„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

MINISTERSTWO EDUKACJI

NARODOWEJ

Romuald Smyrak

Posługiwanie się językiem angielskim zawodowym

314[05].O1.03

Poradnik dla ucznia

Wydawca

Instytut Technologii Eksploatacji – Państwowy Instytut Badawczy

Radom 2007

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

1

Recenzenci:

mgr inż. Witold Sarnowski

mgr inż. Arkadiusz Pawlik

Opracowanie redakcyjne:

mgr Romuald Smyrak

Konsultacja:

mgr inż. Ryszard Dolata

dr inż. Andrzej Rypulak

Poradnik stanowi obudowę dydaktyczną programu jednostki modułowej 314[05].O1.03

„Posługiwanie się językiem angielskim zawodowym”, zawartego w modułowym programie

nauczania dla zawodu technik mechanik lotniczy.

Wydawca

Instytut Technologii Eksploatacji – Państwowy Instytut Badawczy, Radom 2007

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

2

SPIS TREŚCI

1. Wprowadzenie

3

2. Wymagania wstępne

4

3. Cele kształcenia

5

4. Materiał nauczania

6

4.1. Konstrukcja statku powietrznego

6

4.1.1. Materiał nauczania

6

4.1.2. Pytania sprawdzające

11

4.1.3. Ćwiczenia

11

4.1.4. Sprawdzian postępów

14

4.2. Systemy i instalacje samolotu

15

4.2.1. Materiał nauczania

15

4.2.2. Pytania sprawdzające

22

4.2.3. Ćwiczenia

23

4.2.4. Sprawdzian postępów

25

4.3. Silniki lotnicze

26

4.3.1. Materiał nauczania

26

4.3.2. Pytania sprawdzające

33

4.3.3. Ćwiczenia

33

4.3.4. Sprawdzian postępów

35

4.4. Urządzenia radiowe i radiowo-nawigacyjne

36

4.4.1. Materiał nauczania

36

4.4.2. Pytania sprawdzające

42

4.4.3. Ćwiczenia

42

4.4.4. Sprawdzian postępów

46

4.5. Podstawowe operacje obróbki ręcznej i mechanicznej

47

4.5.1. Materiał nauczania

47

4.5.2. Pytania sprawdzające

53

4.5.3. Ćwiczenia

53

4.5.4. Sprawdzian postępów

55

4.6. Podstawowe słownictwo używane w formularzach i przepisach lotniczych

56

4.6.1. Materiał nauczania

56

4.6.2. Pytania sprawdzające

60

4.6.3. Ćwiczenia

61

4.6.4. Sprawdzian postępów

61

5. Sprawdzian osiągnięć

62

6. Literatura

66

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

3

1. WPROWADZENIE

Poradnik będzie Ci pomocny w przyswajaniu technicznego języka angielskiego, który

jest niezbędny do posługiwania się dokumentacją techniczną statków powietrznych.

W poradniku zamieszczono:

−

wymagania wstępne – wykaz umiejętności, jakie powinieneś mieć już ukształtowane,

abyś bez problemów mógł korzystać z poradnika,

−

cele kształcenia – wykaz umiejętności, jakie ukształtujesz podczas pracy z poradnikiem,

−

materiał nauczania – wiadomości teoretyczne niezbędne do opanowania treści jednostki

modułowej,

−

zestaw pytań, abyś mógł sprawdzić, czy już opanowałeś określone treści,

−

ćwiczenia, które pomogą Ci zweryfikować wiadomości teoretyczne oraz ukształtować

umiejętności praktyczne,

−

sprawdzian postępów,

−

sprawdzian osiągnięć, przykładowy zestaw zadań. Zaliczenie testu potwierdzi

opanowanie materiału całej jednostki modułowej,

−

literaturę uzupełniającą.

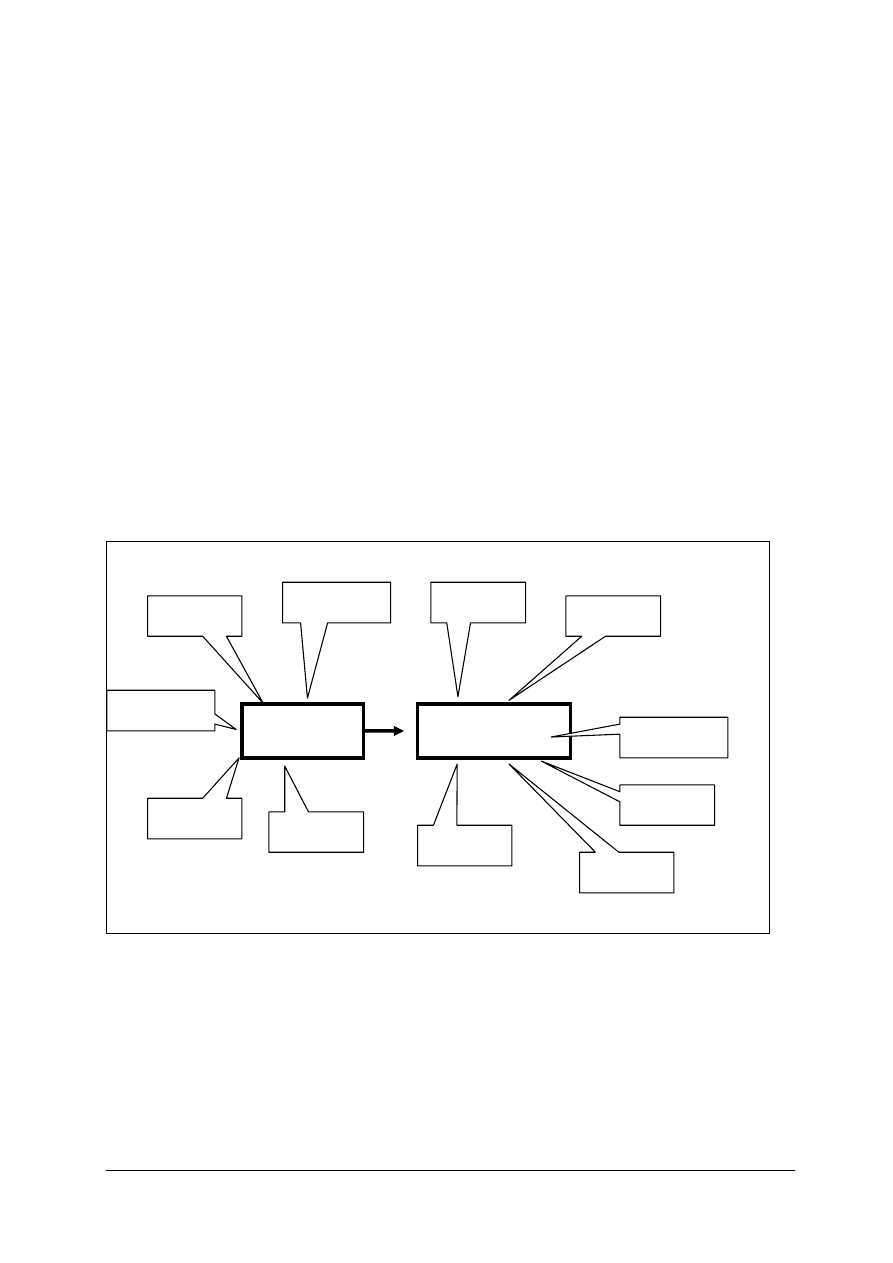

Schemat układu jednostek modułowych

314[05].O1

Środowisko pracy

314[05].O1.01

Przestrzeganie przepisów

bezpieczeństwa i higieny

pracy, ochrony

przeciwpożarowej i ochrony

środowiska

314[05].O1.02

Określanie

warunków

funkcjonowania

człowieka w

środowisku pracy

314[05].O1.03

Posługiwanie się

językiem

angielskim

zawodowym

314[05].O1.04

Przestrzeganie

przepisów

lotniczych

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

4

2. WYMAGANIA WSTĘPNE

Przystępując do realizacji programu jednostki modułowej, powinieneś umieć:

−

posługiwać się językiem angielskim na poziomie B1/B2, lub FCE,

−

poprawnie interpretować znaczenia rzeczowników złożonych w języku angielskim,

−

pisać prosty list formalny,

−

posługiwać się podstawową wiedzę w zakresie techniki lotniczej w języku polskim,

−

posługiwać się podstawowymi pojęciami z zakresu matematyki, geometrii, fizyki,

chemii, elektrotechniki i elektroniki,

−

korzystać z różnych źródeł informacji,

−

obsługiwać komputer, korzystać z Internetu i wyszukiwarek internetowych,

−

współpracować w grupie.

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

5

3. CELE KSZTAŁCENIA

W wyniku realizacji programu jednostki modułowej, powinieneś umieć:

– scharakteryzować statek powietrzny stosownie do rodzaju i przeznaczenia,

– scharakteryzować elementy statków powietrznych i ich zespoły,

– opisać i sklasyfikować przyrządy i urządzenia wchodzące w skład awioniki,

– zastosować

terminologię

dotyczącą

podstawowych

operacji

obróbki

ręcznej

i mechanicznej,

– odczytać ze zrozumieniem dokumentację techniczną statków powietrznych,

– dokonać pisemnego i ustnego zamówienia części zamiennych do wykonania obsługi

statku powietrznego,

– wypełnić formularze poświadczenia obsługi technicznej statku powietrznego,

– odczytać ze zrozumieniem przepisy organizacji: JAA, ICAO i UE(EASA),

– napisać list, pismo, faks, e-mail w sprawach zawodowych,

– poprowadzić rozmowy w sprawach zawodowych i sytuacjach z życia codziennego.

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

6

4. MATERIAŁ NAUCZANIA

4.1. Konstrukcja statku powietrznego

4.1.1. Materiał nauczania

aircraft

manned

RPV

surround

UAV

unmanned

vehicle

1) An aircraft is a vehicle which is able to fly through the air (or through

any other atmosphere). All the human activity which surrounds aircraft is

called aviation. (Most rocket vehicles are not aircraft because they are

not supported by the surrounding air).

Manned aircraft are flown by a pilot. Until ca. the 1960s, unmanned

aircraft were called drones. During the 1960s, the US military brought

the term Remotely Piloted Vehicles (RPV) into use. More recently the

term Unmanned Aerial Vehicle (UAV) has become common.

aerodynes

aerostats

airship

buoyancy

canopies

density

displace

float

gasbags

hydrogen

power

powered

structure weight

2) Aircraft fall into two broad categories: Lighter-than-air, called

aerostats, and heavier-than-air, called aerodynes.

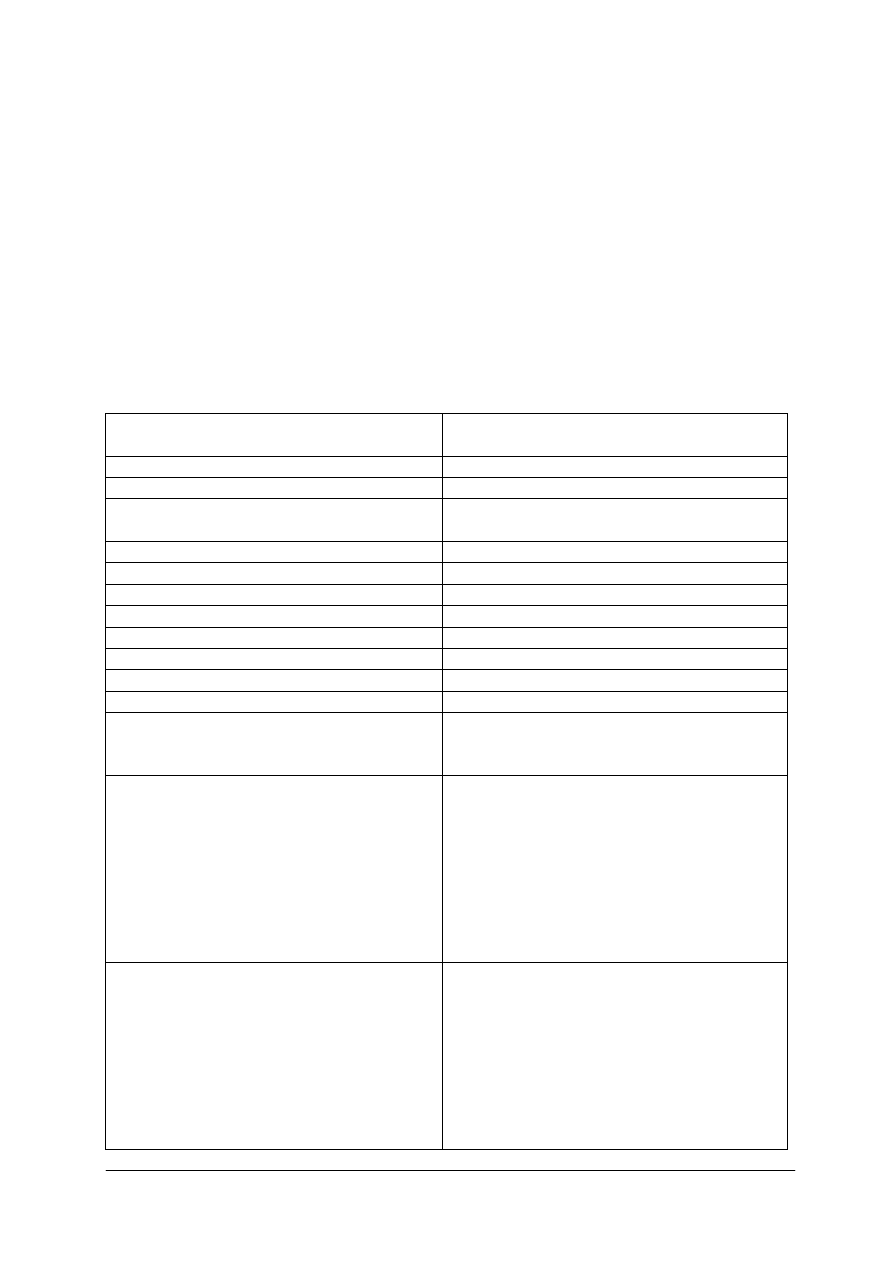

Rys.1. A hot air balloon in flight. [9]

Aerostats use buoyancy to float in the air in much the same way that

ships float on the water. They are characterized by one or more large

gasbags or canopies, filled with a relatively low density gas such as

helium, hydrogen or hot air, which is lighter than the surrounding air.

When the weight of this is added to the weight of the aircraft structure, it

adds up to the same weight as the air that the craft displaces.

Small hot air balloons called sky lanterns date back to the 3rd Century

BC and were only the second type of aircraft to fly, the first being kites.

Nowadays we say that a balloon is an unpowered aerostat, whilst an

airship is a powered one.

law

lift

push

thrust

ward

3) Heavier than air – aerodynes

Heavier-than-air aircraft must find some way to push air or gas

downwards, so that a reaction occurs (by Newton's laws of motion) to

push the aircraft upwards. This dynamic movement through the air is the

origin of the term aerodyne. There are two ways to produce dynamic

upthrust: aerodynamic lift, and powered lift in the form of engine thrust.

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

7

aerodynamics

aerofoil

craft

horizontal

spin

wing

rotor

4) Aerodynamic lift is the most common, with airplanes kept in the air by

the forward movement of wings, and rotorcraft by spinning wing-shaped

rotors. A wing is a flat, horizontal surface, usually shaped in cross-

section as an aerofoil. To fly it must move forwards through the air; this

movement of air over the aerofoil shape deflects air downward to create

an equal and opposite upward force, called lift, according to Newton's

third law of motion.

steady

STOL

take off

transfer

vertical

VTOL

5) The initialism VTOL (vertical take off and landing) is applied to

aircraft that can take off and land vertically. Most are rotorcraft. Others,

such as the Hawker Siddeley Harrier, take off and land vertically using

powered lift and transfer to aerodynamic lift in steady flight. STOL

stands for short take off and landing.

fixed- wing

canard

configuration

control surface

elevator

foreplane

fuselage

rudder

stabilizer

tailless

tailplane

tandem wing

6) Airplanes or airplanes are technically called fixed-wing aircraft.

Airplanes are generally characterized by their wing configuration.

In a conventional configuration, the main wings are placed in front of

a smaller stabilizer surface or tailplane. The canard reverses this, placing

a small foreplane forward of the wings, near the nose of the aircraft.

Canards are becoming more common as supersonic aerodynamics grows

more mature and because the forward surface contributes lift during

straight-and-level flight. The tandem wing type has two wings of similar

size, one at the front and one at the back. In a tailless design the lift and

horizontal control surfaces are combined. The ultimate expression of this

is the flying wing, where there is no central fuselage, and perhaps even

no separate vertical control surface (e.g., the B-2 Spirit).

biplane

drag

sesquiplane

strut

triplane

7) Sometimes two or more wings are stacked one above the other.

A biplane has two wings, and a triplane has three, quadruplanes (four)

and above have never been successful. Up until the 1930's, biplanes were

the most common. Triplanes were only occasionally made, especially for

a brief period during the First World War due to their high

manoeuvrability as fighters.

brace

cantilever

high-wing

low-wing

mid-wing

monoplane

multiplane

multi-plane

wire

8) A sesquiplane is similar to a biplane, but with the lower wing much

reduced in size. Most multi-plane designs are braced, with struts and/or

wires holding the wings in place. A monoplane has only one wing. Some,

especially early designs, are also braced, because this allows a much

lighter weight than a clean, unbraced cantilever design. But bracing

causes a large amount of drag at higher speeds, so it is no longer used for

faster designs. Monoplanes are also classified as high-wing, mid-wing or

low-wing, according to where on the fuselage the wing is attached.

chord

forward sweep

swept wing

tapered

9) Most low-speed airplanes have a straight wing, which may be

constant-chord, or tapered so that it decreases in chord towards the tip.

For flight near or above the speed of sound, a swept wing is usually used,

where the wing angles backwards towards the tips (though forward

sweep is occasionally experimented with, and M-wing designs which

reverse direction half way along have been suggested).

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

8

crescent

crop

delta

double-curved

ogival delta

leading edge

sharp

swing-wing

trailing edge

10) A notable variation is the delta wing, which is shaped like a triangle:

the leading edge is sharply swept, but the trailing edge is straight; one

common form is the cropped delta, which merges into the tapered swept

category, and an especially graceful form is the double-curved ogival

delta found for example on Concorde. Another variation is the crescent

wing, seen for example on the Handley Page Victor, which is sharply

swept inboard, with reduced sweep for the outboard section. A variable-

geometry wing, or swing-wing, can change the angle of sweep in flight.

It has been employed in a few examples of combat aircraft, the first

production type being the General Dynamics F-111.

bulkheads

formers

frames

longerons

monocoque

semimonocoque

stringers

11) Semimonocoque construction.

The semimonocoque fuselage is constructed primarily of the alloys of

aluminum and magnesium, although steel and titanium are found in areas

of high temperatures. Primary bending loads are taken by the longerons,

which usually extend across several points of support. The longerons are

supplemented by other longitudinal members, called stringers. Stringers

are more numerous and lighter in weight than longerons. The vertical

structural members are referred to as bulkheads, frames, and formers.

The heaviest of these vertical members are located at intervals to carry

concentrated loads and at points where fittings are used to attach other

units, such as the wings, powerplants, and stabilizers.

lateral axis

longitudinal

parallel

Principal member

ribs

spars

truss

12) Wing construction.

The main structural parts of a wing are the spars, the ribs or bulkheads,

and the stringers or stiffeners. Spars are the principal structural members

of the wing. They correspond to the longerons of the fuselage. They run

parallel to the lateral axis, or toward the tip of the wing, and are usually

attached to the fuselage by wing fittings, plain beams, or a truss system.

Spars may be made of metal or wood depending on the design criteria of

a specific aircraft. Most aircraft recently manufactured use spars of solid

extruded aluminum or short aluminum extrusions riveted together to

form a spar.

floatplane

seaplane

13) Seaplanes and floatplanes differ in that a seaplane has the bottom of

its fuselage shaped hydrodynamically and it sits directly on the water

when at rest, while a floatplane has two or more floats attached below the

rest of the aircraft so that the fuselage remains clear of the water at all

times.

aerofoil

autogyro

directly

disc

gyrodyne

hybrid

propulsion

rotor kite

spin

tether

tether

tilt

14) Rotorcrafts, or rotary-wing aircraft, use a spinning rotor with aerofoil

section blades (a rotary wing) to provide lift. Types include helicopters,

autogyros and various hybrids such as gyrodynes and compound

rotorcraft. Helicopters have powered rotors. The rotor is driven (directly

or indirectly) by an engine and pushes air downwards to create lift. By

tilting the rotor forwards, the downwards flow is tilted backwards,

producing thrust for forward flight.

Autogyros or gyroplanes have unpowered rotors, with a separate power

plant to provide thrust. The rotor is tilted backwards. As the autogyro

moves forward, air blows upwards through it, making it spin. This

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

9

tow

ward

spinning dramatically increases the speed of airflow over the rotor, to

provide lift. Juan de la Cierva (a Spanish civil engineer) used the product

name autogiro, and Bensen used gyrocopter. Rotor kites, such as the

Focke Achgelis Fa 330 are unpowered autogyros, which must be towed

by a tether to give them forward speed.

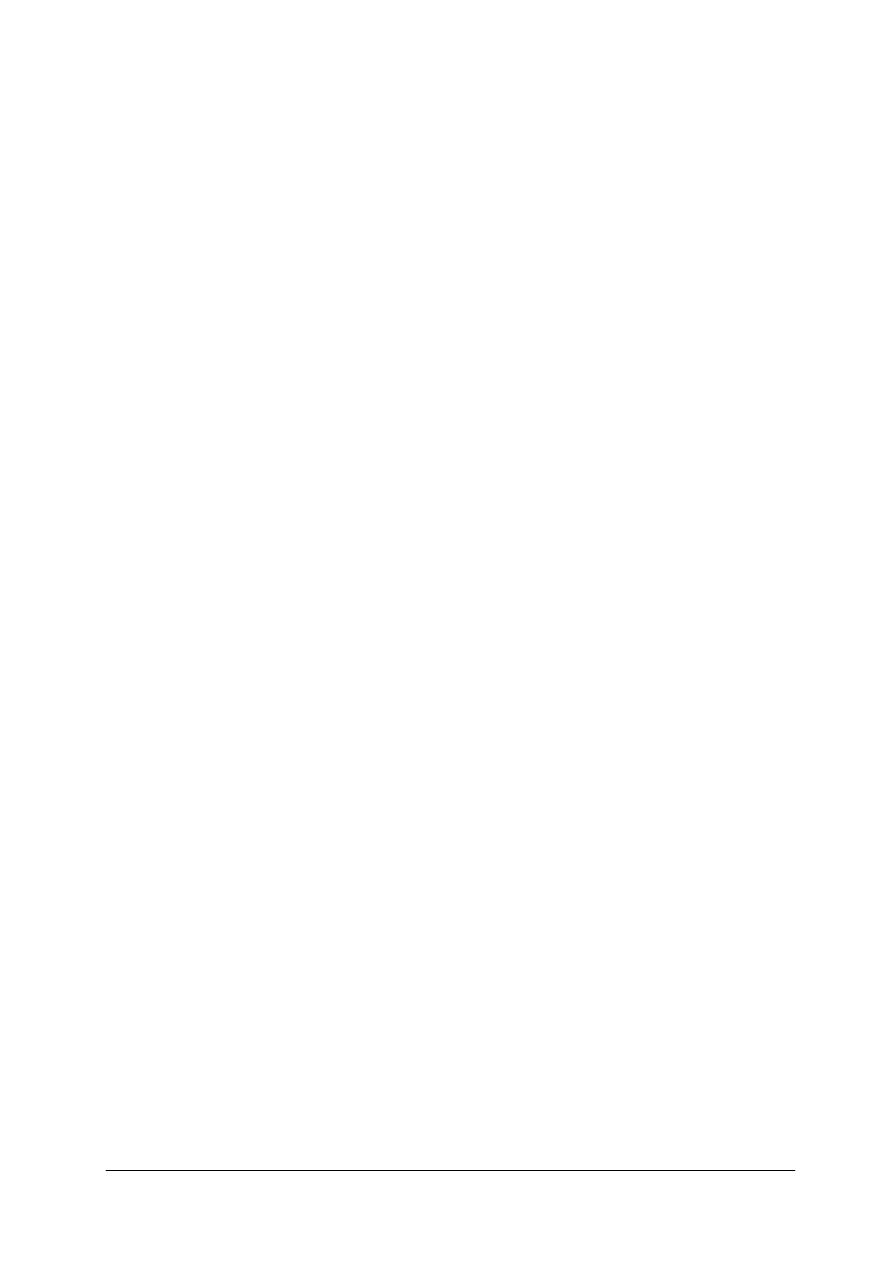

Rys.2. Bell 206B JetRanger III helicopter [10]

Gyrodynes are a form of helicopter, where forward thrust is obtained

from a separate propulsion device rather than from tilting the rotor. The

definition of a 'gyrodyne' has changed over the years, sometimes

including equivalent autogiro designs. The most important characteristic

is that in forward flight air does not flow significantly either up or down

through the rotor disc but primarily across it. The Heliplane is a similar

idea.

Compound rotorcrafts have wings which provide some or all of the lift in

forward flight.

axis

contra-prop

duct

fairing

fan

gear

hub

jet

propeller

propfan

ring

turbine

turboprop

15) A propeller comprises a set of small, wing-like aerofoils set around a

central hub and aligned in the direction of travel. Spinning the propeller

creates aerodynamic lift, or thrust, in a forward direction. A contra-prop

arrangement has a second propeller close behind the first one on the same

axis, which rotates in the opposite direction.

Turbine engines need not be used as jets (see below), but may be geared

to drive a propeller in the form of a turboprop. Modern helicopters also

typically use turbine engines to power the rotor.

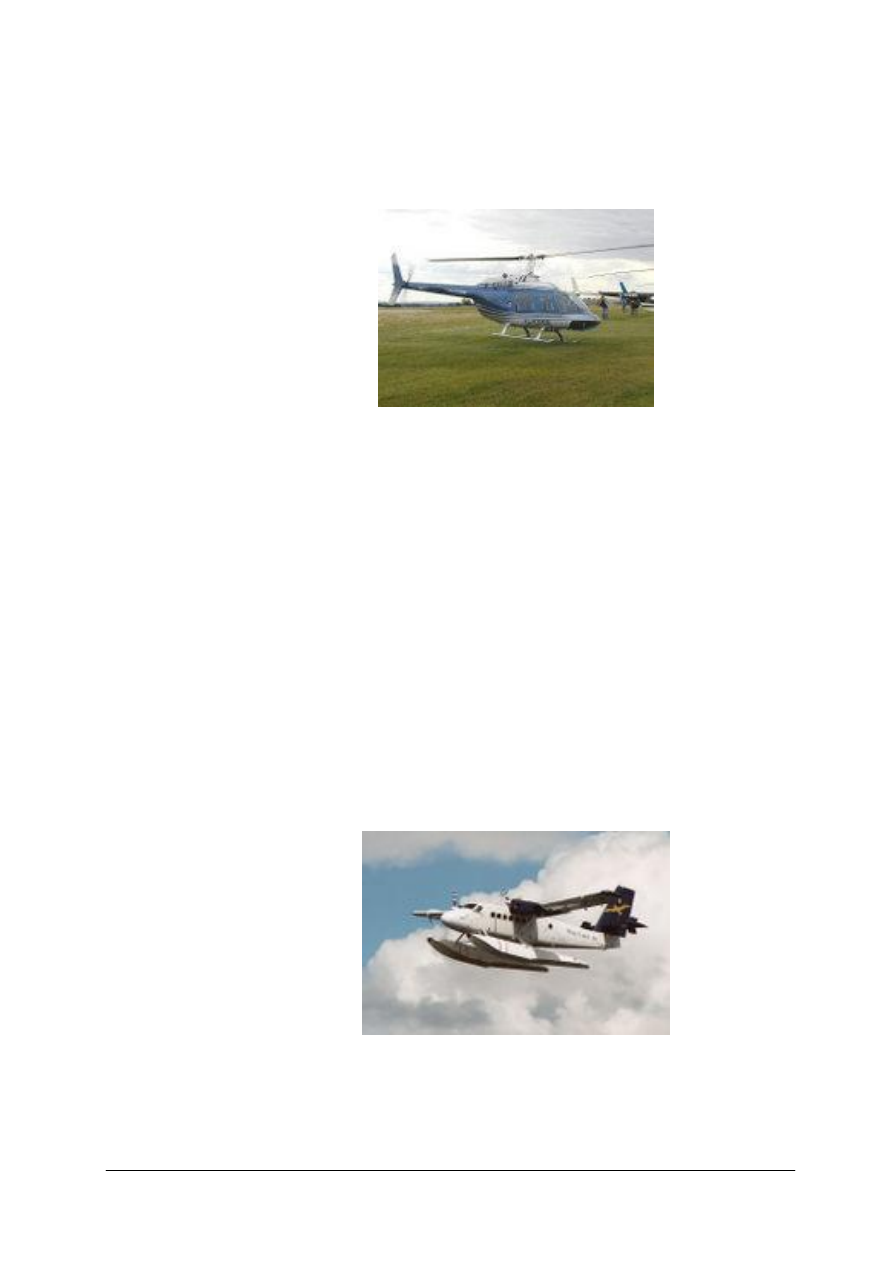

Rys.3. A turboprop-engined DeHavilland Twin Otter adapted as a floatplane [11]

A variation on propellers is to use many broad blades to create a fan.

These fans are traditionally surrounded by a ring-shaped fairing or duct,

as ducted fans. Some experimental designs do not use a duct, and are

sometimes called propfans. How to tell whether it's a propeller or a fan?

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

10

Look at it from the front when stationary: if you can see in between the

blades then it is a propeller, while if the blades pretty much block the

view it is a fan.

acceleration

altitude

burning

efficient

eject

exhaust

magnitude

mass

take in

16) Jet engines

Jet engines provide thrust by taking in air, burning it with fuel, and

accelerating the exhaust rearwards so that it ejects at high speed. The

reaction against this acceleration provides the engine thrust.

F = m · a, where “m” is the mass of accelerated air and fuel throughout

the engine and “a” is the magnitude of acceleration.

Jet engines can provide much higher thrust than propellers, and are

naturally efficient at higher altitudes, being able to operate above

40,000 ft (12,000 m). They are also much more fuel-efficient than

rockets. Consequently, nearly all high-speed and high-altitude aircraft

use jet engines.

booster

bypass

crude

hybrid design

pulse jet

ramjet

ramjet

refuel

stationary

tanker

turbojet

17) The early turbojet and modern turbofan use a spinning turbine to

create airflow for takeoff and to provide thrust, but this is not absolutely

necessary. Other designs include the crude pulse jet, high-speed ramjet

and the still-experimental supersonic-combustion ramjet or scramjet.

These designs require an existing airflow to work and cannot work when

stationary, so they must be launched by a catapult or rocket booster, or

dropped from a mother ship. The engines of the Lockheed blackbird were

a hybrid design - the aircraft took off and landed in jet turbine

configuration, and for high-speed flight the turbine was bypassed to form

a ramjet.

airliner

bomber

fighter

transport

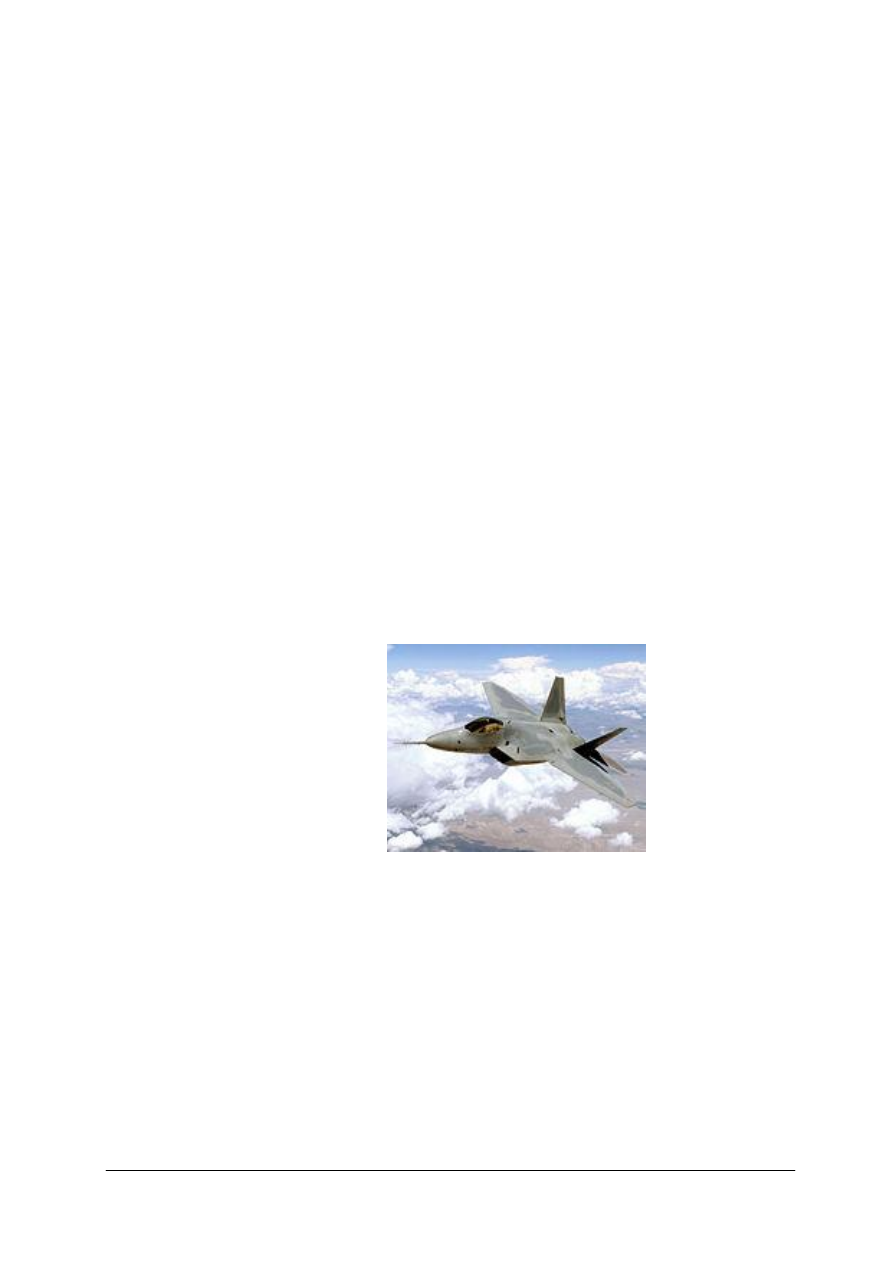

18) Military aircraft

Rys.4. The fifth-generation Military Aircraft, F-22 Raptor [12]

Combat aircraft like fighters or bombers represent only a minority of the

category. Many civil aircraft have been produced in separate models for

military use, such as the civil Douglas DC-3 airliner, which became the

military C-47/C-53/R4D transport in the U.S.

19) List of aircraft by category

1 Civilian Aircraft

1.1 Airliners

1.2 Cargo planes

1.3 General aviation

1.4 Agricultural aircraft

1.5 Business aircraft

1.6 Civilian Seaplane, Flying Boats, and Amphibious Aircraft

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

11

1.7 Civilian Helicopters

1.8 Sailplanes

1.9 Civil Research Aircraft, Prototypes and Specials

2 Military Aircraft

2.1 Bombers, Strike, Ground attack, gunships

2.2 Patrol, Anti-Submarine and Electronic Warfare aircraft

2.3 Military transports, tankers, and utility

2.4 Reconnaissance aircraft

2.5 Close air support/Counterinsurgency

2.6 Fighter aircraft, nightfighters and heavy fighters

2.7 Military Trainers

2.8 Military Helicopters and autogyros

2.9 Military Research Aircraft, Prototypes and Specials

4.1.2. Pytania sprawdzające

Odpowiadając na pytania, sprawdzisz, czy jesteś przygotowany do wykonania ćwiczeń.

1. Are all aircraft flown by a pilot?

2. Why is and isn’t a space-shuttle an aircraft?

3. What is a UAV flown by?

4. What does RPV refer to?

5. What was the first aircraft to fly?

6. What makes aerostats fly in the air?

7. What makes the heavier than air aircraft fly?

8. What is the difference between conventional aircraft and flying wing?

9. How many wings has a quadruplane got?

10. What are advantages and disadvantages of a cantilever wing design?

11. What are the most common shapes of aircraft wings?

12. What is the difference between a seaplane and a floatplane?

13. What is the main difference between helicopters and autogyros?

14. What are the main parts of an aircraft structure?

4.1.3. Ćwiczenia

Ćwiczenie 1

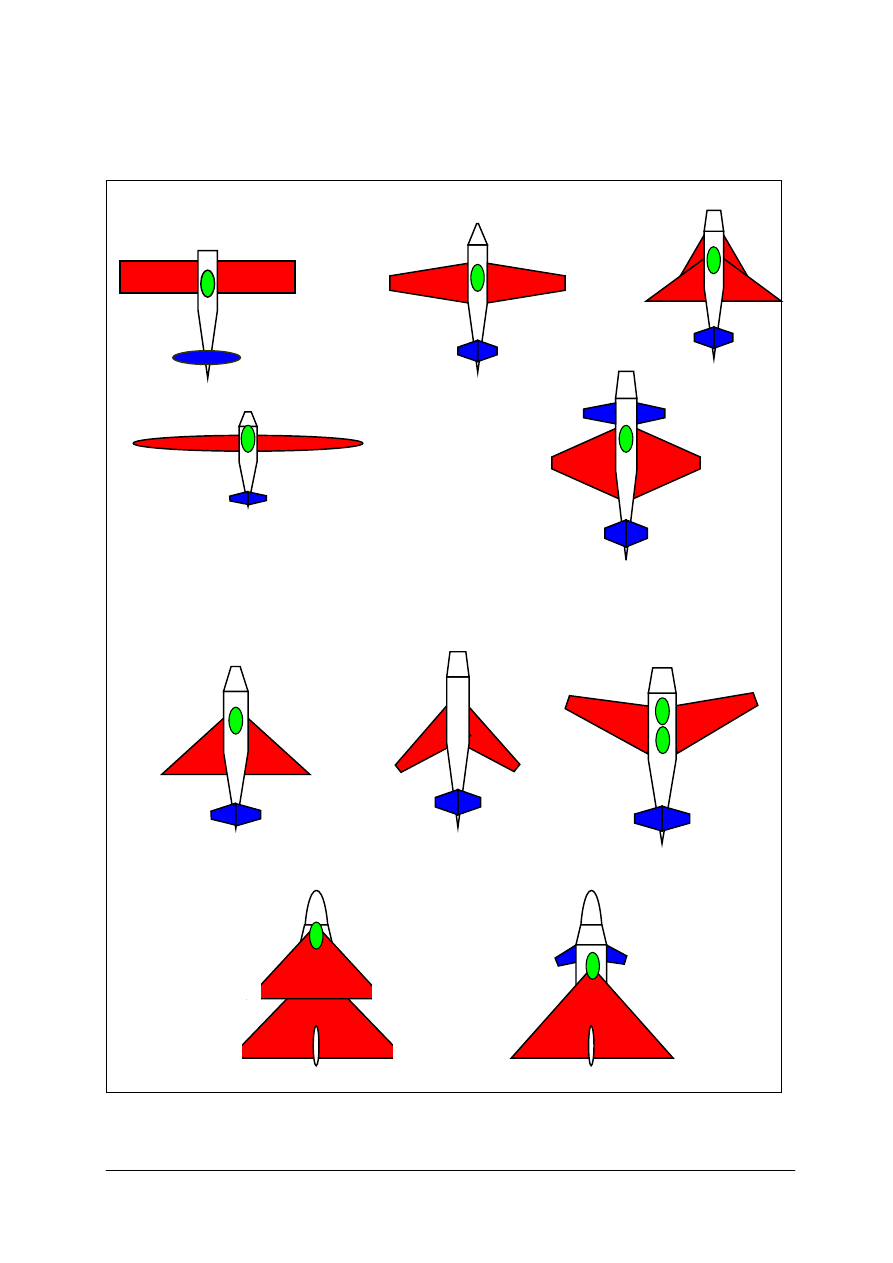

Na podstawie fragmentów 6–10 materiału nauczania z rozdziału 4.1.1. Poradnika dla

ucznia określ układ aerodynamiczny statków powietrznych przedstawionych na rysunku do

ćwiczenia 1. Określ kształty elementów tworzących rysunek statku powietrznego.

Sposób wykonania ćwiczenia

Aby wykonać ćwiczenie, powinieneś:

1) zorganizować stanowisko pracy do wykonania ćwiczenia,

2) przeanalizować zadania,

3) sprawdzić w słowniku określenia dotyczące podstawowych figur geometrycznych,

4) porównać nazwy figur geometrycznych z nazwami frazeologicznymi używanymi

w lotnictwie,

5) porównać wynik pracy z pracami innych uczniów.

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

12

Wyposażenie stanowiska pracy:

–

słownik,

–

materiały do pisania.

Rys. do ćwiczenia 1. Wing planforms.

A

B

C

D

E

F

G

H

I

J

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

13

Ćwiczenie 2

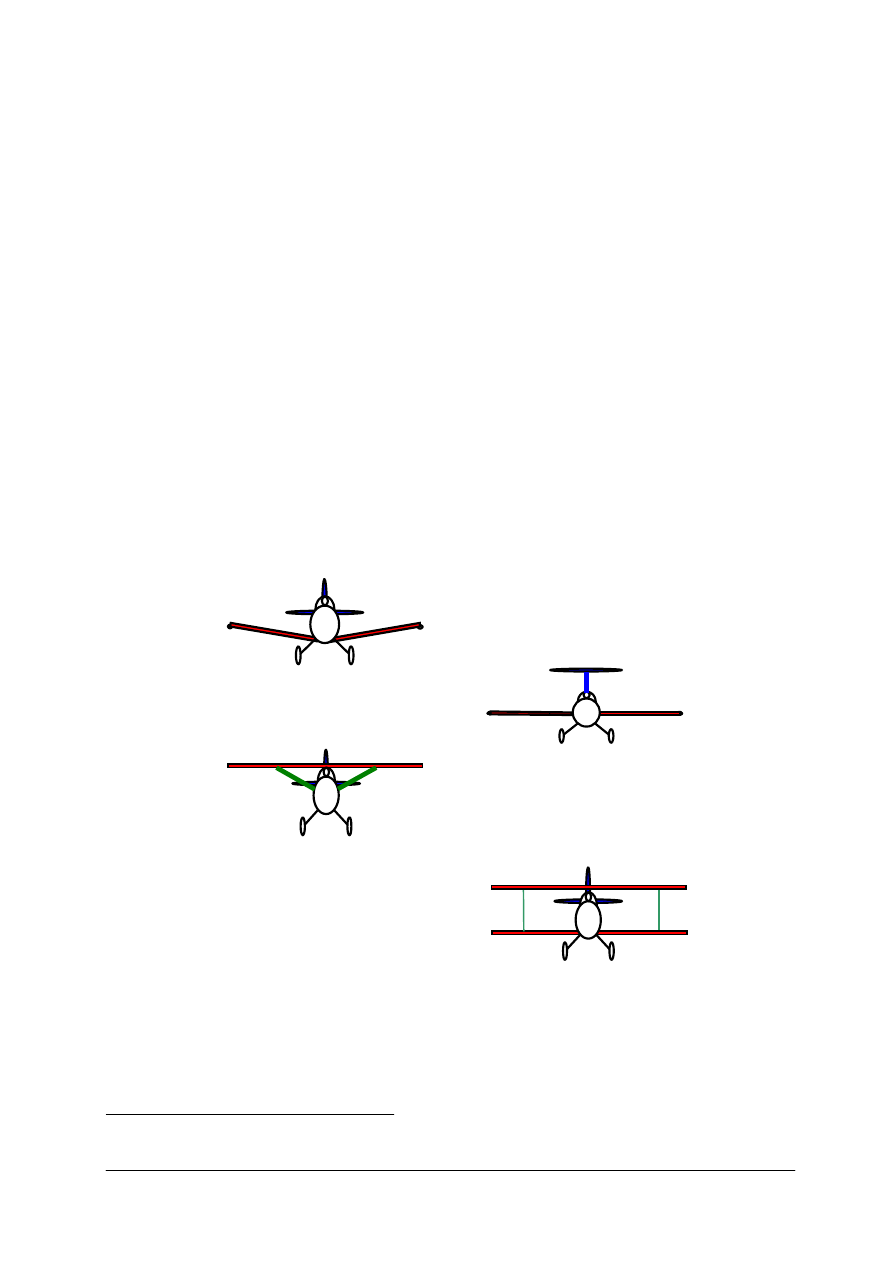

Na rysunku do ćwiczenia 2 przedstawione są cztery konfiguracje ustawienia skrzydeł

w stosunku do kadłuba. Podaj słowną instrukcję do narysowania podobnego rysunku

używając określeń geometrycznych (okrąg, linia ukośna). Wykonaj to samo ćwiczenie

używając fachowych określeń lotniczych (kadłub, skrzydło, ster wysokości). Pozostałe osoby

w grupie będą rysowały zgodnie z twoimi instrukcjami. Powtórz ćwiczenie dla sylwetek

samolotów z rysunku do ćwiczenia 1.

Sposób wykonania ćwiczenia

Aby wykonać ćwiczenie, powinieneś:

1) zorganizować stanowisko pracy do wykonania ćwiczenia,

2) przeanalizować zadania,

3) sprawdzić w słowniku określenia dotyczące podstawowych figur geometrycznych,

4) porównać nazwy figur geometrycznych z nazwami frazeologicznymi używanymi

w lotnictwie,

5) porównać wynik pracy z pracami innych uczniów.

Wyposażenie stanowiska pracy:

– papier formatu A4,

– ołówek,

– flamastry,

– poradnik dla ucznia,

– słownik.

Rys. do ćwiczenia 2. Wing position.

Ćwiczenie 3

Przygotuj trwającą 4-5 minut prezentację w programie PowerPoint, lub Impress

przedstawiającą budowę wybranego typu statku powietrznego.

Aby znaleźć potrzebne informacje i ilustracje skorzystaj z encyklopedii internetowej

http://en.wikipedia.org/wiki/Main_Page, lub innych źródeł. Wykorzystaj słownictwo podane

w 19 fragmencie materiału nauczania 4.1.1.

A

C.

D

B

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

14

Proponowane typy statków powietrznych:

– PZL M-28,

– AN-2,

– Aviat Eagle II,

– PA 34 Seneca,

– Curtiss_YA-14,

– Bell XP-83,

– Cessna 172,

– PZL-104 Wilga,

– Mirage 2000,

– Airbus A-380,

– Boeing 767,

– B-2 Spirit,

– F-16,

– Eurofighter Typhoon,

– MQ1 Predator.

Sposób wykonania ćwiczenia

Aby wykonać ćwiczenie, powinieneś:

1) zorganizować stanowisko pracy do wykonania ćwiczenia,

2) przeanalizować zadania,

3) wyszukać w Internecie charakterystykę wybranego statku powietrznego,

4) wykonać prezentację uwzględniając słownictwo zawarte w materiale nauczania,

5) porównać wynik pracy z pracami innych uczniów.

Wyposażenie stanowiska pracy:

–

słownik,

–

komputer z dostępem do Internetu,

–

materiały do pisania.

4.1.4. Sprawdzian postępów

Czy potrafisz:

Tak

Nie

1) dokonać podziału statków powietrznych ze względu na wielkość

załogi?

2) dokonać podziału statków powietrznych ze względu na ciężar?

3) wyjaśnić zasadę lotu aerostatu?

4) wyjaśnić mechanizm powstawania siły nośnej na skrzydle?

5) wymienić główne elementy konstrukcyjne statku powietrznego?

6) opisać układ aerodynamiczny samolotu?

7) opisać sposób powstawania siły nośnej w śmigłowcu?

8) opisać sposób powstawania siły nośnej w wiatrakowcu?

9) podać przykłady zastosowania silników turbinowych i odrzutowych?

10) wymienić główne rodzaje silników lotniczych?

11) wymienić rodzaje statków powietrznych cywilnych i wojskowych ze

względu na przeznaczenie?

12) wymienić główne elementy konstrukcyjne skrzydła?

13) wymienić główne elementy konstrukcyjne kadłuba?

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

15

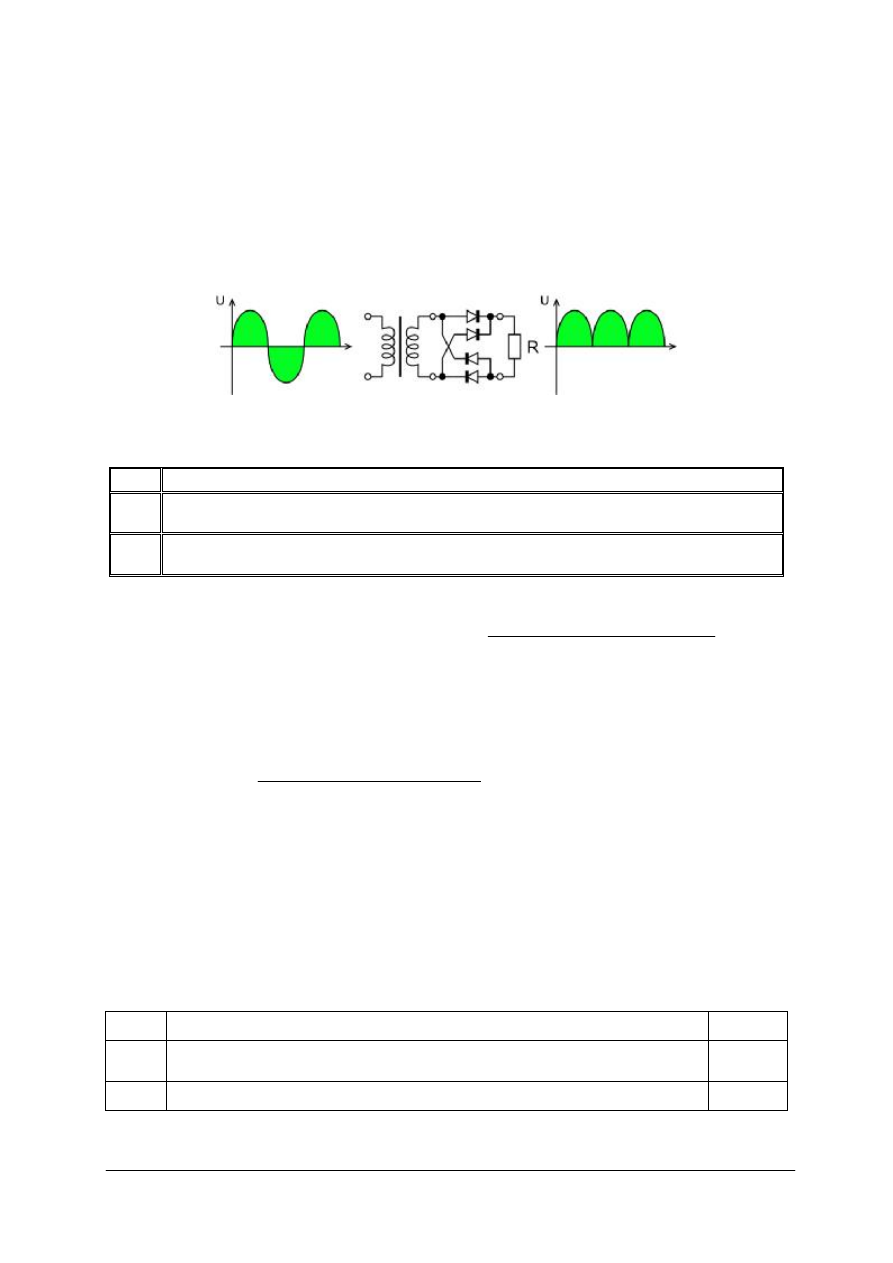

4.2. Systemy i instalacje samolotu

4.2.1. Materiał nauczania

combustion

filters

fluid

generator

hydraulic

hydrostatic

kinetic energy

liquid

piping

pump

valves

1) A hydraulic or hydrostatic drive system or hydraulic power

transmission is a drive or transmission system that makes use of

a hydraulic fluid under pressure to drive machinery. All liquids and all

gases are fluids. Such a system basically consists of: Generator part of

the transmission, in general a hydraulic pump, driven by an electric

motor, a combustion engine or a windmill. Valves, filters, piping etc. to

guide and control the system. Motor part of the transmission a hydraulic

motor or hydraulic cylinder to drive the machinery. Hydrostatic means

that the energy comes from the flow and the pressure, but not from the

kinetic energy of the flow.

actuated

confined

confined liquid

diminish

fluid

gas

incompressible

law

liquid

rest

transmit

2) Principle of hydraulic drive system.

Pascal's law is the basis of hydraulic drive systems. Hydraulic system

liquids are used primarily to transmit and distribute forces to various

units to be actuated. Liquids are able to do this because they are almost

incompressible. Pascal's Law states that pressure applied to any part of

a confined and connected body of an incompressible fluid at rest is

transmitted with undiminished intensity to every other part.

dilute

flow

resistance

viscosimeter

viscosity

3) Viscosity.

One of the most important properties of any hydraulic fluid is its

viscosity. Viscosity is internal resistance to flow. A liquid such as

gasoline flows easily (has a low viscosity) while a liquid such as tar

flows slowly (has a high viscosity). Viscosity increases with temperature

decreases. The viscosity of a liquid is measured with a viscosimeter or

viscometer.

breakdown

bypass

bypass valve

clogged

contamination

deposit

impurity

inline

malfunction

objectionable

particles

pressure line

pump

reservoir

route

safeguard

screen

secured

selector valve

strain

suspension

wear

4) Filters.

A filter is a screening or straining device used to clean the hydraulic

fluid, thus preventing foreign particles and contaminating substances

from remaining in the system. If such objectionable material is not

removed, it may cause the entire hydraulic system of the aircraft to fail

through the breakdown or malfunctioning of a single unit of the system.

The hydraulic fluid holds in suspension tiny particles of metal that are

deposited during the normal wear of selector valves, pumps, and other

system components. Filters may be located within the reservoir, in the

pressure line, in the return line, or in any other location where the

designer of the system decides that they are needed to safeguard the

hydraulic system against impurities. Most filters used in modern aircraft

are of the inline type. The inline filter assembly is comprised of three

basic units: head assembly, bowl, and element. The head assembly is that

part which is secured to the aircraft structure and connecting lines.

Within the head there is a bypass valve which routes the hydraulic fluid

directly from the inlet to the outlet port if the filter element becomes

clogged with foreign matter.

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

16

adjustable

efficiency

ratio

servo-motors

swept volume

throttling

plunger

torque

5) A hydraulic pump with a small swept volume that asks for a small

torque combined with a hydraulic motor with a large swept volume that

gives a large torque. In such a way a transmission with a certain ratio can

be built. Most hydraulic drive systems make use of hydraulic cylinders.

Here the same principle is used. A small torque can be transmitted in

a large force. By throttling the fluid between generator part and motor

part, or by using hydraulic pumps and/or motors with adjustable swept

volume, the ratio of the transmission can be changed easily. In case

throttling is used, the efficiency of the transmission is limited, If

adjustable pumps and motors are used, the efficiency however is very

large. In fact up to say 1980, a hydraulic drive system had hardly

competition from other adjustable (electric) drive systems. Nowadays

electric drive systems using electric servo-motors can be controlled in an

excellent way and can easily compete with rotating hydraulic drive

systems. Hydraulic cylinders are in fact without competition for linear

(high) forces. For these cylinders anyway hydraulic systems will remain

of interest and if such a system is available, it is easy and logical to use

this system also for the rotating drives of the system.

compensator

fixed delivery

pumps

quantity of fluid

variable/constant

delivery

6) Hydraulic pump

The smallest gear pumps (except miniature ones) have a swept volume of

1 cm³ and the largest axial plunger pump that is available from stock will

have a swept volume of 1000 cm³. For continuous hydraulic drives, the

maximum working pressure will be some 200 bars.

7) Power Driven Pumps

Many of the power driven hydraulic pumps of current aircraft are of

variable delivery, compensator controlled type. There are some constant

delivery pumps in use. Principles of operation are the same for both types

of pumps.

pressure

regulator

pump rpm

varying output

automatically

output

within

8) Constant delivery pumps are sometimes called constant volume or

fixed delivery pumps. They deliver a fixed quantity of fluid per

revolution, regardless of the pressure demands. Since the constant

delivery pump provides a fixed quantity of fluid during each revolution

of the pump, the quantity of fluid delivered per minute will depend upon

pump rpm. When a constant delivery pump is used in a hydraulic system

in which the pressure must be kept at a constant value, a pressure

regulator is required.

9) A variable delivery pump has a fluid output that is varied to meet the

pressure demands of the system by varying its fluid output. The pump

output is changed automatically by a pump compensator within the

pump.

durability

gear

gerotor

piston

vane

10) Pumping Mechanisms

Various types of pumping mechanisms are used in hydraulic pumps, such

as gears, gerotors, vanes, and pistons. The piston type mechanism is

commonly used in power driven pumps because of its durability and

capability to develop high pressure. In 3,000 psi hydraulic systems,

piston type pumps are nearly always used.

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

17

clearance

clockwise

counterclockwise

gear teeth

housing

inlet port

meshed gears

outlet port

reservoir

trapped

11) Gear Type Pump

A gear type power pump consists of two meshed gears that revolve in

a housing. The driving gear is driven by the aircraft engine or some other

power unit. The driven gear meshes with, and is driven by, the driving

gear. Clearance between the teeth as they mesh, and between the teeth

and the housing, is very small. The inlet port of the pump is connected to

the reservoir, and the outlet port is connected to the pressure line. When

the driving gear turns in a counterclockwise direction, it turns the driven

gear in a clockwise direction. As the gear teeth pass the inlet port, fluid is

trapped between the gear teeth and the housing, and is then carried

around the housing to the outlet port.

blades

bore

coupling

displaced

drawn

hollow rotor

off center

sleeve

slots

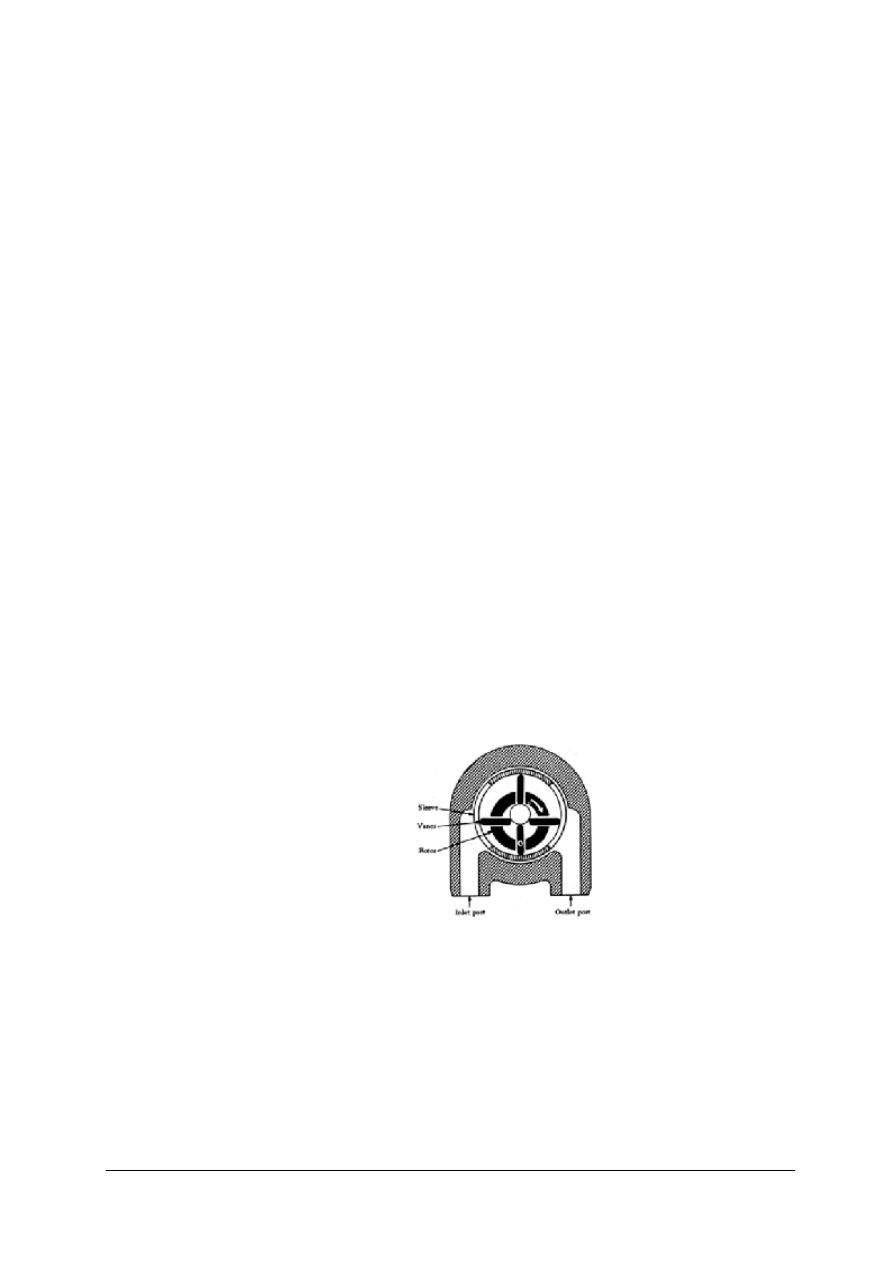

12) Vane Type Pump

The vane type power pump consists of a housing containing four vanes

(blades), a hollow steel rotor with slots for the vanes, and a coupling to

turn the rotor.

The rotor is positioned off center within the sleeve. The vanes, which are

mounted in the slots in the rotor, together with the rotor, divide the bore

of the sleeve into four sections. As the rotor turns, each section, in turn,

passes one point where its volume is at a minimum, and another point

where its volume is at a maximum. The volume gradually increases from

minimum to maximum during one-half of a revolution, and gradually

decreases from maximum to minimum during the second half of the

revolution. As the volume of a given section is increasing, that section is

connected to the pump inlet port through a slot in the sleeve. Since

a partial vacuum is produced by the increase in volume of the section,

fluid is drawn into the section through the pump inlet port and the slot in

the sleeve. As the rotor turns through the second half of the revolution,

and the volume of the given section is decreasing, fluid is displaced out

of the section, through the slot in the sleeve, through the outlet port, and

out of the pump.

Rys.5. Vane type pump. [4]

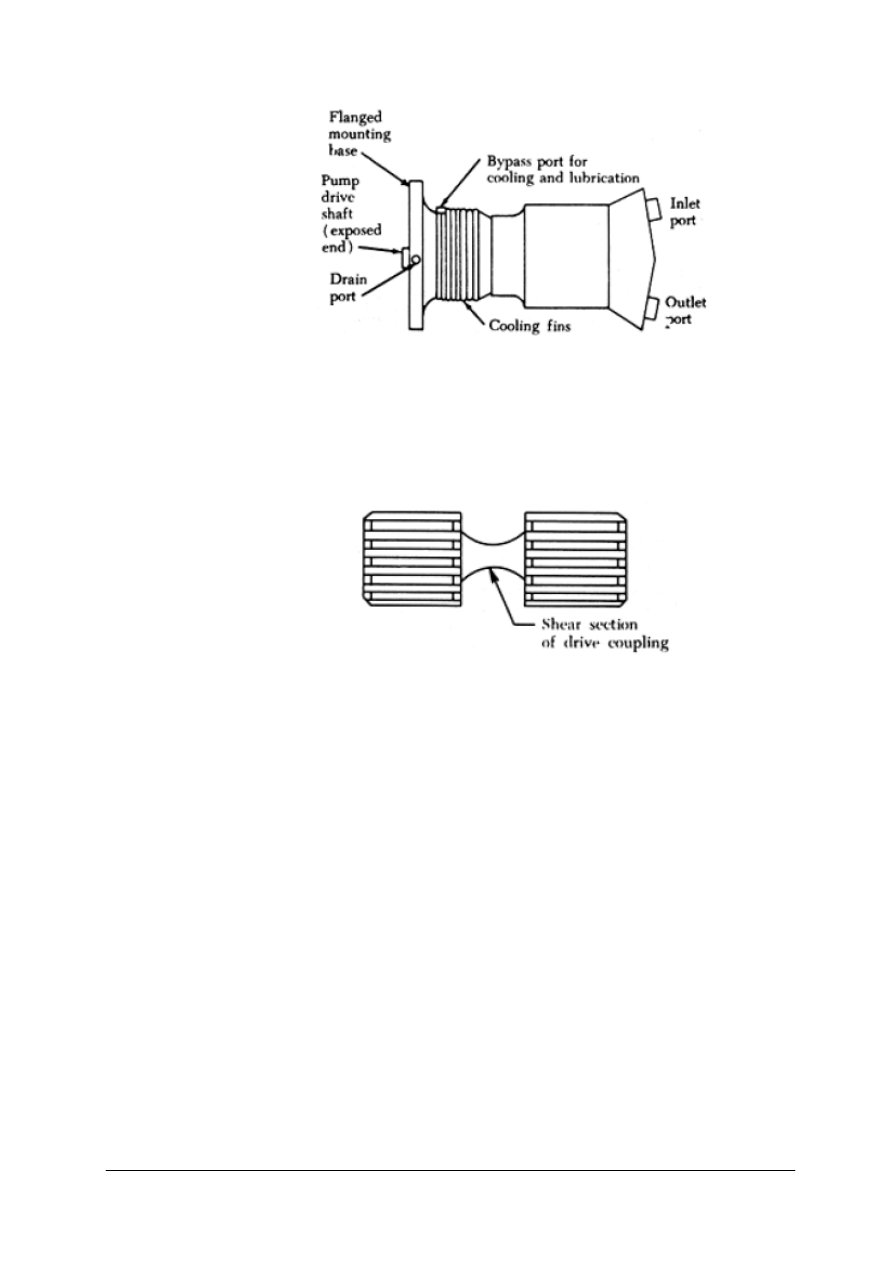

accessory drive

case

base

drive coupling

engage

female splines

flange

housing

male splines

piston

plunger

13) Piston type power driven pumps have flanged mounting bases for the

purpose of mounting the pumps on the accessory drive cases of aircraft

engines and transmissions. A pump drive shaft, which turns the

mechanism, extends through the pump housing slightly beyond the

mounting base.

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

18

shaft

torque

Rys.6. Piston type pump. [4]

Torque from the driving unit is transmitted to the pump drive shaft by

a drive coupling. The drive coupling is a short shaft with a set of male

splines on both ends. The splines on one end engage with female splines

in a driving gear; the splines on the other end engage with female splines

in the pump drive shaft.

Rys.7. Pump drive male coupling with shear section. [4]

diameter

jammed

midway

parallel

perpendicular

rotary

reciprocal

motion

safety devices

shear

symmetrical

valving

14) Pump drive couplings are designed to serve as safety devices. The

shear section of the drive coupling, located midway between the two sets

of splines, is smaller in diameter than the splines. If the pump becomes

unusually hard to turn or becomes jammed, this section will shear,

preventing damage to the pump or driving unit.

The basic pumping mechanism of piston type pumps consists of

a multiple bore cylinder block, a piston for each bore, and a valving

arrangement for each bore. The purpose of the valving arrangement is to

let fluid into and out of the bores as the pump operates. The cylinder

bores lie parallel to and symmetrically around the pump axis. The term

"axial piston pump" is often used in referring to pumps of this

arrangement. Basically these types of pumps changes rotary motion into

reciprocal piston motion.

actuator

clevis

cylinder head

linear motor

multiply

piston rod

sealed

shell

stroke

volume

15) Hydraulic cylinders (also called linear hydraulic motors) are

mechanical actuators that are used to give a linear force through a linear

stroke. Very simple hydraulic cylinders are used in presses; here the

cylinder consists out of a volume in a piece of iron with a plunger pushed

in it and sealed with a cover. By pumping hydraulic fluid in the volume,

the plunger is pushed out with a force of plunger area multiplied by

pressure. More sophisticated cylinders have a body with end cover,

a piston rod with piston and a cylinder head. At one side the bottom is

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

19

connected to a single clevis, whereas at the other side, the piston rod also

is foreseen with a single clevis. The cylinder shell normally has hydraulic

connections at both sides. A connection at bottom side and one at

cylinder head side. If oil is pushed under the piston, the piston-rod is

pushed out and oil that was between the piston and the cylinder head is

pushed back to the oil-tank again.

balanced

actuator

double acting

extend

retract

single acting

16) In case the retracted length of the cylinder is too long for the cylinder

to be build in the structure. In this case telescopic cylinders can be used.

One has to realize that for simple pushing applications telescopic

cylinders might be available easily; for higher forces and/or double

acting cylinders, they must be designed especially and are very

expensive. If hydraulic cylinders are only used for pushing and the piston

rod is brought in again by other means, one can also use plunger

cylinders. Plunger cylinders have no sealing over the piston, or the piston

does not exist. This means that only one oil connection is necessary. In

general the diameter of the plunger is rather large compared with

a normal piston cylinder.

conceptually

interchangeable

motor

rotary

17) The hydraulic motor is the rotary counterpart of the hydraulic

cylinder. Conceptually, a hydraulic motor should be interchangeable with

hydraulic pump, because it performs the opposite function. However,

most hydraulic pumps cannot be used as hydraulic motors because they

cannot be backdriven.

excessive

heavy duty

relief

stand up

thermal

thermal

expansion

18) Hydraulic valves

These valves are usually very heavy duty to stand up to high pressures.

Some special valves can control the direction of the flow of fluid and act

as a control unit for a system.

Thermal relief valve. The pressure relief valve is used to relieve

excessive pressures that may exist due to thermal expansion of the fluid.

pressure gauge

pressure

regulator

pressure relief

valve

rupture

19) Pressure regulation.

Hydraulic pressure must be regulated in order to use it to perform the

desired tasks. Pressure regulating systems will always use three

elemental devices; a pressure relief valve, a pressure regulator and a

pressure gauge.

A pressure relief valve is used to limit the amount of pressure being

exerted on a confined liquid. This is necessary to prevent failure of

components or rupture of hydraulic lines under excessive pressures. The

pressure relief valve is, in effect, a system safety valve.

acute angle

angle

ball type

cone

contoured

leakage

machined

matched angles

obtuse angle

poppet type

20) The most common types of valve are:

Ball type. In pressure relief valves with a ball type valving device, the

ball rests on a contoured seat. Pressure acting on the bottom of the ball

pushes it off its seat, allowing the fluid to bypass.

Sleeve type. In pressure relief valves with a sleeve type valving device,

the ball remains stationary and a sleeve type seat is moved up by the fluid

pressure. This allows the fluid to bypass between the ball and the sliding

sleeve type seat.

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

20

right angle

sleeve type

valve seat

Poppet type. In pressure relief valves with a poppet type valving device,

a cone shaped poppet may have any of several design configurations;

however, it is basically a cone and seat machined at matched angles to

prevent leakage.

predeterminated

pressurized

range

resistance

termed

virtually

21) Pressure Regulators

The term "pressure regulator" is applied to a device used in hydraulic

systems that are pressurized by constant delivery type pumps. One

purpose of the pressure regulator is to manage the output of the pump to

maintain system operating pressure within a predetermined range. The

other purpose is to permit the pump to turn without resistance (termed

unloading the pump) at times when pressure in the system is within

normal operating range. The pressure regulator is so located in the

system that pump output can get into the system pressure circuit only by

passing through the regulator. The combination of a constant delivery

type pump and the pressure regulator is virtually the equivalent of

a compensator controlled, variable delivery type pump.

bourdon tube

drain

face

moisture

vent

22) Pressure Gauge

The purpose of this gauge is to measure the pressure, in the hydraulic

system, used to operate hydraulic units on the aircraft. The gauge uses

a Bourdon tube and a mechanical arrangement to transmit the tube

expansion to the indicator on the face of the gauge. A vent in the bottom

of the case maintains atmospheric pressure around the Bourdon tube. It

also provides a drain for any accumulated moisture.

chambers

continually

cycle

dampen

leak

preset

rubber

diaphragm

sphere

supplement

supplement

surge

23) The accumulator is a steel sphere divided into two chambers by

a synthetic rubber diaphragm. The upper chamber contains fluid at

system pressure, while the lower chamber is charged with air.

The function of an accumulator is to:

a. Dampen pressure surges in the hydraulic system caused by actuation of

a unit and the effort of the pump to maintain pressure at a preset level.

b. Aid or supplement the power pump when several units are operating at

once by supplying extra power from its "accumulated" or stored power.

c. Store power for the limited operation of a hydraulic unit when the

pump is not operating.

d. Supply fluid under pressure to compensate for small internal or

external (not desired) leaks which would cause the system to cycle

continuously by action of the pressure switches continually "kicking in."

as such

check valve

exclusively

hose

integral part

must be made

to flow

orifice

restricted

tubing

within itself

24) Check Valves

For hydraulic components and systems to operate as intended, the flow of

fluid must be rigidly controlled. Fluid must be made to flow according to

definite plans. Many kinds of valve units are used for exercising such

control. One of the simplest and most commonly used is the check valve

which allows free flow of fluid in one direction, but no flow or

a restricted flow in the opposite direction.

Check valves are made in two general designs to serve two different

needs. In one, the check valve is complete within itself. It is

interconnected with other components with which it operates, by means

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

21

of tubing or hose. Check valves of this design are commonly called in-

line check valves. There are two types of in-line check valves, the simple

type in-line check valve and the orifice type in-line valve. In the other

design, the check valve is not complete within itself because it does not

have a housing exclusively its own. Check valves of this design are

commonly called integral check valves. This valve is actually an integral

part of some major component and, as such, shares the housing of that

component.

pathway

reverse

select

actuating unit

pathway

simultaneous

flow

25) Line Disconnect or Quick Disconnect Valves

These valves are installed in hydraulic lines to prevent loss of fluid when

units are removed. Such valves are installed in the pressure and suction

lines of the system just in front of and immediately behind the power

pump.

26) Selector valves.

Selector valves are used to control the direction of movement of an

actuating unit. A selector valve provides a pathway for the simultaneous

flow of hydraulic fluid into and out of a connected actuating unit.

A selector valve also provides a means of immediately and conveniently

switching the directions in which the fluid flows through the actuator,

reversing the direction of movement.

building pressure

do exist

reservoir

tank

utilizing

27) Pneumatic systems components.

Pneumatic systems are often compared to hydraulic systems, but such

comparisons can only hold true in general terms. Pneumatic systems do

not utilize reservoirs, hand pumps, accumulators, regulators, or engine

driven or electrically driven power pumps for building normal pressure.

But similarities do exist in some components.

chamber

lever

lobe

passage

poppet

spring

vent port

28) Control valves are also a necessary part of a typical pneumatic

system. The control valve consists of a three port housing, two poppet

valves, and a control lever with two lobes. A spring holds the poppet

closed so that compressed air entering the pressure port cannot flow to

the brakes.

One lobe of the lever holds the left poppet open, and a spring closes the

right poppet. Compressed air now flows around the opened left poppet,

through a drilled passage, and into a chamber below the right poppet.

Since the right poppet is closed, the high pressure air flows out of the

brake port and into the brake line to apply the brakes.

To release the brakes, the control valve is returned to the "off" position.

The left poppet now closes, stopping the flow of high pressure air to the

brakes. At the same time, the right poppet is opened, allowing

compressed air in the brake line to exhaust through the vent port and into

the atmosphere.

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

22

airflow

orifice

rate

29) Restrictors

Restrictors are a type of control valve used in pneumatic systems. An

orifice type restrictor have a large inlet port and a small outlet port. The

small outlet port reduces the rate of airflow and the speed of operation of

an actuating unit.

application

assembly

brake shuttle

valve

float

hollow

return line

seal

trap

30) Brake Shuttle Valve

The valve consists of a shuttle enclosed by a four port housing. The

shuttle is a sort of floating piston that can move up or down in the hollow

housing. Normally, the shuttle is down, and in this position it seals off

the lower air port and directs hydraulic fluid from the upper port into the

two side ports, each of which leads to a brake assembly. But when the

emergency pneumatic brakes are applied, high pressure air raises the

shuttle, seals off the hydraulic line, and connects air pressure to the side

ports of the shuttle valve. This action sends high pressure air into the

brake cylinder to apply the brakes.

After application and when the emergency brakes are released, the air

valve closes, trapping pressure in the air bottle. At the same time, the air

valve vents the pneumatic brake line to outside air pressure. Then as air

pressure in the brake line drops, the shuttle valve moves to the lower end

of the housing, again connecting the brake cylinders to the hydraulic line.

Air pressure remaining in the brake cylinders then flows out the upper

port of the shuttle valve and into the hydraulic return line.

4.2.2. Pytania sprawdzające

Odpowiadając na pytania, sprawdzisz, czy jesteś przygotowany do wykonania ćwiczeń.

1. What is the source of pressure in a hydraulic system?

2. How is the pressure distributed in confined fluid?

3. How big resistance does low wiscosity fluid offer?

4. What are filters in a hydraulic system used for?

5. What does “swept volume” refer to?

6. What kind of pump displaces equal volume of liquid per one revolution?

7. What type of hydraulic pump delivers the highest pressure?

8. What is the purpose of the shear section in a drive coupling?

9. What does the linear hydraulic motor stroke refer to?

10. What are telescoping cylinders used for?

11. What does the hydraulic motor stand for?

12. Does a thermal relief valve operate with regard to temperature?

13. Why are walve seats always machined?

14. Why do some hydraulic systems require using pressure regulators?

15. What are the main parts of the accumulator?

16. Where are in-line check walves placed in a hydraulic system?

17. What is the primary function of a selector walve?

18. How does a control walve operate?

19. What is a shuttle walve made up of?

20. What does the force in a hydraulic system depend on?

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

23

4.2.3. Ćwiczenia

Ćwiczenie 1

Cechą charakterystyczną języka angielskiego, szczególnie widoczną w tekstach

technicznych, jest istnienie „noun strings”, czyli rzeczowników złożonych. Zapisz znaczenie

poniższych „noun strings” w języku polskim. Zwróć uwagę na zmianę znaczenia

poszczególnych rzeczowników złożonych. Zwróć uwagę na odwrotną kolejność zapisu

wyrazów w języku polskim.

Valve;

……………

Check valve;

………………………………..

Hydraulic check valve;

…………………………………………………

High pressure hydraulic check valve;

………………………………………………………………………………

Engine high pressure hydraulic check valve;

……………………………………………………………………………………….

Auxiliary engine high pressure hydraulic check valve;

………………………………………………………………………………………………

Port auxiliary engine high pressure hydraulic check valve;

…………………………………………………………………………………………………

Ostatnie wyrażenie w wersji polskiej to: „hydrauliczny zawór jednokierunkowy wysokiego

ciśnienia lewego silnika pomocniczego”.

Sposób wykonania ćwiczenia

Aby wykonać ćwiczenie, powinieneś:

1) zorganizować stanowisko pracy do wykonania ćwiczenia,

2) sprawdzić w słowniku znaczenia poszczególnych rzeczowników,

3) w liniach kropkowanych wpisać polską interpretację rzeczownika złożonego,

4) porównać wynik pracy z pracami innych uczniów oraz ze zdaniem podanym na końcu

ćwiczenia.

Wyposażenie stanowiska pracy:

– papier formatu A4, ołówek, długopis,

– poradnik dla ucznia, słownik techniczny.

Ćwiczenie 2

Podaj znaczenia poniższych “noun strings”. Zwróć uwagę na całkowitą zmianę znaczenia

przy dodawaniu kolejnych rzeczowników.

Auxiliary;

……………………..

Auxiliary port;

………………………….

Auxiliary port engine;

……………………………………

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

24

Auxiliary port engine high pressure;

……………………………………………

Auxiliary port engine high pressure hydraulic;

………………………………………………………

Auxiliary port engine high pressure hydraulic check;

………………………………………………………………

Auxiliary port engine high pressure hydraulic check valve;

……………………………………………………………………

Auxiliary port engine high pressure hydraulic check valve spring;

……………………………………………………………………………

Auxiliary port engine high pressure hydraulic check valve spring retainer;

……………………………………………………………………………………

Auxiliary port engine high pressure hydraulic check valve spring retainer lock;

…………………………………………………………………………………………

Auxiliary port engine high pressure hydraulic check valve spring retainer lock pin;

…………………………………………………………………………………………………

Ostatni, dosyć sztuczny przykład, mógłby oznaczać:

„zawleczkę blokującą uchwytu sprężyny znajdującej się w jednokierunkowym zaworze

hydraulicznym wysokiego ciśnienia znajdującym się w lewym silniku pomocniczym”.

Zwróć uwagę na to, że błędne określenie ostatniego rzeczownika w „noun string”

spowoduje całkowicie błędną interpretację rzeczownika złożonego. Innym typowym błędem

jest nadanie jednemu z rzeczowników znaczenia czasownika.

Sposób wykonania ćwiczenia:

Aby wykonać ćwiczenie, powinieneś:

1) zorganizować stanowisko pracy do wykonania ćwiczenia,

2) przeanalizować pojęcia,

3) sprawdzić w słowniku technicznym znaczenia poszczególnych rzeczowników,

4) w liniach kropkowanych wpisać polską interpretację rzeczownika złożonego,

5) porównać wynik pracy z pracami innych uczniów oraz przykładem podanym na końcu

ćwiczenia.

Wyposażenie stanowiska pracy:

−

papier formatu A4, ołówek, długopis,

−

poradnik dla ucznia, słownik techniczny.

Ćwiczenie 3

W materiale nauczania z rozdziału 4.2.1. Poradnika dla ucznia znajdź jak największą

liczbę „noun strings”. Zapisz je i podaj polską interpretację.

Sposób wykonania ćwiczenia

Aby wykonać ćwiczenie, powinieneś:

1) zorganizować stanowisko pracy do wykonania ćwiczenia,

2) przeanalizować materiał nauczania,

3) znaleźć i wypisać podaną przez nauczyciela liczbę rzeczowników złożonych (nie mniej

niż 10),

4) porównać wynik pracy z innymi uczniami.

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

25

Wyposażenie stanowiska pracy:

−

papier formatu A4, ołówek, długopis,

−

poradnik dla ucznia, słownik techniczny.

Ćwiczenie 4

Wykonaj trwającą 4–5 minut prezentację w programie PowerPoint, lub Impress

przedstawiającą budowę i zasadę działania zaworu trójdrożnego.

Sposób wykonania ćwiczenia

Aby wykonać ćwiczenie, powinieneś:

1) przeanalizować zadanie,

2) na kartce papieru A4 wykonać plan prezentacji,

3) przeanalizować fragment 30 z materiału nauczania z rozdziału 4.2.1. Poradnika dla

ucznia,

4) wyszukać w Internecie schemat zaworu trójdrożnego,

5) wykonać prezentację,

6) przygotować się do przeprowadzenia prezentacji.

Wyposażenie stanowiska pracy:

−

papier formatu A4, ołówek, długopis,

−

poradnik dla ucznia,

−

komputer z dostępem do Internetu i programem PowerPoint lub Impress.

4.2.4. Sprawdzian postępów

Czy potrafisz:

Tak

Nie

1) zidentyfikować i zinterpretować rzeczowniki złożone?

2) opisać budowę prostej instalacji hydraulicznej?

3) wyjaśnić prawo Pascala?

4) opisać drogę przepływu płynu przez filtr olejowy?

5) opisać działanie zaworu jednokierunkowego?

6) opisać działanie siłownika hydraulicznego?

7) opisać zasadę pracy pompy zębatej?

8) opisać zasadę pracy pompy łopatkowej?

9) opisać zasadę pracy pompy tłokowej?

10) opisać zasadę pracy pompy zaworu trójdrożnego?

11) nazwać podstawowe rodzaje naprężeń, którym podlegają ciała stałe?

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

26

4.3. Silniki lotnicze

4.3.1. Materiał nauczania

reciprocal

Piston

Heat

convert

cylinder

ignition

internal

combustion

engine

heat exchanger

expand

shaft

motion

flywheel

1) A reciprocating engine, also often known as a piston engine, is a heat

engine that uses one or more pistons to convert pressure into a rotating

motion. There may be one or more pistons. Each piston is inside

a cylinder, into which a gas is introduced, either already hot and under

pressure (steam engine), or heated inside the cylinder either by ignition

of a fuel air mixture (internal combustion engine) or by contact with a hot

heat exchanger in the cylinder (sterling engine). The hot gases expand,

pushing the piston to the bottom of the cylinder. The piston is returned to

the cylinder top (Top Dead Centre) either by a flywheel or the power

from other pistons connected to the same shaft. In most types the

expanded or "exhausted" gases are removed from the cylinder by this

stroke. The exception is the Sterling engine, which repeatedly heats and

cools the same sealed quantity of gas. In some designs the piston may be

powered in both directions in the cylinder in which case it is said to be

double acting is steam engine.

four-stroke

intake

compression

combustion

exhaust

crankshaft

dead center

descend

fuel-air mixture

2) Today Internal combustion engines in cars, trucks, motorcycles,

construction machinery and many others, most commonly use a four-

stroke cycle. The four strokes refer to intake, compression, combustion

and exhaust strokes that occur during two crankshaft rotations per

working cycle. The four steps in this cycle are often informally referred

to as "suck, squeeze (or squash), bang, blow." The cycle begins at top

dead center (TDC), when the piston is furthest away from the crankshaft.

On the first stroke (intake/induction) of the piston, as the piston descends

it reduces the pressure in the cylinder, a mixture of fuel and air is forced,

by at least atmospheric pressure, into the cylinder through the intake

(inlet) port. The intake (inlet) valve (or valves) then close(s) and the

following stroke (compression) compresses the fuel-air mixture.

spark plug

gasoline

exhaust valve

3) The air-fuel mixture is then ignited, usually by a spark plug for

a gasoline or by the heat and pressure of compression for a diesel cycle

or compression ignition engine, at approximately the top of the

compression stroke. The resulting expansion of burning gases pushes the

piston downward for the third stroke (power) and in the fourth stroke

(exhaust) the piston pushes the products of combustion from the cylinder

through an exhaust valve or valves.

valve train

camshaft

cam

tappet

slide

push rod

rocker arms

crankcase

stem

clearance

heel

4) Valve train. The valves are typically operated by a camshaft, with

a series of cams along its length, each designed to open a valve

appropriately for the execution of intake or exhaust strokes while rotating

at half crankshaft speed. A tappet between valve and cam furnishes

a contact surface on which the cam slides to open the valve. The location

of the camshaft varies, as does the quantity. Most engines use overhead

cams, in which cams directly actuate valves through a flat tappet. In other

engine designs, the cam shaft is placed in the crankcase and its motion

transmitted by a push rod, rocker arms, and valve stems.

Valve clearance is measured with the valve closed, typically at top dead

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

27

cam lobe

feeler gauge

blade

overhead

centre of the compression stroke. The tappet will be resting on the heel of

the cam lobe. A feeler gauge must pass through the clearance space. The

feeler gauge should fit in and out with a slight drag. If the feeler gauge

will not fit in, then the clearance is too small. If the blade of the feeler

gauge fits in too loose then the clearance is too big.

inline

v-type

radial

opposed

excess

surround

heat transfer

coolant

radiator

airstream

metal fins

5) Reciprocating engines may be classified according to cylinder

arrangement with respect to the crankshaft (inline, V-type, radial, and

opposed) or according to the method of cooling (liquid cooled or air

cooled). Actually, all engines are cooled by transferring excess heat to

the surrounding air. In air cooled engines, this heat transfer is direct from

the cylinders to the air. In liquid cooled engines, the heat is transferred

from the cylinders to the coolant, which is then sent through tubing and

cooled within a radiator placed in the air stream. The radiator must be

large enough to cool the liquid efficiently. Heat is transferred to air more

slowly than it is to a liquid. Therefore, it is necessary to provide thin

metal fins on the cylinders of an air cooled engine in order to have

increased surface for sufficient heat transfer. Most aircraft engines are air

cooled.

crankcase

bearing

revolve

tight

attachment

assembly

rigid

misalignment

forged

alloy

cast

6) The foundation of an engine is the crankcase. It contains the bearings

in which the crankshaft revolves. Besides supporting itself, the crankcase

must provide a tight enclosure for the lubricating oil and must support

various external and internal mechanisms of the engine. It also provides

support for attachment of the cylinder assemblies, and the power plant to

the aircraft. It must be sufficiently rigid and strong to prevent

misalignment of the crankshaft and its bearings. Cast or forged aluminum

alloy is generally used for crankcase construction because it is light and

strong.

backbone

subjected

connecting rod

crank

throw

machined

crank pin

off center

main journal

crank cheeks

counterweight

damper

forging offsets

7) The crankshaft is the backbone of the reciprocating engine. It is

subjected to most of the forces developed by the engine. Its main purpose

is to transform the reciprocating motion of the piston and connecting rod

into rotary motion for rotation of the propeller. The crankshaft, as the

name implies, is a shaft composed of one or more cranks located at

specified points along its length. The cranks, or throws, are formed by

forging offsets into a shaft before it is machined. Since crankshafts must

be very strong, they generally are forged from a very strong alloy, such

as chromium nickel molybdenum steel.

The crank pin is the section to which the connecting rod is attached. It is

off center from the main journals and is often called the throw. Two

crank cheeks and a crank pin make a throw. Cranckschaft is balanced

with a counterweight and a dynamic damper.

link

rigid

load

inertia

plain-type

fork

blade

master

articulated

8) The connecting rod is the link which transmits forces between the

piston and the crankshaft. Connecting rods must be strong enough to

remain rigid under load and yet be light enough to reduce the inertia

forces which are produced when the rod and piston stop, change

direction, and start again at the end of each stroke. There are three types

of connecting rod assemblies: The plain-type connecting rod, the fork

and blade connecting rod, and the master and articulated rod assembly.

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

28

member

back and forth

combustion

chamber

charge

downward

forgings

grooves

surface

receive

piston rings

adequate strength

wear resistance

cooling fins

uppermost

drill

scraped

pass back

skirt

excessive

ring lands

piston head

pin boss

guide

surplus

flat

convex

recess

concave

interference

force

9) The piston of a reciprocating engine is a cylindrical member which

moves back and forth within a steel cylinder. The piston acts as a moving

wall within the combustion chamber. As the piston moves down in the

cylinder, it draws in the fuel/air mixture. As it moves upward, it

compresses the charge, ignition occurs, and the expanding gases force the

piston downward. This force is transmitted to the crankshaft through the

connecting rod. On the return upward stroke, the piston forces the

exhaust gases from the cylinder.

The majority of aircraft engine pistons are machined from aluminum

alloy forgings. Grooves are machined in the outside surface of the piston

to receive the piston rings, and cooling fins are provided on the inside of

the piston for greater heat transfer to the engine oil.

Pistons may be either the trunk type or the slipper type. Slipper-type

pistons are not used in modern, high powered engines because they do

not provide adequate strength or wear resistance. The top face of the

piston, or head, may be either flat, convex, or concave. Recesses may be

machined in the piston head to present interference with the valves. As

many as six grooves may be machined around the piston to accommodate

the compression rings and oil rings. The compression rings are installed

in the three uppermost grooves; the oil control rings are installed

immediately above the piston pin. The piston is usually drilled at the oil

control ring grooves to allow surplus oil scraped from the cylinder walls

by the oil control rings to pass back into the crankcase. An oil scraper

ring is installed at the base of the piston wall or skirt to prevent excessive

oil consumption. The portions of the piston walls that lie between each

pair of ring grooves are called the ring lands. In addition to acting as

a guide for the piston head, the piston skirt incorporates the piston pin

bosses. The piston pin bosses are of heavy construction to enable the

heavy load on the piston head to be transferred to the piston pin.

conductivity

commence

burning

spark

10) Cylinder Hades. The purpose of the cylinder head is to provide

a place for combustion of the fuel/air mixture and to give the cylinder

more heat conductivity for adequate cooling. The fuel/air mixture is

ignited by the spark in the combustion chamber and commences burning

as the piston travels toward top dead center on the compression stroke.

barrel

good bearing

material

tensile strength

hardened

bear

exposing

soaks up

nitrided

replaceable

11) Cylinder Barrels. In general, the cylinder barrel in which the piston

operates must be made of a high strength material, usually steel. It must

be as light as possible, yet have the proper characteristics for operating

under high temperatures. It must be made of a good bearing material and

have high tensile strength. The cylinder barrel is made of a steel alloy

forging with the inner surface hardened to resist wear of the piston and

the piston rings which bear against it. This hardening is usually done by

exposing the steel to ammonia or cyanide gas while the steel is very hot.

The steel soaks up nitrogen from the gas which forms iron nitrides on the

exposed surface. As a result of this process, the metal is said to be

nitrided. Some air cooled cylinder barrels have replaceable aluminum

cooling fins attached to them, while others have the cooling fins

machined as an integral part of the barrel.

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

29

corrosion

stress

factors

nichrome

steel

ground face

seal

durable

welded

silchrome

shock and wear

stem

neck

junction

tip

hammering

rocker arm

split ring stem

keys

lock ring

spring

retain

washer

hollow

heat conductor

melt

dissipate

circulate

valve guide

angle

12) Valve Construction. The valves in the cylinders of an aircraft engine

are subjected to high temperatures, corrosion, and operating stresses;

thus, the metal alloy in the valves must be able to resist all these factors.

Exhaust valves are usually made of nichrome, silchrome, or cobalt-

chromium steel. The valve head has a ground face which forms a seal

against the ground valve seat in the cylinder head when the valve is

closed. The face of the valve is usually ground to an angle of either 30°

or 45°. Valve faces are often made more durable by the application of

a material called stellite. About 1/16 inch of this alloy is welded to the

valve face and ground to the correct angle. Stellite is resistant to high

temperature corrosion and also withstands the shock and wear associated

with valve operation. The valve stem acts as a pilot for the valve head

and rides in the valve guide installed in the cylinder head for this

purpose. The valve stem is surface hardened to resist wear. The neck is

the part that forms the junction between the head and the stem. The tip of

the valve is hardened to withstand the hammering of the valve rocker arm

as it opens the valve. A machined groove on the stem near the tip

receives the split ring stem keys. These stem keys form a lock ring to

hold the valve spring retaining washer in place. Some intake and exhaust

valve stems are hollow and partially filled with metallic sodium. This

material is used because it is an excellent heat conductor. The sodium

will melt at approximately 2080 F, and the reciprocating motion of the

valve circulates the liquid sodium and enables it to carry away heat from

the valve head to the valve stem, where it is dissipated through the valve

guide to the cylinder head and the cooling fins.

camshaft

mates

lobe

tappet

clearance

13) The valve mechanism of an opposed engine is operated by

a camshaft. The camshaft is driven by a gear that mates with another gear

attached to the crankshaft. As the camshaft revolves, the lobes cause the

tappet assembly to rise in the tappet guide, transmitting the force through

the push rod and rocker arm to open the valve. Some aircraft engines

incorporate hydraulic tappets which automatically keep the valve

clearance at zero, eliminating the necessity for any valve clearance

adjustment mechanism.

push rod

tubular

lift

rocker arm

plain

pivot

helical

coil

spring

vibrate

surge

roller

14) The push rod, tubular in form, transmits the lifting force from the

valve tappet to the rocker arm. A hardened steel ball is pressed over or

into each end of the tube.

The rocker arms transmit the lifting force from the cams to the valves.

Rocker arm assemblies are supported by a plain, roller, or ball bearing, or

a combination of these, which serves as a pivot.

Each valve is closed by two or three helical coiled springs. If a single

spring were used, it would vibrate or surge at certain speeds. To

eliminate this difficulty, two or more springs (one inside the other) are

installed on each valve.

intake

compression

combustion

exhaust

exclusive

15) Turbine engine construction. In a reciprocating engine the functions

of intake, compression, combustion, and exhaust all take place in the

same combustion chamber; consequently, each must have exclusive

occupancy of the chamber during its respective part of the combustion

„Projekt współfinansowany ze środków Europejskiego Funduszu Społecznego”

30

simultaneously

section

inlet

Turbine

Exhaust

Accessory

lubrication

supply

feature

axial flow

centrifugal flow

anti-icing

auxiliary

cycle. A significant feature of the gas turbine engine, however, is that a

separate section is devoted to each function, and all functions are

performed simultaneously without interruption.

1. A typical gas turbine engine consists of:

2. An air inlet.

3. Compressor section.

4. Combustion section.

5. Turbine section.

6. Exhaust section.

7. Accessory section.

8. The systems necessary for starting, lubrication, fuel supply, and

auxiliary purposes, such as anti-icing, cooling, and pressurization.

The greatest single factor influencing the construction features of any gas

turbine engine is the type compressor (axial flow or centrifugal flow) for

which the engine is designed.

operation

control

mounting

electric

generators

oil reservoir

mounting pad

gear train

bearing support

oil sump

16) The accessory section of the turbojet engine has various functions.

The primary function is to provide space for the mounting of accessories

necessary for operation and control of the engine. Generally, it also

includes accessories concerned with the aircraft such as electric

generators and fluid power pumps. Secondary functions include acting as

an oil reservoir and/or oil sump, and housing the accessory drive gears

and reduction gears.

The basic elements of the centrifugal flow engine accessory section are:

1. the accessory case, which has machined mounting pads for the engine

driven accessories,

2. the gear train, which is housed within the accessory case.

The accessory case may be designed to act as an oil reservoir. If an oil

tank is utilized, a sump is usually provided below the front bearing