Biomaterials 23 (2002) 4523–4531

A bone substitute composed of polymethylmethacrylate

and a-tricalcium phosphate: results in terms of osteoblast

function and bone tissue formation

Milena Fini

a,

*, Gianluca Giavaresi

a

, Nicol

"o Nicoli Aldini

a

, Paola Torricelli

a

,

Rodolfo Botter

b

, Dario Beruto

b

, Roberto Giardino

a,c

a

Servizio di Chirurgia Sperimentale, Istituto di Ricerca Codivilla-Putti, Istituti Ortopedici Rizzoli via di Barbiano 1/10, 40136 Bologna, Italy

b

Dipartimento di Edilizia Urbanistica e Ingegneria dei Materiali, Universit

"a di Genova, Pzz le JF Kennedy-Pad D, 16129 Genova, Italy

c

Fisiopatologia Chirurgica, Facolt

"a di Medicina e Chirurgia, Universit"a di Bologna via di Barbiano 1/10, 40136 Bologna, Italy

Received 21 December 2001; accepted 16 May 2002

Abstract

The biological properties of a composite polymeric matrix (PMMA+a-TCP) made of polymethylmethacrylate (PMMA) and

alfa-tricalciumphosphate (a-TCP) was tested by means of in vitro and in vivo investigations. PMMA was used as a comparative

material. Osteoblast cultures (MG 63) demonstrated that PMMA+a-TCP significantly and positively affected osteoblast viability,

synthetic activity and interleukin-6 level as compared to PMMA. At 12 weeks, the PMMA+a-TCP implants in rabbit bone

successfully osteointegrated in trabecular and cortical tissue (affinity index: 57.14

78.84% and 68.3176.18%, respectively). The

newly formed bone after tetracycline labelling was histologically observed inside PMMA+a-TCP porosity. The microhardness test

at the bone–PMMA+a-TCP interface showed a significantly higher rate of newly formed bone mineralization compared with

PMMA (+83.5% and +58.5%, respectively), but differences still existed between newly formed and pre-existing normal bone. It is

herein hypothesized that the present positive results may be ascribed to the porous macroarchitecture of PMMA+a-TCP and the

presence of the bioactive ceramic material that could have a synergic effect and be responsible for the improvement of (a) the

material colonization by bone cells, (b) osteoblast activity, (c) osteoinduction and osteoconduction processes, (d) bone remodelling.

r

2002 Elsevier Science Ltd. All rights reserved.

Keywords: Bone substitutes; a-tricalciumphosphate; Polymethylmethacrylate; Biocompatibility; Osteoblasts; Osteointegration; Osteoinduction

1. Introduction

The need for bone substitutes is rapidly increasing in

the field of orthopaedic surgery, since advanced

procedures are now being performed in reconstructive

surgery after traumatic pathologies and iatrogenic bone

losses secondary to bone resections for tumours,

infections or pseudoarthroses. Moreover, the increasing

number of elderly patients or individuals with various

systemic pathologies and biological drawbacks related

to bone healing processes, often requires the use of bone

substitutes as an adjuvant therapy to be associated with

prosthetic implants in order to improve biological

fixation and osteointegration processes [1,2].

So far autologous bone has been considered as the

most effective bone substitute because of its osteocon-

ductive and osteoinductive properties [3]. However, its

limited availability and second site harvest morbidity

limit its application in favour of other biological bone

substitutes, such as banked bone and derivatives (i.e.

demineralised and morcelized bone), which unfortu-

nately have less osteoconductive capacity and poor

mechanical characteristics [3–5]. Additionally, synthetic

materials rarely show all the fundamental characteristics

of an optimal bone substitute: biocompatibility, os-

teoinductive or osteoconductive properties (bioactivity),

and biomechanical similarity to bone. Moreover, the

possibility that bone substitutes may release antibiotic

or chemotherapeutic agents seems to be greatly

*Corresponding author. Tel.: +39-51-6366557; fax: +39-51-

6366580.

E-mail address:

milena.fini@ior.it (M. Fini).

0142-9612/02/$ - see front matter r 2002 Elsevier Science Ltd. All rights reserved.

PII: S 0 1 4 2 - 9 6 1 2 ( 0 2 ) 0 0 1 9 6 - 5

appreciated by clinicians who search for improved anti-

infective or antitumoral therapies [6,7]. All of the above

features have rarely been found in one single material

and composite materials seem therefore to be the most

suitable for clinical applications.

Polymethylmethacrylate

(PMMA)

has

been

im-

planted in bone since 1960 [8] to improve implant

fixation. Although undesired side effects related to its in

vitro and in vivo application are well known [9–11], its

use is an effective way to improve primary implant

stability in patients with poor bone stock (revision

arthroplasty or osteoporosis), and prevents fractures

secondary to bone rarefaction [12–14].

Osteointegration of PMMA is known to be poor

[15,16] and its effect on enhancing bone attachment is

only mechanical. Consequently, many studies have

taken into consideration both mechanical and biological

properties, such as osteoconduction and osteoinduction,

and have obtained bioactivated PMMA by adding

bioactive materials to PMMA [17–21]. Moreover, the

addition of bioactive and resorbable materials to

PMMA may also improve its physical characteristics,

thus obtaining a porous composite with osteogenetic

activity [22].

Tricalcium phosphates (TCP) are frequently used as

bone substitutes. a-TCP, in particular, is known to be

biocompatible, osteoconductive, osteoinductive and

with a high biodegradation rate [23–25]. A porous

matrix of PMMA has already been developed in the past

where capillary cavities were obtained by adding a-TCP

powders as an aqueous dispersion to the matrix, as

described in previous papers [26,27]. The aim was to

create a porous and bioactive polymeric composite

whose resorbable ceramic should be slowly replaced

with natural bone. The total open porosity of the

material was found to be a function of the amount of

water added. The water, which is the pore-forming

agent, vaporises after the polymerisation process,

leaving behind empty spaces in the polymeric matrix

[26,27]. The initial characterisation of the material

demonstrated that it was comparable to the porous

bioceramics

currently

used

as

bone

substitute

compounds in terms of mechanical properties. The

obtained macrostructure could also promote osteoblast

and vascular colonization towards and inside the

material [27].

The aim of the present work was to evaluate the

biological characteristics of the biomaterial developed.

The

investigation

was

conducted

both

in

vitro

and in vivo using osteoblast-like cells and rabbits for

inserting bone implants in cortical and trabecular

bone. The viability test, biochemical and cytokine

dosages were performed on osteoblasts, and histomor-

phometry and microhardness were used to evaluate

PMMA+a-TCP osteointegration in comparison with

PMMA.

2. Materials and methods

2.1. Materials

A two-component bone cement currently used in

orthopaedic surgery [28] and previously decribed [26],

was used for the composite polymeric matrix through-

out this study. The prepolymeric component in bone

cement is constituted of PMMA spherical particles with

an appropriate size distribution [29] allowing a very low

use of monomer, about 25% of the total mass of the

bone cement.

A solid-state reaction between CaCO

3

and CaH-

PO

4

2H

2

O powders was carried out to produce a-TCP

at 1573 K [30,31]. Once the reaction was completed, a

rapid quenching treatment was performed to stabilize

the a-phase. The final solid product was sieved to

eliminate agglomerates greater than 250 mm. The phase

composition of the calcium phosphate powders used was

controlled by X-ray diffraction analysis using a Philips

PW 1050/81 powder diffractometer with CuKa radia-

tion (40 mA, 40 kV). All the peaks in the resulting

spectra belong to a-TCP phase. No traces of impurities

were recorded. The powder has particles of irregular

shape, somewhat elongated and interconnected with an

average width of about 10 mm.

PMMA and PMMA+a-TCP slabs for in vitro test

and nails for bone implant test were prepared as

described below.

Dense PMMA samples were prepared by adding the

methylmethacrylate

monomer

(MMA)

(33.3%

by

weight) to the PMMA prepolymerised powders. The

mixture was stirred until a smooth paste was formed.

The resulting dough was placed between two glass

slides and squeezed to form a 1 mm-thick slab. The

slab were marked following a 10 mm 10 mm square

array, with a blade of stainless steel before that

polymerisation was complete. After the curing time the

square chips of polymer were broken apart and stored in

a desiccator.

The porous PMMA+a-TCP composites were pre-

pared using the following method. Three grams of

calcium phosphate powders were mixed with distilled

water to obtain a dispersion with a concentration of

solid equal to 20% v/v, its weight was checked, and it

was then mixed with the previously prepared concen-

trated organic mixture (MMA and PMMA) [32] for 40 s.

The amount of PMMA and MMA to be mixed with the

cake was so calculated as to ensure the same amount of

dry calcium phosphate phase for all final composite

samples, i.e. 25.2% dry weight. The resulting organic/

inorganic dough was folded in on itself 6 times. This

method yielded a paste with a sufficient degree of

homogeneity. Finally, the paste was moulded into a

1 mm-thick slab and cut in a square shape as described

above and stored in desiccator.

M. Fini et al. / Biomaterials 23 (2002) 4523–4531

4524

A different moulding procedure was adopted to

produce PMMA+a-TCP composites and pure PMMA

samples (cylindrical nails) for bone implants. Glass tube

segments of about 12 mm in length and 2 mm in inner

diameter were filled with a polymerising composite

dough with the aid of a spatula. The paste was then

slightly pressed with two glass rods, after about 5 min

was pulled out from the moulds and stored in

desiccator. The nails were cut into a length of 6 mm.

The water, which was initially present in the

phosphate dispersion, was totally removed by treatment

in desiccator leaving a percolating pore network in its

place [26].

Both slabs and nails were sterilised with ethylene

oxide before their use.

2.2. In vitro tests

An MG-63 human osteoblast cell line was used. Cells

were maintained in DMEM supplemented with 10%

FCS, 100 IU/ml penicillin and 100 mg/ml streptomycin

solution, and placed in a cell incubator with 5% CO

2

at

371C until confluence. After the cells had formed the

monolayer, they were detached with 0.05% (w/v) trypsin

and 0.02% (w/v) EDTA, counted (cell Coulter) and

seeded onto 24-multiwell plates at the concentration of

1 10

4

cells/ml. Cells were cultured in contact with

PMMA+a-TCP (PMMA+a-TCP Group) and PMMA

(PMMA Group) specimens (10 mm 10 mm). Cells

cultured with no material were used as negative controls

(Polystyrene Group). After 72 h the following tests were

done: MTT (Sigma, UK), bone alkaline phosphatase (B-

ALP, Alkphase-B immunoassay, Metra Biosystems.

CA, USA), lactate dehydrogenase (LDH, Sigma kit,

UK), nitric oxide (NO, Sigma calorimetric assay, St

Louis, MO, USA), osteocalcin (OC, Novocalcin enzyme

immunoassay kit, Metra Biosystem, CA, USA), pro-

Collagen (PICP, Prolagen-C enzyme immunoassay kit,

Metra Biosystem, CA, USA), interleukin 6 (IL-6,

Human IL-6 Immunoassay Kit, Biosource Int, CA,

USA), Transforming Growth Factor-b1 (TGF-b1,

Quantikine human TGF-b1 Immunoassay, R&D Sys-

tems, MN, USA).

2.3. In vivo tests

The in vivo study was performed following European

and Italian Law on animal experimentation and

according to the Animal Welfare Assurance #A5424-

01 by the National Institute of Health (NIH-Rockville,

MD, USA). The experimental protocol was sent to the

Italian Ministry of Health.

2.3.1. Bone implants

Cylindrical nails, 2 mm in diameter and 6 mm in

length, were implanted in the femoral condylar trabe-

cular and diaphyseal cortical bone of 12 adult male New

Zealand rabbits (b.w. 3.250

70.350 kg). Both femurs

were used. The nails were made of PMMA+a-TCP and

PMMA (control material).

General anaesthesia was induced with an i.m. injec-

tion of 44 mg/kg ketamine (Ketavet 100, Farmaceutici

Gellini SpA, Aprilia Lt, Italy) and 3 mg/kg xylazine

(Rompun Bayer AG, Leverkusen, Germany), and

assisted ventilation (O

2

: 1 l/min; N

2

O: 0.4 l/min; iso-

fluorane: 2.5–3%). The distal femurs and middiaphyses

were exposed and 2 defects with a 1.9 mm diameter were

drilled at low speed and under continuous saline

irrigation in the trabecular (distal femurs) and cortical

(middiaphyses) bone of the right and left femurs. Using

press-fit techniques, PMMA cylinders were transversally

implanted in the left femurs of all rabbits, while

PMMA+a-TCP cylinders were positioned in the right

femurs, up to a total of 12 trabecular and 12 cortical

implants. Finally, the skin was sutured in 2 layers.

Antibiotic therapy (Cefazolin, 100 mg/kg) was adminis-

tered preoperatively, immediately after surgery and after

24 h. Analgesics (metamizole chloride, 50 mg/kg) were

prescribed in the immediate postoperative period. Seven

days prior to sacrifice, the animals received an i.m.

injection of oxytetracycline (30 mg/kg). Twelve weeks

after surgery, the animals were sacrificed by pharmaco-

logical euthanasia under general anaesthesia with

intravenous administration of Tanax (Hoechst, Frank-

furt am Main, Germany).

Femurs were removed, cleaned of soft tissues and

prepared for histomorphometry and microhardness test.

2.4. Histomorphometry

The distal parts of the middiaphyses and of the

femoral condylar trabecular bone were fixed in 4%

buffered paraformaldehyde for 48 h for undecalcified

bone processing. Each part contained an implant. The

samples were then dehydrated in graded series of

alcohols until the absolute was reached. Finally, they

were embedded in epoxy resin (Struers Co., Copenha-

gen, Denmark). Blocks were sectioned along a plane

perpendicular to the bone surface and a series of

sections of about 30 mm in thickness, spaced 200 mm

apart, were obtained with a Leica 1600 diamond saw

microtome (Leica SpA, Milan, Italy). They were stained

with Fast Green, and were processed for routine

histological and histomorphometric analyses by using

a transmission and polarized light Axioskop Microscope

(Carl Zeiss GmbH, Jena, Germany) and a computerized

image analysis system with Kontron KS 300 software

(Kontron Electronic GmbH, Eiching bei Munchen,

Germany). Bone histomorphometry measurements were

taken semi-automatically on three sections for each

samples. Affinity Index (AI: the length of bone directly

opposed to the implant without the presence of a fibrous

M. Fini et al. / Biomaterials 23 (2002) 4523–4531

4525

membrane/the total length of the bone–implant inter-

face multiplied by 100) and the newly formed bone

inside the implanted materials (the bone area/the total

implant area multipled by 100) were calculated at

12.5 . Each measurement was performed semiautoma-

tically by a blinded investigator.

2.5. Microhardness

After the histological analysis, the resin-embedded

blocks containing the residual part of the implanted

materials were ground and polished, and used to

measure the level of bone hardness by means of an

indentation test (Microhardness VMHT 30, Leica,

Wien, Austria). The microhardness measurements were

performed in the tangential direction to the interface

with a Vickers indenter (four-sided pyramid with square

base and an apex angle between opposite sides of

1361

715

0

) applied at a load of 0.05 kgf and dwell time of

5 s to the cortical and cancellous bone. The Vickers

hardness degree (HV) was calculated by dividing the

indentation force by the surface of the imprint (4

pyramid surfaces) observed at the microscope. The

resulting formula was

HV ¼

2F sin b

d

2

;

where F is the weight applied to the pyramid expressed

in kg, b is half of the pyramid angle, and d is the average

diagonal length of the imprint expressed in mm. The

average value for each sample was calculated on a mean

of 10 for each examined area (5 for each implant side) at

the following sites: within 200 mm from the interface and

at 1000 mm from it. A minimum distance of about 3d

was allowed between the imprints to avoid their mutual

influence.

2.6. Statistical analysis

Statistical analysis was performed using SPSS v.10.1

software (SPSS/PC Inc., Chicago, IL). Data are

reported as mean

7SD at a significance level of

p

o0:05: After having verified normal distribution and

homogeneity of variances, analysis of variance (ANO-

VA) and Scheff

!e’s post hoc multiple comparison tests

were done in order to highlight any significant in vitro

difference between groups. The student’s t-test was used

to compare in vivo data between the PMMA+a-TCP

and PMMA groups (histomorphometry and microhard-

ness).

3. Results

3.1. In vitro tests

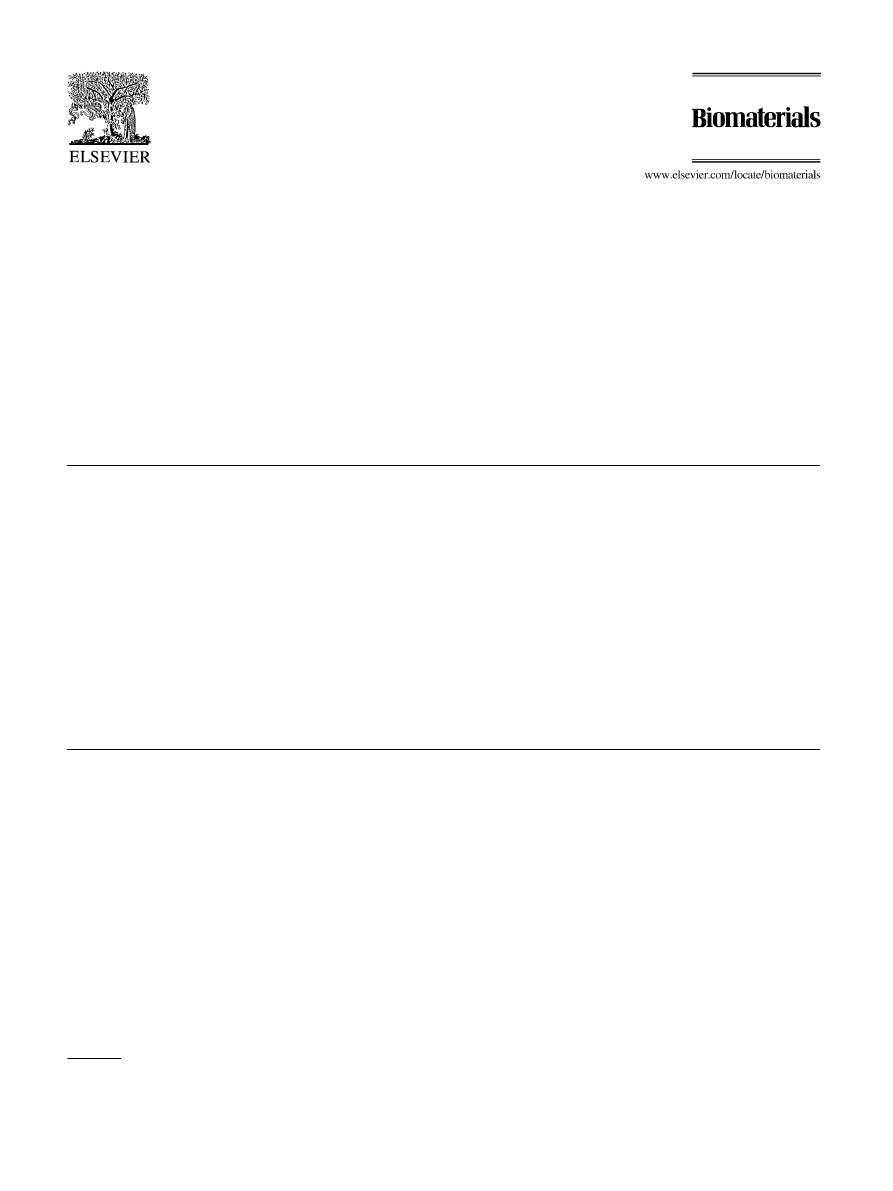

One-way ANOVA showed significant differences

between groups for all biochemical parameters, except

for B-ALP, NO and TGF-b1 as reported in Table 1 and

Fig. 1. Significant decreases in MTT of about 26–29%

were found in MG63 cultures plated with PMMA when

compared

to

the

Polystyrene

(p

o0:001)

and

PMMA+a-TCP (p

o0:0005) groups. In the same way,

B-ALP, OC, PICP and TGF-b1 decreased in the

PMMA group as compared to other groups, while

LDH and IL-6 increased. The Scheff

!e’s test showed

significant decreases in OC and PICP of the PMMA

group compared to the Polystyrene (OC: 11%,

p

o0:0005; PICP: 27%, po0:005) and PMMA+a-

TCP (OC: 14%, p

o0:0005; PICP: 22%, po0:05)

groups. In the PMMA group, LDH (Table 1) increased

significantly of about 49% (p

o0:0005) when compared

to the other groups, while IL-6 (Fig. 1) increased of

about 35% (p

o0:001) and 16% (po0:01) compared to

the Polystyrene and PMMA+a-TCP groups, respec-

tively.

3.2. In vivo tests

All animals survived without any local or general

complications until the scheduled experimental time.

3.3. Histomorphometry

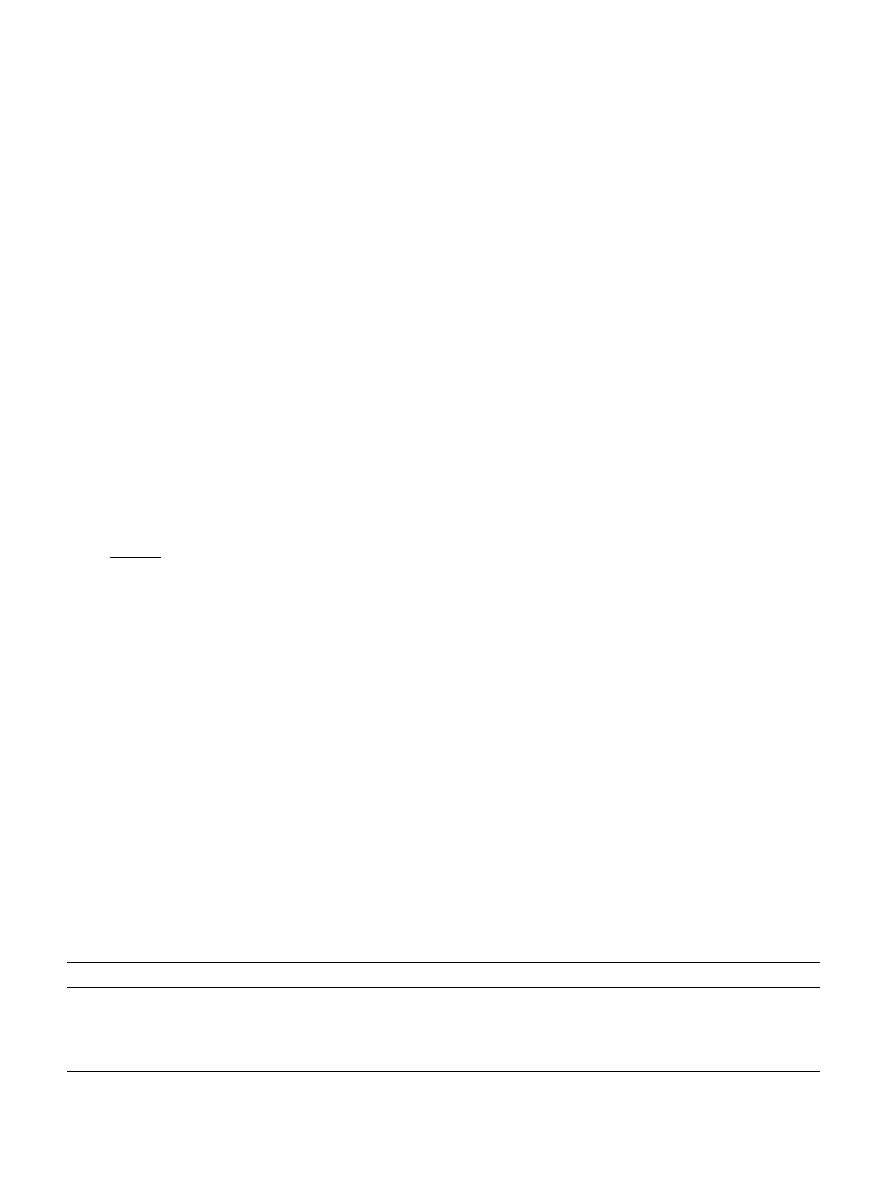

In PMMA+a-TCP implants the histological study

demonstrated that the surface of the material was

covered with newly formed bone, and direct bone

Table 1

In vitro study on bone cells after a 72-h culture without any material (polystyrene Group) and with PMMA and PMMA

6 -TCP. Mean7SD, n ¼ 5

triplicates

MG63

MTT (OD 550 nm)

B-ALP

LDH

NO (mmol)

OC (ng/ml)

PICP (ng/ml)

Polystyrene

0.919

70.039

8.47

71.35

13.47

70.74

5.74

70.30

21.46

70.70

15.83

70.27

PMMA

0.677

70.116

a,b

6.47

70.53

20.14

70.96

c

5.86

70.36

19.00

70.68

c

11.50

72.47

d,c

PMMA

6 -TCP

0.960

70.057

8.01

71.87

13.61

70.67

5.95

70.13

22.02

70.25

14.82

71.26

ANOVAF, p

19.46,

o0.0005

2.85, ns

113.05,

o0.0005

0.73, ns

38.06,

o0.0005

9.88,

o0.005

Scheff

!e’s post hoc multiple comparison test:

a

, p

o0.001 vs Polystyrene;

b

, p

o0.005 vs PMMA

6 -TCP;

c

, p

o0.005 vs others;

d

, p

o0.005 vs

Polystyrene;

e

, p

o0.05 vs PMMA

6 -TCP.

M. Fini et al. / Biomaterials 23 (2002) 4523–4531

4526

bonding was observed both in cancellous and in cortical

bone. In PMMA implants an intervening fibrous tissue

layer of 40

75 mm in thickness was observed in various

areas at the interface, both in cancellous and in cortical

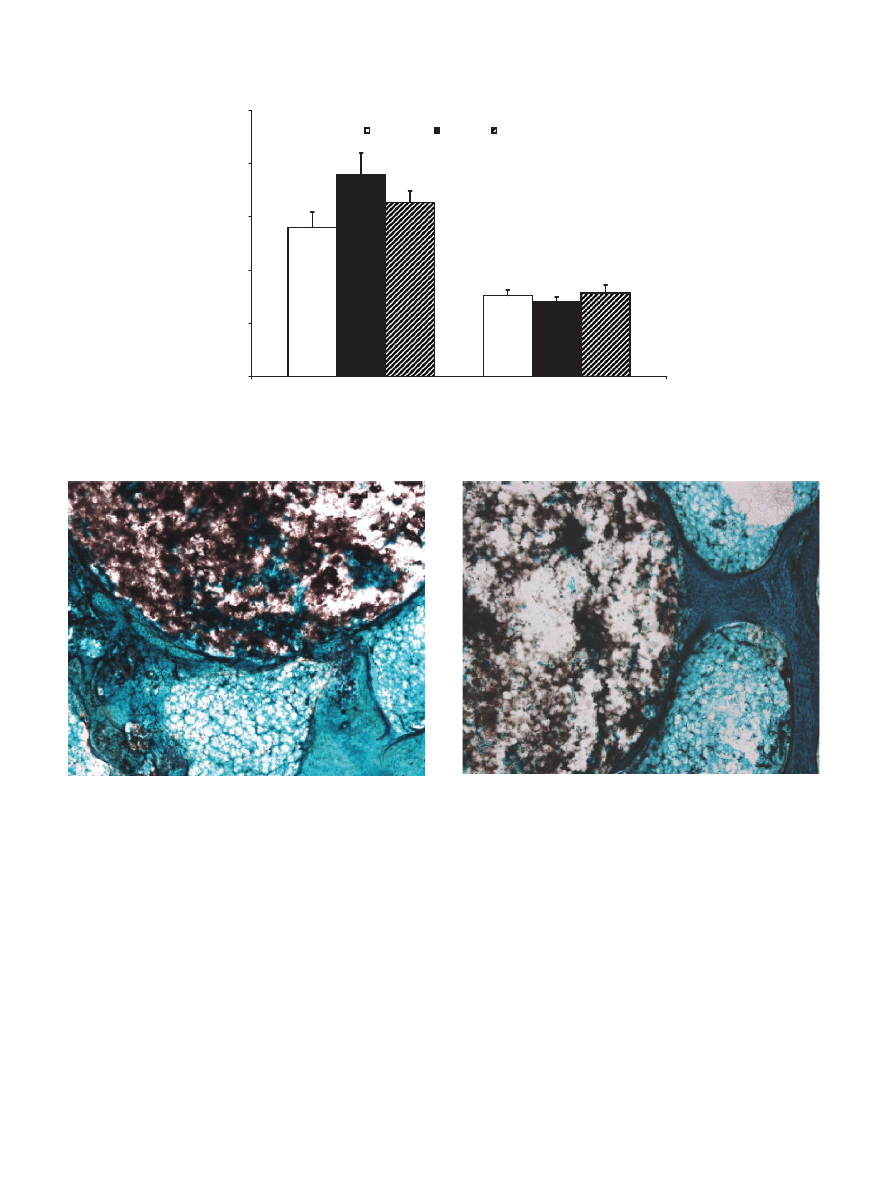

bone. Some pictures of the PMMA+a-TCP implants in

cancellous bone are shown in Figs. 2 and 3, while the

histological appearance in cortical bone is shown in

Figs. 4 and 5. Fig. 6 depicts the presence of newly

formed bone inside the porosity of PMMA+a-TCP

implanted in trabecular bone.

AI results for both cortical and trabecular bone

revealed significantly (p

o0:0005) higher percentages for

PMMA+a-TCP Versus PMMA (Table 2). The newly

formed bone regrown inside the porosity of PMMA+a-

TCP averaged 18.33

72.85% and 8.3374.88% in

trabecular and cortical bone, respectively.

3.4. Microhardness

Table 3 reports the microhardness measurements

taken at the bone–biomaterial interface and in the pre-

existing bone. The microhardness values of the cortical

bone adjacent to the implant surface and at 1000 mm

from the implant were significantly higher than those of

the trabecular bone for both materials. Additionally,

there were significant differences between data measured

at 200 and 1000 mm for both materials and both tissues.

Bone at the interface was significantly less hard than the

Fig. 2. PMMA+a-TCP implanted in cancellous bone. Direct apposi-

tion of bone to the material surface. (Undecalcified section, Fast

Green, 4 .)

Fig. 3. PMMA+a-TCP implanted in cancellous bone. A bone

trabecula is rounding the material surface. (Undecalcified section,

Fast Green, 4 .)

0

50

100

150

200

250

pg/ml

Polystyrene

PMMA

PMMA+aTCP

IL-6 (pg/ml)

TGF-

β

1 (*10 pg/ml)

a

b

Fig. 1. In vitro study on bone cells after a 72 h culture without any material (Polystyrene) and with PMMA and PMMA+a-TCP. Data on IL-6 and

TGF-b1. Mean

7SD, n ¼ 5 triplicates. Scheff!e’s post hoc multiple comparison test: PMMA versus Polystyrene (

a

, p

o0:001); PMMA versus

PMMA+a-TCP (

b

, p

o0:01).

M. Fini et al. / Biomaterials 23 (2002) 4523–4531

4527

pre-existing healthy bone (PMMA: cortical bone: –55%,

p

o0:0005;

trabecular

bone:

–53%,

p

o0:001;

PMMA+a-TCP: cortical bone: 26%, p

o0:001; tra-

becular bone: 12%, p

o0:05). Both trabecular and

cortical bone revealed significant decreases (p

o0:0005)

at 200 mm both for the PMMA and PMMA+a-TCP

groups (cortical bone: 37%; trabecular bone: 46%).

4. Discussion

Among the various characteristics required for a bone

substitute to be used in reconstructive orthopaedic

surgery, the capability to improve cell colonization

inside and on the surface of a material is now recognised

to be of basic importance [3,33]. The synthetic activity of

the cells around and inside the materials should in fact

allow implant incorporation in tissue with time.

Fig. 4. PMMA+a-TCP implanted in cortical bone. Direct apposition

of the cortical bone to material surface. (Undecalcified section, Fast

Green, 1.25 .)

Fig. 5. PMMA+a-TCP in cortical bone. A particular of the bone–

material interface at the endosteal perimeter. (Undecalcified section,

Fast Green 4 .)

Fig. 6. PMMA+a-TCP implanted in cancellous bone. Newly formed

bone regrown inside the pores of the implanted PMMA+a-TCP (a).

Under fluorescence the newly formed bone incorporated the fluor-

escent dye (b) (Undecalcified section, Fast Green and fluorescent stain,

20 ): M=Material; B=Bone.

Table 2

Affinity Index (%) of PMMA

6 -TCP in cortical and trabecular bone.

Mean

7SD, n ¼ 5

Material

Cortical bone

Trabecular bone

PMMA

6 -TCP

68.31

76.18

a

57.14

78.84

b

PMMA

13.16

710.04

9.63

77.17

Student’s t test between:

a

, p

o0.0005 vs PMMA implants in cortical

bone:

b

, p

o0.0005 vs PMMA implants in trabecular bone.

M. Fini et al. / Biomaterials 23 (2002) 4523–4531

4528

A porous polymeric composite material containing an

osteoinductive ceramic in the cavities was developed and

described in previous studies [26,27], as part of a larger

project investigating bone substitutes [34]. The addition

of a-TCP as an aqueous dispersion to a PMMA matrix

was shown to produce a class of composites that due to

their macrostructure and mechanical properties may be

suitable for application as bone substitutes in orthopae-

dics. After adding the inorganic component as an

aqueous dispersion, the PMMA formed a cellular

polymeric matrix with open cells of about 100 mm. The

mechanical properties of the new composite were similar

to those of the porous hydroxyapatite currently used as

a bone substitute [27].

However, when investigating a biomaterial for ortho-

paedic purposes, biological investigations by means of in

vitro and in vivo tests are mandatory in order to obtain

a true overall picture of biocompatibility, including

osteogenetic and osteointegration properties. The com-

monest tests on bone implants are histologic, histomor-

phometric and biomechanical investigations which may

follow in vitro tests [25]. They provide a complete

characterization of the osteogenetic and osteointegra-

tion properties of the material showing potential as bone

substitute for orthopaedic surgery [35].

In the present study, PMMA+a-TCP did not

negatively affect cell vitality and synthetic activity and

its positive effect on osteoblast function could be

demonstrated by OC and PICP increased levels.

Regarding PMMA in vitro behaviour, the present

findings concerning its inhibitory effect on cell vitality

and collagen synthesis were consistent with those

obtained by other authors, with the exception of the

OC production that was similarly inhibited by PMMA

in the present study, whereas it was stimulated by

PMMA in other studies [11]. The current discrepancy

between OC behaviours could be ascribed to the fact

that most in vitro studies on PMMA have been

conducted on polymerised PMMA in powder form.

However, a higher OC production in osteoblast cultures

is usually considered as a positive stimulation factor for

bone formation [36,37]. The production of IL-6 by cells

is recognized to increase with bone resorption around

implants, since the level of this cytokine is higher in

patients with loosened prostheses [38]. The expression of

IL-6 by the osteoblasts lining the surface of newly

formed bone around the implant is assumed to maintain

the inflammatory response within the interface and to

have an inhibitory effect on bone remodelling [39].

Therefore,

the

good

osteointegration

rate

of

PMMA+a-TCP versus PMMA observed in vivo could

also be partially explained by its action which decreases

IL-6 production by cells at the interface.

The material, in fact, successfully osteointegrated

both in trabecular and in cortical bone, while the

capability of PMMA to achieve a direct contact with

bone was negligible, as reported by other authors [15,1].

AI values were higher in cortical bone as compared to

trabecular bone. These findings are consistent with those

obtained by other authors who have implanted ceramic

materials into rabbits [40]. The implant site in fact

greatly affects both osteointegration and the rate of

biodegradation in those ceramic materials with higher

osteogenesis in cortical than in trabecular sites and

higher material degradation in trabecular than in

cortical sites [41]. The lower rate of TCP degradation

in cortical bone could be partially responsible for the

lower amount of bone regrown inside the porosity of the

material in this implant site.

The microhardness test confirmed the histomorpho-

metric data and demonstrated that the rate of miner-

alization and maturation was higher for the bone

around PMMA+a-TCP than for the bone in contact

with PMMA. As reported by Huja et al. [41], this non-

destructive technique enables the comparative study of

bone hardness variations at different distances from the

interface. This information should be considered in the

evaluation of bone adaptation around an implant.

Additionally, a good correlation coefficient was ob-

served between microhardness, elastic modulus, yield

stress, volume fraction of mineral and calcium content,

together with a close relationship between mineraliza-

tion and hardness [41]. Microhardness results demon-

strated that PMMA+a-TCP significantly improved

cortical and trabecular bone status at the bone-material

interface as compared to PMMA. However, the

Table 3

Microhardness measurements (HV) at the bone-PMMA and bone-PMMA

6 -TCP interface (200 mm from the material surface) and at 1000 mm from

it, both in cortical and in trabecular bone (Media

7SD, n ¼ 5)

Material

200 mm

1000 mm

Cortical bone

Trabecular bone

Cortical bone

Trabecular bone

PMMA

42.97

76.53

a

32.19

76.03

b

95.28

75.39

c

68.28

76.73

d

PMMA

6 -TCP

68.10

72.71

59.09

73.16

91.57

74.98

c

67.07

75.65

f

Student’s t test:

a

, p

o0.0005 vs 200 mm PMMA

6 -TCP in cortical bone;

b

, p

o0.0005 vs 200 mm PMMA

6 -TCP in trabecular bone;

c

, p

o0.0005 vs

200 mm PMMA in cortical bone;

d

, p

o0.001 vs 200 mm PMMA in trabecular bone;

e

, p

o0.001 vs 200 mm PMMA

6 -TCP in cortical bone;

f

, p

o0.05

vs 200 mm PMMA

6 -TCP in trabecular bone.

M. Fini et al. / Biomaterials 23 (2002) 4523–4531

4529

difference still existing between newly formed and pre-

existing normal tissue confirms that bone mineralization

and maturation around implants are slow processes

which take a long time. The present and other authors

have also experienced that bone at the interface does not

reach physiologic hardness values at 6 or 12 weeks even

after implanting osteoconductive materials, such as

titanium and hydroxyapatite [42–44].

The positive results obtained are probably due to the

porous

macroarchitecture

of

the

bone

substitute

brought about by adding a-TCP as an aqueous

dispersion. Its porosity and the presence of a bioactive

ceramic material could have a synergic effect and be

responsible for the improvement of (a) the material

colonization by bone cells, (b) osteoblast activity, (c)

osteoinduction and osteoconduction processes (d) bone

remodelling.

Acknowledgements

This work was partially supported by Progetto

Finalizzato ‘‘Materiali Speciali per Tecnologie Avanzate

II’’ and Rizzoli Orthopaedic Institute (ricerca corrente).

The authors are indebted to P. Di Denia, C. Dal Fiume,

N. Corrado, P. Nini and F. Rambaldi for their technical

assistance.

References

[1] Ignatius AA, Augat P, Ohnmacht M, Pokinsky JP, Kock HJ,

Claes LE. A new bioresorbable polymer for screw augmentation

in the osteosynthesis of osteoporotic cancellous bone: a biome-

chanical evaluation. J Biomed Mater Res (Appl Biomater)

2001;58:254–60.

[2] Griffon DJ, Dunlop DG, Howie CR, Pratt JN, Gilchrist TJ,

Smith N. An ovine model to evaluate the biological properties of

impacted morselized bone graft substitutes. J Biomed Mater Res

2001;56:444–51.

[3] Murphey MD, Sartoris DJ, Bramble JM. Radiograph assessment

of bone grafts. In: Habal MB, Hari Reddi A, editors. Bone grafts

and bone substitutes. Philadelphia: W.B. Saunders, 1992. p. 9–36.

[4] Malinin T. Acquisition and banking of bone allografts. In: Habal

MB, Hari Reddi A, editors. Bone grafts and bone substitutes.

Philadelphia: W.B. Saunders, 1992. p. 206–25.

[5] Goldberg VM. Selection of bone grafts for revision total hip

arthroplasty. Clin Orthop Rel Res 2000;381:68–76.

[6] Arcos D, Ragel CV, Vallet-Regi. Bioactivity in glass/PMMA

composites used as drug delivery system. Biomaterials 2001;

22(79):701–708.

[7] Gautier H, Daculsi G, Merle C. Association of vancomycin and

calcium phosphate by dynamic compaction: in vitro charateriza-

tion and microbiological activity. Biomaterials 2001;22:2481–7.

[8] Charnley J. Anchorage of the femoral head prosthesis to the shaft

of the femur. J Bone Joint Surg Br 1960;42:28–30.

[9] Ohsawa K, Neo M, Matsuoka H, Akijama H, Ito H, Nakamura

T. Tissue responses around polymethylmethacrylate particles

implanted into bone: analysis of expression of bone matrix

protein mRNA by in situ hybridization. J Biomed Mater Res

2001;54:501–8.

[10] Herman JH, Sowder WG, Anderson D, Applel AM, Hopson CN.

PMMA-induced release of bone-resorbing factors. J Bone Joint

Surg Am 1989;71:1530–41.

[11] Zambonin G, Colucci S, Cantatore F, Grano M. Response of

human osteoblasts to polymethylmethacrylate in vitro. Calcif

Tissue Int 1998;62:362–5.

[12] Heini PF, Walchli B, Berlemann U. Percutaneous transpedicular

vertebroplasty with PMMA: operative technique and early

results. A prospective study for the treatment of osteoporotic

compression fractures. Eur Spine J 2000;9:445–50.

[13] Ranawat CS, Peters LE, Ulmas ME. Fixation of the acetabular

component. The case for cement. Clin Orthop 1997;344:207–15.

[14] Giddings VL, Kurtz SM, Jewett CW, Foulds JR, Edidin AA. A

small punch test technique for characterizing the elastic modulus

and fracture behaviour of PMMA bone cement used in total joint

replacement. Biomaterials 2001;22:1875–81.

[15] Heikkila JT, Aho AJ, Kangasniemi I, Yli-Urpo A. Polymethyl-

methacrylate composites: disturbed bone formation at the surface

of bioactive glass and hydroxyapatite. Biomaterials 1996;17:

1755–60.

[16] Mousa WF, Kobayashi M, Shinzato S, Kamimura M, Neo M,

Yoshihara S, Nakamura T. Biological and mechanical properties

of PMMA-based bioactive bone cements. Biomaterials 2000;21:

2137–46.

[17] Vallo CI, Montemartini PE, Fanovich MA, Porto Lopez JM,

Cuadrato T. Polymethylmethacrylate-based bone cement mod-

ified with hydroxyapatite. J Biomed Mater Res 1999;48:150–8.

[18] Okada Y, Kawanabe K, Fujita H, Nishio K, Nakamura T.

Repair of segmental bone defects using bioactive bone cement:

comparison with PMMA bone cement. J Biomed Mater Res 1999;

47:353–9.

[19] Fujita H, Kazuhiro I, Hirozaku I, Oka M, Kitamura Y,

Nakamura T. Evaluation of bioactive bone cement in canine

total hip arthroplasty. J Biomed Mater Res 2000;49:273–88.

[20] Shinzato S, Kobayashi M, Mousa WF, Kamimura M, Neo M,

Kitamura Y, Kokubo T, Nakamura T. Bioactive polymethyl-

methacrylate-based bone cement: comparison of glass beads,

apatite- and wollastonite-containing glass–ceramic, and hydro-

xyapatite fillers on mechanical and biological properties. J

Biomed Mater Res 2000;51:258–72.

[21] Shinzato S, Nakamura T, Kokubo T, Kitamura Y. A new

bioactive bone cement: effect of glass bead filler content on

mechanical and biological properties. J Biomed Mater Res 2001;

54:491–500.

[22] Mayr-Wohlfart U, Fiedler J, Gunther KP, Puhl W, Kessler S.

Proliferation and differentiation rates of a human osteoblast-like

cell line (SaOS-2) in contact with different bone substitutes

materials. J Biomed Mater Res 2001;57:132–9.

[23] Herten HA, Wiltfang J, Grohmann U, Hoenig JF. Intraindividual

comparative animal study of a- and b-tricalcium phosphate

degradation in conjunction with simultaneous insertion of dental

implants. J Craniofac Surg 2001;12:59–68.

[24] Yuan H, Yang Z, de Bruijn J, de Groot K, Zhang X. Material-

dependent bone induction by calcium phosphate ceramics: a 2.5-

year study in dogs. Biomaterials 2001;22:2617–23.

[25] Knabe C, Driessens FCM, Plannel JA, Gildenhar R, Berger G,

Reif D, Fitzner R, Radlanski RJ, Gross U. Evaluation of

calcium phosphates and experimental calcium phosphate bone

cements using osteogenic cultures. J Biomed Mater Res 2000;52:

498–508.

[26] Beruto DT, Mezzasalma SA, Capurro M, Botter R, Cirillo P. Use

of a-tricalcium phosphate (TCP) as powders and as an aqueous

dispersion to modify processing, microstructure, and mechanical

properties of polymethylmethacrylate (PMMA) bone cements and

to produce bone-substitute compounds. J Biomed Mater Res

2000;49:498–505.

M. Fini et al. / Biomaterials 23 (2002) 4523–4531

4530

[27] Beruto D, Botter R, Fini M. The effects of water in inorganic

microsponges of calcium phosphates on the porosity and

permeability of composites made with polymethylmethacrylate.

Biomaterials, in press.

[28] Freeman MA, Tennant R. The scientific basis of cement versus

cementless fixation. Clin Orthop 1992;276:19–25.

[29] De Bastiani B, Faccioli G, Magnan B, Soffiatti R. Two phase

cement mixture, particularly suitable for orthopaedics. Patent no.

US5004501, 1991.

[30] Elliott JC. General chemistry of the calcium orthophosphates. In:

Elliott JC, editor. Structure and chemistry of the apatites and

other calcium orthophosphates. Amsterdam: Elsevier Science,

1994. p. 1–61.

[31] Bigi A, Boanini E, Botter R, Panzavolta S, Rubini K. a-tricalcium

phosphate hydrolysis to octacalcium phosphate: effect of sodium

polyacrylate. Biomaterials, in press.

[32] Nzihou A, Attias L, Sharrok P, Ricard A. A rheological, thermal

and mechanical study of bone cement-from a suspension to a solid

biomaterial. Powder Technol 1998;99:60–9.

[33] Dalton BA, McFarland CD, Gengenbach TR, Griesser HJ, Steele

JG. Polymer surface chemistry and bone cell migration. J

Biomater Sci Polym Ed 1998;9:781–99.

[34] Project MSTA II-Biomaterials P.F. CNR Italy.

[35] Lopes MA, Santos JD, Monteriro FJ, Ohtsuki C, Osaka A,

Kaneko S, Inoue H. Push-out testing and histological evaluation

of glass reinforced hydroxyapatite composites implanted in the

tibia of rabbits. J Biomed Mater Res 2001;54:463–9.

[36] Yamaguchi M, Sugimoto E, Hachya S. Stimulatory effect of

menaquinone-7 (vitamin K2) on osteoblastic bone formation in

vitro. Mol Cell Biochem 2001;223:131–7.

[37] Mayr-Wohlfart U, Fiedler J, Gunther KP, Puhl W, Kessler S.

Proliferation and differentiation rates of a human osteoblast-like

cell line (SaOS-2) in contact with different bone substitute

materials. J Biomed Mater Res 2001;57:132–9.

[38] Goodman SB, Huie P, Song Y, Schurman D, Maloney W,

Woolson S, Sibley R. Cellular profile and cytokine production at

prosthetic interfaces. Study of tissues retrieved from revised

hip and knee replacements. J Bone Joint Surg Br 1998;80:

531–9.

[39] Al Saffar N, Revell PA, Khwaja HA, Bonfield W. Assessment of

the role of cytokines in bone resorption in patients with total joint

replacement. J Mater Sci Mater Med 1995;6:762–7.

[40] Lu XJ, Gallur A, Flautre B, Anselme K, Descamps M, Thierry B,

Hardouin P. Comparative study of tissue reactions to calcium

phosphate ceramics among cancellous, cortical, and medullar

bone in rabbits. J Biomed Mater Res 1998;42:357–67.

[41] Huja SS, Katona TR, Moore BK, Roberts WE. Microhardness

and anisotropy of the vital osseous interface and endosseous

implants supporting bone. J Orthop Res 1998;16:54–60.

[42] Fini M, Giavaresi G, Rimondini L, Giardino R. Titanium

alloy osteointegration in cancellous and cortical bone of

ovariectomized

animals:

histomorphometric

and

bone

hardness measurements. Int J Oral Maxillofac Implants 2002;17:

28–37.

[43] Fini M, Cadossi R, Can

"e V, Cavani F, Giavaresi G, Krajewski A,

Martini L, Nicoli Aldini N, Ravaglioli A, Rimondini L, Torricelli

P, Giardino R. The effect of pulsed electromagnetic fields on the

osteointegration of hydroxyapatite implants in cancellous bone: a

morphologic and microstructural in vivo study. J Orthop Res, in

press.

[44] Stea S, Visentin M, Savarino L, Ciapetti G, Donati ME, Moroni

A, Caja V, Pizzoferrato A. Microhardness of bone at the interface

with ceramic-coated metal implants. J Biomed Mater Res 1995;29:

695–9.

M. Fini et al. / Biomaterials 23 (2002) 4523–4531

4531

Document Outline

Wyszukiwarka

Podobne podstrony:

Resorbability of bone substitute biomaterials by human osteo

bone graft substitutes

Palestrina O Bone Jesu (Satb)

Maternal Bone Lead Contribution to Blood Lead during and after Pregnancy

Metastatic bone disease,Wykł B Drozdzowska

Acetylenic Polymers, Substituted

T 6 Narzędzia KJ fish bone

Cancer induced bone dis Wyk B Drozdzowska

le bone, psychologia tłumu streszczenie

Bone formers id 91722 Nieznany (2)

ATX power switch substitute

Stek „bavette” i T bone stek

Metastatic bone disease,Wyk B Drozdzowska 2

Cancer induced bone dis Wykł B Drozdzowska

firstword bone

patomorfologia - nowotwory kosci, Cancer-induced bone disease; osteolytic tumour-induced bone diseas

więcej podobnych podstron