14.1 Introduction: technofunctional uses of egg constituents

Hen egg was categorised by Baldwin in 1986 as a polyfunctional ingredient, as it

can simultaneously realise several technological functions in the same

formulated foodstuff. Its emulsifying, foaming, gelling, thickening, colouring

and aromatic properties make it still today a universal basic ingredient for the

domestic kitchen and the food processing industry. Whereas egg yolk is well

recognised for its emulsifying properties, egg white (or albumen) is a reference

in terms of foaming and both parts are used as gelling ingredient in many foods.

Yolk takes part in the formation and the stabilisation of emulsions. In spite of

the intensive use of yolk in formulated foodstuffs, and since the invention of

mayonnaise three centuries ago, the role of its major constituents is not clear

because of its complex structure. Yolk is a mixture of proteins and lipids

forming natural assemblies at various scales. These natural assemblies contri-

bute to the nano- and the microstructure of yolk. Thus, an understanding of the

emulsifying properties of yolk lies in the comprehension of these various levels

of structure.

14

Egg proteins

M. Anton, INRA Nantes Unite 1268 BiopolymeÁres Interactions

Assemblages, France and F. Nau and V. Lechevalier, UMR INRA

Science et Technologie du Lait et de l'Oeuf, France

Abstract: This chapter deals with the chemical composition and structural

characteristics of egg yolk and white in relation to three important functional

properties: emulsifying, foaming and gelling properties.

Key words: egg, yolk, white, emulsions, foams, gels, structure, assemblies,

interfaces.

The exceptional foaming properties of the albumen are also the base of

traditional recipes among which meringues act certainly as reference. Indeed, the

extreme simplicity of their formula (albumen and sugar, possibly added with

flavours) allows albumen to express in an optimal way its foaming properties.

However, the technological parameters influence the final quality of foam

obtained, and three types of meringues (traditional meringue, Swiss meringue

and Italian meringue) can be distinguished, depending on whether whipping is

achieved in the presence or absence of sugar, and at ambient or warm

temperature. But there is also a great number of other products in which

previously foamed albumen is added, which are either fat-free formulas (angel

food cake) or lipid-containing formulas (spoon biscuits, `sponge' cake, blown).

In such products, the complexity of the phenomena is extreme, foaming and

emulsification taking place simultaneously, which makes the control of the

physico-chemical and technological parameters of these operations very delicate.

Concerning the gelling properties of albumen and yolk, they are related to the

heat-gelation capacity of egg proteins. Then, these properties imply a cooking

step during the food processing. The heat gelation of egg proteins completely

conforms to the model of heat gelation of globular proteins. The corresponding

mechanisms have been extensively studied, on egg proteins as well as on other

ones, and the key technological parameters have now been identified. However,

the addition of other ingredients in mixture with egg (polysaccharides, for

example) complicates the understanding of the egg gelation behaviour, and

developments with more complex models are still needed.

14.2 Physico-chemistry and structure of egg constituents

14.2.1 Egg yolk

Chemical composition

Yolk correspond to 36% of whole hen egg weight. Its dry matter is about 50±

52% according to the age of the laying hen and the duration of preservation

(Kiosseoglou, 1989; Thapon and Bourgeois, 1994; Li-Chan et al., 1995). The

compositions of fresh and dry yolks are presented in Table 14.1: the main

components are lipids (about 65% of the dry matter) and the lipid to protein ratio

is about 2:1. Yolk lipids are exclusively associated with lipoprotein assemblies.

They are made up of 62% triglycerides, 33% phospholipids, and less than 5%

cholesterol. Carotenoids represent less than 1% of yolk lipids, and give it its

colour. Proteins are present as free proteins or apoproteins (included in

lipoprotein assemblies). The interactions between lipids and proteins result in

the formation of lipoproteins (low and high density), which represent the main

constituents of yolk.

Macrostructure and main constituents

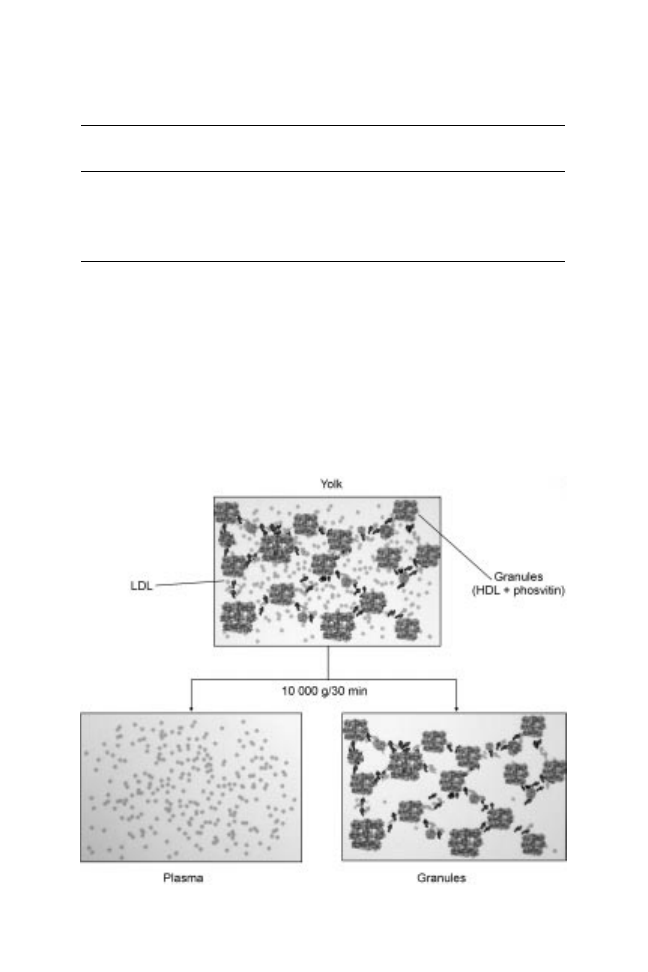

Yolk is a complex system with different structuration levels consisting in

aggregates (granules) in suspension in a clear yellow fluid (plasma) that contains

360 Handbook of hydrocolloids

lipoproteins and proteins. Granules consist in circular complexes ranging in

diameter from 0.3 m to 2 m (Chang et al., 1977). Consequently, yolk can be

easily separated into two fractions after a dilution (two times) with 0.3 M NaCl

and a centrifugation at 10,000 g (30 min) according to the method of McBee and

Cotterill (1979): a dark orange supernatant called plasma and a pale pellet called

granules (Fig. 14.1).

Granules represent 22% of yolk dry matter, accounting for about 50% of yolk

proteins and 7% of yolk lipids. The dry matter content of granules is about 44%,

with about 64% proteins, 31% lipids and 5% ash (Dyer-Hurdon and Nnanna,

Table 14.1 Composition of hen egg yolk

Fresh yolk

Dry yolk

(%)

(%)

Water

51.1

Ð

Lipids

3.6

62.5

Proteins

16.0

33.0

Carbohydrates

0.6

1.2

Minerals

1.7

3.5

Source: Powrie and Nakai (1986)

Fig. 14.1 Fractionation of plasma and granules from hen egg yolk.

Egg proteins 361

1993; Anton and Gandemer, 1997). They are mainly constituted by high density

lipoproteins (HDL) (70%) and phosvitin (16%) linked by phosphocalcic bridges

between the phosphate groups of their phosphoseryl residues (Burley and Cook,

1961; Saari et al., 1964). Low density lipoproteins (LDL) (12%) are included in

the granular structure (Table 14.2).

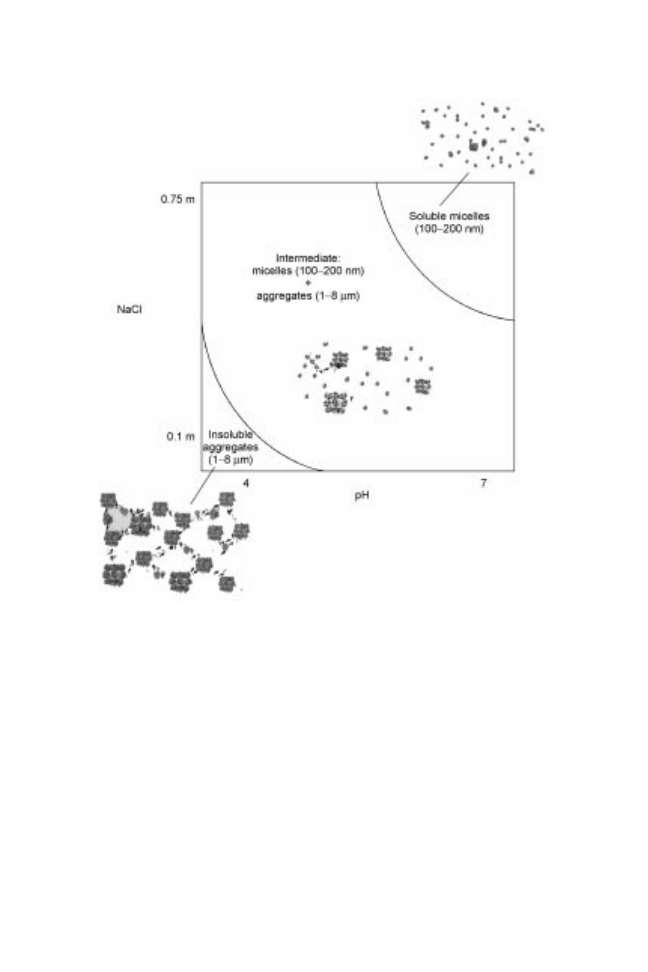

At low ionic strength, granules mainly form insoluble HDL-phosvitin

complexes linked by phosphocalcic bridges as HDL and phosvitin contain a high

proportion of phosphoserin amino acids able to bind calcium (Causeret et al.,

1991). The numerous phosphocalcic bridges make the granule structure very

compact, poorly hydrated, weakly accessible to enzymes, and lead to an efficient

protection against thermal denaturation and heat gelation.

At an ionic strength over 0.3 M NaCl, the phosphocalcic bridges are disrupted

because monovalent sodium replaces divalent calcium. In such conditions, the

solubility of granules reaches 80% because phosvitin is a soluble protein and

HDL behave like soluble proteins (Cook and Martin, 1969; Anton and

Gandemer, 1997). Complete disruption of granules occurs when ionic strength

reaches 1.71 M NaCl. Acidification or alkalinisation similarly cause the disrup-

tion of granules and the solubilisation of these constituents by increasing the

number of the positive (NH

3

+

) or negative (COO

-

) charges inducing electrostatic

repulsions between granule constituents. Recently, we have established

(Sirvente, 2007) a phase diagram drawing the different states of granules as a

function of pH and ionic strength (Fig. 14.2).

Plasma comprises 78% of yolk dry matter and is composed of 85% LDL and

15% livetins (Burley and Cook, 1961; Table 14.2). It forms the aqueous phase

where yolk particles are in suspension. It accounts for about 90% of yolk lipids

(including nearly all the carotenoids), and 50% of yolk proteins. Plasma contains

about 73% lipids, 25% proteins and 2% ash. Lipids of plasma are distributed

thus: 70% triglycerides, 25% phospholipids and 5% cholesterol.

Table 14.2 Repartition of hen egg yolk constituents

Yolk

Yolk

Yolk

Lipids

Proteins

D.M.

lipids

proteins

(%)

(%)

(%)

(%)

(%)

Yolk

100

100

100

64

32

Plasma

78

93

53

73

25

LDL

66

61

22

88

10

Livetins

10

Ð

30

Ð

96

Others

2

Ð

1

Ð

90

Granules

22

7

47

31

64

HDL

16

6

35

24

75

Phosvitin

4

Ð

11

Ð

95

LDLg

2

1

1

88

10

Source: Powrie and Nakai (1986)

362 Handbook of hydrocolloids

LDL are spherical particles (17±60 nm in diameter with a mean of about

35 nm) with a lipid core in a liquid state (triglycerides and cholesterol esters)

surrounded by a monofilm of phospholipid and protein (Cook and Martin, 1969;

Evans et al., 1973). LDL are soluble in aqueous solution (whatever the pH and

ionic conditions) due to their low density (0.982). Phospholipids take an

essential part in the stability of the LDL structure because association forces are

essentially hydrophobic (Burley, 1975). Some cholesterol is included in the

phospholipid film, increasing its rigidity. LDL are composed of 11±17% protein

and 83±89% lipid, out of which 74% is neutral lipid and 26% phospholipid

(Martin et al., 1964).

14.2.2 Egg white

Egg white represents about 60% of the total egg weight. It consists of an

aqueous protein solution, containing few minerals and carbohydrates (Table

Fig. 14.2 Physical state of granules as function of pH and ionic strength.

Egg proteins 363

14.3). During egg storage, different physico-chemical modifications happen,

among them the CO

2

departure that induces a pH increase, from 7.5 at the laying

moment to 9.5 after a few days. This pH modification should be the cause of the

egg white liquefaction, because of the dissociation of a protein complex

(ovomucin-lysozyme complex) (Kato et al., 1975). Another evolution observed

concerns the ovalbumin modification toward S-ovalbumin, which is a more

heat-stable form (Smith and Back, 1965), resulting from isomerisation of three

serine residues (Yamasaki et al., 2003).

Proteins

Proteins represent more than 90% of the dry matter of egg white, but until very

recently, only the major ones have been identified. However, the recent and

powerful techniques for separation and analysis enabled the identification of

many minor proteins (Table 14.4) (GueÂrin-Dubiard et al., 2006; Mann, 2007).

The egg white proteins are predominantly globular proteins, and acidic or

neutral, except lysozyme and avidin which are highly alkaline proteins. All are

glycosylated, except cystatin and the major form of lysozyme. Some of them are

very heat-sensitive and/or sensitive to surface denaturation, explaining their

noteworthy functional properties.

The major egg white protein (more than 50% of the total proteins) is

ovalbumin, a 45 kDa globular and phosphorylated protein. Half of its amino

acids are hydrophobic, and one-third are electrically charged, essentially

negatively at physiologic pH. Ovalbumin possess six buried Cys residues, two

being involved in a disulfide bridge (Cys

73

-Cys

120

). Ovalbumin is then the only

egg white protein with free thiol groups, capable of inducing some

rearrangements with variations of storage conditions, pH and surface

denaturation.

Ovotransferrin (13% of total proteins) molecular weight is around 78 kDa.

This protein consists of two lobes, each containing a specific binding site for

iron (or copper, zinc, aluminium) (Kurakawa et al., 1995). It is the most heat-

sensitive egg white protein, but the complexation of iron or aluminium

significantly increases its heat stability (Lin et al., 1994).

OvomucoõÈde is a highly glycosylated protein (up to 25% carbohydrates, w/w)

of 28 kDa. At pH 7, its denaturation temperature is around 77 ëC, but this protein

Table 14.3 Composition of hen egg white

% of hen egg white

Water

88.0

Lipids

Ð

Proteins

10.6

Carbohydrates

0.8

Minerals

0.6

Source: Thapon and Bourgeois (1994)

364 Handbook of hydrocolloids

is much more heat resistant at acidic pH (Lineweaver and Murray, 1947).

Ovomucin is also a highly glycosylated protein, with a very high molecular

weight (10

4

kDa). Electrostatic interactions can be observed between ovomucin

and some of the other egg white proteins. In the freshly laid eggs (pH 7.5), the

carboxylic groups of the ovomucin sialic acids especially interacts with the -

NH

3+

of lysozyme lysine residues to form a lysozyme-ovomucin complex that

may be responsible for the gel-like structure of egg white (Kato et al., 1975).

Lysozyme is a small (14 kDa) globular, and strongly basic protein. Its structure

is very rigid, stabilised by four disulfide bridges.

Glucidic and mineral fractions

The glucidic fraction of egg white consists of free glucose (0.5% w/w) and carbo-

hydrates linked to proteins (0.5% w/w). The mineral fraction is predominantly

composed of Na

+

, K

+

and Cl

ÿ

, as free minerals, whereas P and S are essentially

constitutive elements of proteins. Egg white also contains CO

2

, in equilibrium

with bicarbonate, which plays a major role for pH control (Thapon, 1994).

14.3 Egg yolk emulsions

14.3.1 Basic principles

Emulsifying activity is related to the capacity of surface active molecules to

cover the oil±water interface created by mechanical homogenisation, thus

Table 14.4 Composition and some physico-chemical and functional properties of egg

white proteins

Protein

%

M

w

(kDa)

pI

Major biological properties

Ovalbumin

54

45

5

Immunogenic phosphoproteine

Ovalbumin Y

5

44

5.2

nd

Ovalbumin X

0.5

56

6.5

nd

Ovotransferrin

13

76

6.7

Iron binding, bacteriostatic activity

OvomucoõÈd

11

28

4.8

Trypsin inhibitor

Ovomucin

1.5±3.5

230±8300

4.5±5

Highly glycosylated, viral

hemaglutination inhibition

Lysozyme

3.5

14.4

10.7

Lysis of Gram bacteria wall

Ovoinhibitor

0.1±1.5

49

5.1

Serine protease inhibitor

Ovoglycoprotein

0.5±1

24.4

3.9

nd

Flavoprotein

0.8

32

4

Riboflavin (vitamin B2) binding

Ovostatin

0.5

760±900

4.6

Serine protease inhibitor

Cystatin

0.05

12.7

5.1

Cysteine protease inhibitor

Avidin

0.05

68.3

10

Biotine binding

Ex-FABP

nd

18

5.5

Lipocaline family

Cal gamma

nd

20.8

6

Lipocaline family

TENP

nd

47.4

5.6

BPI (bactericidal permeability-

increasing protein) family

Hep 21

nd

18

6.4

uPar/Ly6/Snake neurotoxin family

Sources: Li-Chan and Nakai (1989), Stevens (1991), GueÂrin et al. (2006).

Egg proteins 365

reducing the interfacial tension. Consequently, the more active the emulsifying

agent, the more the interfacial tension is lowered. Emulsion stability indicates

the capacity to avoid flocculation, creaming, and/or coalescence of oil droplets.

Creaming and flocculation are reversible phenomena which can be avoided by a

simple agitation of the emulsion. Coalescence is the irreversible fusion of oil

droplets due to the rupture of the interfacial film created by emulsifying agents.

This phenomenon leads to a complete destruction of the emulsion. This relates

the importance of the structure and the viscoelasticity of the interfacial film.

14.3.2 Role of egg yolk constituents

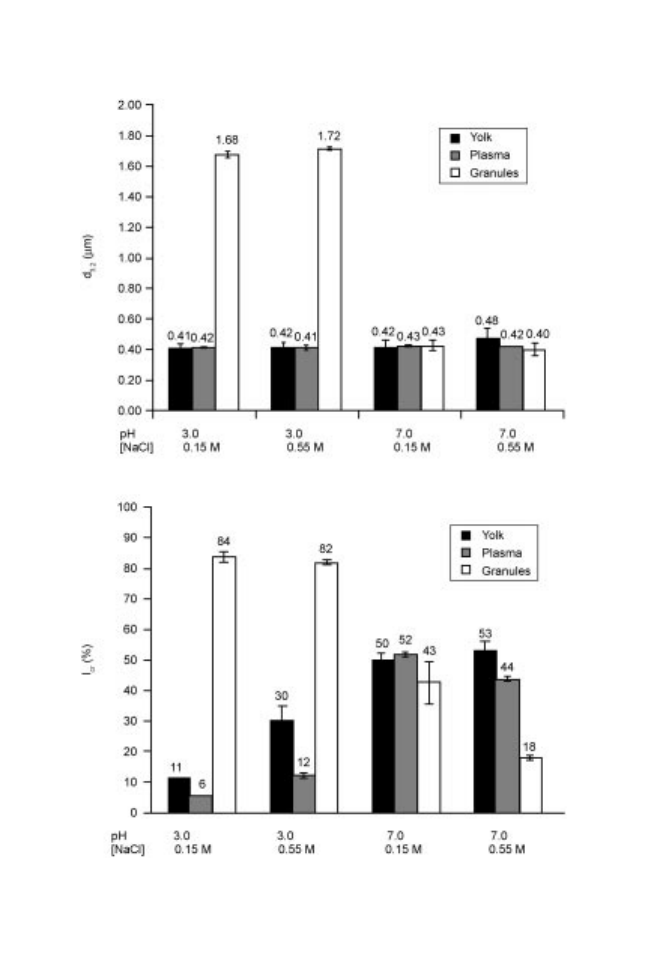

In researching the principal contributor to yolk emulsifying properties,

numerous authors have separated yolk into its main fractions: plasma and

granules. Large similarities have been observed between emulsifying properties

of yolk and plasma, whereas emulsions made with granules behaved very

differently (Dyer-Hurdon and Nnanna, 1993; Anton and Gandemer, 1997; Le

Denmat et al., 2000). Specifically, emulsions made with granules are more

coarse (more important oil droplet size) than emulsions made with yolk and

plasma, and notably at acidic pH where granules are not soluble (Le Denmat et

al., 2000) (Fig. 14.3).

Concerning the parameters of emulsion stability (creaming), we showed (Le

Denmat et al., 2000) that emulsions made with yolk and plasma had the same

creaming rate, in function of the medium conditions, whereas emulsions made

with granules behaved very differently (Fig. 14.3). Consequently, these studies

demonstrated that yolk emulsifying power was situated in plasma.

Among plasma constituents, some authors demonstrated that LDL are better

emulsifiers than bovine serum albumin (BSA) (Mizutani and Nakamura, 1984)

and casein (Shenton, 1979). Even though some authors suggested that, in certain

conditions, HDL were more efficient than LDL to form and stabilise O/W

emulsions (Hatta et al., 1997; Mine, 1998), a large number of studies confirm

the prevalent role of LDL in yolk emulsions. These findings have been

confirmed recently (Aluko et al., 1998; Mine and Keeratiurai, 2000; Anton et

al., 2003; Martinet et al., 2003). In particular, it has been established that LDL

made emulsions finer than HDL, along different conditions of pH and ionic

strength (Martinet et al., 2003). The next question is how to explain the

exceptional efficiency of LDL at the interfaces.

14.3.3 Importance of assemblies

Given that any destructurating treatment affects the emulsifying properties of

LDL, it appears that the integrity of the structure of LDL seems essential to

ensure their interfacial properties (Tsutsui, 1988). Direct adsorption of

apoproteins and phospholipids from LDL is not easy because of the non-

solubility of these species in water or in aqueous buffer. So the interactions

between apoproteins and lipids to assemble the LDL particles are essential to

366 Handbook of hydrocolloids

Fig. 14.3 Mean droplet diameter (d3.2) and creaming index (Icr) in oil/water emulsions

(30 : 70) prepared with yolk, plasma and granules, protein concentration: 25 mg/ml,

homogenisation pressure: 200 bars, n 3.

Egg proteins 367

transport the surfactants in a soluble form in the neighbourhood of the interface

and then to release them at the interface.

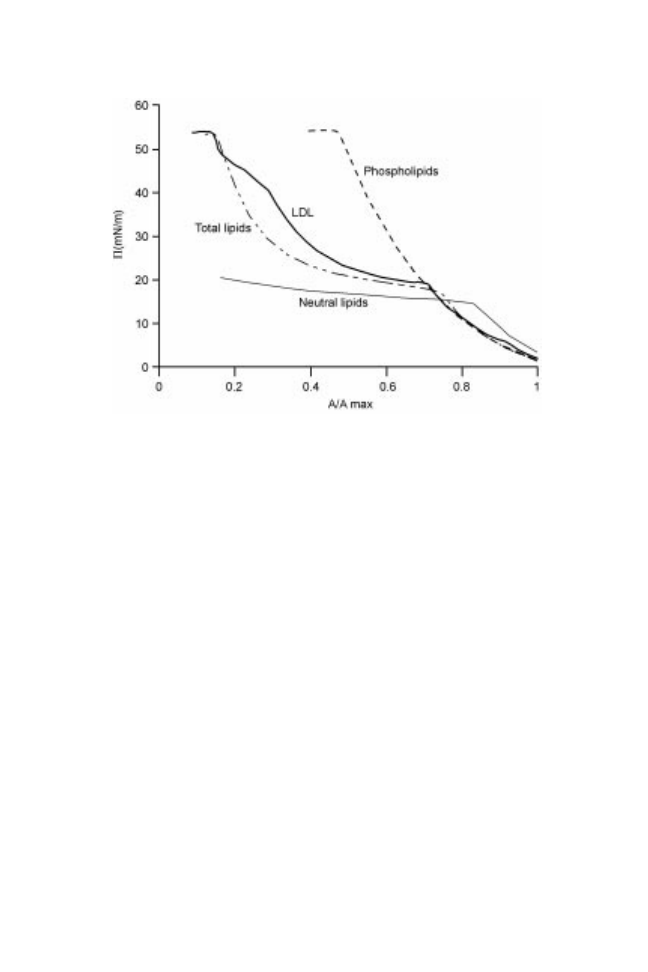

Using Langmuir film balance (air±water interface), three phase transitions

have been detected in compression isotherms and these three transitions (19, 41

and 54 mN/m) have been attributed, respectively, to neutral lipids, apoproteins

and phospholipids by comparison with films of neutral lipids, phospholipids and

total lipids extracted from LDL (Fig. 14.4) (Martinet et al., 2003). The transition

observed at 19 mN/m corresponds to the collapse of neutral lipids, and the

transition at 54 mN/m corresponds to phospholipid collapse. These different

transitions show that LDL actually break down when they come into contact

with the interface to release neutral lipids, phospholipids and apoproteins from

the lipoprotein core and to allow their spreading. In a recent study made with

atomic force microscopy (AFM) after a Langmuir±Blodgett transfer of the

layers from the air±water interface to a silica plate, it has been shown that the

second transition (previously attributed to apoproteins alone) is not due to

apoproteins alone, but to apoprotein±lipids complexes (Dauphas et al., 2006).

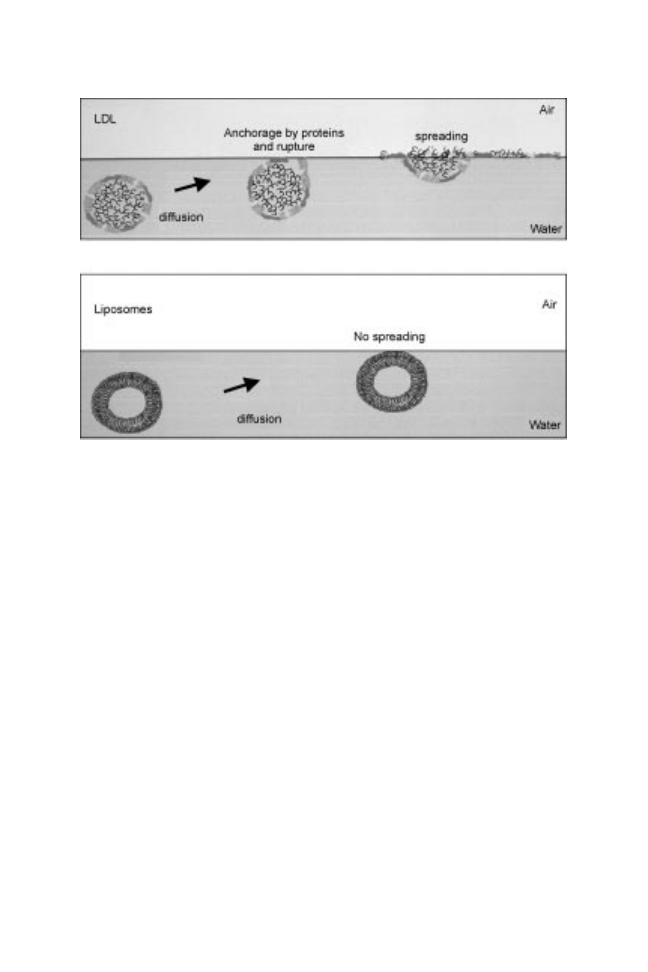

So, it has been deduced that LDL serve as vectors of surfactant constituents

(apoproteins and phospholipids) that could not be soluble in water, until the

interface. At this step the conservation of the LDL structure is essential. Once

LDL are near the interface, the structure is then broken up to release surfactant

constituents at the interface (Fig. 14.5).

Furthermore, comparing interfacial behaviour of LDL and liposomes (double

phospholipid layer not containing proteins), it has been shown that the

apoproteins situated on the LDL surface start the LDL disruption mechanism by

Fig. 14.4 /A isotherms of the different lipid constituents extracted from LDL and

spread at the air±water interface; neutral lipids = 85 g, phospholipids = 198 g, total

lipids = 287 g, compression rate = 100 cm

2

/min.

368 Handbook of hydrocolloids

their initial anchorage. This anchorage provokes an unfolding of the protein

leading to the destabilisation of the external layer of the LDL. Then this

phenomenon could be followed by a deformation of the particle due to the

creation of a neutral lipid lens conducive to the spreading of the LDL

constituents. In the case of liposomes, without external proteins, the structure

remains steady at the interface and then this structure is not able to adsorb

efficiently and to decrease interfacial tension (Fig. 14.5).

14.4 Egg white foams

14.4.1 Formation and stabilisation mechanisms

Foam formation is a highly energetic and dynamic process, in which interfacial

area is created. The ability of a protein solution, such as egg white, to foam

depends on protein structure and conformation, depending themselves on

extrinsic factors such as pH, ionic strength, etc. The formation mechanism of

globular protein foams can be divided into three phases happening near gas

bubbles: protein diffusion towards the air±solution interface, conformation

changes of adsorbed proteins, and irreversible rearrangement of the protein film

(McRitchie, 1991).

Foams are short-lived states and there is any correlation between foam

stability and protein adsorption kinetic (Dickinson, 1996). Foam stability,

indeed, depends on protein association at the air±solution interface to form a

Fig. 14.5 Hypothetical mechanism of LDL adsorption at an oil±water interface as

compared with liposome behaviour.

Egg proteins 369

continuous intermolecular network. Foam stability is affected by the protein film

cohesion, drainage and Ostwald disproportionation.

14.4.2 Interfacial properties of egg white proteins

Interfacial properties of egg white proteins are responsible for egg white's

excellent foaming properties. Table 14.5 gathers some data on the kinetics of

diffusion towards the air±solution interface of three major egg white proteins.

Ovalbumin interfacial behaviour is well known, since a large set of data is

available about its tensioactivity, adsorption kinetics, interfacial shear and

dilatational rheology (de Feijter et al., 1978; de Feijter and Benjamins, 1987;

Benjamins and van Voorst Vader, 1992; Benjamins and Lucassen-Reynders,

1998; Damodaran et al., 1998; Lucassen-Reynders and Benjamins, 1999;

Pezennec et al.; 2000; Razumovsky and Damodaran, 2001; Croguennec et al.,

2007) but also on its structure at the air±water interface (Renault et al., 2002;

Lechevalier et al., 2003, 2005; Kudryashova et al., 2003). It is now known that

ovalbumin forms a single layer at the air±water interface, whatever its

concentration in the bulk (Renault et al., 2002). As for ovalbumin, lysozyme

interfacial behaviour has been extensively studied (de Feijter and Benjamins,

1987; Damodaran et al., 1998; Razumovsky and Damodaran, 2001; Kim et al.,

2002; Postel et al., 2003; Chang et al., 2005; Roberts et al., 2005; Perriman and

White, 2006) as well as its structure at the air±water interface (Lechevalier et al.,

2003, 2005). However, its interfacial behaviour differs as lysozyme forms films

that are much thicker than a protein monolayer whereas the surface pressure is

definitely smaller than the ovalbumin one (Le Floch-FoueÂre et al., 2009). These

different behaviours observed on planed air±water interface result in different

foaming properties. Ovalbumin foaming properties are much better than those of

lysozyme, since in native state at pH 7.0, the foaming capacity of lysozyme is

very weak (Townsend and Nakai, 1983), probably because of its little surface

hydrophobicity and its rigidity due to its four disulfide bonds.

Egg white proteins thus show different behaviour at 2D and 3D air±water

interfaces. When they are in mixture, their behaviour is again different. Indeed,

Damodaran et al. (1998) showed that the adsorption kinetics of egg white

proteins are different depending on whether they are in single protein systems or

in mixture. They suggested the formation of electrostatic complexes between

positively charged lysozyme and other negatively charged egg white proteins.

Moreover, the mixture ovalbumin-lysozyme forms films that are much thicker

than those of both proteins in single protein systems, suggesting a synergy in

interfacial adsorption between the two proteins (Le Floch-FoueÂre et al., 2007).

14.4.3 Egg white foams

Egg white is the reference for foaming properties: compared with other protein

ingredient of vegetable or animal origin, it still offers the best foaming

properties (Vani and Zayas, 1995; Matringe et al., 1999; Pernell et al., 2002;

370 Handbook of hydrocolloids

Table 14.5 Parameters of the kinetic of diffusion towards the air±solution interface of three major egg white proteins

Parameters

Ovalbumin

Ovotransferrine

Lysozyme

Reference

Apparent diffusion

0.5 (C=10

ÿ4

% prot.)

0.2 (C=10

ÿ4

% prot.)

De Feijter and Benjamins

coefficient

(in solution: 0.7)

(in solution: 1)

(1987)

(10

ÿ10

m

2

s

ÿ1

)

0.15 (C=1.510

ÿ4

% prot.)

Xu and Damodaran (1993)

0.5 to 1 (C=0.1% prot.)

Pezennec et al. (2000)

Surface concentration

1.6 (C=10

ÿ4

% prot.)

2.4 (C=10

ÿ4

% prot.)

De Feijter and Benjamins

(mg m

ÿ2

)

(1987)

1.5 (C=5.410

ÿ4

% prot.)

0.8 (C=1.210

ÿ4

% prot.)

0.5 (C=0.3510

ÿ4

% prot.)

Damodaran et al. (1998)

2.1 (native protein) to 2.9

Pezennec et al. (2000)

(heat-treated protein)

Croguennec et al. (2007)

(C=0.01% prot.)

1.4 (pH 4) to 3 (pH 11)

Perriman and White (2006)

(C=0.1% prot.)

Surface pressure

1 (C=10

ÿ4

% prot.)

3.5 (C=10

ÿ4

% prot.)

De Feijter and Benjamins

(mN m

ÿ1

)

(1987)

14 (C=5.410

ÿ4

% prot.)

2.5 (C=1.210

ÿ4

% prot.)

2.5 (C=0.3510

ÿ4

% prot.)

Damodaran et al. (1998)

24 (C=0.01% prot.)

Pezennec et al. (2000)

8 (pH 5.6) to 14 (pH 11)

Roberts et al. (2005)

(C=0.012% prot.)

9 (C=510

ÿ4

% prot.) to

Chang et al. (2005)

24.5 (C=0.1% prot.)

Lag phase

YES if C<0.01%

YES if C<0.01%

De Feijter and Benjamins

Not enough molecules at

Not enough molecules at

(1987)

the interface to create

the interface to create

an increase of

an increase of

NO

YES

YES

Damodaran et al. (1998)

Foegeding et al., 2006; Davis and Foegeding, 2007). Egg white can be

considered as a solution of efficient surfactants. Its proteins are amphiphilic and

show a relatively high surface hydrophobicity, thus diffusing quite rapidly

towards the air±water interface where they adsorb efficiently. Their molecular

flexibility ensures conformational rearrangement at the interface, resulting in a

great decrease in surface tension. Their ability to form a continuous inter-

molecular network, especially when a certain denaturation level is previously

obtained, enable them to form a viscoelastic interfacial film responsible for foam

stability. However, egg white proteins do not present at the same level these

different characteristics, and thus do not participate in the same way to egg white

foaming properties (Table 14.6). A lot of studies have been performed on the

different egg white protein foaming properties (Nakamura, 1963; Johnson and

Zabik, 1981a; Mine, 1995). However, it is now well known that the complexity

and the synergy of the phenomena mean that it is impractical to distinguish the

role of the different egg white properties (Lechevalier et al., 2005). It is thus

quite difficult to predict foaming properties of any mixture of egg white proteins

since phenomena of competition for the interface and possible exchange

between proteins at the air±water interface may occur. Nevertheless, foaming

properties of isolated egg white proteins are always lower than those of egg

white, which tend to confirm the existence and the role of the interactions

between proteins. It is thus generally admitted that the natural coexistence in egg

white of alkaline protein (lysozyme) and acid ones (most of the other) enables

electrostatic interactions, thus explaining the good foaming properties of egg

white (Poole et al., 1984; Damodaran et al., 1998).

Egg white foams are an integral component of many foods such as meringue,

nougat and angel food cake. A recent study showed that the properties of foams

do not predict performance in angel food cake (Foegeding et al., 2006).

14.4.4 Key parameters

Many physico-chemical parameters are susceptible to influence foam formation

and stability. In the specific case of egg white proteins, surface hydrophobicity

(that conditions the efficiency of protein adsorption at the air±water interface),

Table 14.6 Interfacial characteristics of the main egg white proteins

Protein

Surface tension (mN m

ÿ1

)

Foamability (cm

3

g

ÿ1

min

ÿ1

)

Globulins

45.4

4.71

Ovalbumin

51.8

0.59

Ovotransferrin

42.4

0.34

Lysozyme

42.0

0.12

OvomucoõÈd

39.0

0

Ovomucin

nd

0

Mixture in the egg white ratio

46.7

3.08

Source: Mine (1995)

372 Handbook of hydrocolloids

the number of disulfide bonds (that conditions protein flexibility/rigidity) and

the number of free sulfhydryl groups (that conditions protein reactivity) are

decisive in the structural modifications that occur at the air±water interface.

Moreover, the number and the nature of inter- and intramolecular interactions

determine the rheological properties of the interfacial film and so foam stability.

These interactions are favoured by a certain degree of denaturation, however,

too much denaturation weakens the interfacial film and the foam collapses

(Kinsella, 1976; Trziszka, 1993; Kato et al., 1994; Van der Plancken et al.,

2007). Another special feature of egg white foams is their dependence on thick

egg white proportion and quality. Foamability increases with egg white natural

liquefaction during its storage (Sauveur et al., 1979; Thapon, 1981; Baldwin,

1986), whereas foam stability decreases (Nau et al., 1996). Egg white foaming

properties can also be improved by the addition of sucrose (effect on foam

stability) and sodium chloride (effect on foamability), as suggested by Raikos et

al. (2007a).

14.5 Gels

14.5.1 Basic principles

A gel consists of polymers linked through covalent and/or non-covalent

interactions, to create a three-dimensional network. In whole egg as well as in

white and yolk, proteins are responsible for the gelling properties. Gelation

occurs when the protein stability in solution is modified, i.e., when the

equilibrium between attractive (Van der Waals) and repulsive (electrostatic,

steric) interactions is disrupted. The electrostatic repulsions vary with the net

charge of the proteins, that means with the ionisable protein groups and with the

physico-chemical characteristics of the solvent (pH, ionic strength). The

treatments that decrease the repulsive interactions, such as adjustment of pH

at proteins pI or addition of salts, induce destabilisation and thus can result in the

formation of aggregates or gels.

Moreover, some treatments can modify the protein structure, with

consequences for the repulsive and attractive interactions mentioned above.

This is especially the case during heat treatments, which are the major techno-

logical treatments used in the food industry for egg white and yolk gelation.

Heat-induced gelation of egg conforms completely with the model of heat

gelation of globular proteins. It is a two-step phenomenon: in the first stage,

unfolding of native proteins occurs, disrupting the well-defined secondary and

tertiary structures and producing denatured proteins exposing their inner

hydrophobic regions; following unfolding, the denatured proteins interact to

form high molecular weight aggregates that can further interact with each other

to result in a three-dimensional gel (Clark et al., 2001). The unfolding and

aggregation steps depend on many factors (protein concentration, ionic strength,

pH, presence of sucrose, etc.) that can modify the number and/or the kind of

interactions, with final consequences on the gel rheology. In the heat-induced

Egg proteins 373

gels of egg proteins, the interactions involved are predominantly hydrophobic

and electrostatic, but some highly energetic interactions can be observed

(disulfide bridges); thiol and amine groups are indeed very reactive, especially

in alkaline conditions.

14.5.2 Egg yolk gels

Yolk undergoes a gelation when it is subjected to a freezing-thawing process or

a heat treatment. LDL are responsible for yolk gelation, while the other

constituents of yolk do not participate directly (Kojima and Nakamura, 1985;

Kurisaki et al., 1981; Nakamura et al., 1982; Tsustui, 1988; Wakamatu et al.,

1982; Le Denmat et al., 1999).

Freezing-thawing gelation of yolk appears for a temperature below ÿ6 ëC

(Lopez et al., 1954). This gelation is undesirable because it makes yolk difficult

to handle. Freezing-thawing gelation is influenced by rate and temperature of

freezing and thawing, and length and temperature of storage (Kiosseoglou,

1989). Rapid freezing and thawing results in less gelation than slow freezing and

thawing. Freezing-thawing gelation is partially reversible and the initial

viscosity of yolk is recovered after heating for 1 h at 45±55 ëC.

The mechanism of freezing-thawing gelation of LDL remains hypothetical.

Freezing causes the formation of ice crystals which mobilise water (at ÿ6 ëC,

about 80% of the water in yolk is in ice crystals) and causes a dehydration of

apoproteins of LDL. This dehydration favours a rearrangement of apoproteins of

LDL, interactions between their amino acid residues and an aggregation which

leads to gelation.

LDL is the constituent of yolk responsible for heat-induced gelation of yolk

(Saari et al., 1964). LDL solution (4% w/v) start denaturing at 70 ëC and form

gels at 75 ëC (Tsutsui, 1988). LDL solutions, heated at 80 ëC for 5 min, form

more stable gels than ovalbumin and BSA (Kojima and Nakamura, 1985).

Unlike ovalbumin and BSA, LDL present a heat-induced gelation in a large

range of pH (4±9) with a minimal value around their pHi (Nakamura et al.,

1982). Between pH 6 and 9, LDL solutions form coagulum gels (opaque)

whereas LDL solutions form translucents gels for extreme pH (4±6 and 8±9)

(Kojima and Nakamura, 1985; Nakamura et al., 1982).

Heat-induced gelation of yolk is governed by the unfolding of proteins during

heating. Then the functional groups are exposed and attracted to one another

through hydrophobic bonds resulting in a gel (Nakamura et al., 1982).

The primary stage of the two phenomena (freezing-thawing and heat-induced

gelation) is the disruption of the LDL structure (Kurisaki et al., 1981). This

disruption is favoured by dehydration in the case of freezing-thawing, or by

unfolding under heating. Lipid-protein interactions are disrupted under freezing or

heating and interactions between proteins are increased. These interactions are both

principally of non-polar nature because a LDL gel is solubilised by SDS which

interacts with the hydrophobic residues of apoproteins (Mahadevan et al., 1969).

The aggregation product of LDL certainly contains lipids included in the structure

374 Handbook of hydrocolloids

(Tsutsui, 1988). Apoproteins of LDL present a large proportion of hydrophobic

amino acids and, consequently, they have a high ability to form such gels.

More recently, Le Denmat et al. (2000) have measured the critical concen-

trations (Cg) for heat gelation of dispersions of yolk, plasma and granules in pH

and NaCl ranges of respectively 3±7 and 0.15±0.55 M. In all cases, the domain Cg

for plasma is 12±28 mg protein/ml, whereas it is 26±120 mg protein/ml for

granules. For yolk solution Cg is comprised between 16 and 39 mg protein/ml.

This confirms the preponderant influence of LDL, the major compound of

plasma, in the heat gelation of yolk. This underlines the excellent capacity of

granules to resist to heat treatments, that could be used for industrial applications.

14.5.3 Egg white gels

The heat gelation of egg white is used in many food applications involving a

cooking step. Except ovomucin and ovomucoõÈd, all the egg white proteins

coagulate when heated (Johnson and Zabik, 1981b). But the heat sensitivity of

egg white proteins varies significantly: the temperature of denaturation at pH 7

in egg white is 84.5, 74 and 65 ëC for ovalbumin, lysozyme and ovotransferrin,

respectively (Donovan et al., 1975). Ovotransferrin is then the more heat-

sensitive, which is why it is generally considered as the gelation initiator, and

finally as a limiting factor considering the gelling properties. Therefore,

ovotransferrin elimination has been suggested to improve egg white gelling

properties (Kusama et al., 1990). However, ovotransferrin is more stable at

alkaline pH, at high ionic strength, and when metal ions are bound on it. Thus,

the gelation temperature of egg white can also be significantly increased by

modification of these parameters, and especially by Fe

3+

or Al

3+

addition

(Cunningham and Lineweaver, 1965).

The extent and the kind of the interactions between the denatured proteins

depend on the protein structure, that means on the extent of unfolding at the end

of the denaturation step. Indeed, the unfolding governs the more or less

important exposure of reactive groups or regions on the protein molecule. The

interactions also depend on the physico-chemical conditions that can be either

limiting or favouring, resulting in an increase or a decrease of aggregation rate

respectively, and then in a decrease or an increase of the denaturation extent

before interactions take place (Totosaus et al., 2002).

These mechanisms have been extensively studied for egg white and

ovalbumin heat-gelation, with a focus on ionic strength effect on the structure

and characteristics of the gels (Holt et al., 1984; Woodward and Cotterill, 1986;

Woodward, 1990; Croguennec et al., 2002; Raikos et al., 2007b). Heat

denaturation induces an increase of the protein surface hydropbobicity. When

heating occurs at high ionic strength, the protein charges are screened, inducing

a shielding effect on the repulsive forces between proteins, thus favouring the

hydrophobic interactions (Doi, 1993). In these conditions, random aggregates of

slightly denatured proteins appear, corresponding to opaque gels, with low

rigidity, elasticity and water retention capacity. On the other hand, at low ionic

Egg proteins 375

strength, the electrostatic repulsions are so high that it delays the aggregation

(Raikos et al., 2007b), favouring denaturation. Finally, the further aggregation

involves some specific area (hydrophobic regions), and induces linear polymeric

aggregates. Once placed in higher ionic strength conditions, these aggregates

can interact to form performing gels. Thus, a two-step heating process has been

proposed to produce translucent gels from egg white, very firm and elastic, and

with an exceptional water retention capacity (Kitabatake et al., 1988a). As well

as ionic strength influences the net charge of the proteins, pH is another major

parameter for egg white gelation control. Close to their pI, the proteins tend to

form random aggregates, similar to those obtained at high ionic strength. This

phenomenon explains the minimal rheological properties of the egg white gels

around pH 5. In contrast, at alkaline pH, egg white offers the best gelling

properties (Ma and Holme, 1982; Kitabatake et al., 1988b). The higher reactivity

of the thiol groups in these pH conditions probably also contributes to the

improvement of the gelling properties, because of disulfide bridges taking place.

On the other hand, at acidic pH (2.0), the limited protein solubility would be

responsible for the low gelation temperature and the low rheological properties

observed (Raikos et al., 2007b).

To improve the gelling properties of egg white, Kato et al. (1989) proposed

an original approach consisting of an extensive denaturation of proteins while

preventing aggregation. Such conditions can be obtained by heating of egg white

powder at high temperatures (80 ëC) for a long time (up to 10 days). This

treatment increase protein flexibility and exposure of reactive groups that can

further interact to strengthen the gel formed when previously dry-heated egg

white is solubilised and heated in solution. The efficiency of this process can be

improved by pH control (Mine, 1996, 1997). The dry-heating process is today

the basis for mass production practices of high-gel egg white powders.

14.6 Conclusion

Hen egg contains very high functional proteins, lipids and lipoproteins. These

functionalities are due partly to their chemical composition and structure, and

partly to the supramolecular assemblies they form naturally or under the action

of thermo-mechanical treatments during industrial processes. One of the major

challenges for the future is the control of the design of these assemblies and the

understanding of their functionalities (interfacial, emulsifying, foaming, phase

separation, etc.) to enhance the quality of existing products or to conceive

innovative products.

14.7 References

ALUKO RE, KEERATIURAI M

and

MINE Y

(1998), `Competitive adsorption between egg yolk

lipoproteins and whey proteins on oil-in-water interfaces', Colloids Surf B:

Biointerfaces, 10, 385±393.

376 Handbook of hydrocolloids

ANTON M

and

GANDEMER G

(1997), `Composition, solubility and emulsifying properties of

granules and plasma of hen egg yolk', J Food Sci, 62 (3), 484±487.

ANTON M, MARTINET V, DALGALARRONDO M, BEAUMAL V, DAVID-BRIAND E

and

RABESONA H

(2003) `Structural and chemical characterization of low-density lipoprotein

purified from hen egg yolk', Food Chem, 83, 175±183.

BALDWIN RE

(1986), `Functional properties of eggs in foods', in Stadelman WJ and

Cotterill OJ, eds, Egg Science and Technology, London, The Haworth press.

BENJAMINS J

and

LUCASSEN-REYNDERS EH

(1998), `Surface dilational rheology of proteins

absorbed air/water interfaces', in MoÈbius D and Miller R, Proteins at Liquid

Interfaces, Amsterdam, Elsevier, 341±384.

BENJAMINS J

and

VAN VOORST VADER F

(1992), `The determination of the surface shear

properties of adsorbed protein layers', Colloids Surf B: Biointerfaces, 65, 161±174.

BURLEY RW

(1975), `Recent advances in the chemistry of egg yolk', CSIRO Food Res

Quaterly, 35, 1±5.

BURLEY RW

and

COOK WH

(1961), `Isolation and composition of avian egg yolk granules

and their constituents - and -lipovitellins', Canadian J Biochem Physiol, 39,

1295±1307.

CAUSERET D, MATRINGE E

and

LORIENT D

(1991), `Ionic strength and pH effects on

composition and microstructure of yolk granules', J Food Sci, 56, 1532±1536.

CHANG CM, POWRIE WD

and

FENNEMA O

(1977), `Microstructure of egg yolk', J Food Sci,

42, 1193±1200.

CHANG S-H, CHEN L-Y

and

CHEN W-Y

(2005), `The effects of denaturants on protein

conformation and behavior at air/solution interface', Colloids Surf B:

Biointerfaces, 41, 1±6.

CLARK AH, KAVANAGH GM

and

ROSS-MURPHY SB

(2001) `Globular protein gelation ± theory

and experiment', Food Hydrocolloids, 15, 383±400.

COOK WH

and

MARTIN WG

(1969), `Egg lipoproteins', in Tria E and Scanu AM, eds,

Structural and Functional Aspects of Lipoproteins in Living Systems, New York,

Academic Press.

CROGUENNEC T, NAU F

and

BRULEÂ G

(2002), `Influence of pH and salts on egg white

gelation', J. Food Sci, 67, 608±614.

CROGUENNEC T, RENAULT A, BEAUFILS S, DUBOIS J-J

and

PEZENNEC S

(2007), `Interfacial

properties of heat-treated ovalbumin', J Colloids Interfaces Sci, 315, 627±636.

CUNNINGHAM FE

and

LINEWEAVER H

(1965), `Stabilization of egg white proteins to

pasteurizing temperatures above 60 ëC', Food Technol, 19, 136±141.

DAMODARAN S, ANAND K

and

RAZUMOVSKY L

(1998), `Competitive adsorption of egg

white proteins at the air water interface: direct evidence for electrostatic complex

formation between lysozyme and other egg proteins at the interface', J Agric Food

Chem, 46, 872±876.

DAUPHAS S, BEAUMAL V, RIAUBLANC A

and

ANTON M

(2006), `Hen egg yolk low density

lipoproteins film spreading at the air-water and oil-water interfaces', J Agric Food

Chem, 54 (10), 3733±3737.

DAVIS JP

and

FOEGEDING EA

(2007), `Comparisons of the foaming and interfacial

properties of whey protein isolate and egg white proteins', Colloids Surf B:

Biointerfaces, 54, 200±210.

DE FEIJTER JA

and

BENJAMINS J

(1987), `Adsorption kinetics of protein at the air-water

interface', in Dickinson E and Stainsby G, eds, Food Emulsions and Foams,

London, Royal Society of Chemistry.

DE FEIJTER JA, BENJAMINS J

and

VEER FA

(1978), `Ellipsometry as a tool to study the

Egg proteins 377

adsorption behavior of synthetic and biopolymers at the air-water interface',

Biopolymers, 17, 1759±1772.

DICKINSON E

(1996), Les colloõÈdes alimentaires, Paris, Dunod.

DOI E

(1993) `Gels and gelling of globular proteins', Trends in Food Sci. & Technol., 4,

1±5.

DONOVAN JW, MAPES CJ, DAVIS J

and

GARIBALDI J

(1975), `A differential scanning calori-

metric study of the stability of egg white to heat denaturation', J Sci Food Chem,

26, 73±83.

DYER-HURDON JN

and

NNANNA IA

(1993), `Cholesterol content and functionality of plasma

and granules fractionated from egg yolk,' J Food Sci, 58, 1277±1281.

EVANS RJ, BAUER DH, BANDEMER SL, VAGHEFI SB

and

FLEGEL CJ

(1973), `Structure of egg

yolk very low density lipoprotein: polydispersity of the very low density

lipoprotein and the role of lipovitellenin in the structure', Arch Biochem Biophys,

154, 493±500.

FOEGEDING EA, LUCK PJ

and

DAVIS JP

(2006), `Factors determining the physical properties

of protein foams', Food Hydrocolloids, 20, 284±292.

GUEÂRIN-DUBIARD C, PASCO M, MOLLEÂ D, DEÂSERT C, CROGUENNEC T

and

NAU F

(2006),

`Proteomic analysis of hen egg white', J Agric Food Chem, 54, 3901±3910.

HATTA H, OZEKI M

and

TSUDA K

(1997), `Egg yolk antibody IgY and its application', in

Yamamoto T, Juneja L, Hatta H, Kim M, eds, Hen Eggs: Their Basic and Applied

Science, CRC Press, Boca Raton, FL, pp. 151±178.

HOLT DL, WATSON MA, DILL CW, ALFORD ES, EDWARDS RL, DIEHL KC

and

GARDNER FA

(1984)

`Correlation of the rheological behaviour of egg albumen to temperature, pH, and

NaCl concentration', J Food Chem, 49, 137±141.

JOHNSON TM

and

ZABIK ME

(1981a), `Egg albumen proteins interactions in an angel food

cake system', J Food Sci, 46, 1231±1236.

JOHNSON TM

and

ZABIK ME

(1981b), `Gelation properties of albumen proteins, singly and

in combination', Poultry Sci, 60, 2071±2083.

KATO A, IMOTO T

and

YAGISHITA K

(1975), `The binding groups in ovomucin-lysozyme

interaction', Agric Biol Chem, 39, 541±544.

KATO A, IBRAHIM HR, WATANABE H, HONMA K

and

KOBAYASHI K

(1989), `New approach to

improve the gelling and surface functional properties of dried egg white by heating

in dry state', J Agric Food Chem, 37, 433±437.

KATO A, IBRAHIM HR, NAKAMURA S

and

KOBAYASHI K

(1994), `New methods for improving

the functionality of egg white proteins', in Sim JS and NakaõÈ S, eds, Egg Uses and

Processing Technologies. New Developments, Oxon, CAB International.

KIM G, GURAU M, KIM J

and

CREMER PS

(2002), `Investigations of lysozyme adsorption at

the air/water and quartz/water interfaces by vibrational sum frequency

spectroscopy', Langmuir, 18, 2807±2811.

KINSELLA JE

(1976), `Functional properties of proteins in foods: a survey', Crit Rev in

Food Sci and Nutrition, 219±276.

KIOSSEOGLOU VD

(1989), `Egg yolk', in Charalambous G and Doxastakis G, eds, Food

Emulsifiers: Chemistry, Technology, Functional Properties and Applications,

London, Elsevier.

KITABATAKE N, SHIMIZU A

and

DOI E

(1988a), `Preparation of transparent egg white gel

with salt by two-step heating method', J Food Sci, 53, 735±738.

KITABATAKE N, SHIMIZU A

and

DOI E

(1988b), `Preparation of heat-induced transparent gels

from egg white by the control of pH and ionic strength of the medium', J Food Sci,

53, 1091±1095.

378 Handbook of hydrocolloids

KOJIMA E

and

NAKAMURA R

(1985), `Heat gelling properties of hen's egg yolk low density

lipoprotein (LDL) in the presence of other protein', J Food Sci, 50, 63±66.

KUDRYASHOVA EV, MEINDERS MBJ, VISSER AJWG, VAN HOEK A

and

DE JONGH HHJ

(2003),

`Structure and dynamics of egg white ovalbumin adsorbed at the air±water

interface', Eur Biophys J, 32, 553±562.

KURAKAWA H, MIKAMI B

and

HIROSE M

(1995), `Crystal structure of differic hen

ovotransferrin at 2.4 AÊ resolution', J Mol Biol, 254, 196±207.

KURISAKI J, YAMAUCHI K, ISSHIKI H

and

OGIWARA S

(1981), `Differences between - and -

lipovitellin from hen egg yolk', Agric Biol Chem, 45, 699±704.

KUSAMA T, YOSHIDA K

and

HONMA K

(1990), Japan Patent No. HEI.2-257857.

LE DENMAT M, ANTON M

and

GANDEMER G

(1999), `Protein denaturation and emulsifying

properties of plasma and granules of egg yolk as related to heat treatment', J Food

Sci, 64 (2), 194±197.

LE DENMAT M, ANTON M

and

BEAUMAL V

(2000), `Characterisation of emulsion properties

and of interface composition in oil-in-water emulsions prepared with hen egg yolk,

plasma and granules', Food Hydrocolloids, 14, 539±549.

LE FLOCH-FOUEÂREÂ C, PEZENNEC S, LECHEVALIER V, BEAUFILS S, DESBAT B, PEÂZOLET M

and

RENAULT A

(2009), `Synergy between ovalbumin and lysozyme leads to non-

additive interfacial and foaming properties of mixtures', Food Hydrocolloids, 23,

352±365.

LECHEVALIER V, CROGUENNEC T, PEZENNEC S, GUEÂRIN-DUBIARD C, PASCO M

and

NAU F

(2003), `Ovalbumin, ovotransferrin, lysozyme: three model proteins for structural

modifications at the air±water interface', J Agric Food Chem, 51, 6354±6361.

LECHEVALIER V, CROGUENNEC T, PEZENNEC S, GUEÂRIN-DUBIARD C, PASCO M

and

NAU F

(2005), `Evidence for synergy in the denaturation at the air±water interface of

ovalbumin, ovotransferrin and lysozyme in ternary mixture', Food Chem, 92, 79±

87.

LI-CHAN ECY

and

NAKAI S

(1989), `Biochemical basis for the properties of egg white',

Critical Rev Poultry Biol, 2, 21±57.

LI-CHAN ECY, POWRIE WD

and

NAKAI S

(1995), `The chemistry of eggs and egg products',

in Stadelman WJ and Cotterill OJ, eds, Egg Science and Technology, 4th edn, New

York, Food Product Press, chap. 6.

LIN LN, MASON AB, WOODWORTH RC

and

BRANDTS JF

(1994), `Calorimetric studies of serum

transferring and ovotransferrin. Estimates of domain interactions and study of the

kinetic complexities of ferric ion binding', Biochem, 33, 1881±1888.

LINEWEAVER H

and

MURRAY CW

(1947), `Identification of the trypsin inhibitor of egg

white with ovomucoid', J Biol Chem, 171, 565±581.

LOPEZ A, FELLERS CR

and

POWRIE WD

(1954), `Some factors affecting gelation of frozen

egg yolk', J Milk Food Tech, 17, 334.

LUCASSEN-REYNDERS EH

and

BENJAMINS J

(1999), `Interfaces, interactions and stability', in

Dickinson E and Rodriguez Patino JM, eds, Food Emulsions and Foams,

Cambridge, Royal Society of Chemistry, 195.

MA C

and

HOLME J

(1982), `Effect of chemical modifications on some physicochemical

properties and heat coagulation of egg albumen', J Food Sci, 47, 1454±1459.

MAHADEVAN S, SATYANARAYANA T

and

KUMAR SA

(1969), `Physico-chemical studies on

the gelation of hen's egg yolk separation of gelling components from yolk plasma',

J Agric Food Chem, 17, 767±771.

MANN K

(2007), `The chicken egg white proteome', Proteomics, 7, 3558±3568.

Egg proteins 379

MARTIN WG, AUGUSTYNIAK J

and

COOK WH

(1964), `Fractionation and characterization of

the low-density lipoproteins of hen's egg yolk', Biochim Biophys Acta, 84, 714±

720.

MARTINET V, SAULNIER P, BEAUMAL V, COUTHAUDON JL

and

ANTON M

(2003), `Surface

properties of hen egg yolk low-density lipoproteins spread at the air-water

interface', Colloids Surf B: Biointerfaces, 31, 185±194.

MATRINGE E, PHAN TAN LUU R

and

LORIENT D

(1999), `Functional properties of milk-egg

mixtures', J Food Sci, 64, 787±791.

M

C

BEE LE

and

COTTERILL OJ

(1979), `Ion-exchange chromatography and electrophoresis of

egg yolk proteins', J Food Sci, 44, 657±666.

M

C

RITCHIE F

(1991), `Air/water interface studies of protein', Anal Chim Acta, 249, 241±

245.

MINE Y

(1995), `Recent advances in the understanding of egg white protein functionality',

Trends Food Sci Technol, 61, 225±232.

MINE Y

(1996), `Effect of pH during the dry heating on the gelling properties of egg white

proteins', Food Res Int, 29, 155±161.

MINE Y

(1997), `Effect of dry heat and mild alkalin treatment on functional properties of

egg white proteins', J Agric Food Chem, 45, 2924±2928.

MINE Y

(1998), `Adsorption behavior of egg yolk low-density-lipoproteins in oil-in-water

emulsions', J Agric Food Chem, 46, 36±41.

MINE Y

and

KEERATIURAI M

(2000), `Selective displacement of caseinate proteins by hens

egg yolk lipoproteins at oil-in-water interfaces', Colloids Surf B: Biointerfaces, 18,

1±11.

MIZUTANI R

and

NAKAMURA R

(1984), `Emulsifying properties of egg yolk low density

lipoprotein (LDL): comparison with bovine serum albumin and egg lecithin',

Lebensmittel Technol, 17, 213±216.

NAKAMURA R

(1963), `Studies on the foaming property of chicken egg white. Spread

monolayer of the protein fraction of the chicken egg white', Agric Biol Chem, 27,

427.

NAKAMURA R, FUKANO T

and

TANIGUSHI M

(1982), `Heat induced gelation of hen's egg

yolk LDL', J Food Sci, 47, 1449±1453.

NAU F, GESTIN L, PROTAIS J, AWADE A

and

THAPON JL

(1996), `Etude compareÂe des

proprieÂteÂs fonctionnelles et de la composition des fractions eÂpaisse et liquide du

blanc d'úuf de poule', Ind Alim Agr, 113, 5±10.

PERNELL CW, FOEGEDING EA, LUCK PJ

and

DAVIS JP

(2002), `Properties of whey and egg

white protein foams', Colloids and Surfaces A: Physicochemical Engineering

Aspects, 204, 9±21.

PERRIMAN AW

and

WHITE JW

(2006), `Kinetics of adsorption of lysozyme at the air±water

interface and the role of protein charge', Physica B, 385±386, 716±718.

PEZENNEC S, GAUTHIER F, ALONSO C, GRANER F, CROGUENNEC T, BRULE G

and

RENAULT A

(2000), `The protein net electric charge determines the surface rheological

properties of ovalbumin adsorbed at the air±water interface', Food Hydrocolloids,

14, 463±472.

POOLE S, WEST SI

and

WALTERS CL

(1984), `Protein±protein interactions: their importance

in the foaming of heterogeneous protein systems', J Sci Food Agric, 35, 701±711.

POSTEL C, ABILLON O

and

DESBAT B

(2003), `Structure and denaturation of adsorbed

lysozyme at the air±water interface', J Colloid Interface Sci, 266, 74±81.

POWRIE WD

and

NAKAI S

(1986), `The chemistry of eggs and egg products', in Egg Science

and Technology, 3rd edn. Westport, CN, AVI Publishing Co., 105±175.

380 Handbook of hydrocolloids

RAIKOS V, CAMPBELL L

and

EUSTON SR

(2007a), `Effects of sucrose and sodium chloride on

foaming properties of egg white proteins', Food Res Int, 40, 347±355.

RAIKOS V, CAMPBELL L

and

EUSTON SR

(2007b), `Rheology and texture of hen's egg protein

heat-set gels as affected by pH and the addition of sugar and/or salt', Food

Hydrocolloids, 21, 237±244.

RAZUMOVSKY L

and

DAMODARAN S

(2001), `Incompatibility of mixing of proteins in

adsorbed binary protein films at the air±water interface', J Agric Food Chem, 49,

3080±3086.

RENAULT A, PEZENNEC S, GAUTHIER F, VIEÂ V

and

DESBAT B

(2002), `The surface rheological

properties of native and S-ovalbumin are correlated with the development of an

intermolecular -sheet network at the air±water interface', Langmuir, 18, 6887±

6895.

ROBERTS SA, KELLAWAY IW, TAYLOR KMG, WARBURTON B

and

PETERS K

(2005), `Combined

surface pressure-interfacial shear rheology study of the effect of pH on the

adsorption of proteins at the air±water interface', Langmuir, 21, 7342±7348.

SAARI A, POWRIE WD

and

FENNEMA O

(1964), `Isolation and characterization of low-density

lipoproteins in native egg yolk plasma', J Food Sci, 29, 307±315.

SAUVEUR B, ZYBKO A

and

COLAS B

(1979), `ProteÂines alimentaires et qualite de l'úuf. 1.

Effet de quelques proteÂines sur la qualite interne de l'úuf et les proprieÂteÂs

fonctionnelles', Ann Zootech, 28, 271±295.

SIRVENTE H

(2007), `FonctionnaliteÂs des fractions du jaune d'oeuf dans les emulsions

alimentaires huile-dans-eau alleÂgeÂes en matieÁre grasse: impact des diffeÂrents

niveaux de structuration', Ph D thesis, University of Nantes, France.

SHENTON AJ

(1979), `Membrane composition and performance of food emulsions', PhD

thesis, University of London, UK.

SMITH LJ

and

BACK JF

(1965), `Studies on ovalbumin. The formation and properties of S-

ovalbumin, a more stable form of ovalbumin', Aus J Biol Sci, 21, 539±545.

STEVENS L

(1991), `Mini-review: egg white proteins', Comp Biochem Physiol, 100, 1±9.

THAPON JL

(1981), `Effets de divers facteurs sur les proprieÂteÂs physico-chimiques et

fonctionnelles du blanc d'úuf', PhD thesis, ENSAR ± Universite Rennes 1.

THAPON JL

(1994) `Evolution de l'uf au cours de la conservation', In Thapon JL,

Bourgeois CM, eds, L'úuf et les ovoprodutis, Paris, Tec et Doc Lavoisier, pp. 84±

94.

THAPON JL

and

BOURGEOIS CM

(1994), L'úuf et les ovoproduits, Paris, Tec et Doc

Lavoisier, chap. 1.

TOTOSAUS A, MONTEJANO JG, SALAZAR JA

and

GUERRERO I

(2002), `A review of physical

and chemical protein-gel induction', Int J Food Sci Technol, 37, 589±601.

TOWNSEND A

and

NAKAI S

(1983), `Relationship between hydrophobicity and foaming

characteristics of food proteins', J Food Sci, 48, 588±594.

TRZISZKA T

(1993), `Protein aggregation during whipping of egg white and its effect on

the structure and mechanical properties of foams', Arch GefluÈgelkd, 57, 27±34.

TSUTSUI T

(1988), `Functional properties of heat-treated egg yolk low density lipoprotein',

J Food Sci, 53, 1103±1106.

VAN DER PLANCKEN I, VAN LOEY A

and

HENDRICKX ME

(2007), `Foaming properties of egg

white proteins affected by heat or high pressure treatment', J Food Eng, 78, 1410±

1426.

VANI B

and

ZAYAS JF

(1995), `Foaming properties of selected plant and animal proteins', J

Food Sci, 60, 1025±1028.

Egg proteins 381

WAKAMATU T, SATO Y

and

SAITO Y

(1982), `Identification of the component responsible

for the gelation of egg yolk during freezing', Agric Biol Chem, 46, 1495±1503.

WOODWARD SA

(1990), `Egg protein gels', in Harris R, ed., Food Gels, London, Elsevier

Applied Science, pp. 175±199.

WOODWARD SA

and

COTTERILL OJ

(1986), `Texture and microstructure of heat-formed egg

white gels', J Food Sci, 51, 333±339.

XU S

and

DAMODARAN S

(1993), `Mechanism of adsorption of lysozyme at the air±water

interface', in Schwenke KD and Mothes R, eds, Food Proteins ± Structure and

Functionality, Wiley, New York.

YAMASAKI M, TAKAHASHI N

and

HIROSE M

(2003), `Crystal structure of S-ovalbumin as a

non-loop-inserted thermostabilized serpin form', J Biol Chem, 278, 35524±35530.

382 Handbook of hydrocolloids

Document Outline

- Front Matter

- Table of Contents

- 14. Egg Proteins

- Index

Wyszukiwarka

Podobne podstrony:

wyklad 14

Vol 14 Podst wiedza na temat przeg okr 1

Metoda magnetyczna MT 14

wyklad 14 15 2010

TT Sem III 14 03

Świecie 14 05 2005

2 14 p

i 14 0 Pojecie administracji publicznej

Wyklad 14 2010

14 Zachowanie Przy Wypadkach 1 13

Wyklad 14 PES TS ZPE

14 Ogniwa słoneczne

Wyklad 14

Wykład z fizyki 14

1 Wprowadzenie do psychologii pracy (14)id 10045 ppt

ZO NST 14 ĆW1CZ 1, 2 STUD F F3

więcej podobnych podstron