Emergency Stop with Embedded Safety

SCS16/0514

2014-06-26

Emergency Stop Pushbutton / Contactor

Cat.3 PL d, SIL 2 / Stop Category 0

Emergency Stop with Embedded Safety Module

- 1 -

Emergency Stop Pushbutton / Contactor

Cat.3 PL d, SIL 2 / Stop Category 0

Function:

•

Safety-related stop function initiated by

pushbutton to minimize the consequences of

event.

•

The pushing of emergency stop pushbutton is detected from

opening contacts, which are checked by the safety module.

•

Opening these contacts causes the deactivation of the safety

module outputs (stop category 0 according to EN/IEC 602

which results in a switch-off of the motor power supply to

minimize hazard in case of emergenc

contactors (K3 and K4).

Typical applications:

Machine-tools or similar machines with low inertia (no rundown time),

where the access to the hazardous area is limited to maintenance

interventions.

Design:

•

The safety function employs well-tried safety principles and is

robust in the event of one component failure by me

contactors (K3 and K4) and an emergency pushbutton (

•

A contactor fault is detected by the safety module at the next

demand upon the safety function by the restart interlock

pushbutton.

•

The start button (S2) must be located outside the hazardous area

and at a point from which the potential danger is visible.

•

The emergency pushbutton (S1) has direct opening action in

accordance with EN/IEC 60947-5-1 and is regarded as well

component.

•

The safety module satisfies the requirements

level up to PL d according to EN ISO 13849

according to EN/IEC 62061.

•

The contactors (K3 and K4) have mirror contacts in accordance

with EN/IEC 60947-4-1, meaning that the normally closed

auxiliary contacts cannot be in the closed state unless the main

poles are open. They are also considered as well

components.

•

Protection against overcurrent must be provided in accordance

with EN/IEC 60947-4-1.

Module

related stop function initiated by emergency stop

pushbutton to minimize the consequences of possibly harmful

The pushing of emergency stop pushbutton is detected from

opening contacts, which are checked by the safety module.

Opening these contacts causes the deactivation of the safety

module outputs (stop category 0 according to EN/IEC 60204-1),

off of the motor power supply to

minimize hazard in case of emergency by means of the

tools or similar machines with low inertia (no rundown time),

he hazardous area is limited to maintenance

tried safety principles and is

robust in the event of one component failure by means of two

) and an emergency pushbutton (S1).

actor fault is detected by the safety module at the next

demand upon the safety function by the restart interlock

(S2) must be located outside the hazardous area

and at a point from which the potential danger is visible.

1) has direct opening action in

1 and is regarded as well-tried

The safety module satisfies the requirements for performance

according to EN ISO 13849-1 and SIL

CL

2

) have mirror contacts in accordance

1, meaning that the normally closed

auxiliary contacts cannot be in the closed state unless the main

poles are open. They are also considered as well-tried

Protection against overcurrent must be provided in accordance

Emergency Stop with Embedded Safety Module

SCS16/0514

2014-06-26

- 2 -

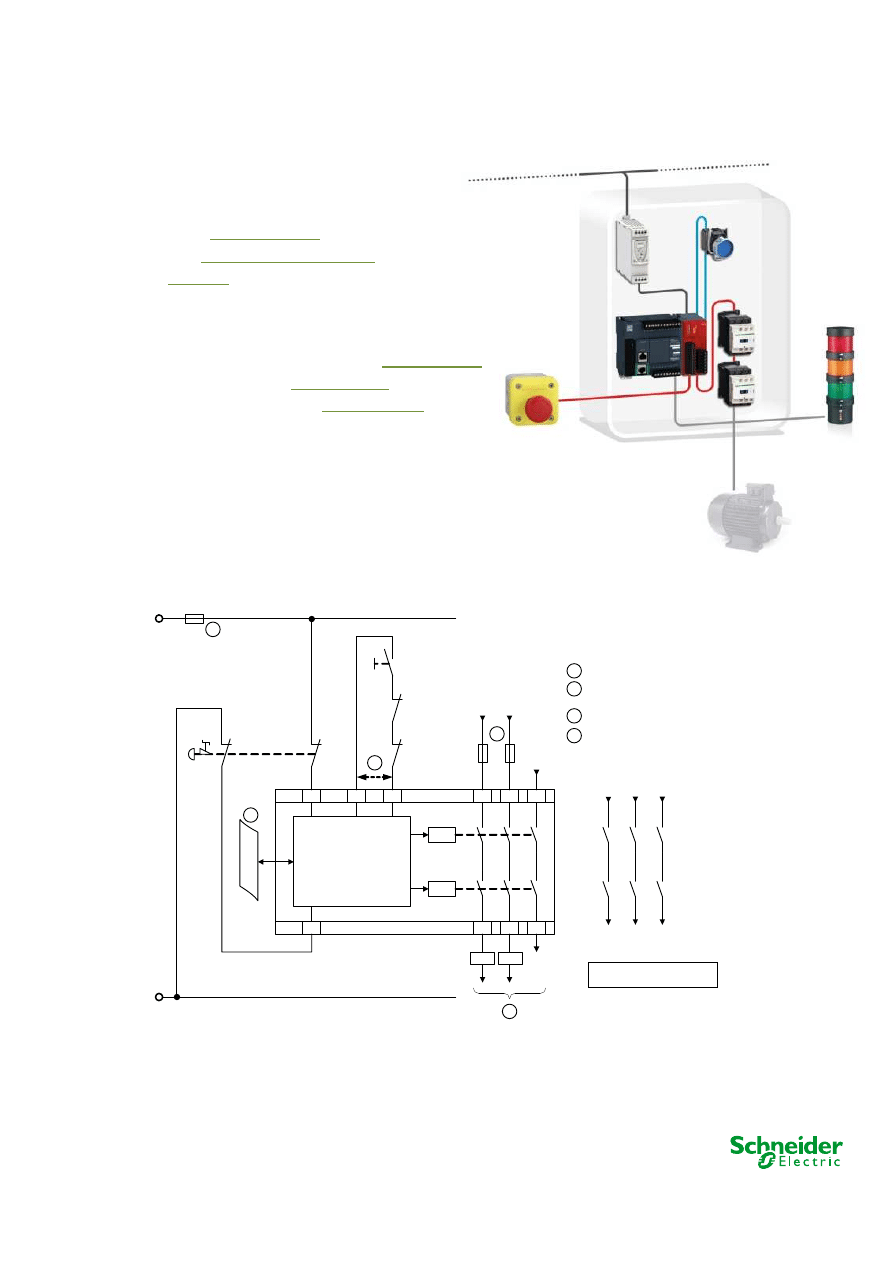

Safety Chain Products:

•

Safety switches -

Preventa XALK

•

Safety Module -

Modicon TM3SAC5R(G)

•

Contactor -

TeSys D

Related Products:

•

Switches, pushbuttons, emergency stop -

Harmony XB4

•

Switch mode Power supply -

Phaseo ABL8

•

Modular beacon and tower light -

Harmony XVB

1

2

Safety Outputs

K2

K1

13

23

33

14

24

34

T

M

3

-B

u

s

A1

A2

Y1

Y2

Logic

+24 VDC

0

K4

K3

K3

K3

K4

K4

K3

K4

K3

K4

S2

S1

S1: Emergency Stop

S2: Start Button

1

Automatic Start, when Y1-Y2

jumpered

2

3

3

For fuse rating see data sheet

F1

F2

F3

3

4

4

Non-safe Bus

SCS16/0514D

Emergency Stop with Embedded Safety Module

SCS16/0514

2014-06-26

- 3 -

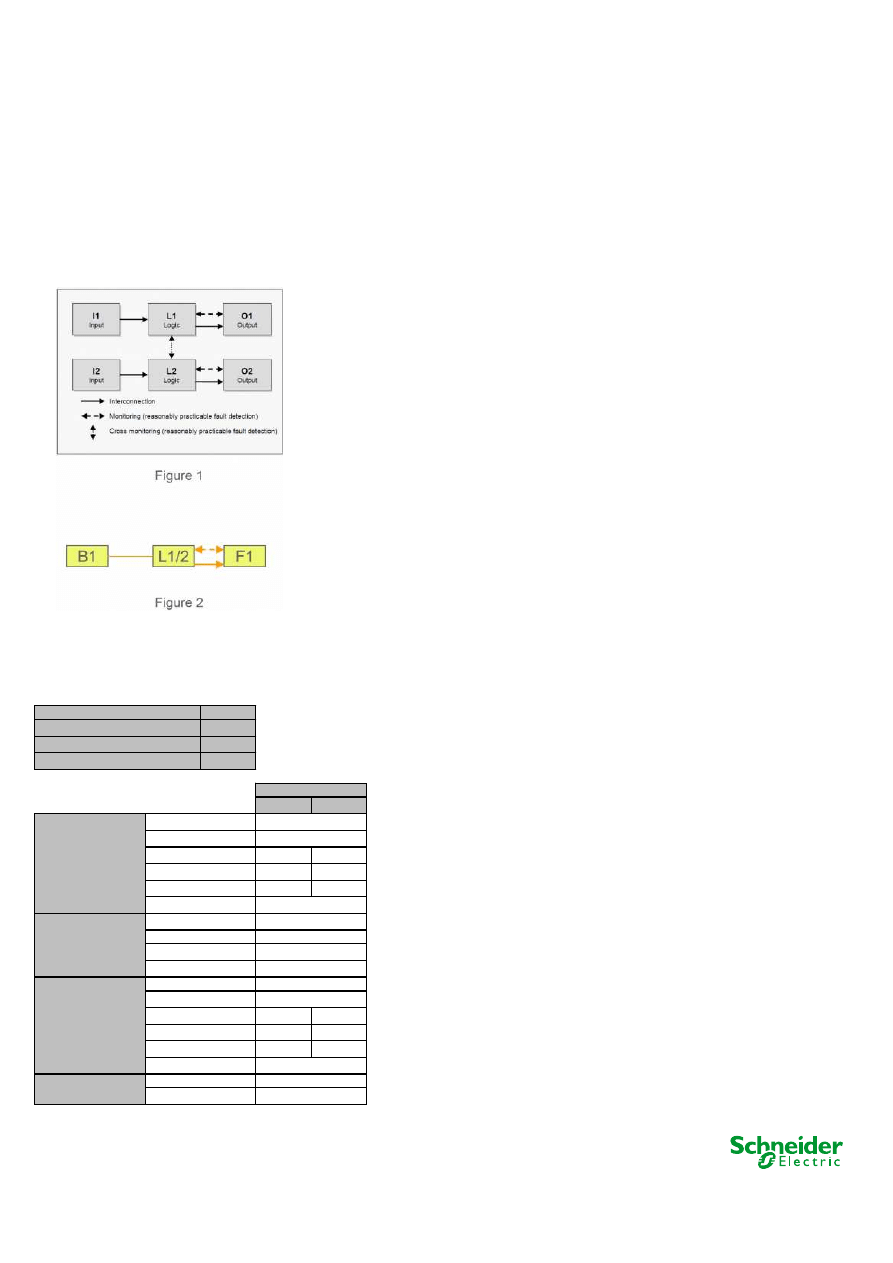

Chain structure:

•

The circuit diagram SCS16/0514D is a conceptual schematic diagram

and is limited to present the safety function with only the relevant safety

components.

•

For the designated architecture of category 3, two redundant channels

are implemented.

•

The circuit arrangement can be divided into three function blocks per

channel with the input (I), logic (L) and output (O) blocks on each

channel.

•

The possibility of fault detection by monitoring the outputs is indicated by

the broken lines (see figure 1).

•

The functional channel can be represented by a single emergency

pushbutton (i.e. B1) that would correspond to the input (see figure 2).

•

The safety module (TM3SAC5R(G)) corresponds to the logic block

(L1/L2), which maintains the internal redundancy of the safety circuits

required for this architecture.

•

The output block is represented by two redundant contactors (K3 and K4)

that are monitored by the logic block (safety module) to detect any failure.

•

The complete wiring must be in accordance to EN 60204-1 and the

necessary means to avoid short circuits has to be provided (EN ISO

13849-2 Table D.4).

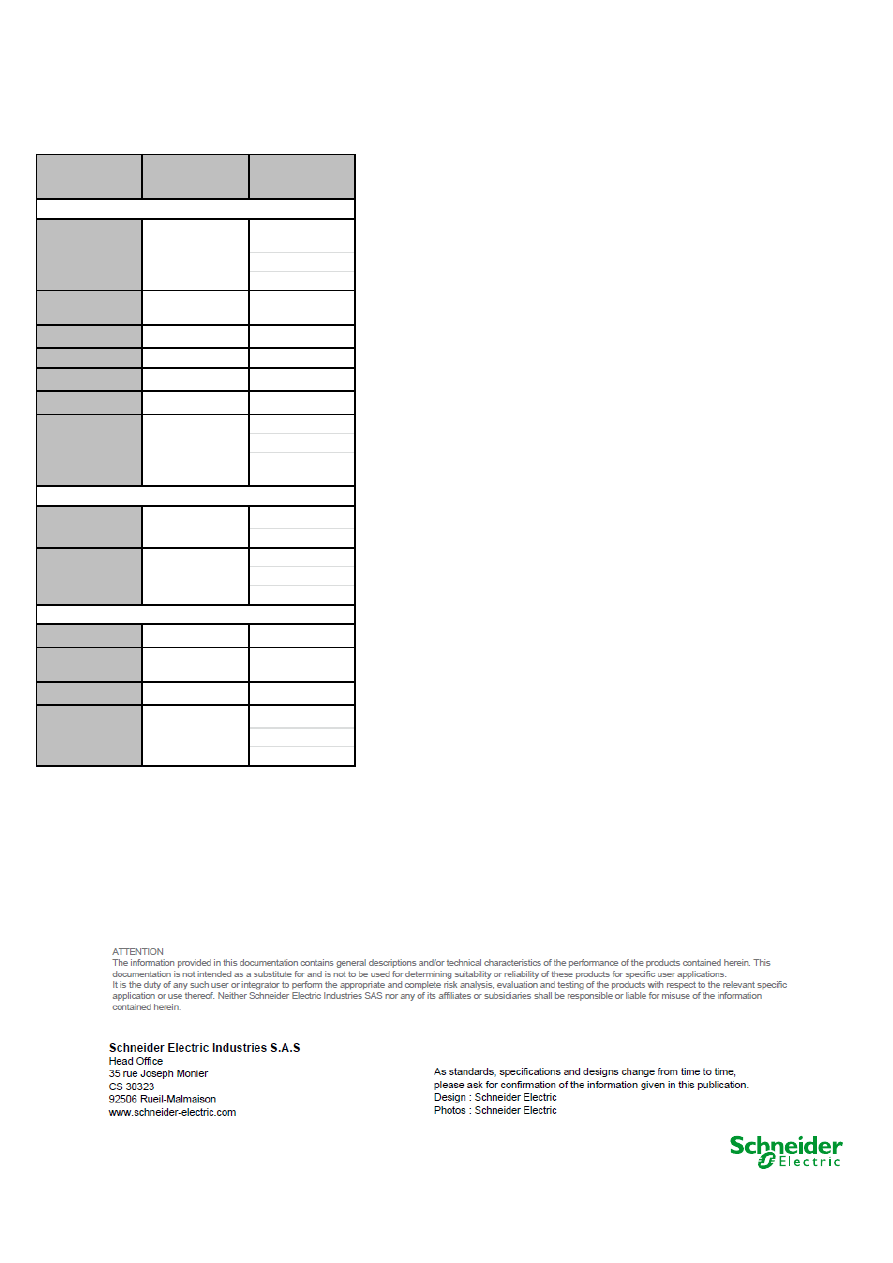

Safety level calculation:

•

A required performance level (PL

r

) must be specified for each

intended safety function following a risk evaluation. The

performance level (PL) attained by the control system must

be validated by verifying if it is greater than or equal to the

PL

r

.

•

The emergency stop push button is operated once a month.

•

Mean time to dangerous failure (MTTF

d

) values exceeding

100 years will be limited to this value in order for the

component reliability not to be overstated in comparison with

the other main influencing variables such as the architecture

or tests.

•

A B10

d

value of 1 500 000 cycles is stated for the mechanical

aspects of S1. In accordance with the assumed n

op

value, the

MTTF

d

would be 4 090 909 years.

•

This value is therefore limited to 100 years ("high").

2592000

12

220

3,67

Channel 1

Channel 2

100

100

95%

95%

65

65

Logic TM3SAC5R(G)

Output TeSys D

PL

e

Category

4

MTTF

d

resulting (years)

100

100

DC

avg

99%

99%

CCF

75

75

PFH

d

resulting (1/h)

2,47E-08

Safety function

PL attained

d

PFH

d

resulting (1/h)

6,25E-08

DC

95%

e

4

3

d

3,28E-08

5,00E-09

PFH

d

Category

Input device XALK

PL

PFH

d

resulting (1/h)

CCF

PL

Category

DC

avg

MTTF

d

resulting (years)

Cycle time (s)

Number of hours' operation per day

Number of days' operation per year

Number of operations per year

Values

Emergency Stop with Embedded Safety Module

SCS16/0514

2014-06-26

- 4 -

•

A PFHd value of 5 x 10-9 is stated for the safety module

(TM3SAC5R(G)). This value comes directly from the safety

device data and it is certified by an accepted standards body.

•

For the redundant contactors K3 and K4, the B10 value

corresponds under nominal load to an electrical lifetime of

1 000 000 switching cycles. If 73% of failures are assumed to

be dangerous, the B10

d

value is 1 369 863 operations. With

the assumed value for n

op

, it results in a MTTF

d

of 3 735 990

years for each component. These values are therefore

limited to 100 years ("high").

•

Measures against common cause failures (Annex F of EN

ISO 13849-1) must attain at least 65 points (i.e. separation

(15), overvoltage protection etc. (15) and environmental

conditions (25+10)).

•

The safety-related control system corresponds to category 3

with high MTTF

d

. The complete functional safety chain

results in average probability of dangerous failure (PFH

d

) of

6.25 x 10

-8

.

•

This combination of safety devices allows PL d and SIL 2.

ENVIRONM ENTA L

CONDITIONS

Emergency P ush B utto n

P reventa XA LK o utside o f

a cabinet

Safety mo dule

TM 3SA C5R/G and

Co ntacto r - TeSys D

inside a cabinet

Degree o f pro tectio n

acco rding to IEC/EN

60529

Terminals:

IP 20

Enclo sure:

IP 20

A mbient o perating

temperature (ho rizo ntal

installatio n)

-25...70 °C

– 5...+ 55 °C (+ 14...+ 130 °F)

Fo r use in max. height

abo ve sea o f

2000 m (6560 ft)

Sto rage temperature

-40...70 °C

- 40...+ 70 °C (- 40...158 °F)

Fo r sto rage in max.

relative humidity o f

95 %, no n co ndensing

Fo r sto rage in height

abo ve sea level o f

0…3000 m (0...9842 ft)

Overvo ltage catego ry

III (4 kV)

P o llutio n degree

2

Rated insulatio n vo ltage

acco rding to IEC/EN

60664-1

~ 300 V

Supply vo ltage

SELV/P ELV c 24 V – 15/

+20 %

M ax. pro tectio n

4 A fuse gG

Rated po wer

B us 5 VDC

0.2 W

External Supply 24 VDC

2.4 W

M ax. current per o utput

path

6:00 A M

The sum o f simultaneo us

currents o n all o f the

o utputs is limited to

Σ

Ith

≤

18 A

P ro tectio n o f o utputs

max.: 4 A fuse gG o r 6 A

fast blo w

M aximum switching

capacity o f o utputs

A C-15

~ 230 V, 5 A

DC-13

24 VDC, 4 A

Output circuit

General

IP 65

Supply

Wyszukiwarka

Podobne podstrony:

17 EmergencyStop TM3 XALK TeSysD 4e3 sc0

18 GuardMonitoring TM3 XCS TeSysD 4e3 sc0

20 PerimeterGuarding TM3 XUSL TeSysD 4e3 sc0

19 PerimeterGuarding TM3 XUSL ATV32 3d2 sc1

Idealny 1 16 by emergency69

Sld 16 Predykcja

Ubytki,niepr,poch poł(16 01 2008)

16 Metody fotodetekcji Detektory światła systematyka

wyklad badania mediow 15 i 16

RM 16

16 Ogolne zasady leczenia ostrych zatrucid 16903 ppt

Wykład 16 1

(16)NASDAQid 865 ppt

16 2id 16615 ppt

Temat6+modyf 16 05 2013

bn 16

16 Tydzień zwykły, 16 wtorek

więcej podobnych podstron