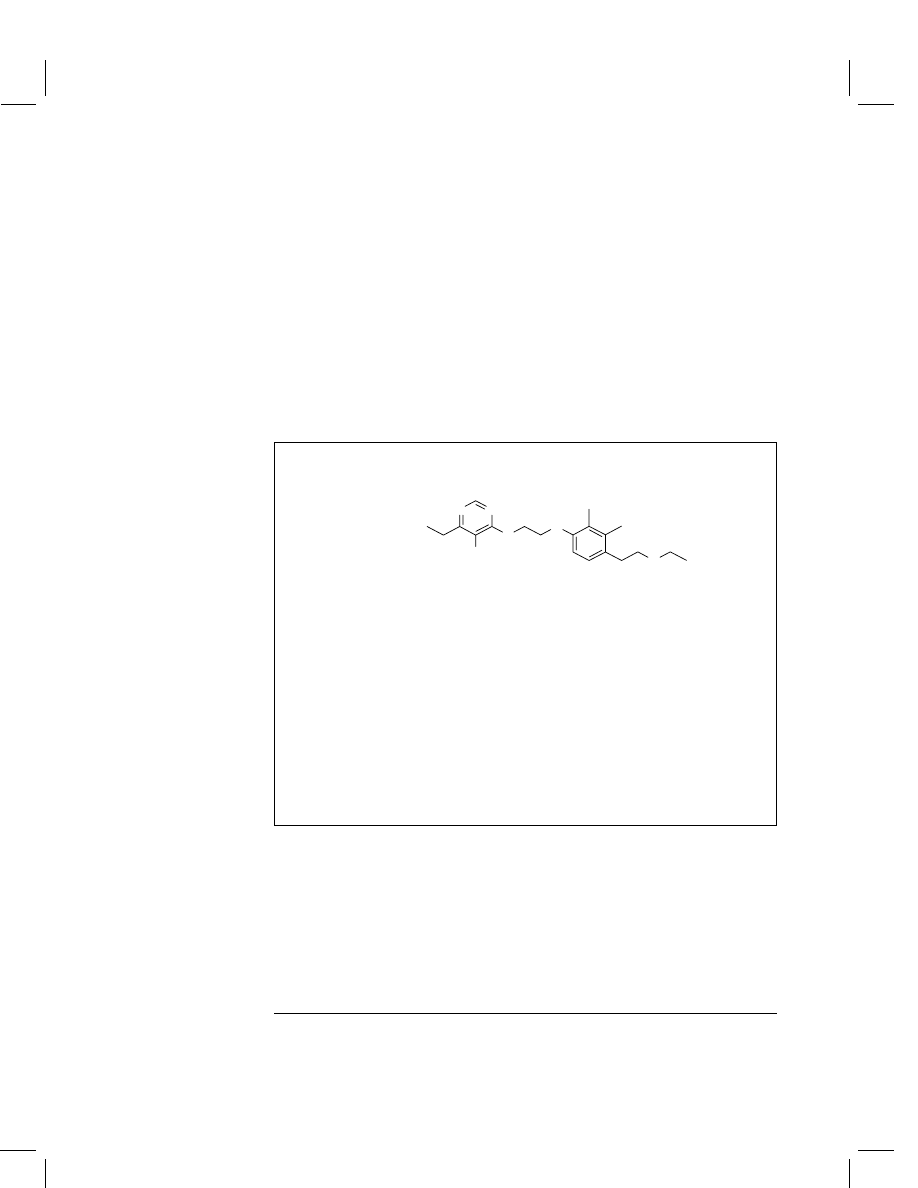

Chemical name

(IUPAC)

5-Chloro-N-

{2-[4-(2-ethoxyethyl)-2,3-dimethyl-

phenoxy] ethyl

}-6-ethylpyrimidin-4-amine

Structural formula

N

N

N

H

O

O

Cl

Empirical formula

C

20

H

28

ClN

3

O

2

Molar mass

377.9

Form

Colorless crystals

Melting point

69.4–70.9

◦

C

Vapor pressure

1.6

× 10

−4

mPa (25

◦

C)

Log P

4.59 (23

◦

C)

Solubility

Water 2.17 mg L

−1

(25

◦

C)

Stability

Stable in acid and alkali

Use pattern

Pyrimidifen is used as an acaricide for apple, pear,

orange, peach, strawberry, cabbage, radish and tea

Regulatory position

The definition of residue is for the parent, pyrimidifen,

only

2

Outline of method

Pyrimidifen is extracted from plant materials with methanol–water (7 : 3, v/v). The

extracts are concentrated and pyrimidifen is partitioned with n-hexane after addition

of sodium chloride. The organic phase is collected and concentrated. Pyrimidifen in

the organic phase is purified by silica gel column chromatography. Pyrimidifen is

dissolved in acetonitrile and injected into a high-performance liquid chromatography

Handbook of Residue Analytical Methods for Agrochemicals.

C

2003 John Wiley & Sons Ltd.

Pyrimidifen

1337

(HPLC) system equipped with an ODS column and ultraviolet (UV) detector for

quantitative determination.

3

Apparatus

Volumetric flask, 300-mL

Round-bottom flask, 500-mL

Separatory funnel, 150-mL

Rotary evaporator: Model NE-1 (Tokyo Rikakikai Co., Japan)

High-performance liquid chromatograph: Model LC-10A (Shimadzu Co., Japan)

Integrator: Chromatopac Model C-R7A (Shimadzu Co., Japan)

4

Reagents

Pyrimidifen: analytical standard,

>99% purity

Methanol, n-hexane, ethyl acetate, distilled water, sodium chloride, sodium sulfate,

reagent grade for residue analysis (Wako Pure Chemical Industries, Ltd, Japan)

Acetonitrile, methanol, distilled water, reagent grade for high-performance liquid

chromatography

Silica gel: for column chromatography (200-mesh, Nakalai Tesque, Japan)

Celite No. 545: for chemical analysis (Nakalai Tesque, Japan)

5

Sampling and preparation

No specific sample preparation and processing are needed for this method.

6

Procedure

6.1

Extraction

A 10-g amount of each minced and homogenized plant sample is weighed into a

300-mL volumetric flask, 100 mL of methanol–water (7 : 3, v/v) are added and the

mixture is shaken vigorously for 30 min. The resulting mixture is filtered with a

glass filter by suction. The residue is re-extracted with 100 mL of the same solvent

and filtered. The combined aqueous methanol extracts are transferred into a 500-mL

round-bottom flask and concentrated to 30 mL under reduced pressure below 45

◦

C.

6.2

Cleanup

6.2.1

Partition into n-hexane

The resulting solution obtained from above is transferred into a 150-mL separatory

funnel and 50 mL of n-hexane and 3 g of sodium chloride are added. After shaking

1338

Individual compounds

for 5 min, the n-hexane layer is collected. To the aqueous layer, 50 mL of n-hexane

are added and the partition procedure is repeated. The combined n-hexane extracts

are dried by passing through a funnel containing 50 g of anhydrous sodium sulfate.

The filtrate is collected in a round-bottom flask and concentrated to dryness under

reduced pressure below 45

◦

C.

6.2.2

Silica gel column chromatography

A 5-g amount of a mixture of silica gel and Celite 545 (3 : 1, w/w) is packed into a

glass column (2-cm i.d., length 30-cm) with n-hexane–ethyl acetate (4 : 1, v/v). The

residue obtained from Section 6.2.1 is dissolved in 15 mL of n-hexane–ethyl acetate

(4 : 1, v/v), transferred on to the column and drained. The column is washed with

another 35 mL of the same solvent and drained. Pyrimidifen is eluted with 150 mL of

the same solvent. The eluate is concentrated to dryness under reduced pressure below

45

◦

C.

6.3

Determination

The cleaned-up sample is dissolved in 4 mL of acetonitrile and 20 µL of the solution

are injected into the previously conditioned HPLC system and the residue concentra-

tion is determined.

Operating conditions

Column

Cosmosil 5C

18

4.6-mm i.d.

× 250-mm length

(Nakalai Tesque, Japan)

Mobile phase

Methanol–acetonitrile–water (9 : 6 : 5, v/v/v)

Flow rate

1 mL min

−1

Column temperature

40

◦

C

UV wavelength

245 nm

Retention time

17 min

7

Evaluation

7.1

Method

Quantitation is performed by the calibration technique. The calibration curve is con-

structed with pyrimidifen standard solutions, plotting the peak height against the

injected amount of pyrimidifen.

7.2

Limit of detection

The limit of detection of pyrimidifen by this method is 0.005 mg kg

−1

, as shown

below.

Minimum detectable amount: 0.25 ng

Detection limit

= (0.25 ng × 4 mL)/(20 µL × 10 g) = 0.005 mg kg

−1

Pyrimidifen

1339

Sample volume injected: 20 µL

Final solution volume: 4 mL

Sample weight: 10 g

7.3

Recovery

The recovery of pyrimidifen from an apple fruit sample fortified at the 0.2 mg kg

−1

level is 95%.

7.4

Calculation of residue

The residue R, expressed in mg kg

−1

pyrimidifen, is calculated using the following

equation:

R

= (W × V

End

)

/(V

i

× G)

where

G

= sample weight (g)

V

End

= terminal volume of sample solution from Section 6.3 (mL)

V

i

= portion of volume of V

End

injected into the HPLC system (µL)

W

= amount of pyrimidifen for V

i

read from the calibration curve (ng)

8

Important point

Pyrimidifen residues in fruits such as apple and orange are stable (

>90%) after frozen

storage for 2 months.

Shingo Sadakane, Takashi Ueda, Takashi Saito,

Setsuko Katsurada and Mariko Sabi

Sankyo Co. Ltd, Shiga, Japan

Document Outline

- Front Matter

- Table of Contents

- Volume I

- Volume II

- Recent Advances in Analytical Technology, Immunoassay and Other Nonchromatographic Methods

- Best Practices in the Generation and Analyses of Residues in Environmental Samples

- Compound Class

- Individual Compounds

- Azoxystrobin

- Famoxadone

- Fluthiacet-Methyl

- Flutolanil

- Hymexazol

- Imibenconazole

- Mepanipyrim

- Mepronil

- Tebuconazole

- Acetamiprid

- Alanycarb

- Azinphos-Methyl

- Benfuracarb

- Buprofezin

- Cyfluthrin

- Fenothiocarb

- Fenoxycarb

- Fenpyroximate

- Hexythiazox

- Imidacloprid

- Isoxathion

- Milbemectin

- Pyrimidifen

- Pyriproxyfen

- Index

Wyszukiwarka

Podobne podstrony:

Elektrotechnika i elektronika 07 i 08w

91942 abb

91942 08q

91942 04m

91942 05d

91942 03d

91942 01e

91942 08j

91942 05b

91942 08p

91942 04b

91942 08u

91942 06c

91942 04i

91942 01c

91942 03c

91942 01a

91942 08x

91942 03f

więcej podobnych podstron