Acetamiprid

Materials to be

analyzed

Cabbage, potato, radish (leaf), radish (root), grape, citrus,

apple, pear, strawberry, cucurbits, green pepper, egg-

plant, tomato, green tea (powder), green tea (leachate)

and soil

Instrumentation

Gas-chromatographic determination for plant materials

High-performance liquid chromatographic determination

for soil

1

Introduction

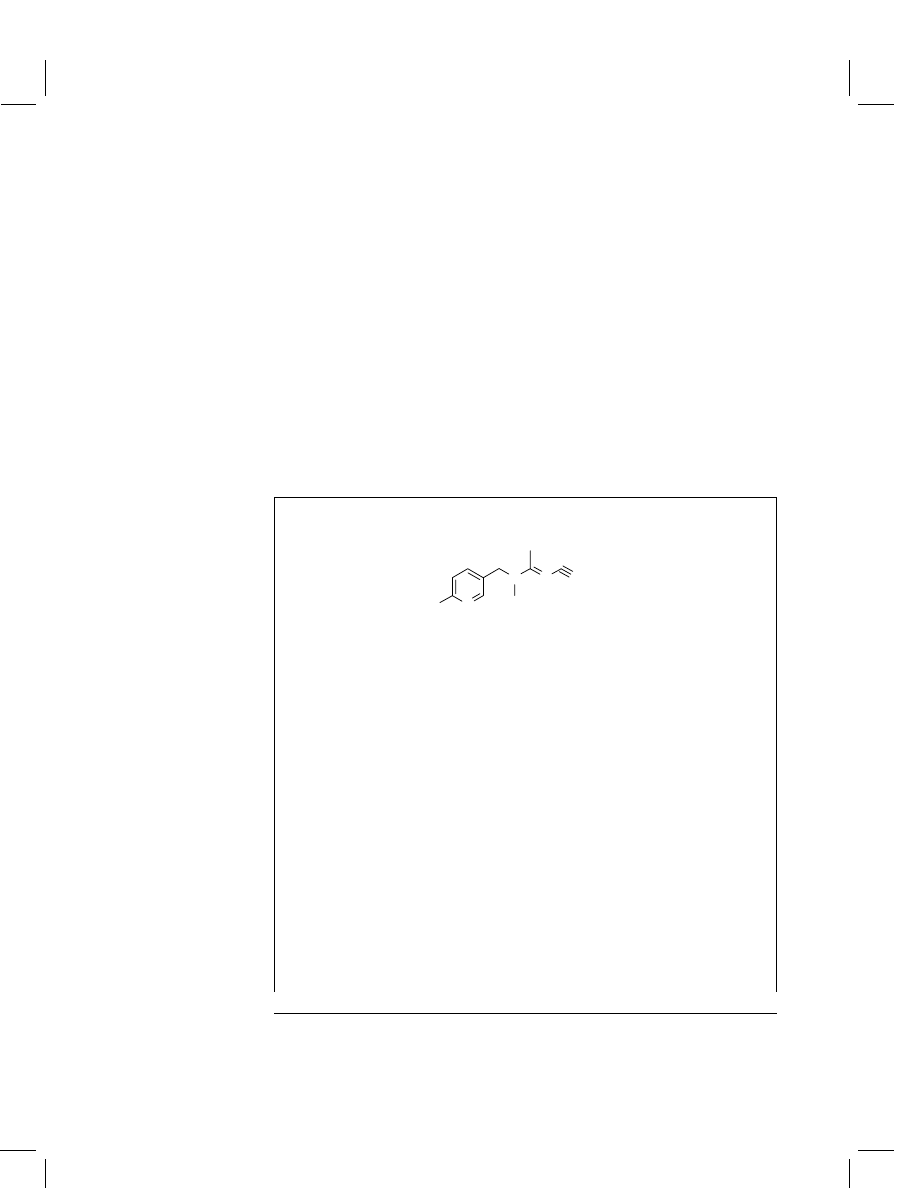

Chemical name

(IUPAC)

(E )-N

1

-[(6-Chloro-3-pyridyl)methyl-N

2

-cyano-N

1

-methyl-

acetamidine

Structural formula

N

N

N

N

CI

Empirical formula

C

10

H

11

Cl N

4

Molar mass

222.7

Melting point

98.9

◦

C

Vapor pressure

<1×10

−6

Pa at 25

◦

C

Solubility

Water 4.25 g L

−1

at 25

◦

C

Readily soluble in organic solvents such as ace-

tone, acetonitrile, chloroform, dichloromethane and

methanol

Stability

Stable in an acidic to neutral aqueous solution. Unsta-

ble in strongly basic conditions

Stable in most organic solvents

Use pattern

Acetamiprid is a neonicotinoid insecticide with out-

standing systemic activities and a broad insecticidal

spectrum. Acetamiprid controls diverse soil and foliar

insect pests infesting cotton, sugar beet, vegetables,

fruits and other major food crops by both contact and

stomach action

Regulatory position

The residue definition for plant samples is acetamiprid

only. In soil, it includes acetamiprid and three of its

Handbook of Residue Analytical Methods for Agrochemicals.

C

2003 John Wiley & Sons Ltd.

Acetamiprid

1243

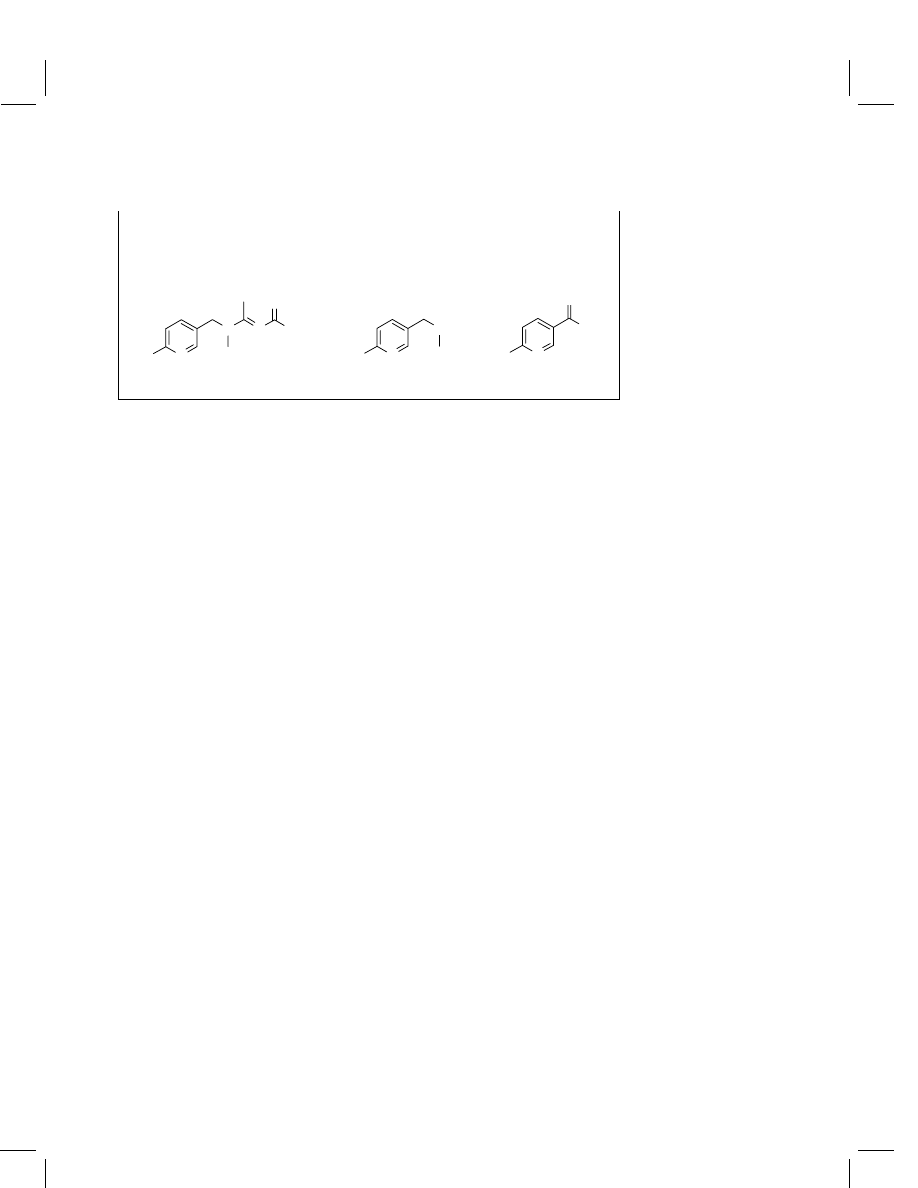

metabolites, (E )-N

2

-carbamoyl-N

1

-[(6-chloro-3-

pyridyl)methyl-N

1

-methylacetamidine (IM-1-2),

N-methyl-[(6-chloro-3-pyridyl)methylamine (IM-

1-4) and 6-chloronicotinic acid (IC-0)

IM-1-2

N

N

N

CI

NH

2

O

IM-1-4

N

NH

CI

IC-0

N

OH

CI

O

2

Outline of method

2.1

Plant

Plant materials are homogenized with methanol. Acetamiprid residue is extracted with

dichloromethane by liquid–liquid partitioning. Dichloromethane is removed by rotary

evaporation, and the residue is subjected to a clean-up procedure using Florisil PR

column chromatography. The concentrated eluate is analyzed by gas chromatography

(GC).

2.2

Soil

Soil sample is extracted with a mixture of methanol and 0.1 M ammonium chlo-

ride. Acetamiprid, IM-1-2 and IM-1-4 residues are extracted with dichloromethane

under alkaline conditions. After adding diethylene glycol, dichloromethane in the

extract is removed by rotary evaporation, and the residue is subjected to a cleanup

procedure using Florisil PR column chromatography and then with a packed Extrelut

20 column.

IC-0 residue is cleaned up with a mixture of dichloromethane and acetone by

liquid–liquid partitioning under neutral conditions and then extracted into diethyl

ether under acidic conditions. The diethyl ether in the extract is removed by rotary

evaporation and the residue is dissolved in buffer solution, which is subjected to a

cleanup procedure using a Sep-Pak C

18

Env. column.

The concentrated eluate is subjected to high-performance liquid chromatography

(HPLC) analysis.

3

Apparatus

High-speed blender fitted with leak-proof glass jar and explosion-proof motor

Balances

Macerator (Polytron)

Laboratory mechanical shaker

1244

Individual compounds

Glass tube for column chromatography, 15-mm i.d., 30-mm length

Separatory funnels, 200-mL, 500-mL and 1-L

Filter paper

Erlenmeyer flask, 500-mL

Round-bottom flasks, 300-mL

Rotary vacuum evaporator

Stainless-steel centrifuge tube, 250-mL

Ultracentrifuge

pH meter

Packed column (Extrelut 20)

Packed column (Sep-Pak C

18

)

Packed column (Sep-Pak C

18

Env.)

Gas chromatograph equipped with an electron capture detector

High-performance liquid chromatograph

4

Reagents

Methanol, guaranteed reagent grade

Celite (No. 545)

Sodium chloride, guaranteed reagent grade

n-Hexane, guaranteed reagent grade

Dichloromethane, guaranteed reagent grade

Sodium hydroxide, guaranteed reagent grade

Sodium sulfate, anhydrous, guaranteed reagent grade

Florisil, nonactivated (Florisil PR)

Ammonium chloride, guaranteed reagent grade

Diethylene glycol, guaranteed reagent grade

Hydrochloric acid, guaranteed reagent grade

Acetone, guaranteed reagent grade

Diethyl ether, guaranteed reagent grade

Acetonitrile, guaranteed reagent grade

Disodium hydrogenphosphate, guaranteed reagent grade

Citric acid, anhydrous

Nitrogen, repurified

5

Sampling and preparation

5.1

Green tea

Grind leaves with dry-ice using a high-speed blender.

5.2

Fruits and vegetables

Cut into pieces with a kitchen knife.

Acetamiprid

1245

6

Procedure

6.1

Extraction

6.1.1

Plant material

Homogenize 20 g of a prepared sample with 100 mL of methanol in a macerator

for 3 min and shake for 30 min with a mechanical shaker. In the case of green tea

(powder), soak 4 g of a prepared sample with 16 mL of distilled water for 2 h. Add

100-mL of methanol and shake for 30 min.

Filter the homogenate through a Celite layer (1–2 cm thickness) under reduced

pressure. Wash the cake and vessel twice with 25 mL of methanol and filter the wash-

ings through the same Celite layer. Combine these filtrates and transfer to a 500-mL

separatory funnel. Add 150 mL of 5% sodium chloride solution to the filtrate and

wash twice with 100 mL of hexane for 10 min. Discard the hexane extract. Transfer

the aqueous methanol to another 500-mL separatory funnel. In the case of green tea

(leachate), soak 4 g of the ground sample in 240 mL of boiling water for 5 min. Filter

the mixture through a filter paper and cool to ambient temperature. Remove half of the

filtrate for further analysis (corresponds to 2 g of green tea dried). Add 5 g of sodium

chloride and 120 mL of methanol to the filtrate and then wash twice with 100 mL of

hexane for 10 min. Discard the hexane extract. Transfer the aqueous methanol into

a 500-mL separatory funnel. Extract the solution with two portions of 100 mL of

dichloromethane for 10 min. Collect the dichloromethane in a flask. In the case of

citrus, wash the dichloromethane with 100 mL of 0.05 M sodium hydroxide solution

for 5 min and discard the alkaline solution.

Pass the dichloromethane through a filter paper with anhydrous sodium sulfate and

collect the dichloromethane in a 300-mL round-bottom flask. Add 1-g of Florisil PR

and then evaporate dichloromethane to near dryness on a water-bath at ca 40

◦

C by

rotary evaporation.

6.1.2

Soil

Recovery of acetamiprid, IM-1-2 and IM-1-4. Combine 20 g of the air-dried

soil with 100 mL of a mixed solvent of methanol and 0.1 M ammonium chloride

(4 : 1, v/v) in a 250-mL stainless-steel centrifuge tube, shake the mixture with a

mechanical shaker for 30 min and centrifuge at 8000 r.p.m. for 2 min. Filter the su-

pernatant through a Celite layer (1-cm thick) under reduced pressure into a 500-mL

flask. Add a second 100 mL of mixed solvent to the residue and then extract and filter

in the same manner. Combine the filtrates and add 150 mL of distilled water with

1 g of sodium chloride. Transfer the aqueous methanol solution into a 1-L separatory

funnel and shake the solution with 200 mL of dichloromethane for 5 min. Collect the

dichloromethane in a flask and adjust the pH of aqueous methanol to 13 with sodium

hydroxide. Extract the solution with two portions of 200 mL of dichloromethane for

5 min. Combine the dichloromethane extracts and pass through a filter paper with

anhydrous sodium sulfate. Add 0.5 mL of diethylene glycol and then concentrate

the dichloromethane extract to about 0.5 mL on a water-bath at ca 40

◦

C by rotary

evaporation.

1246

Individual compounds

Recovery of IC-0. Combine 20 g of the air-dried soil with 100 mL of a mixed

solvent of methanol and 0.1 M ammonium chloride (4 : 1, v/v) in a 250-mL stainless-

steel centrifuge tube, shake the mixture with a mechanical shaker for 30 min and

centrifuge at 8000 r.p.m. for 2 min. Filter the supernatant through a Celite layer

(1-cm thick) under reduced pressure into a 500-mL flask. Add 100 mL of mixed

solvent of methanol and 0.5 M sodium hydroxide solution (4 : 1, v/v) to the residue

and then extract and filter in the same manner. Combine the filtrates and concentrate to

approximately 40 mL on a water-bath at ca 40

◦

C by rotary evaporation. Add 10 mL

of distilled water and adjust the pH of the aqueous layer to 7 with hydrochloric

acid. Transfer the aqueous solution into a 200-mL separatory funnel and shake the

solution with 50 mL of mixed solvent of dichloromethane and acetone (1 : 1, v/v)

for 5 min. Discard the mixed solvent and adjust the pH of the aqueous layer to 1.5

with hydrochloric acid. Extract the solution with three portions of 50 mL of diethyl

ether. Combine the diethyl ether extracts and dry over anhydrous sodium sulfate.

Concentrate to dryness on a water-bath at ca 40

◦

C by rotary evaporation.

6.2

Cleanup

6.2.1

Plant materials

Transfer the residue with 1 g of Florisil PR on to the top of the column packed with 9 g

of Florisil PR with the aid of hexane. Rinse the column with 150 mL of hexane-acetone

(4 : 1, v/v). Elute acetamiprid with 120 mL of a mixed solvent of acetone-hexane (1 : 1,

v/v) and concentrate the eluate to near dryness by rotary evaporation at 40

◦

C. Dissolve

the residue with 5 mL of distilled water and apply the solution to the top of the packed

Sep-Pak C

18

column pretreated with 20 mL each of methanol and distilled water.

Elute acetamiprid with 30 mL of a mixed solution of water-acetonitrile (17 : 3, v/v).

Concentrate to dryness on a water-bath at ca 40

◦

C by rotary evaporation. Prepare the

GC-ready sample by dissolving the residue in acetone.

6.2.2

Soil

Cleanup procedures for acetamiprid, IM-1-2 and IM-1-4. Dilute the concentrate

with 10 mL of distilled water and apply the solution to an Extrelut 20 column, equili-

brate for 20 min at ambient temperature and pass 100 mL of dichloromethane through

the column. Collect the eluate and add 0.5 mL of diethylene glycol and then concen-

trate the dichloromethane to about 0.5 mL by rotary evaporation. Prepare the HPLC-

ready sample solution by dissolving the residue in 50% aqueous acetonitrile.

Cleanup procedure for IC-0. Dissolve the residue with 10 mL of pH 5 phosphate

buffer solution and apply the solution to the top the Sep-Pak C

18

Env. column pre-

treated with 10 mL each of methanol and distilled water. Discard the passed solution

and elute IC-0 with 15 mL of a second buffer solution. Add 35 mL of distilled water

and adjust the pH of solution to 1.5 with hydrochloric acid. Extract the solution with

three portions of 50 mL of diethyl ether. Combine the diethyl ether extracts and dry

over anhydrous sodium sulfate. Concentrate to dryness on a water-bath at ca 40

◦

C

Acetamiprid

1247

by rotary evaporation. Prepare the HPLC-ready sample solution by dissolving the

residue in 50% aqueous acetonitrile solution.

6.3

Determination

6.3.1

Plant materials

Inject an aliquot of the GC-ready sample solution into the gas chromatograph.

Operating conditions

Gas chromatograph

Model GC-14B, Shimadzu

Column

5% PEG HT/Chromosorb W HP column, 60–80

mesh, 3.2-mm i.d., 1.0-m length short column

Column temperature

260

◦

C

Injection port temperature

320

◦

C

Detector

Electron capture detector

Detector temperature

320

◦

C

Gas flow rates

Nitrogen carrier gas, column head pressure

1.5 kg cm

−2

Injection volume

2 µL

6.3.2

Soil

Inject an aliquot of the HPLC-ready sample solution into the high-performance liquid

chromatograph.

Operating conditions

High-performance liquid

Model LC-10AD, Shimadzu

chromatograph

Column

Stainless-steel column, 4.6-mm i.d., 150 mm-length

Stationary phase

Inertsil ODS-3

(1) Determination of acetamiprid, IM-1-2 and IM-1-4

.

Mobile phase

(A) 0.1 M ammonium acetate adjusted to pH 8.5 with

aqueous ammonia

(B) Acetonitrile

Gradient rate

0–20 min 85% A–15% B to 70% A–30% B

20–22 min 70% A–30% B to 30% A–70% B

22–30 min 85% A–15% B

Flow rate

1.0 mL min

−1

Column temperature

50

◦

C

Detection

UV detector (SPD-10AV) at 270 nm (IM-1-4) for initial

11 min and then change at 246 nm (acetamiprid, IM-

1-2) for 19 min

Injection volume

25 µL

1248

Individual compounds

(2) Determination of IC-0

Mobile phase

Acetonitrile–1% acetic acid (1 : 4, v/v)

Flow rate

1.0 mL min

−1

Column temperature

50

◦

C

Detection

UV detector (SPD-10AV) at 270 nm (IC-0)

Injection volume

25 µL

7

Evaluation

7.1

Method

7.1.1

Plant materials

Quantification is performed by the calibration technique. Construct a new calibration

curve with acetamiprid standard solutions using acetone for each set of analyses.

Inject 2-µL aliquots of the standard solution containing acetamiprid from 0.04 to 1 ng

in 2µL of acetone. The acetamiprid peak usually appears at a retention time around

4 min. Plot the peak height against the injected amount of acetamiprid.

7.1.2

Soil

Quantification is performed by the calibration technique. Construct a new calibration

curve with the mixed standard solutions of acetamiprid, IM-1-2 and IM-1-4 for each

set of analyses. Inject 25-µL aliquots of the standard solutions containing compounds

from 1 to 10 ng in 25 µL of 50% aqueous acetonitrile. With regard to IC-0, prepare

the calibration curve in the same manner. The retention times are around 8 min for

IM-1-4 and IC-0, 12 min for IM-1-2 and 20 min for acetamiprid. Plot the peak area

against the injected amount of each standard.

7.2

Recoveries, limit of detection and limit of determination

7.2.1

Plant materials

With a fortification level of 0.1 mg kg

−1

, recoveries from untreated plant matrices

ranged from 90 to 104%. The limit of detection (LOD) was 0.005 mg kg

−1

(fruits and

vegetables). With regard to green tea (powder and leachate), the method recoveries

were 95 and 98%, respectively, at the 0.5 mg kg

−1

fortification level. The LOD was

0.05 mg kg

−1

.

7.2.2

Soil

At the fortification levels at 0.1 and 0.2 mg kg

−1

, recoveries of acetamiprid, IM-1-2,

IM-1-4 and IC-0 from soils ranged from 70 and 95%. The LOD for each compound

was 0.01 mg kg

−1

.

Acetamiprid

1249

7.3

Calculation of residues

The amount of acetamiprid and its related compounds (R, mg kg

−1

) in the sample is

calculated by the following equation:

R

= C × V/G

where

C

= concentration of compound in the final solution (µg mL

−1

)

V

= final sample volume (mL)

G

= original sample weight (g)

8

Important points

Since IM-1-4 is a volatile compound, diethylene glycol should be added to the solution

containing IM-1-4 to reduce the amount of sample lost in the concentration step under

reduced pressure.

Further reading

M. Tokieda, K. Iiyoshi, K. Sugioka, and T. Gomyo, J. Pestic. Sci., 22, 129 (1997).

M. Tokieda, T. Tanaka, M. Ozawa, and T. Gomyo, J. Pestic. Sci., 23, 296 (1998).

Shigeji Sugimoto

Nippon Soda Co. Ltd, Tokyo, Japan

Document Outline

- Front Matter

- Table of Contents

- Volume I

- Volume II

- Recent Advances in Analytical Technology, Immunoassay and Other Nonchromatographic Methods

- Best Practices in the Generation and Analyses of Residues in Environmental Samples

- Compound Class

- Individual Compounds

- Azoxystrobin

- Famoxadone

- Fluthiacet-Methyl

- Flutolanil

- Hymexazol

- Imibenconazole

- Mepanipyrim

- Mepronil

- Tebuconazole

- Acetamiprid

- Alanycarb

- Azinphos-Methyl

- Benfuracarb

- Buprofezin

- Cyfluthrin

- Fenothiocarb

- Fenoxycarb

- Fenpyroximate

- Hexythiazox

- Imidacloprid

- Isoxathion

- Milbemectin

- Pyrimidifen

- Pyriproxyfen

- Index

Wyszukiwarka

Podobne podstrony:

91942 08w

91942 abb

91942 08q

91942 04m

91942 05d

91942 03d

91942 01e

91942 05b

91942 08p

91942 04b

91942 08u

91942 06c

91942 01c

91942 03c

91942 01a

91942 08x

91942 03f

91942 toc

więcej podobnych podstron