Fenothiocarb

Materials to be

analyzed

Mandarin oranges (juice, pulp, rind), leaves of mandarin

orange tree, soil

Instrumentation

Gas-chromatographic determination

1

Introduction

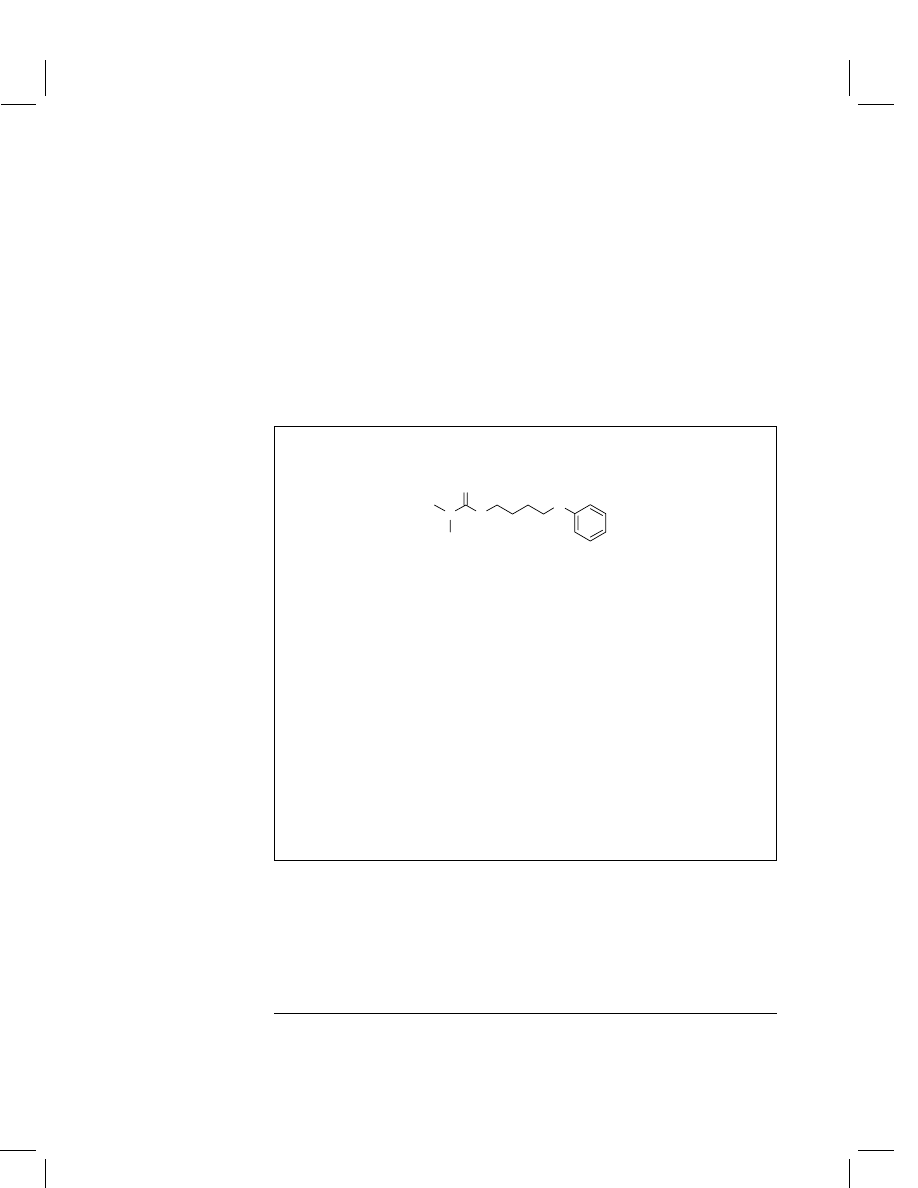

Chemical name

(IUPAC)

(S)-4-Phenoxybutyl dimethylthiocarbamate

Structural formula

O

S

N

O

Empirical formula

C

13

H

19

NO

2

S

Molar mass

253.4

Melting point

40–41

◦

C

Boiling point

155

◦

C at 0.02 mmHg

Vapor pressure

0.166 mPa at 23

◦

C

Solubility

In water 30 mg L

−1

(20

◦

C). In cyclohexanone 3800,

acetonitrile

3120,

acetone

2530,

xylene

2464,

methanol 1426, kerosene 80, hexane 66 g L

−1

(20

◦

C).

Stability

Slowly decomposed by sunlight. Stable to hydrolysis

for 5 days (pH 5–9, 40

◦

C);

<1% decomposition after

60 days at 55

◦

C.

Use pattern

Fenothiocarb is a nonsystemic acaricide used to con-

trol the eggs and larval stages of Panonychus spp.

Regulatory position

The residue definition is for the parent, fenothiocarb

only.

2

Outline of method

Plant substances (juice, pulp, rind, and leaf) are homogenized with anhydrous sodium

sulfate and methanol and fenothiocarb residue is extracted with acidic methanol [0.5 N

hydrochloric acid–methanol (1 : 3, v/v)] by refluxing for soil. Fenothiocarb in the

Handbook of Residue Analytical Methods for Agrochemicals.

C

2003 John Wiley & Sons Ltd.

Fenothiocarb

1289

extract of plant substances is extracted with hexane. Since oily plant substances af-

fect the subsequent cleanup process, fenothiocarb in the hexane extract is partitioned

into acetonitrile. The concentrated acetonitrile extracts are purified by silica gel col-

umn chromatography with benzene. Fenothiocarb in the soil extract is dissolved in

dichloromethane and purified by silica gel column chromatography with benzene.

Fenothiocarb is determined by gas chromatography using a sulfur-specific flame

photometric detector.

3

Apparatus

Blender (kitchen type)

Juicer mixer (automatic juicer)

High-speed blender (Waring blender, or equivalent)

Bell jar-type filtering apparatus

Buchner funnel, 11-cm i.d.

Rotary vacuum evaporator, 40

◦

C bath temperature

Water-bath, electrically heated, temperature 70

◦

C

Condenser

Round-bottom flasks, 500- and 300-mL

Separatory funnels, 1000-, 300-, and 200-mL

Glass funnel, 10-cm i.d.

Glass chromatography column, 1.5-cm i

.d. × 30 cm with a stopcock

Silica gel column: place a cotton wool plug at the bottom of a glass chromatography

column. Pack 10 g of silica gel slurried with benzene into the glass column. Make

an anhydrous sodium sulfate layer about 1-cm above and below the silica gel bed.

Gas chromatograph equipped with a sulfur-specific flame photometric detector

Microsyringe, 10-µL

4

Reagents

Acetone, acetonitrile, benzene, dichloromethane, n-hexane, and methanol, pesticide

residue analysis grade

Distilled water, HPLC grade

Anhydrous sodium sulfate, hydrochloric acid (36%), sodium chloride, special grade

Silica gel, Wakogel C-100, adjust water content to 6.5% with distilled water (Wako

Pure Chemical Industries, Ltd)

Filter aid, Celite 545 (Johns-Manville Products Corporation)

Filter paper, 11-cm i.d.

Fenothiocarb, analytical grade (Ihara Chemical Industries Co., Ltd)

Fenothiocarb standard solutions: 0.2, 0.5, 1, 2, and 3 µg mL

−1

in acetone

5

Sampling and sample preparation

Collect 2 kg of orange fruits randomly and use 1 kg for juice and the other 1 kg for

pulp and rind. Prepare the juice by crushing oranges directly with a juicer mixer.

1290

Individual compounds

Homogenize pulp with a blender and rind by chopping with a knife. Collect 50 g of

leaf randomly and homogenize by chopping with a knife. Soil, collected from the

top10-cm surface layer, is homogenized and passed through a 5-mm sieve.

6

Procedure

6.1

Extraction

6.1.1

Orange juice and pulp

Homogenize 50 g of the sample for 5 min with 75 mL of methanol and 10 g of

anhydrous sodium sulfate. Add 10 g of Cellite-545 to the homogenate and mix well,

and filter the mixture through a filter paper in a Buchner funnel into a 300-mL round-

bottom flask. Rinse the residue in a blender with 50 mL of a mixture of water and

methanol (1 : 1, v/v). Combine the filtrates.

6.1.2

Orange rind

Homogenize 25 g of the sample for 5 min with 75 mL of methanol, 25 mL of water

and 10 g of anhydrous sodium sulfate. Conduct the subsequent procedures in a similar

manner as described for juice and pulp.

6.1.3

Orange leaves

Homogenize 5 g of the sample for 5 min with 45 mL of methanol, 25 mL of water

and 5 g of anhydrous sodium sulfate. Conduct the subsequent procedures in a similar

manner as described for juice and pulp. Rinse the residue with 30 mL of a mixture of

water and methanol (1 : 1, v/v).

6.1.4

Soil

Weigh 40 g (dry soil weight) of the sample into a 300-mL round-bottom flask, add

120 mL of acid–methanol solution [a mixture of 0.5 N hydrochloric acid and methanol

(1 : 3, v/v)], and reflux the sample at 70

◦

C for 4 h after attaching a condenser.

Add 15 g of Cellite-545 to the sample and mix well, then filter the mixture through a

filter paper in a Buchner funnel into a 500-mL flask. Rinse the 300-mL round-bottom

flask and the residue with 100 mL of methanol.

6.2

Cleanup

6.2.1

Orange juice, pulp and rind

Transfer the sample extract (from Section 6.1) into a 300-mL separatory funnel,

add 50 mL of water and extract the sample with 50 mL of n-hexane three times.

Separate and dry the n-hexane layer with anhydrous sodium sulfate (plug the funnel

with absorbent cotton and 50 g of anhydrous sodium sulfate), and collect the dried

extract in a 300-mL of separatory funnel. Add 50 mL of acetonitrile to the separatory

funnel and mix well for partitioning with the n-hexane extract three times. Collect the

Fenothiocarb

1291

acetonitrile layer in a 300-mL round-bottom flask. Evaporate the acetonitrile under

reduced pressure. Dissolve the residue in 3 mL of benzene.

Adsorb the benzene solution on the top of the silica gel column (10 g of silica

gel) and elute with benzene. Discard the first 50 mL of eluate. Collect the subsequent

fractions of 150 mL in a 300-mL round-bottom flask and evaporate the solvent un-

der reduced pressure. Dissolve the residue in an appropriate volume of acetone for

analysis.

6.2.2

Orange leaves

Transfer the sample extract (from Section 6.1) into a 200-mL separatory funnel, add

30 mL of water and extract the sample extract three times with 30 mL of n-hexane.

Collect and dry the n-hexane layer with anhydrous sodium sulfate in a funnel in a

similar manner as described for the juice, pulp and rind, and evaporate the solvent

under reduced pressure. Dissolve the residue in 3 mL of benzene and clean up the

sample by silica gel column chromatography in a similar manner as described for

juice, pulp and rind.

6.2.3

Soil

Transfer the soil extract (from Section 6.1) into a 1000-mL separatory funnel, add

200 mL of water and 10 mL of saturated sodium chloride solution, and extract the

sample with 100 mL of dichloromethane three times. Dry the dichloromethane ex-

tract with anhydrous sodium sulfate in a funnel in a similar manner as described for

juice, pulp and rind, and collect the dried solution in a 500-mL round-bottom flask.

Evaporate the dichloromethane under reduced pressure. Dissolve the residue in 3 mL

of benzene.

Cleanup the sample by silica gel column chromatography in a similar manner as

described for juice, pulp and rind.

6.3

Gas-chromatographic determination

Inject an aliquot (V

i

) of the solution prepared from Section 6.2 (V

End

) into the gas

chromatograph

Operating conditions

Gas chromatograph (Hitachi 163)

Column

Glass, 3-mm i

.d. × 1.0-m length, packed with 1% FFAP

on Chromosorb W HP, 100–120 mesh

Column temperature

215

◦

C

Injection port temperature

240

◦

C

Detector

Flame photometric detector fitted with a 394-nm sulfur-

specific filter, temperature 150

◦

C

Gas flow rates

Nitrogen carrier gas, 50 mL min

−1

Hydrogen, 50 mL min

−1

Oxygen, 15 mL min

−1

Attenuation

32

× 100

Chart speed

10 mm min

−1

1292

Individual compounds

Injection volume

1–4 µL

Retention time

3.4 min

Minimum detectable amount

0.2 ng

7

Evaluation

7.1

Method

Quantitation is performed by the calibration technique. Construct a fresh calibration

curve with fenothiocarb standard solutions for each set of analyses.

Inject 1 µL of each fenothiocarb standard solution into the gas chromatograph.

Using log–log paper, plot the peak heights in millimeters against the injected amount

of fenothiocarb in nanograms.

Also inject 1–4-µL aliquots of the sample solutions. From the peak heights of the

peaks obtained for these solutions, read the appropriate amounts of fenothiocarb from

the calibration curve.

7.2

Recoveries, limit of detection and limit of determination

7.2.1

Edible part (juice, pulp)

The recoveries from control samples fortified with fenothiocarb at levels of 0.002–

0.10 mg kg

−1

ranged from 81 to 106% and from 87 to 90%, respectively.

The limit of detection was 0.001 mg kg

−1

and the limit of determination was

0.002 mg kg

−1

.

7.2.2

Inedible part (rind, leaf)

The recoveries from control samples fortified with fenothiocarb at levels of 0.02–

1.0 mg kg

−1

ranged from 88 to 98% and from 80 to 94%, respectively.

The limit of detection was 0.01 mg kg

−1

and the limit of determination was

0.02 mg kg

−1

.

7.2.3

Soil

The recoveries from control samples fortified with fenothiocarb at levels of 0.2–

0.4 mg kg

−1

ranged from 86 to 100% and from 83 to 94%, respectively.

The limit of detection was 0.05 mg kg

−1

.

7.3

Calculation of residues

The residue R, expressed in mg kg

−1

fenothiocarb, is calculated from the following

equation:

R

= (W

A

× V

End

)

/(V

i

× G)

Fenothiocarb

1293

where

G

= sample weight (g)

V

End

= terminal volume of sample solution from Section 6.2 (mL)

V

i

= portion of volume V

End

injected into gas chromatograph (µL)

W

A

= amount of fenochiocarb for V

i

read from calibration curve (ng)

8

Important points

1. Solvent for extraction of fenothiocarb in plant substances. Based on the exami-

nation using the field sample, methanol was selected as the solvent for extracting

fenothiocarb in orange. The extraction efficiency of fenothiocarb was higher with

acetone or methanol and was slightly lower with acetonitrile and dichloromethane.

For the ability to extract fenothiocarb and metabolites

1

simultaneously,

2

methanol

was superior to acetone.

2. Extraction method of fenothiocarb in soil.

3

The extraction efficient of fenothiocarb

in soil was evaluated using diluvial soil (orange field) and volcanic ash soil allowed

to stand in a greenhouse immediately after and for 5 days and 2 months under an

upland field condition after addition of fenothiocarb at a level of 10 mg kg

−1

.

The extraction recovery of fenothiocarb in the sample immediately and 5 days after

addition showed no marked difference but showed a substantial difference after

2 months, suggesting the extraction of fenothiocarb remaining in soil for a long

time. The optimum time of refluxing for extraction showing the highest recovery

of fenothiocarb was about 1 h for diluvial soil and about 4 h for volcanic ash soil.

3. Water used to adjust water content in silica gel should be sprayed uniformly. The

water content is measured by heating at 105

◦

C. If it is not uniformly sprayed, the

position of the first elution of fenothiocarb hardly changes, but the fraction will

be collected over an extended period.

4. A large amount of oily substance in the plant extract can vary the elution volume

of fenothiocarb in silica gel column chromatography.

5. Packing materials for column chromatography. Adequate cleanup can be achieved

with alumina instead of silica gel. Activated carbon is not suitable for sample

cleanup of ripe orange and leaf.

6. Sample storage stability. The level of fenothiocarb (0.4 mg kg

−1

) in soils stored in

the dark at 3

◦

C decreased to 94–97% after 40 days and to 68–82% after 120 days.

References

1. T. Unai, M. Tamaru, and C. Tomizawa, J. Pestic. Sci., 11, 347 (1986).

2. Y. Fukai, T. Oishi, Y. Asano and K. Ishikawa, ‘An analytical method of fenothiocarb and its

3 metabolites in mandarin oranges (juice, pulp, rind),’ in “Abstracts of the 9th Annual Meeting

of the Pesticide Science Society of Japan,” p. 150 (1984).

3. A. Yagi, Y. Asano, and K. Ishikawa, ‘Extraction method for fenothiocarb in soils,’ in “Abstracts

of the 5th Annual Meeting of the Pesticide Residue Analysis Society,” pp. 35–38 (1981) (in

Japanese).

Akira Yagi, Mitsumasa Ikeda and Yoshihiro Saito

Kumiai Chemical Industry Co. Ltd, Shizuoka, Japan

Document Outline

- Front Matter

- Table of Contents

- Volume I

- Volume II

- Recent Advances in Analytical Technology, Immunoassay and Other Nonchromatographic Methods

- Best Practices in the Generation and Analyses of Residues in Environmental Samples

- Compound Class

- Individual Compounds

- Azoxystrobin

- Famoxadone

- Fluthiacet-Methyl

- Flutolanil

- Hymexazol

- Imibenconazole

- Mepanipyrim

- Mepronil

- Tebuconazole

- Acetamiprid

- Alanycarb

- Azinphos-Methyl

- Benfuracarb

- Buprofezin

- Cyfluthrin

- Fenothiocarb

- Fenoxycarb

- Fenpyroximate

- Hexythiazox

- Imidacloprid

- Isoxathion

- Milbemectin

- Pyrimidifen

- Pyriproxyfen

- Index

Wyszukiwarka

Podobne podstrony:

91942 08w

91942 abb

91942 08q

91942 04m

91942 05d

91942 03d

91942 01e

91942 08j

91942 05b

91942 04b

91942 08u

91942 06c

91942 04i

91942 01c

91942 03c

91942 01a

91942 08x

91942 03f

91942 toc

więcej podobnych podstron