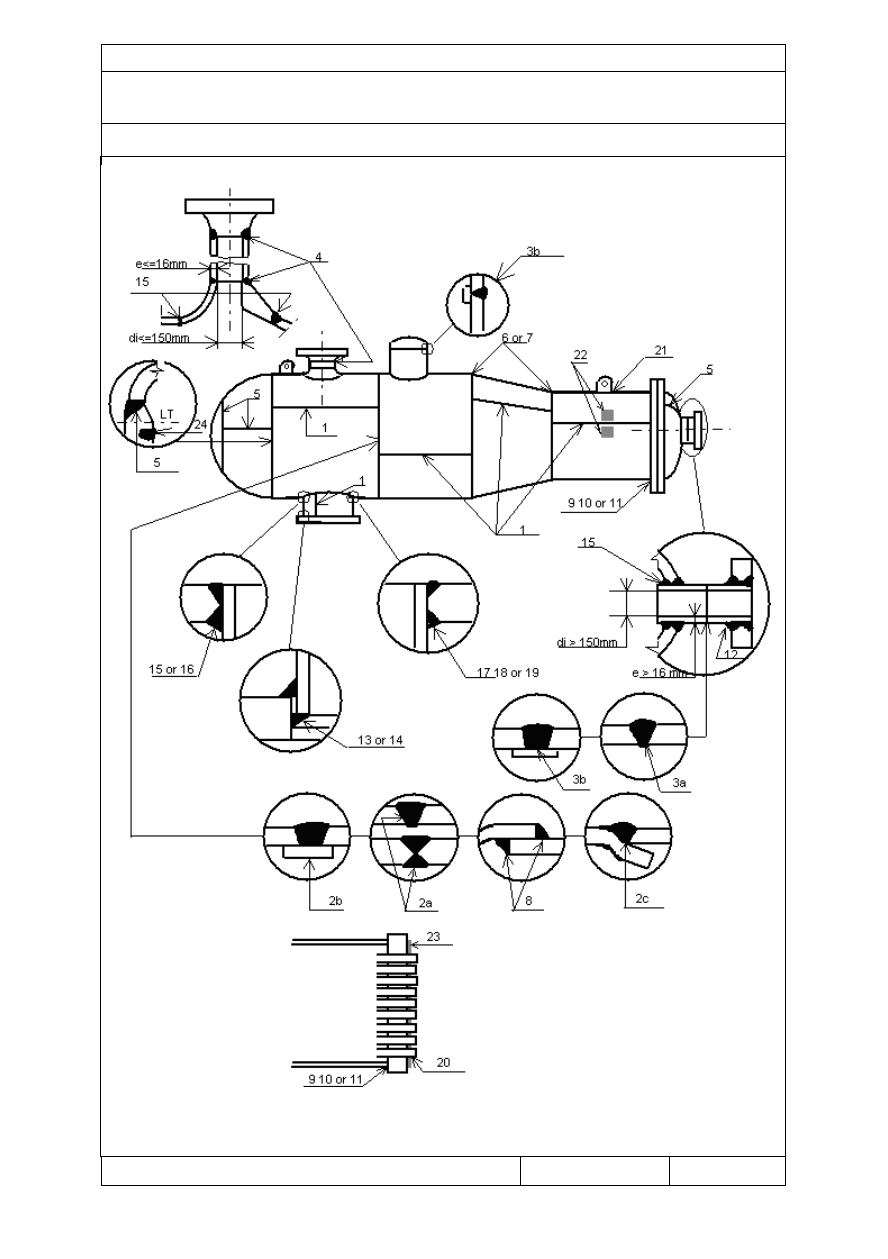

1 Drawing

Drawing

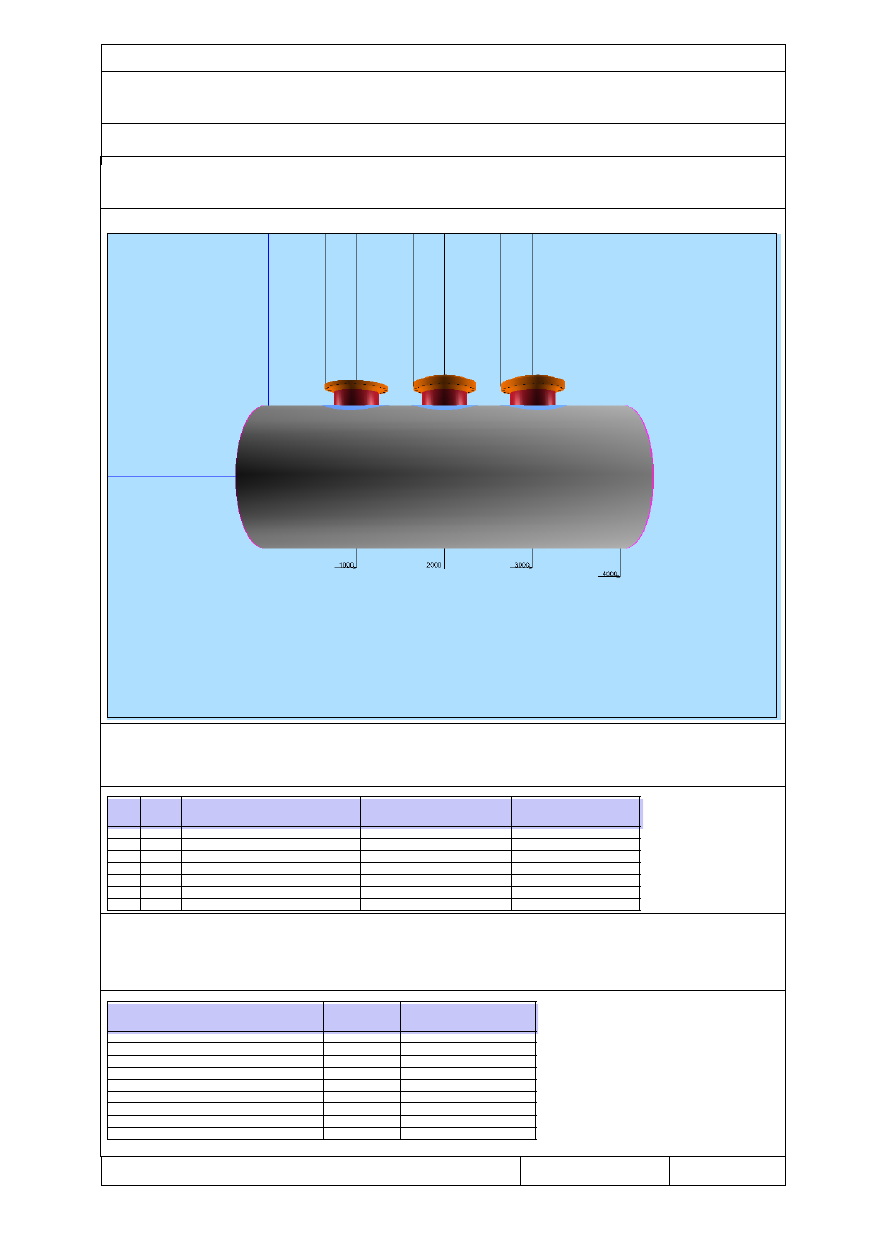

Widok 3D zbiornika (zmiana przez polecenie: Zapisz widok uzytkownika)

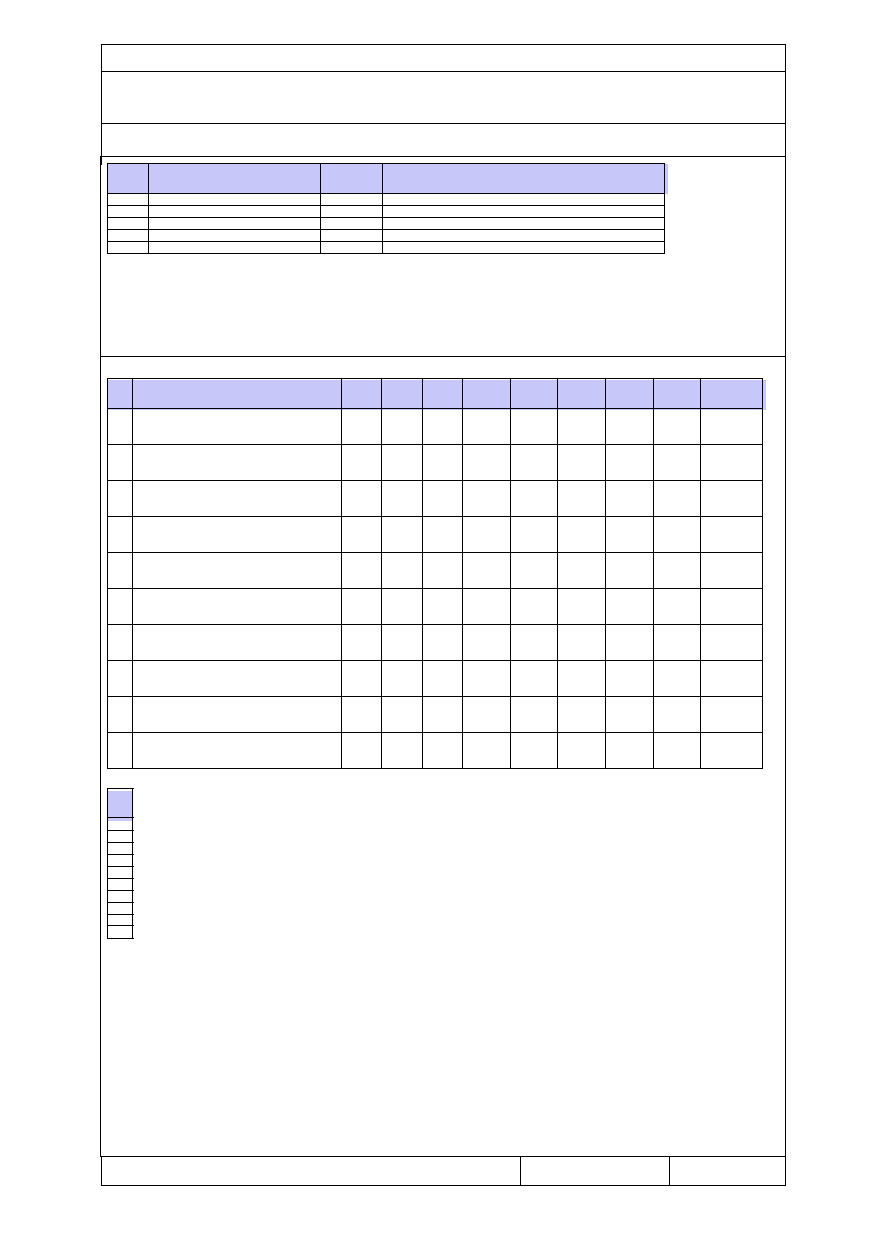

2 Historia rewizji

Historia rewizji

Rev

ID

Rodzaj elementu

Opis elementu

DATA I GODZINA

A

F.1

WN - Kolnierz

Kolnierz metoda I

17 Nov. 2008 20:09

A

F.2

Integral - Flange

kolnierz metoda II

17 Nov. 2008 20:00

A

F.3

Integral - Flange

Ko3nierz 1591

17 Nov. 2008 20:02

A

N.1

Króciec,Blacha korpu

krociec met I

17 Nov. 2008 19:44

A

N.2

Króciec,Blacha korpu

krociec met II

17 Nov. 2008 19:44

A

N.3*

Króciec,Blacha korpu

krociec met 1591

17 Nov. 2008 19:44

A

S1.1

Plaszcz walcowy

plaszcz

17 Nov. 2008 19:44

A First Issue RR 13 Mar. 2007 18:35

3 Parametry projektowe i informacje ruchowe

Parametry projektowe i informacje ruchowe

Opis

Jednostki

DANE PROJEKTOWE

KARTA PROCESOWA

General Design Data

Przepisy projektowe i specyfikacje

EN13445:Issue23

Wewnetrzne cisnienie obliczeniowe (MPa)

MPa

1.2

Zewnetrzne cisnienie obliczeniowe (MPa)

MPa

Cisnienie proby (MPa)

MPa

1.716

Maksymalna temperatura obliczeniowa ('C)

'C

120

Minimalna temperatura obliczeniowa ('C)

'C

Temperatura robocza ('C)

'C

Naddatek korozyjny (mm)

mm

0.3

3 Parametry projektowe i informacje ruchowe

Strona: 1

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9 Operator :RR Rew.:A

Opis

Jednostki

DANE PROJEKTOWE

Zawartosc zbiornika

Ciezar wlasciwy czynnika roboczego

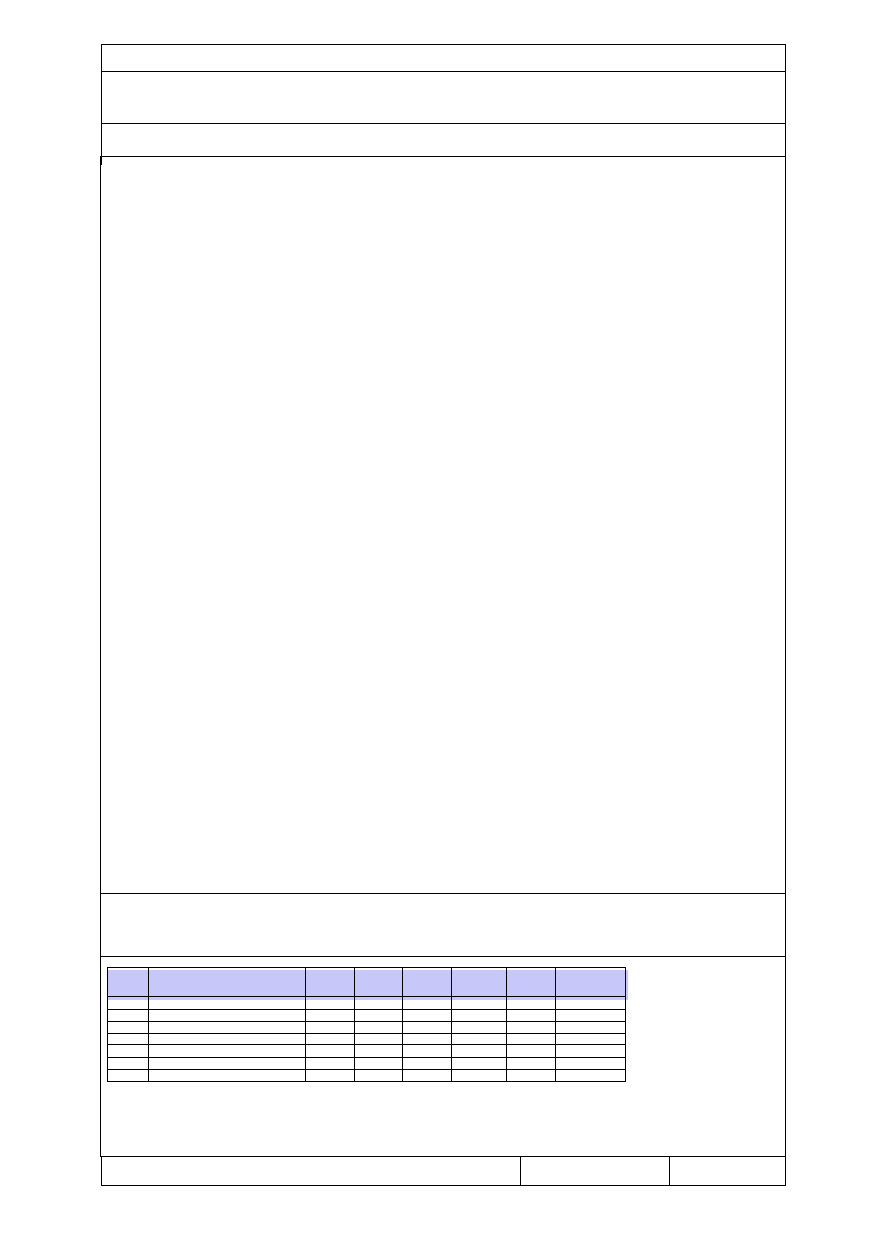

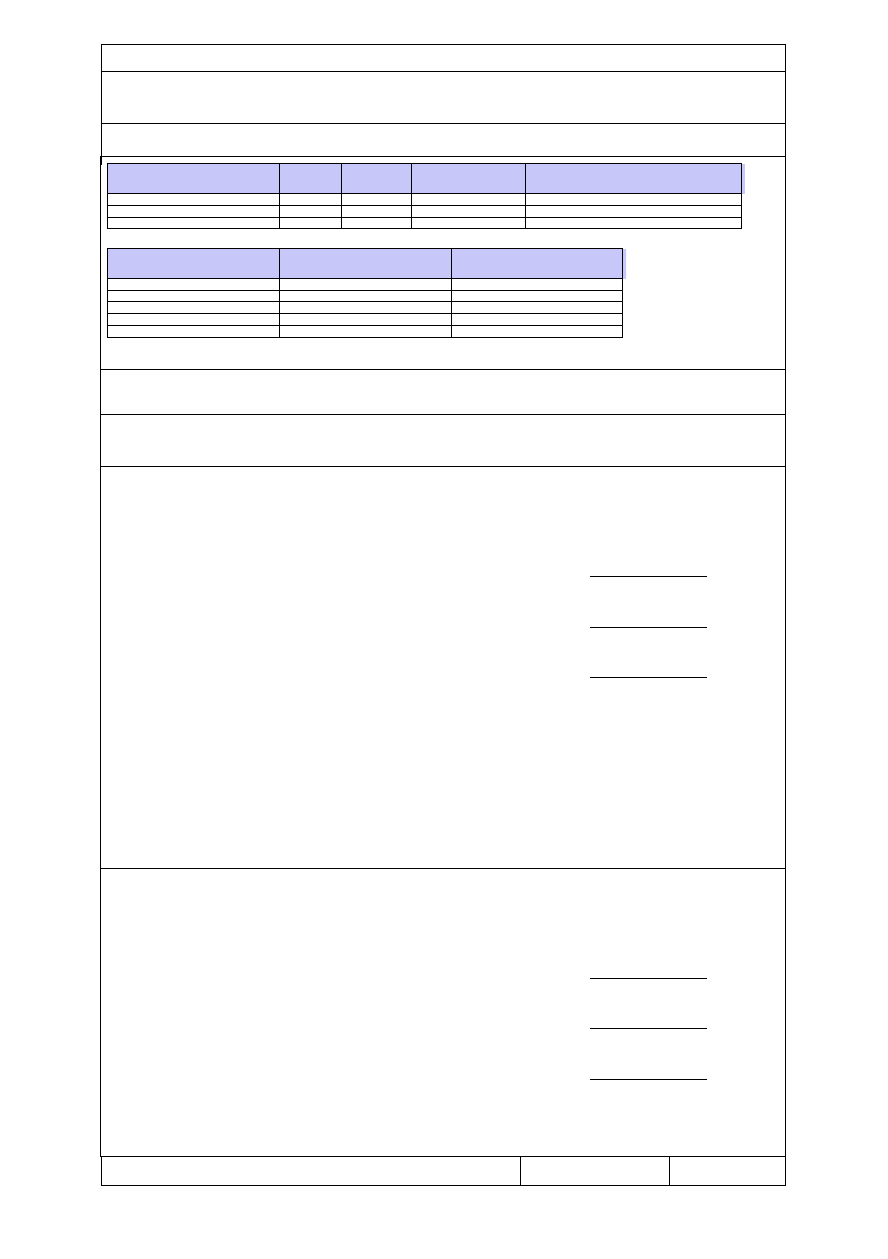

4 Ciezar i pojemnosc zbiornika

Ciezar i pojemnosc zbiornika

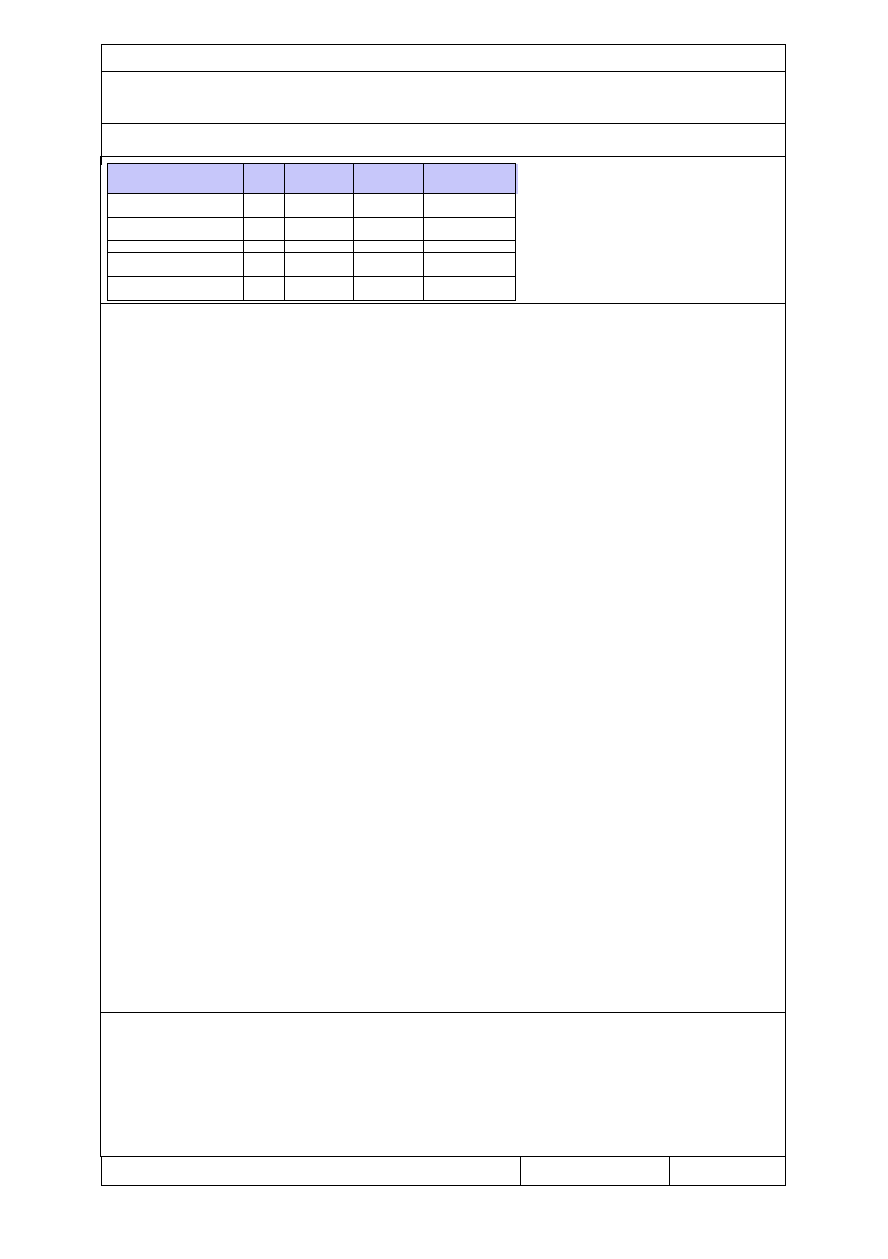

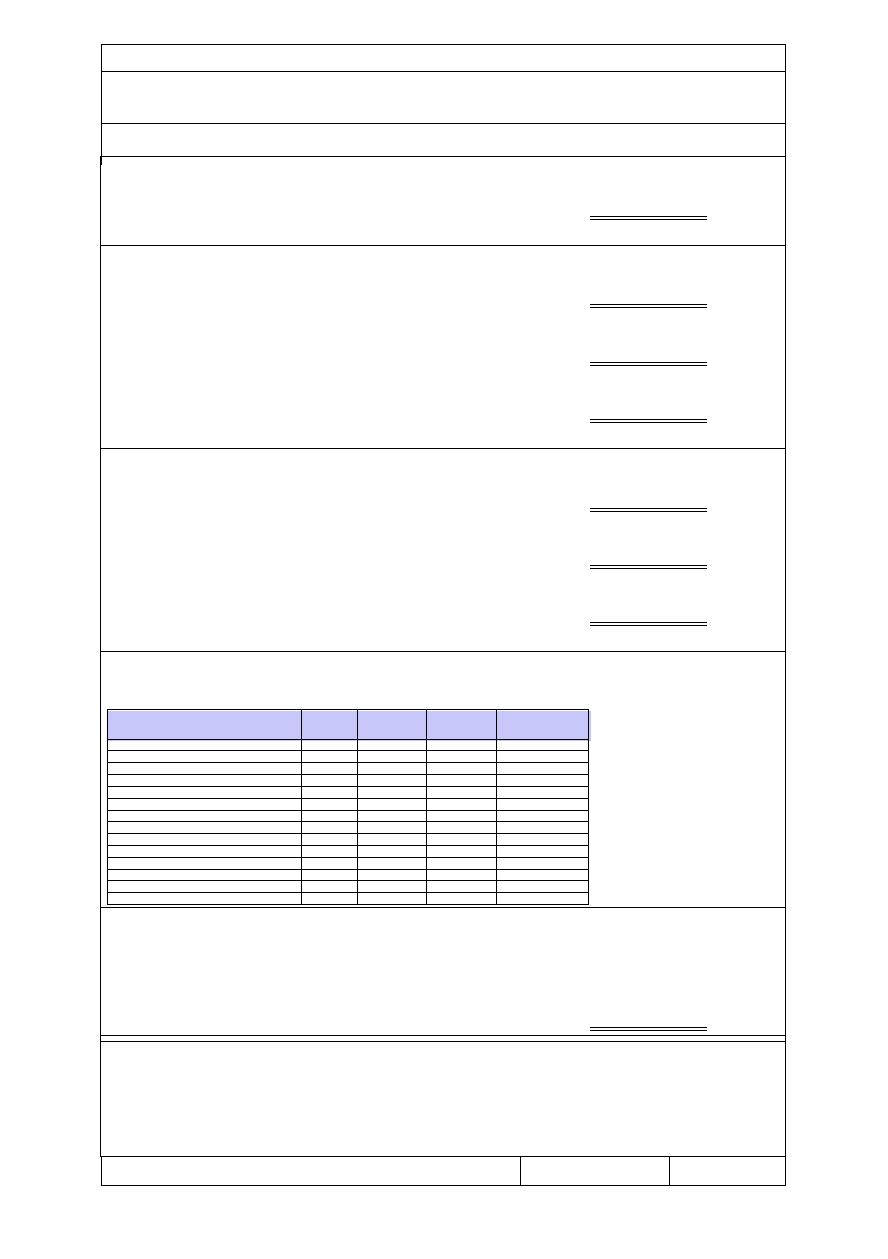

Table :

ID

No.

Ciezar-zbior.niedokoncz.

Ciezar-zbior.dokoncz.

Pojem.calkowita

S1.1

1

1569.0 kg

1520.6 kg

7.855 m3

N.1

1

12.0 kg

12.0 kg

0.031 m3

N.2

1

12.0 kg

12.0 kg

0.031 m3

F.2

2

108.0 kg

108.0 kg

0.028 m3

F.1

1

59.0 kg

59.0 kg

0.014 m3

N.3*

1

12.0 kg

12.0 kg

0.031 m3

F.3

2

108.0 kg

108.0 kg

0.028 m3

:$$12:

Total

9

1880.0 kg

1831.6 kg

8.018 m3

Table Continued

ID

Ciazar cieczy przy probie

Ciezar ruchowy cieczy

S1.1

7855.0 kg

0.0 kg

N.1

31.0 kg

0.0 kg

N.2

31.0 kg

0.0 kg

F.2

28.0 kg

0.0 kg

F.1

14.0 kg

0.0 kg

N.3*

31.0 kg

0.0 kg

F.3

28.0 kg

0.0 kg

:$$12:

Total

8018.0 kg

0.0 kg

Weight Summary/Condition

Weights

Ciezar zbiornika pustego z 5% zawartoscia

1923 kg

Calkowity ciezar zbiornika (War.proby z woda)

9941 kg

Calkowity ciezar ruchowy zbiornika

1923 kg

5 Srodek ciezkosci

Srodek ciezkosci

ID

X-pusty

Y-pusty

Z-pusty

X-proba

Y-proba

Z-proba

X-ruch.

Y-ruch.

Z-ruch.

S1.1

-25

0

1999

0

0

2000

0

0

2000

N.1

847

0

1000

847

0

1000

847

0

1000

N.2

847

0

2000

847

0

2000

847

0

2000

F.2

987

0

2000

987

0

2000

987

0

2000

F.1

987

0

1000

987

0

1000

987

0

1000

N.3*

847

0

3000

847

0

3000

847

0

3000

F.3

987

0

3000

987

0

3000

987

0

3000

CENTER OF GRAVITY AT CONDITIONS BELOW

X

Y

Z

Zbiornik pusty

86

0

1879

Warunki proby zbiornika (proba z woda)

28

0

1972

Warunki ruchowe zbiornika

86

0

1879

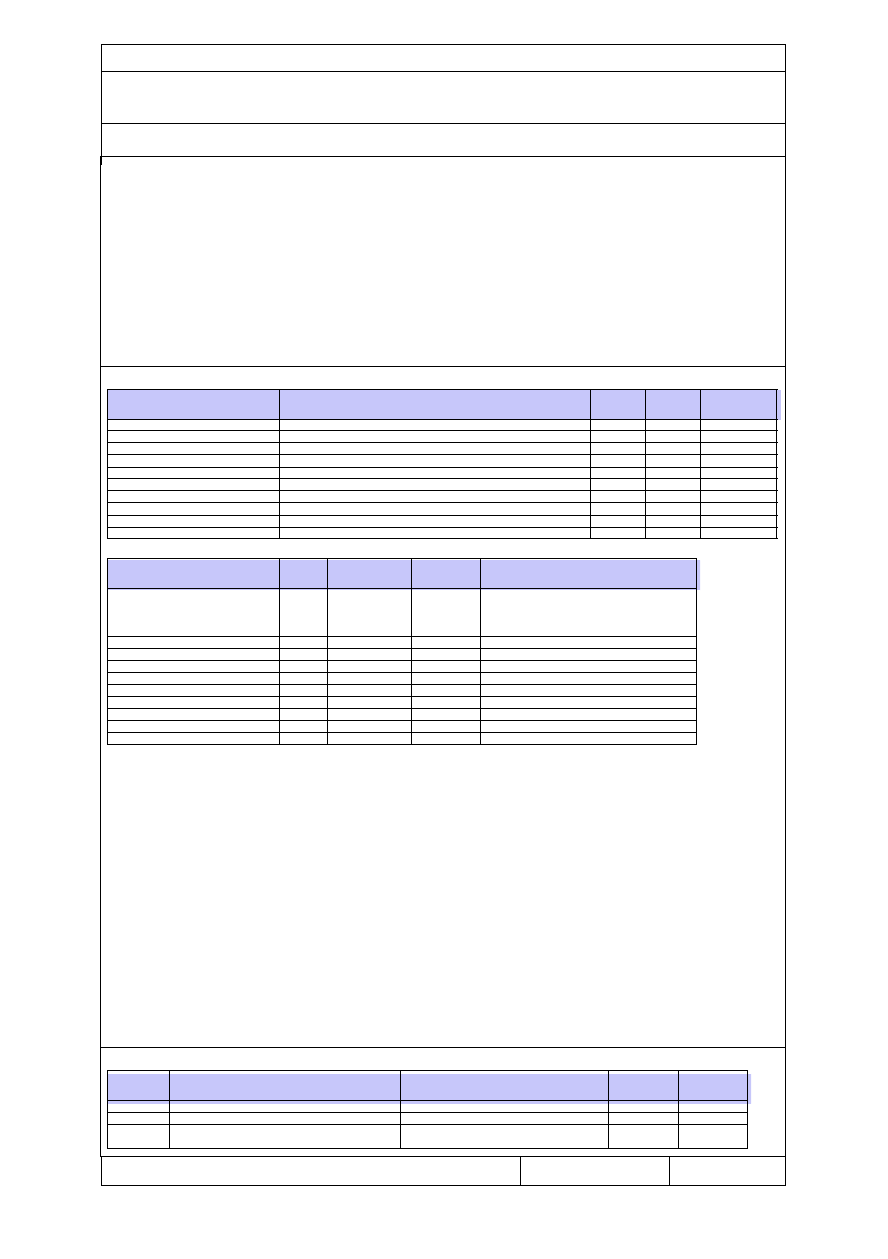

6 Maksymalne cisnienie dopuszczalne MAWP

Maksymalne cisnienie dopuszczalne MAWP

ID

Rodzaj elem.

Liq.Head

MAWP nowy i zimny

MAWP goracy i skorod.

S1.1

Plaszcz walcowy

0.000 MPa

1.771 MPa

1.566 MPa

N.1

Króciec,Blacha korpu

0.000 MPa

1.423 MPa

1.253 MPa

N.2

Króciec,Blacha korpu

0.000 MPa

1.423 MPa

1.253 MPa

F.2

Integral - Flange

0.000 MPa

2.314 MPa

2.314 MPa

6 Maksymalne cisnienie dopuszczalne MAWP

Strona: 2

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9 Operator :RR Rew.:A

ID

Rodzaj elem.

Liq.Head

MAWP nowy i zimny

MAWP goracy i skorod.

F.1

WN - Kolnierz

0.000 MPa

1.450 MPa

1.450 MPa

N.3*

Króciec,Blacha korpu

0.000 MPa

1.423 MPa

1.253 MPa

MAWP

1.423 MPa

1.253 MPa

Przypis: Inne warunki moga ograniczac MAWP ni? te sprawdzone powyzej.

Note : The value for MAWP is at top of vessel, with static liquid head subtracted.

7 Cisnienie próby

Cisnienie próby

CISNIENIE PROBY ZBIORNIKA - NOWY I ZIMNY W PIONIEPOZIOME

Cisnienie obliczeniowe......................: 1.200 MPa

Specified Test Pressure.................: 1.716 MPa

Temperatura obliczeniowa....................: 120.0 C

ID

Opis

Pdesign

PtMax

PtMin

Wat.Head

PtTop

PtTopMax

S1.1

Plaszcz walcowy-plaszcz

1.200

3.078

1.716

0.020

1.696

3.058

N.1

Króciec,Blacha korpu-krociec

met I

1.200

2.102

NA

0.007

NA

2.095

N.2

Króciec,Blacha korpu-krociec

met II

1.200

2.102

NA

0.007

NA

2.095

F.2

Integral - Flange-kolnierz

metoda II

1.200

2.678

NA

0.006

NA

2.672

F.1

WN - Kolnierz-Kolnierz

metoda I

1.200

2.842

NA

0.006

NA

2.836

N.3*

Króciec,Blacha korpu-krociec

met 1591

1.200

2.102

NA

0.007

NA

2.095

HYDRO-TEST

REQUIRED TEST PRESSURE AT TOP OF VESSEL PtReq(Hydro Test) ......: 1.696 MPa

TEST PRESSURE OF: 1.716 MPa AT TOP OF VESSEL IS OK FOR ABOVE COMPONENTS.

Note : Other components may limit Ptlim than the ones checked above.

NOMENCLATURE:

Pdesign- is the design pressure including liquid head at the part under

consideration.

PtMax - is the maximum allowed test pressure determined at the part under

consideration.

PtMin - is the required test pressure determined at the part under consideration.

Wat.Head - is the water head during hydrotesting at the part under consideration.

PtBot - is the required test pressure at bottom of the vessel, for the part

under consideration.

PtTop - is the required test pressure at top of the vessel, for the part under

consideration.

PtTopMax - is the maximum test pressure allowed at top of the vessel, for the

part under consideration.

PtReq - is the required minimum test pressure (largest value of PtTop) at top of

vessel for the listed components.

PtLim - is the maximum allowed test pressure (minimum value for PtTopMax) at top

of vessel for the listed components.

EN13445-5 10.2.3.3.8 Pressure of vessels under test shall be gradually increased

to a value of approximately 50 % of the specified test pressure, thereafter the

pressure shall be increased in stages of approximately 10 % of the specified test

pressure until this is reached. The required test pressure shall be maintained for

not less than 30 min. At no stage shall the vessel be approached for close

examination until the pressure has been positively reduced by at least 10 % to a

level lower than that previously attained. The pressure shall be maintained at

the specified close examination level for a sufficient length of time to permit a

visual inspection to be made of all surfaces and joints.

8 Wykaz materialow

Wykaz materialow

8 Wykaz materialow

Strona: 3

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9 Operator :RR Rew.:A

ID

No

Opis

Opis elementu

Norma materialowa

F.1

1

WN - Kolnierz-Kolnierz

metoda I

OD= 715, ID= 498.46, thk=

34, h= 40, g1= 27.7

ID 2, EN 10028-6:2003, 1.8867 P355QH

plate and strip, HT:QT

F.1

20

Sruby

M30x3 ;, Pole= 544

ID 5, EN 10269:1999, 1.1181 C35E bar,

bolt, HT:QT

F.2

1

Mating Flange

M30x3 ;, Pole= 30

F.2

2

Integral - Flange-kolnierz

metoda II

OD= 715, ID= 499.06, thk=

34.3, h= 40, g1= 7.7

ID 2, EN 10028-6:2003, 1.8867 P355QH

plate and strip, HT:QT

F.2

20

Sruby

M30x3 ;, Pole= 30

ID 5, EN 10269:1999, 1.1181 C35E bar,

bolt, HT:QT

F.3

2

Integral - Flange-Ko3nierz

1591

OD= 715, ID= 499.06, thk=

34.3, h= 40, g1= 7.7

F.3

20

Sruby

M30x3 ;, Pole= 544

N.1

1

Króciec,Blacha korpu-krociec

met I

ND500

do=508,wt=4.77,L=201.9,ho=

150,PAD OD=758

ID 1, EN 10028-2:2003, 1.0425 P265GH

plate and strip, HT:N

N.1

1

Nakladka wzmacniajaca

PAD OD=758, wt= 10,

width= 125

ID 1, EN 10028-2:2003, 1.0425 P265GH

plate and strip, HT:N

N.2

1

Króciec,Blacha korpu-krociec

met II

ND500

do=508,wt=4.77,L=201.9,ho=

150,PAD OD=758

ID 1, EN 10028-2:2003, 1.0425 P265GH

plate and strip, HT:N

N.2

1

Nakladka wzmacniajaca

PAD OD=758, wt= 10,

width= 125

ID 1, EN 10028-2:2003, 1.0425 P265GH

plate and strip, HT:N

N.3*

1

Króciec,Blacha korpu-krociec

met 1591

ND500

do=508,wt=4.77,L=201.9,ho=

150,PAD OD=758

ID 1, EN 10028-2:2003, 1.0425 P265GH

plate and strip, HT:N

N.3*

1

Nakladka wzmacniajaca

PAD OD=758, wt= 10,

width= 125

ID 1, EN 10028-2:2003, 1.0425 P265GH

plate and strip, HT:N

S1.1

1

Plaszcz walcowy-plaszcz

De= 1600, en= 10, L= 4000

ID 1, EN 10028-2:2003, 1.0425 P265GH

plate and strip, HT:N

9 Uwagi, ostrzezenia i bledy

Uwagi, ostrzezenia i bledy

ID & Comp. Description

Przypisy/Uwagi/Informacje o bledach

N.1 Króciec,Blacha korpu krociec

met I

-

NOTE/UWAGA: Szerokosc nakladki uzyta w obliczeniach jest ograniczona do ls = 122.3 mm

N.2 Króciec,Blacha korpu krociec

met II

-

NOTE/UWAGA: Szerokosc nakladki uzyta w obliczeniach jest ograniczona do ls = 122.3 mm

F.2 Integral - Flange kolnierz

metoda II

-

NOTE/NOTE: It is recommended to observe a minimum load ratio FB,min = 0,3 in assembly

condition. A smaller load ratio is in general not good practice, because then the bolts are too thick.

F.1 WN - Kolnierz Kolnierz metoda I

-

NOTE/NOTE : The design may benefit by reducing the bolting area, or reducing the allowable

stress for the bolts.

N.3* Króciec,Blacha korpu krociec

met 1591

-

NOTE/UWAGA: Szerokosc nakladki uzyta w obliczeniach jest ograniczona do ls = 122.3 mm

CALKOWITA ILOSC BLEDOW/OSTRZEZEN: 0

10 Specyfikacja kroccow

Specyfikacja kroccow

ID

Serwis

ROZMIAR

NORMA--KLASA--RODZAJ--PRZYLGA--WYKAZ

N.1

krociec met I

ND500

DIN 2633: Class PN 16

N.2

krociec met II

ND500

Non-standard flange:OD= 715, ID= 499.06, thk= 34.3, h= 40,

g1= 7.7

N.3*

krociec met 1591

ND500

Non-standard flange:OD= 715, ID= 499.06, thk= 34.3, h= 40,

g1= 7.7

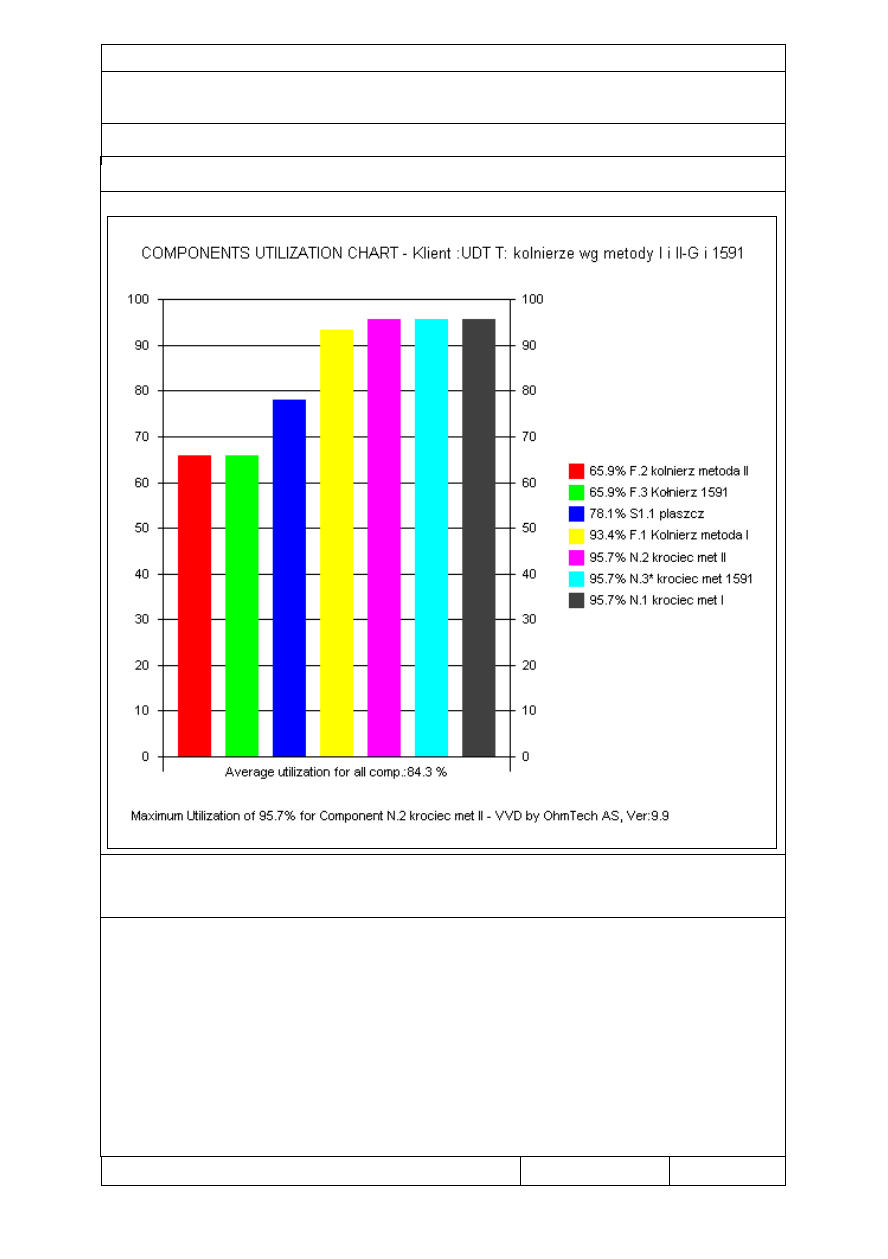

11 Maksymalne wykorzystanie elementu -

Maksymalne wykorzystanie elementu - Umax

ID

Rodzaj elemen.

Umax(%)

Ograniczone przez

S1.1

Plaszcz walcowy

78.1%

Internal Pressure

N.1

Króciec,Blacha korpu

95.7%

Nozzle Reinforcement

11 Maksymalne wykorzystanie elementu -

Umax

Strona: 4

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9 Operator :RR Rew.:A

ID

Rodzaj elemen.

Umax(%)

Ograniczone przez

N.2

Króciec,Blacha korpu

95.7%

Nozzle Reinforcement

F.2

Integral - Flange

65.9%

Flange Load Ratio PhiF

F.1

WN - Kolnierz

93.4%

Radial+Hub Stress

N.3*

Króciec,Blacha korpu

95.7%

Nozzle Reinforcement

F.3

Integral - Flange

65.9%

Flange Load Ratio PhiF

Element z najwyzszym stopniem wykorzystania Umax = 95.7% N.1 krociec met I

Sredni stopien wykorzystania wszystkich elem. Usr= 84.3%

12 Dane materialowe/Wlasnosci mechaniczne

Dane materialowe/Wlasnosci mechaniczne

Table :

ID

Material Name

Temp

Rm

Rp

Rpt

f_d

f20

ftest

E-mod

Przypis

1

EN 10028-2:2003, 1.0425 P265GH plate

and strip, HT:N TG3, CS, Mat.Group:1.1, ,

Max.T= 16mm, SG=7.85

120

410

265

233.8

155.9

170.8

252.4

204605

a)

2

EN 10028-6:2003, 1.8867 P355QH plate

and strip, HT:QT TG3, CS, Mat.Group:1.1, ,

Max.T= 50mm, SG=7.85

120

490

355

300

200

204.2

338.1

204605

a)

3

EN 10028-2:2003, 1.0425 P265GH plate

and strip, HT:N TG3, CS, , Max.T= 16mm,

SG=7.85

120

410

265

233.8

155.9

170.8

252.4

204605

a)

4

EN 10269:1999, 1.1181 C35E bar, bolt,

HT:N TG3, CS, Mat.Group:1.1, , Max.T=

60mm, SG=7.93

120

500

300

262.4

155.9

176.7

150

191484

a)

5

EN 10269:1999, 1.1181 C35E bar, bolt,

HT:QT TG3 , Mat.Group:9.2, , Max.T=

60mm, SG=7.93

120

500

300

262.4

87.5

100

150

191484

a)

6

EN 10269:1999, 1.4938 X12CrNiMoV12-3

bar, bolt, HT:QT TG3, CS, Mat.Group:1.1, ,

Max.T= 160mm, SG=7.93

120

930

760

675.2

225.1

232.5

348.8

191484

a)

7

EN 10273:2000, 1.8867 P355QH bar,

HT:QT TG3, CS, Mat.Group:1.2, , Max.T=

50mm, SG=7.85

120

490

355

300

200

204.2

338.1

204605

a)

8

EN 10222-4:1998, 1.0565 P355NH forging,

HT:N TG3, CS, Mat.Group:1.2, , Max.T=

50mm, SG=7.85

120

490

355

296

197.3

204.2

338.1

204605

a)

9

EN 10222-4:1998, 1.0571 P355QH1

forging, HT:QT TG3, CS, Mat.Group:1.2, ,

Max.T= 100mm, SG=7.85

120

470

315

286.4

190.9

195.8

300

204605

a) f)

10

EN 10028-2:2003, 1.0425 P265GH plate

and strip, HT:N TG3, CS, , Max.T= 16mm,

SG=7.85

120

410

265

233.8

155.9

170.8

252.4

204605

a)

Table Continued

ID

1

2

3

4

5

6

7

8

9

10

Przypisy:

Thickness in mm, stress in N/mm2, temperature in deg.C

TG : Grupa Badan 1 do 4

t maks: Maks.grubosci dla podanego zakresu napr., 0 lub 999= Bez ograniczenia

S/C : CS = Stal weglowa, SS = Stal kwasoodp.

SG : SG = Ciezar wlasciwy (Woda = 1.0)

Rm : MIN. WYTRZYMALOSC NA ROZCIAGANIE w temp. otoczenia

Rp : MIN. GRANICA PLASTYCZNOSCI w temp. otoczenia

Rpt : MIN. GRANICA PLASTYCZNOSCI w temp. obliczeniowej

f_d : NAPREZENIE OBLICZENIOWE w temp. obliczeniowej

f20 : NAPREZENIE OBLICZENIOWE w temp. otoczenia

GRP : 1.1 = stale o okreslonej granicy plastycznosci ReH <=275 N/mm2

GRP : 1.0 = Steels with a specified minimum yield strength ReH <= 460 N/mm2 a and

with analysis in %:C <= 0,25, Si <= 0,60, Mn <= 1,70, Mo <= 0,70b, S <= 0,045, P

12 Dane materialowe/Wlasnosci mechaniczne

Strona: 5

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9 Operator :RR Rew.:A

<= 0,045, Cu <= 0,40b, Ni <= 0,5b, Cr <= 0,3 (0,4 for castings)b, Nb <= 0,05, V <=

0,12b, Ti <= 0,05

GRP : 9.2 = Nickel alloyed steels with 3,0 % < Ni <= 8 %

GRP : 9.0 = Nickel alloyed steels with Ni <= 10 %

GRP : 1.2 = Steels with a specified minimum yield strength 275 N/mm2 < ReH <= 360

N/mm2

GRP : 1.0 = Steels with a specified minimum yield strength ReH <= 460 N/mm2 a and

with analysis in %:C <= 0,25, Si <= 0,60, Mn <= 1,70, Mo <= 0,70b, S <= 0,045, P

<= 0,045, Cu <= 0,40b, Ni <= 0,5b, Cr <= 0,3 (0,4 for castings)b, Nb <= 0,05, V <=

0,12b, Ti <= 0,05

Przypis: a = Materialy powinny spelniac odpowiednie zasadnicze wymagania

bezpieczenstwa Dyrektywy 97/23/WE

Note : f = Additional requirements for forming and welding shall be considered on

a case by case basis.

HT : N = normalizowane

HT : QT = quenched and tempered

HT : N = normalizowane

HT : QT = quenched and tempered

HT : QT = quenched and tempered

HT : QT = quenched and tempered

HT : N = normalizowane

HT : QT = quenched and tempered

Section 6.3 Alternative route for steels

The Alternative Route has been used in obtaining the allowable stress for the

following materials:

4 EN 10269:1999, 1.1181 C35E bar, bolt, HT:N

8 EN 10222-4:1998, 1.0565 P355NH forging, HT:N

9 EN 10222-4:1998, 1.0571 P355QH1 forging, HT:QT

Alternative route allows the use of higher nominal design stress by reducing the

safety factor on tensile strength from 2.4 to 1.875 if all of the following

conditions are met:

a) Material requirements as specified in EN 13445-2:2002 for Design by Analysis -

Direct Route.

b) Restriction in construction and welded joints as specified in Clause 5 and in

Annex A of EN 13445-3:2002 for Design by Analysis - Direct Route.

c) All welds which must be tested by non-destructive testing (NDT) according to

the requirements of EN

13445-5:2002 shall be accessible to NDT during manufacture and also for in-service

inspection.

d) Fatigue analysis according to Clause 17 or 18 in all cases.

e) Fabrication requirements as specified in EN 13445-4:2002 for Design by Analysis

- Direct Route.

f) NDT as specified in EN 13445-5:2002 for Design by Analysis - Direct Route.

g) Appropriate detailed instructions for in-service inspections are provided in

the operating instructions by the manufacturer.

NOTE/NOTE Until sufficient in-house experience can be demonstrated, the

involvement of an independent body, appropriately qualified, is recommended for

the assessment of the design (calculations) and for assurance that all

requirements are met in materials, fabrication and NDT.

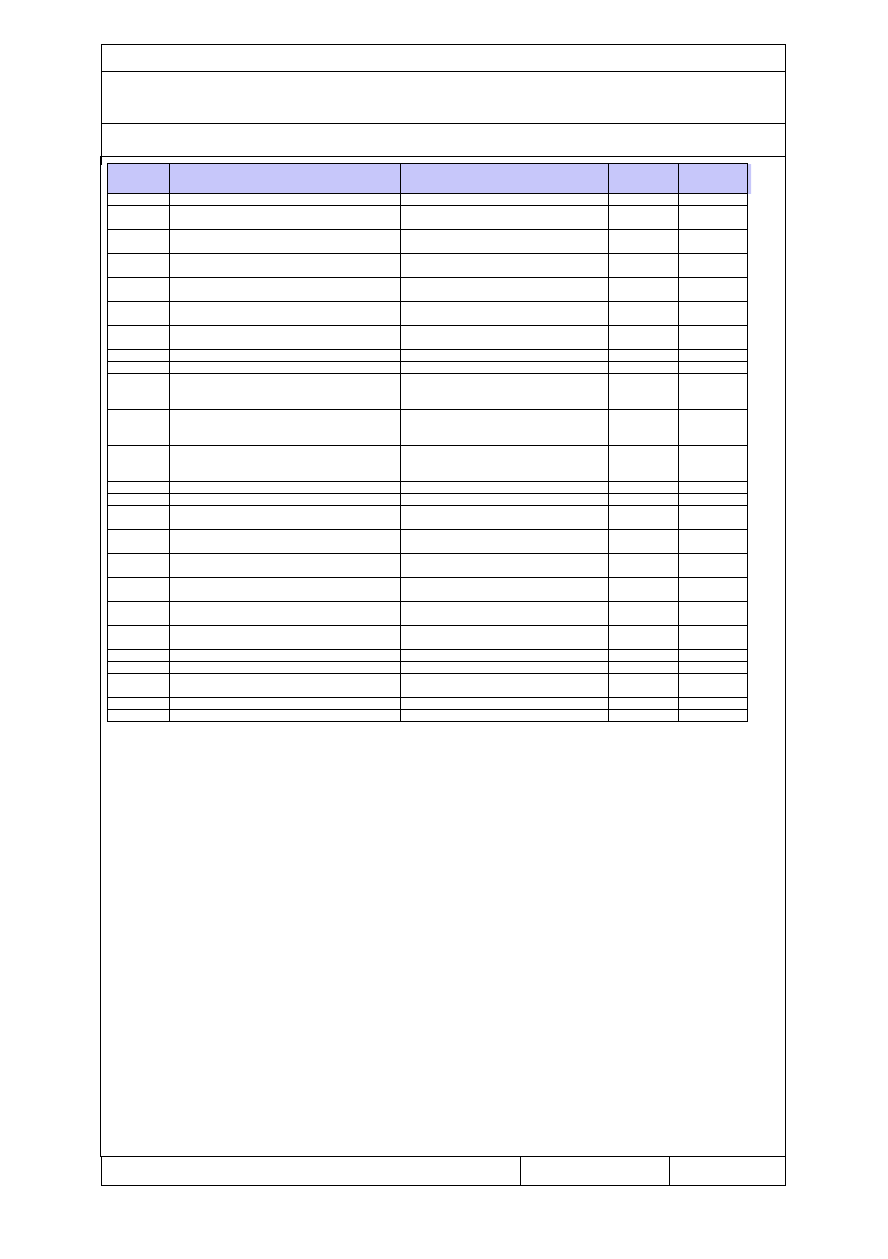

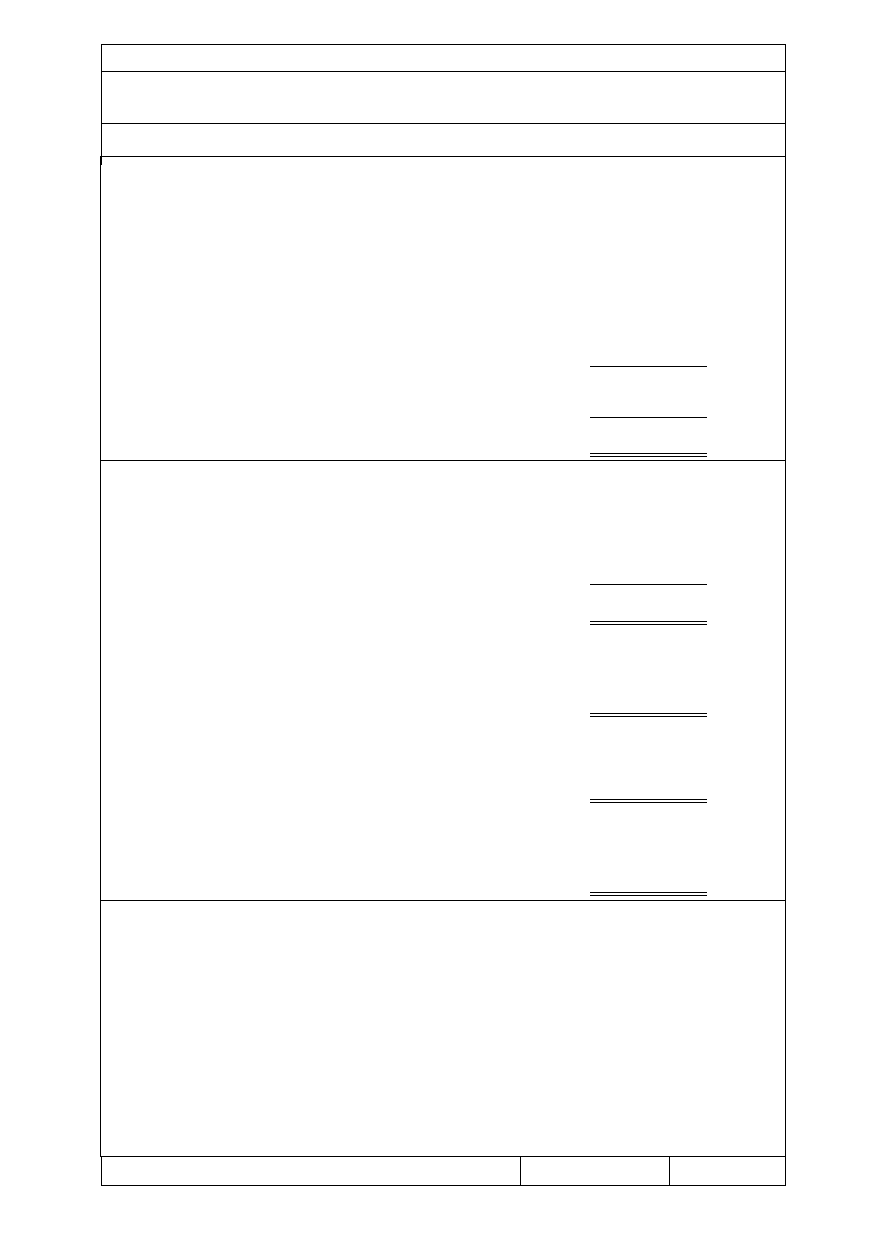

13 Polozenie elementu wzgledem osi wspolrzednych

Polozenie elementu wzgledem osi wspolrzednych

ID

Rodzaj elem.

X

Y

Z

Teta

Phi

ConnID

F.1

WN - Kolnierz

0

0

155

0.0

0.0

N.1

F.2

Integral - Flange

0

0

155

0.0

0.0

N.2

F.3

Integral - Flange

0

0

155

0.0

0.0

N.3*

N.1

Króciec,Blacha korpu

795

0

1000

90.0

0.0

S1.1

N.2

Króciec,Blacha korpu

795

0

2000

90.0

0.0

S1.1

N.3*

Króciec,Blacha korpu

795

0

3000

90.0

0.0

S1.1

S1.1

Plaszcz walcowy

0

0

0

0.0

0.0

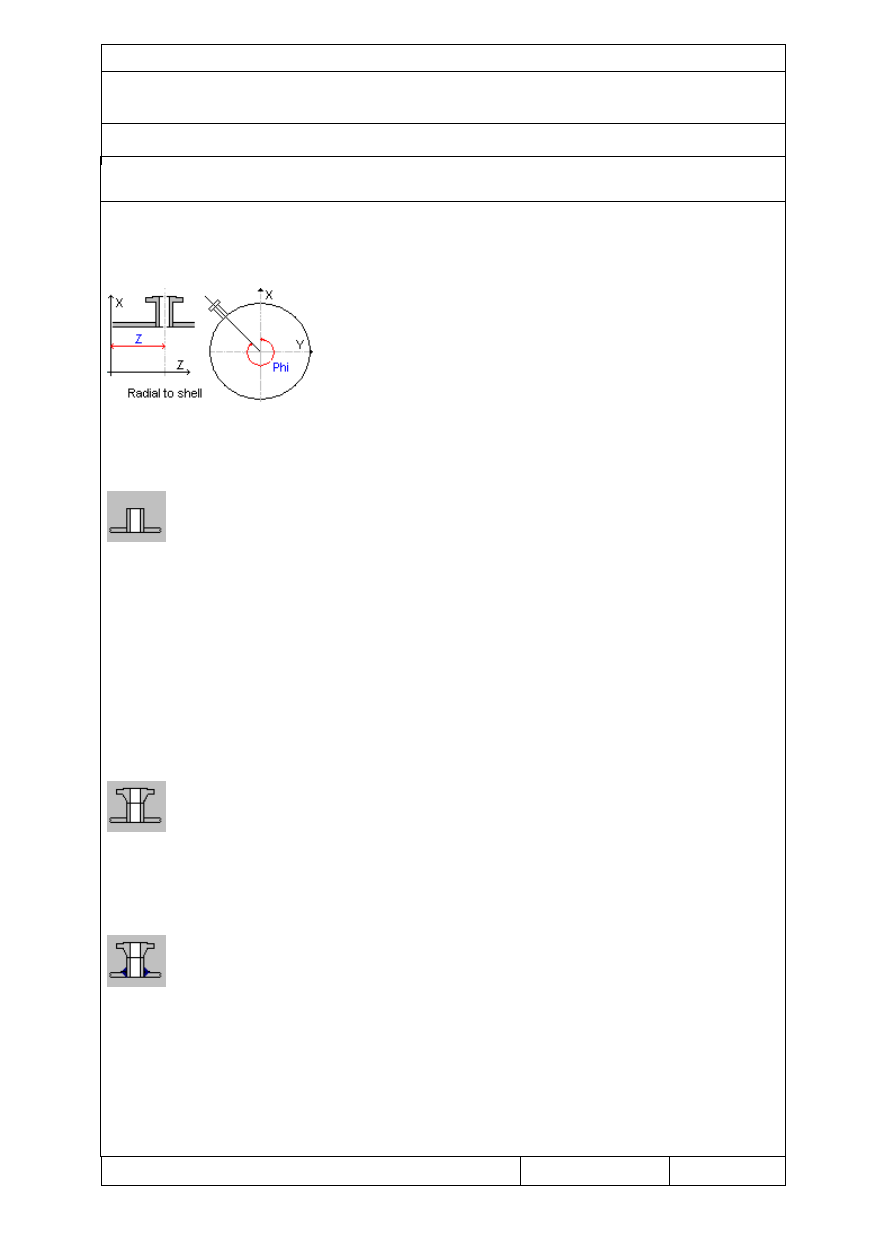

Powyzszy raport pokazuje polozenie punktow polaczen (x, y oraz z)

kazdego elementu w systemie wspolrzednych elementu glownego

(Conn ID). Punkt polaczenia (x, y oraz z) jest zawsze w osi

symetrii obrotu rozpatrywanego elementu, np. punkt

13 Polozenie elementu wzgledem osi wspolrzednych

Strona: 6

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9 Operator :RR Rew.:A

polaczenia krocca z cylindrem powinien byc na przecieciu

osi krocca z srodkiem grubosci scianki plaszcza

referenced to the shell s coordinate system. In addition the orientation s

coordinate system. In addition the orientation

osi elementu okreslone jest przez dwa katy Teta oraz

Phi, gdzie Teta jest katem pomiedzy osiami dwoch elementow, a

Phi jest orientacja plaszczyzny x-y.

Podstawa systemu koordynacji stosowanego w programie jest strona prawa

systemu koordynacyjnego z osia "z" jako geometryczna osia obrotu

elementow, a Teta jako kat polnocy i Phi jako azymut.

14 Impact Test Requirements

Impact Test Requirements

Table :

ID-Description

Material Name

en(mm)

eB(mm)

Re(N/mm2)

F.1 Kolnierz metoda I - Bolts

EN 10269:1999, 1.1181 C35E bar, bolt, HT:QT

30.0

30.0

300.0

F.1 Kolnierz metoda I - Flange

EN 10028-6:2003, 1.8867 P355QH plate and strip, HT:QT

34.0

8.5

355.0

F.1 Kolnierz metoda I - Hub

EN 10028-6:2003, 1.8867 P355QH plate and strip, HT:QT

7.7

7.7

355.0

N.1 krociec met I - Nozzle

EN 10028-2:2003, 1.0425 P265GH plate and strip, HT:N

4.8

4.8

265.0

N.1 krociec met I - Pad

EN 10028-2:2003, 1.0425 P265GH plate and strip, HT:N

10.0

10.0

265.0

N.2 krociec met II - Nozzle

EN 10028-2:2003, 1.0425 P265GH plate and strip, HT:N

4.8

4.8

265.0

N.2 krociec met II - Pad

EN 10028-2:2003, 1.0425 P265GH plate and strip, HT:N

10.0

10.0

265.0

N.3* krociec met 1591 - Nozzle

EN 10028-2:2003, 1.0425 P265GH plate and strip, HT:N

4.8

4.8

265.0

N.3* krociec met 1591 - Pad

EN 10028-2:2003, 1.0425 P265GH plate and strip, HT:N

10.0

10.0

265.0

S1.1 plaszcz - Shell

EN 10028-2:2003, 1.0425 P265GH plate and strip, HT:N

10.0

10.0

265.0

Table Continued

ID-Description

TR(C)

TKVPWHT(C)

TKVAW(C)

Comments

F.1 Kolnierz metoda I - Bolts

0.0

20

-1.1

NOTE: Steel designation unknown, this

method is only applicable for ferritic steels(C,

CMn and fine grain) and 1.5% to 5% Ni-alloy

steels.

F.1 Kolnierz metoda I - Flange

0.0

20

20

F.1 Kolnierz metoda I - Hub

0.0

20

20

N.1 krociec met I - Nozzle

0.0

20

20

N.1 krociec met I - Pad

0.0

20

20

N.2 krociec met II - Nozzle

0.0

20

20

N.2 krociec met II - Pad

0.0

20

20

N.3* krociec met 1591 - Nozzle

0.0

20

20

N.3* krociec met 1591 - Pad

0.0

20

20

S1.1 plaszcz - Shell

0.0

20

20

EN13445-2 Annex B, Requirements for Prevention of Brittle Fracture

B.2.3 Method 2 - Code of practice developed from fracture mechanics

NOMENCLATURE:

en - Nominal thickness of component under consideration(including corr.

allow.).

eB - Reference thickness of component under consideration from Table B.4-1.

Re - Minimum specified yield strength at room temperature.

AW - As Welded condition.

PWHT - Post Weld Heat Treatment.

TR - Design Reference Temperature.

TKVPWHT- Material impact test temperature for PWHT condition from Figure B.4-1

or 3, and required impact energy 27J.

TKVAW - Material impact test temperature for AW condition from Figure B.4-2, 4

or 5, and required impact energy 27J.

15 NDT - Requirements for Test Group:3a

NDT - Requirements for Test Group:3a

Table EN13445-5, 6.6.2-1:

Weld ID

Kategoria spoiny

Rodzaj spoiny

RT or UT

MT or PT

1

Full Penetration butt weld

Longitudinal joints

25%

10%

2a

Full Penetration butt weld

Circumferential joints on a shell

10%

10%

2b

Full Penetration butt weld

Circumferential joints on a shell with

backing strip (k)

NA

NA

15 NDT - Requirements for Test Group:3a

Strona: 7

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9 Operator :RR Rew.:A

Weld ID

Kategoria spoiny

Rodzaj spoiny

RT or UT

MT or PT

2c

Full Penetration butt weld

Circumferential joggle joint (k)

NA

NA

3a

Full Penetration butt weld

Circumferential joints on a nozzle di > 150

mm or e > 16 med mer

10%

10%

3b

Full Penetration butt weld

Circumferential joints on a nozzle di > 150

mm or e > 16 mm with backing strip (k)

NA

NA

4

Full Penetration butt weld

Circumferential joints on a nozzle with di <=

150 mm and e <= 16mm

0

10%

5

Full Penetration butt weld

All welds in spheres, heads and

hemispherical heads to shells

25%

10%

6

Full Penetration butt weld

Assembly of a conical shell with a cylindrical

shell angle <= 30o

10%

10%

7

Full Penetration butt weld

Assembly of a conical shell with a cylindrical

shell angle > 30o

25%

10%

8a

Circumferential lapped joints (k)

General application shell to head

NA

NA

8b

Circumferential lapped joints (k)

Bellows to shell e <= 8 med mer

0

25%

9

Assembly of a flat head or a tubesheet, with a

cylindrical shell Assembly of a flange or a collar

with a shell

With full penetration

25%

10%

10

Assembly of a flat head or a tubesheet, with a

cylindrical shell Assembly of a flange or a collar

with a shell

With partial penetration if a>16 mm (a as

defined in figure 6.6.2-1)(j)

25%

10%

11

Assembly of a flat head or a tubesheet, with a

cylindrical shell Assembly of a flange or a collar

with a shell

With partial penetration if a<=16 mm (a as

defined in figure 6.6.2-1) (j)

0

10%

12

Assembly of a flange or a collar with a nozzle

With full penetration

25%

10%

13

Assembly of a flange or a collar with a nozzle

With partial penetration (j)

0

10%

14

Assembly of a flange or a collar with a nozzle

With full or partial penetration di <= 150 mm

and e <= 16 mm j

0

10%

15

Nozzle or branch (e)

With full penetration di > 150 mm or e > 16

mm

25%

10%

16

Nozzle or branch (e)

With full penetration di <= 150 mm or e <=

16 mm

0

10%

17

Nozzle or branch (e)

With partial penetration for any di a > 16

mm (see figure 6.6.2-2)

25%

10%

18

Nozzle or branch (e)

With partial penetration di > 150 mm a <=

16 mm (see figure 6.6.2-2)

0

10%

19

Nozzle or branch (e)

With partial penetration di <= 150 mm a <=

16 mm (see figure 6.6.2-2)

0

10%

20

Tube ends into tubesheet

-

-

25%

21

Permanent attachments (f)

With full penetration or partial penetration

10%

100%

22

Pressure retaining areas after removal of

temporary attachments

-

-

100%

23

Cladding by welding

-

-

100%

24

Repairs

-

100%

100%

The above requirements are for test group TG:3a

Notes:

(a): See figure 6.6.2-3 for an explanation on Weld ID.

(b): RT=Radiographic Testing, UT=Ultrasonic Testing, MT=Magnetic Particle Testing,

PT=Penetrant Testing.

(c): 2 % if e L 30mm and same WPS as longitudinal, for steel groups 1.1 and 8.1

(d): 10 % if e > 30 mm, 0 % if e <= 30 mm

(e): Percentage in the table refers to the aggregate weld length of all the

nozzles see 6.6.1.2 b).

(f): No RT or UT for weld throat thickness <= 16 mm

(g): 10 % for steel groups 8.2, 9.1, 9.2, 9.3 and 10

(h): Volumetric testing if risks of cracks due to parent material or heat treatment

(i): For explanation of the reduction in NDT in testing group 2, see 6.6.1.2

(j): In exceptional cases or where the design or load bearing on the joint is

critical, it may be necessary to employ both techniques (i.e. RT & UT, MT & PT).

See table 6.6.3-1 for other circumstances for use of both techniques.

(k): For limitations of application see EN 134445-3:2002, 5.7.3.2.l

(l): The percentage of surface examination refers to the percentage of length of

the welds both on the inside and the outsidem.

(m): RT and UT are volumetric while MT and PT are surface testing. When referenced

in this table both volumetric and surface are necessary to the extent shown.

(n): NA means 'Not Applicable'.

(o): In case of cyclic loading refer to Annex G.2.

(p): Annex A of EN 13445-3 gives design limitations on welds.

15 NDT - Requirements for Test Group:3a

Strona: 8

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9 Operator :RR Rew.:A

EN13445-5, Table 6.6.2-3, Map of Weld Types/Weld ID.

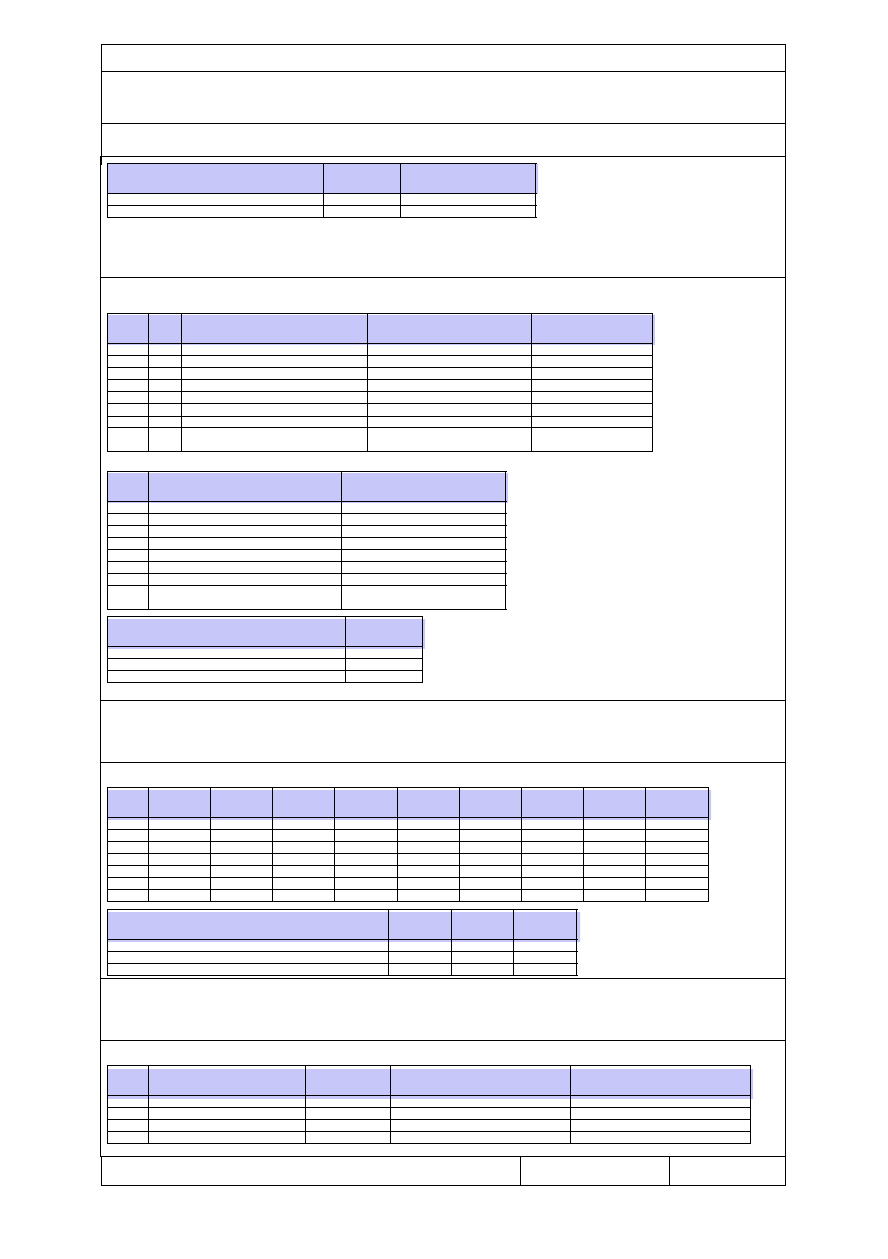

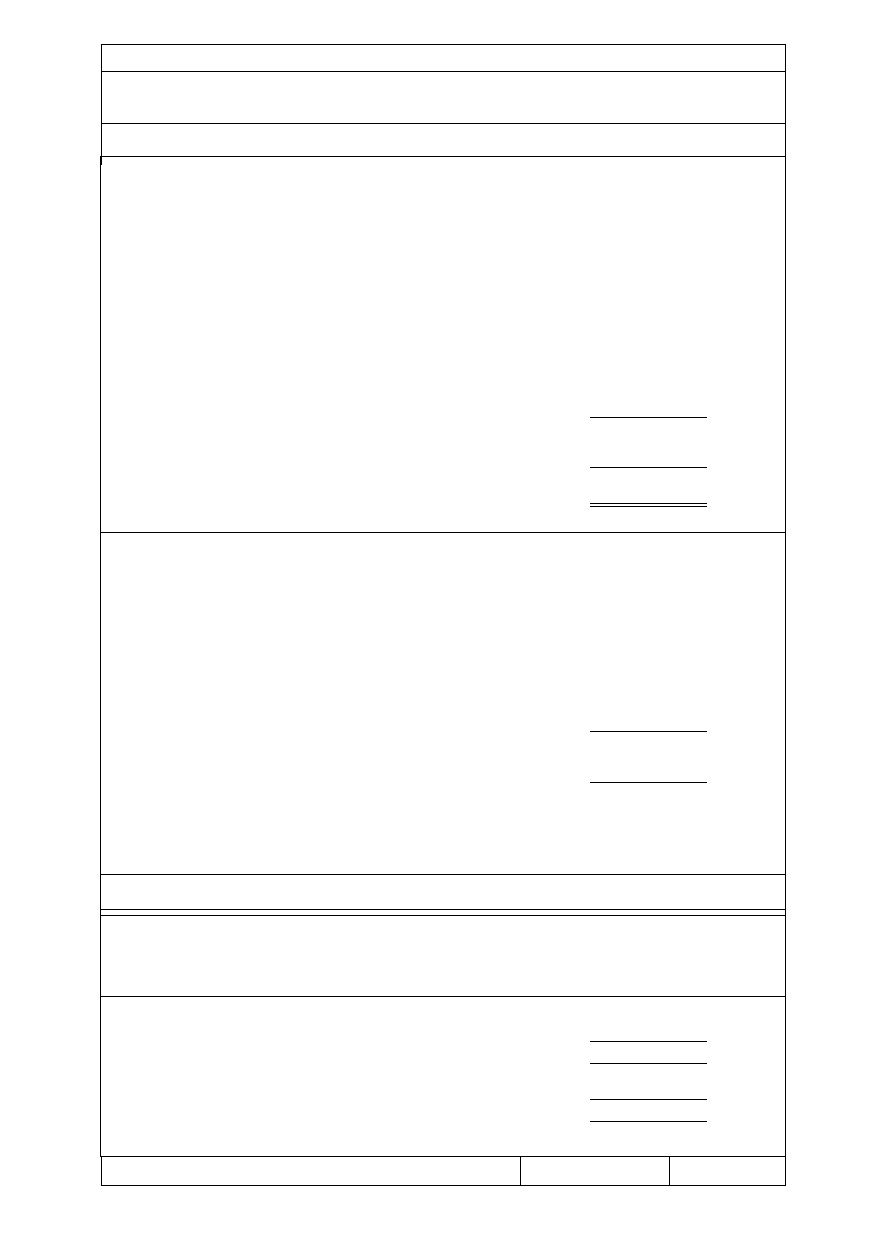

16 DIAGRAM WYKORZYSTANIA

16 DIAGRAM WYKORZYSTANIA

Strona: 9

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9 Operator :RR Rew.:A

DIAGRAM WYKORZYSTANIA

DIAGRAM WYKORZYSTANIA

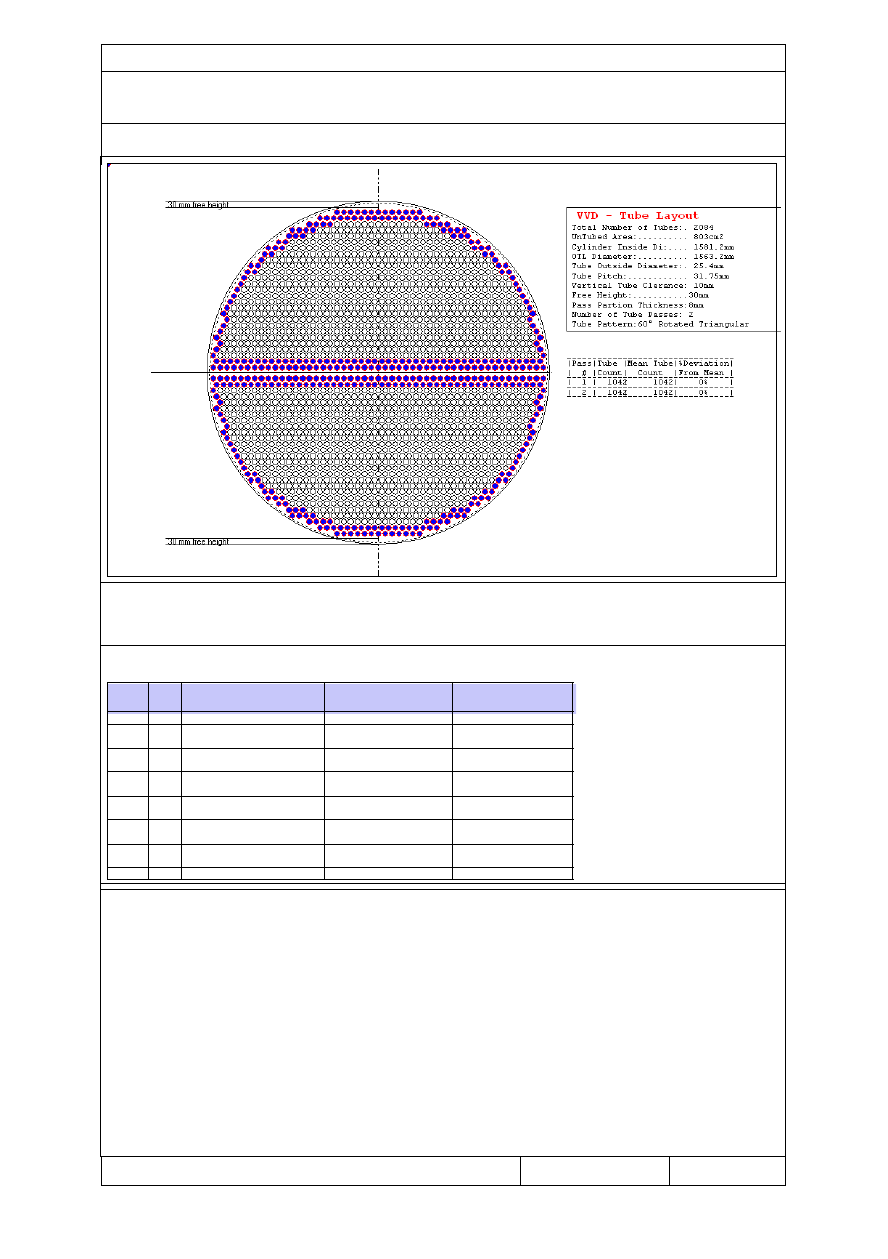

17 Uklad rurek

Uklad rurek

Uklad rurek

17 Uklad rurek

Strona: 10

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9 Operator :RR Rew.:A

18 Surface Area

Surface Area

Table Surface Area:

ID

No.

Opis

Area Outside(m2)

Area Inside(m2)

S1.1

1

Plaszcz walcowy, plaszcz

20.106

19.870

N.1

1

Króciec,Blacha korpu,

krociec met I

0.239

0.235

N.2

1

Króciec,Blacha korpu,

krociec met II

0.239

0.235

F.2

2

Integral - Flange, kolnierz

metoda II

0.678

0.232

F.1

1

WN - Kolnierz, Kolnierz

metoda I

0.339

0.116

N.3*

1

Króciec,Blacha korpu,

krociec met 1591

0.239

0.235

F.3

2

Integral - Flange, Ko3nierz

1591

0.678

0.232

Total

9

22.518

21.155

Strona: 11

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9 Operator :RR Rew.:A

19 S1.1 Plaszcz walcowy plaszcz

DANE WEJSCIOWE

ELEMENT PRZYLACZONY/POLOZENIE

DANE PROJEKTOWE

OBCIAZENIE CISNIENIEM: Obliczanie elementu tylko na cisnienie wewnetrzne

KARTA PROCESOWA: DANE PROJEKTOWE : Temp= 120°C, P= 1.2MPa, c= .3mm, Pext= 0MPa

GESTOSC WLASCIWA PLYNU ROBOCZEGO....................:SG 0.00

SLUP CIECZY.........................................:LH 2190.60 mm

DANE PLASZCZA

RODZAJ MATERIALU: Blacha

WSPÓLCZYNNIK ZLACZA SPAWANEGO: Grupa badan 3 (z=0.85)

DOBÓR SREDNICY: Obliczenie oparte o srednice zewnetrzna plaszcza

EN 10028-2:2003, 1.0425 P265GH plate and strip, HT:N THK<=16mm 120'C

Rm=410 Rp=265 Rpt=233.8 f=155.87 f20=170.83 ftest=252.38 E=204605(N/mm2) ro=7.85

SREDNICA ZEWNETRZNA PLASZCZA........................:De 1600.00 mm

DLUGOSC CZESCI WALCOWEJ PLASZCZA....................:Lcyl 4000.00 mm

RZECZYWISTA GRUBOSC SCIANKI (w stanie nie skorodowanym) :en 10.00 mm

UJEMNA TOLERANCJA WYKONANIA.........................:th 0.3000 mm

WYNIKI OBLICZEN

7.4.2 - PLASZCZE WALCOWE POD CISNIENIEM WEWNETRZNYM

Minimalna wymagana grubosc plaszcza bez naddatku na korozje: emin

emin = De * P / (2 * f * z + P) (7.4-2)

=1600*1.2/(2*155.87*0.85+1.2)= 7.21 mm

Minimalna wymagana grubosc plaszcza z naddatkiem na korozje: emin

emina = emin + c + th =7.21+0.3+0.3= 7.81 mm

Obliczenie grubosci

ea = en - c - th =10-0.3-0.3= 9.40 mm

»7.4.1. Warunki stosowania emin/De=0.0045 <= 0.16« » OK«

»Cisnienie wewnetrzne emina=7.81 <= en=10[mm] « » (U= 78.1%) OK«

MAKSYMALNE DOPUSZCZALNE CISNIENIE ROBOCZE MAWP:

Srednica wewnetrzna plaszcza

Di = De - 2 * ea =1600-2*9.4= 1581.20 mm

Srednia srednica plaszcza

Dm = (De + Di) / 2 =(1600+1581.2)/2= 1590.60 mm

MAWP STAN GORACY I SKOROD. (skorodowany w temp. obliczeniowej)

MAWPHC = 2 * f * z * ea / Dm

=2*155.87*0.85*9.4/1590.6= 1.57 MPa

MAWP STAN NOWY I ZIMNY (nowy przy temp. otoczenia)

MAWPNC = 2 * f20 * z * (ea + c) / Dm

=2*170.83*0.85*(9.4+0.3)/1590.6= 1.77 MPa

MAKSYMALNE CISNIENIE PRÓBY (Stan nieskorodowany w temp. otoczenia)

Ptmax = 2 * ftest * ztest * (ea + c) / Dm

=2*252.38*1*(9.4+0.3)/1590.6= 3.08 MPa

EN13445-5; 10.2.3.3 WYMAGANE MINIMALNE CISNIENIE PRÓBY HYDRAULICZNEJ: Ptmin

NOWY W TEMP. OTOCZENIA DLA GRUPY BADAN 1,2 i 3

Ptmin = MAX( 1.43 * Pd , 1.25 * Pd * f20 / f )

=MAX(1.43*1.2,1.25*1.2*170.83/155.87)= 1.72 MPa

19 S1.1 Plaszcz walcowy plaszcz

Umax= 78.1%

Strona: 12

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-04 Operator :RR Rev.:A

EN13445:Issue26 - 7.4.2 PLASZCZ WALCOWY

S1.1 plaszcz 17 Nov. 2008 19:44

»Cisnienie próby Ptmin=1.716 <= Ptmax=3.08[MPa] « » (U= 55.7%) OK«

MAKSYMALNA SREDNICA OTWORU NIEWZMOCNIONEGO W PLASZCZU

Promien wewnetrzny plaszcza

ris = Di / 2 (9.5-3) =1581.2/2= 790.60 mm

Dlugosc plaszcza uwzgledniana przy obliczaniu wzmocnienia

Is = Sqr(( 2 * ris + ea) * ea) (9.5-2)

=Sqr((2*790.6+9.4)*9.4)= 122.28 mm

Maks. srednica otworu w plaszczu nie wymagajacego wzmocnienia sprawdzona wg zasad

w rozdz. 9

dmax1 = (ea*Is*(f-0.5*P)/P-ris*Is)/(0.5*ris+0.5*ea) (9.5-7,22,23)

=(9.4*122.28*(155.87-0.5*1.2)/1.2-790.6*122.28)/(0.5*790.6+0.5*9.4)

= 130.13 mm

Sprawdzenie maksymalnej srednicy otworu nie wymagajacego wzmocnienia

dmax2 = 0.15 * Sqr(( 2 * ris + ea) * ea) (9.5-18)

=0.15*Sqr((2*790.6+9.4)*9.4)= 18.34 mm

Maks. srednica otworu nie wymagajacego wzmocniena

dmax = MAX( dmax1, dmax2) =MAX(130.13,18.34)= 130.13 mm

STRESZCZENIE OBLICZEN

7.4.2 - PLASZCZE WALCOWE POD CISNIENIEM WEWNETRZNYM

Minimalna wymagana grubosc plaszcza bez naddatku na korozje: emin

emin = De * P / (2 * f * z + P) (7.4-2)

=1600*1.2/(2*155.87*0.85+1.2)= 7.21 mm

Minimalna wymagana grubosc plaszcza z naddatkiem na korozje: emin

emina = emin + c + th =7.21+0.3+0.3= 7.81 mm

»Cisnienie wewnetrzne emina=7.81 <= en=10[mm] « » (U= 78.1%) OK«

MAKSYMALNE CISNIENIE PRÓBY (Stan nieskorodowany w temp. otoczenia)

Ptmax = 2 * ftest * ztest * (ea + c) / Dm

=2*252.38*1*(9.4+0.3)/1590.6= 3.08 MPa

EN13445-5; 10.2.3.3 WYMAGANE MINIMALNE CISNIENIE PRÓBY HYDRAULICZNEJ: Ptmin

NOWY W TEMP. OTOCZENIA DLA GRUPY BADAN 1,2 i 3

Ptmin = MAX( 1.43 * Pd , 1.25 * Pd * f20 / f )

=MAX(1.43*1.2,1.25*1.2*170.83/155.87)= 1.72 MPa

»Cisnienie próby Ptmin=1.716 <= Ptmax=3.08[MPa] « » (U= 55.7%) OK«

MAKSYMALNA SREDNICA OTWORU NIEWZMOCNIONEGO W PLASZCZU

Maks. srednica otworu nie wymagajacego wzmocniena

dmax = MAX( dmax1, dmax2) =MAX(130.13,18.34)= 130.13 mm

Objetosc:7.85 m3 Ciezar:1568.5 kg (SG= 7.85 )

19 S1.1 Plaszcz walcowy plaszcz

Umax= 78.1%

Strona: 13

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-04 Operator :RR Rev.:A

EN13445:Issue26 - 7.4.2 PLASZCZ WALCOWY

S1.1 plaszcz 17 Nov. 2008 19:44

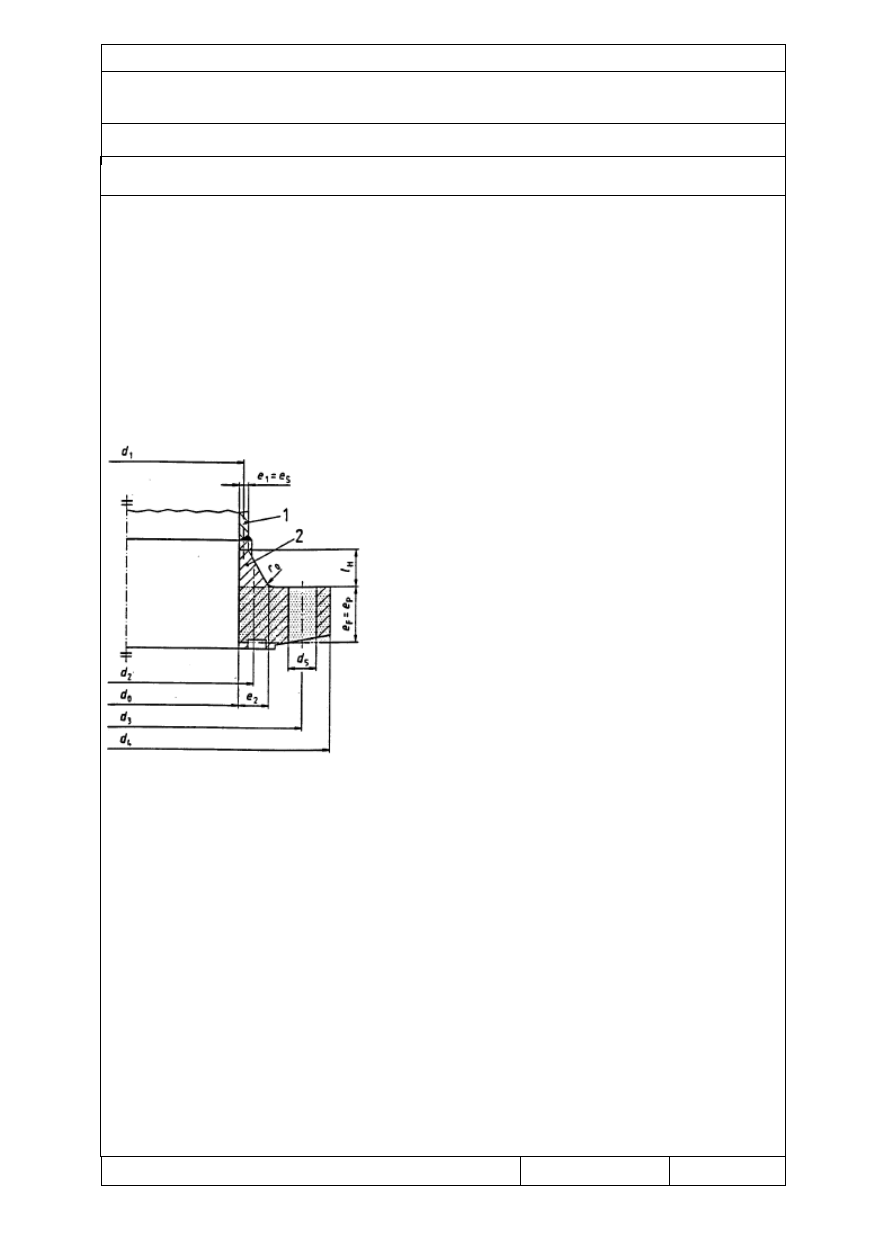

20 N.1 Króciec,Blacha korpu krociec met I

DANE WEJSCIOWE

ELEMENT PRZYLACZONY/POLOZENIE

Mocowanie: S1.1 Plaszcz walcowy plaszcz

Orientacja i polozenie krócca: Promieniowo do plaszcza

Polozenie "z" krócca wzdluz osi przylaczenia........:z 1000.00 mm

Kat obrotu osi krócca w plaszczyznie x-y............:Phi 0.00 Degr.

DANE PROJEKTOWE

Rodzaj otworu: Krócce bez znormalizowanych kolnierzy ANSI lub DIN

OBCIAZENIE CISNIENIEM: Obliczanie elementu tylko na cisnienie wewnetrzne

KARTA PROCESOWA: DANE PROJEKTOWE : Temp= 120°C, P= 1.2MPa, c= .3mm, Pext= 0MPa

GESTOSC WLASCIWA PLYNU ROBOCZEGO....................:SG 0.00

SLUP CIECZY.........................................:LH 605.00 mm

DANE PLASZCZA (S1.1)

Rodzaj plaszcza: Plaszcz walcowy

SREDNICA ZEWNETRZNA PLASZCZA........................:De 1600.00 mm

RZECZYWISTA GRUBOSC SCIANKI (w stanie nie skorodowanym) :en 10.00 mm

UJEMNA TOLERANCJA WYKONANIA.........................:th 0.3000 mm

EN 10028-2:2003, 1.0425 P265GH plate and strip, HT:N THK<=16mm 120'C

Rm=410 Rp=265 Rpt=233.8 fs=155.87 f20=170.83 ftest=252.38 E=204605(N/mm2) ro=7.85

DANE MATERIALU KRÓCCA

Delivery Form: Blacha korpusu

WSPÓLCZYNNIK ZLACZA SPAWANEGO: Grupa badan 3 (z=0.85)

EN 10028-2:2003, 1.0425 P265GH plate and strip, HT:N THK<=16mm 120'C

Rm=410 Rp=265 Rpt=233.8 fb=155.87 f20=170.83 ftest=252.38 E=204605(N/mm2) ro=7.85

DANE WYMIAROWE KRÓCCA

Mocowanie: Króciec wpuszczany

Srednica krócca: Obliczanie w oparciu o Dz krócca

Ksztalt krócca/otworu: Okragly

Application:

9.4.6.3 NOT a critical fatigue area, and calc.temp.is outside creep range.

SREDNICA ZEWNETRZNA KRÓCCA..........................:deb 508.00 mm

RZECZYWISTA GRUBOSC KRÓCCA (w stanie nie skorodowanym):enb 4.77 mm

Wielkosc krócca i kolnierza: ND500

Komentarz (opcjonalnie): .SCH 5S

TOLERANCJA UJEMNA/NADDATEK NA PRZECIENIENIE.........: 0.00 mm

WYSOKOSC KRÓCCA MIERZONA OD SREDNICY ZEWNETRZNEJ ZBIORNIKA:ho 150.00 mm

20 N.1 Króciec,Blacha korpu krociec met I

Umax= 95.7%

Strona: 14

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-01 Operator :RR Rev.:A

EN13445:Issue26 - 9.5 OTWORY POJEDYNCZE W PLASZCZACH

N.1 krociec met I 17 Nov. 2008 19:44 ConnID:S1.1

POLOZENIE KRÓCCÓW / ORIENTACJA

Króciec przechodzacy przez spoine: Króciec nie przechodzi przez spoine plaszcza

KAT PhiC (UKOSNA W PRZEKROJU POPRZECZNYM SEKCJI) Rys. 9.5-2:PhiC 0.00 Degr.

KAT PhiL ( UKOSNA W PRZEKROJU PODLUZNYM SEKCJI) Rys. 9.5-1 :PhiL 0.00 Degr.

DANE DOTYCZACE SPAWANIA

Nozzle/Pad to Shell Welding Area:

Wylaczyc powierzchnie spoiny laczacej króciec z plaszczem

DANE NAKLADKI WZMACNIAJACEJ

Rodzaj nakladki: Nakladka pojedyncza

GRUBOSC NAKLADKI WZMACNIAJACEJ......................:eap 10.00 mm

SZEROKOSC NAKLADKI WZMACNIAJACEJ ...................:Ip 125.00 mm

EN 10028-2:2003, 1.0425 P265GH plate and strip, HT:N THK<=16mm 120'C

Rm=410 Rp=265 Rpt=233.8 fp=155.87 f20=170.83 ftest=252.38 E=204605(N/mm2) ro=7.85

GRANICE WZMOCNIENIA

Zmniejszenie granicy wzmocnienia: Zmniejszenie granicy nie jest wymagane

WYNIKI OBLICZEN

OBLICZENIA PODSTAWOWE

Obliczeniowa grubosc plaszcza eas

eas = en - c - th =10-0.3-0.3= 9.40 mm

Obliczeniowa grubosc krócca eab

eab = enb - c - NegDev =4.77-0.3-0= 4.47 mm

Obliczeniowa grubosc nakladki wzmacniajacej ep

ep = MIN( eap, eas) (9.5-20) =MIN(10,9.4)= 9.40 mm

Zmniejszenie wytrzymalosci materialu krócca z uwagi na spoine wzdluzna krócca

fb = fb * z =155.87*0.85= 132.49 N/mm2

Wewnetrzny promien krzywizny

ris = De / 2 - eas (9.5-3) =1600/2-9.4= 790.60 mm

dib = deb - 2 * eab =508-2*4.47= 499.06 mm

Min. grubosc krócca wynikajaca z cisnienia wewnetrznego ebp

ebp = P * deb / (2 * fb * z + P)

=1.2*508/(2*155.87*0.85+1.2)= 2.29 mm

Naprezenia dopuszczalne

fob = Min( fs, fb) (9.5-8) =Min(155.87,132.49)= 132.49 N/mm2

fop = Min( fs, fp) (9.5-9) =Min(155.87,155.87)= 155.87 N/mm2

OGRANICZENIA GEOMETRYCZNE

»Sprawdz maksymalna grubosc nakladki eap=10 <= 1.5*eas=14.1[mm] «» OK«

»Sprawdenie maksymalnej srednicy krócca dib/(2*ris)=0.3156 <= .5[mm] «» OK«

»Minimalna grubosc krócca ebp=2.29 <= eab=4.47[mm] « » (U= 51.2%) OK«

9.5.2.4.4 Nozzles normal to the shell, with or without reiforcement pads.

Obliczenie efektywnej powierzchni obciazonej naprezeniem jako wzmocnienie

Area of Shell Afs

Granica wzmocnienia wzdluz plaszcza

Iso = Sqr(( 2 * ris + eas) * eas)

=Sqr((2*790.6+9.4)*9.4)= 122.28 mm

Króciec wpuszczany

Afs = eas * Is (9.5-78) =9.4*122.28= 1149.40 mm2

20 N.1 Króciec,Blacha korpu krociec met I

Umax= 95.7%

Strona: 15

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-01 Operator :RR Rev.:A

EN13445:Issue26 - 9.5 OTWORY POJEDYNCZE W PLASZCZACH

N.1 krociec met I 17 Nov. 2008 19:44 ConnID:S1.1

Area of Reinforcement Pad Afp

Granica wzmocnienia wzdluz nakladki

Ip = Min( Ip, Is ) (9.5-86) =Min(125,122.28)= 122.28 mm

ep = Min( ep, eas) (9.5-87) =Min(9.4,9.4)= 9.40 mm

Afp = ep * Ip (9.5-85) =9.4*122.28= 1149.40 mm2

Area of Nozzle Afb

Granice wzmocnienia wzdluz krócca (na zewnatrz plaszcza)

Ibo = MIN( Sqr(( deb - eb) * eb), ho) (9.5-75)

=MIN(Sqr((508-4.47)*4.47,)150)= 47.44 mm

Króciec wpuszczany

Afb = eb * (Ibo + Ibi + eas) (9.5-77) =4.47*(47.44+0+9.4)= 254.09 mm2

Obliczenie powierzchni obciazonej cisnieniem

In the Nozzle Apb

Apb = 0.5 * dib * (Ibo + eas) (9.5-83) =0.5*499.06*(47.44+9.4)= 14183.88 mm2

Element walcowy w przekroju podluznym Aps

ApsL = ris * (Is + a) (9.5-93) =790.6*(122.28+254)= 2,9748E05 mm2

Element walcowy w przekroju poprzecznym Aps

ApsT = 0.5 * ris ^ 2 * (Is + a ) / (0.5 * eas + ris) (9.5-104)

=0.5*790.6^2*(122.28+258.53)/(0.5*9.4+790.6)= 1,4964E05 mm2

Aps = MAX( ApsL ApsT) =MAX(2.9748E05,1.4964E05)= 2,9748E05 mm2

9.5.2 Zasady wzmocnienia

Wymagane pole powierzchni z uwagi na cisnienie pA(req).

pAReqL = P * (ApsL + Apb) (9.5-7) =1.2*(2.9748E05+14183.88)= 374.00 kN

pAReqT = P * (ApsT + Apb + 0.5 * Apphi) (9.5-7)

=1.2*(1.4964E05+14183.88+0.5*0)= 196.59 kN

pAReq = MAX( pAReqL, pAReqT) =MAX(374.,196.59)= 374.00 kN

Dopuszczalne pole powierzchni z uwagi na cisnienie pA(aval).

pAAval = (Afs+Afw)*(fs-0.5*P)+Afp*(fop-0.5*P)+Afb*(fob-0.5*P) (9.5-7)

=(1149.4+0)*(155.87-0.5*1.2)+1149.4*(155.87-0.5*1.2)+254.09*(132.49-0.5*1.2

)= = 390.45 kN

»Wzmocnienie krócca pAAval=390.45 >= pAReq=374.[kN] « » (U= 95.7%) OK«

Maksymalne dopuszczalne cisnienie Pmax

Pmax =(Afs+Afw)*fs+Afp*fop+Afb*fob/((Aps+Apb+0.5*Apphi)+0.5*(Afs+Afw+Afb+Afp))(10)

=+0)*155.87+1149.4*155.87+254.09*132.49/((2.9748E05+14183.88+0.5*0)+0.5*(11

49.4+0+254.09+1149.4))= = 1.25 MPa

Maksymalne dopuszczalne cisnienie próby Ptmax

Ptmax = == 2.10 MPa

STRESZCZENIE OBLICZEN

9.5.2.4.4 Nozzles normal to the shell, with or without reiforcement pads.

Granica wzmocnienia wzdluz plaszcza

Iso = Sqr(( 2 * ris + eas) * eas)

=Sqr((2*790.6+9.4)*9.4)= 122.28 mm

Granica wzmocnienia wzdluz nakladki

Ip = Min( Ip, Is ) (9.5-86) =Min(125,122.28)= 122.28 mm

Granice wzmocnienia wzdluz krócca (na zewnatrz plaszcza)

Ibo = MIN( Sqr(( deb - eb) * eb), ho) (9.5-75)

=MIN(Sqr((508-4.47)*4.47,)150)= 47.44 mm

20 N.1 Króciec,Blacha korpu krociec met I

Umax= 95.7%

Strona: 16

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-01 Operator :RR Rev.:A

EN13445:Issue26 - 9.5 OTWORY POJEDYNCZE W PLASZCZACH

N.1 krociec met I 17 Nov. 2008 19:44 ConnID:S1.1

Wymagane pole powierzchni z uwagi na cisnienie pA(req).

pAReqL = P * (ApsL + Apb) (9.5-7) =1.2*(2.9748E05+14183.88)= 374.00 kN

pAReqT = P * (ApsT + Apb + 0.5 * Apphi) (9.5-7)

=1.2*(1.4964E05+14183.88+0.5*0)= 196.59 kN

pAReq = MAX( pAReqL, pAReqT) =MAX(374.,196.59)= 374.00 kN

Dopuszczalne pole powierzchni z uwagi na cisnienie pA(aval).

pAAval = (Afs+Afw)*(fs-0.5*P)+Afp*(fop-0.5*P)+Afb*(fob-0.5*P) (9.5-7)

=(1149.4+0)*(155.87-0.5*1.2)+1149.4*(155.87-0.5*1.2)+254.09*(132.49-0.5*1.2

)= = 390.45 kN

»Wzmocnienie krócca pAAval=390.45 >= pAReq=374.[kN] « » (U= 95.7%) OK«

Maksymalne dopuszczalne cisnienie Pmax

Pmax =(Afs+Afw)*fs+Afp*fop+Afb*fob/((Aps+Apb+0.5*Apphi)+0.5*(Afs+Afw+Afb+Afp))(10)

=+0)*155.87+1149.4*155.87+254.09*132.49/((2.9748E05+14183.88+0.5*0)+0.5*(11

49.4+0+254.09+1149.4))= = 1.25 MPa

Objetosc:0.03 m3 Ciezar:12 kg (SG= 7.85 )

20 N.1 Króciec,Blacha korpu krociec met I

Umax= 95.7%

Strona: 17

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-01 Operator :RR Rev.:A

EN13445:Issue26 - 9.5 OTWORY POJEDYNCZE W PLASZCZACH

N.1 krociec met I 17 Nov. 2008 19:44 ConnID:S1.1

21 N.2 Króciec,Blacha korpu krociec met II

N.3* krociec met 1591(Copy of N.2)

DANE WEJSCIOWE

ELEMENT PRZYLACZONY/POLOZENIE

Mocowanie: S1.1 Plaszcz walcowy plaszcz

Orientacja i polozenie krócca: Promieniowo do plaszcza

Polozenie "z" krócca wzdluz osi przylaczenia........:z 2000.00 mm

Kat obrotu osi krócca w plaszczyznie x-y............:Phi 0.00 Degr.

DANE PROJEKTOWE

Rodzaj otworu: Krócce bez znormalizowanych kolnierzy ANSI lub DIN

OBCIAZENIE CISNIENIEM: Obliczanie elementu tylko na cisnienie wewnetrzne

KARTA PROCESOWA: DANE PROJEKTOWE : Temp= 120°C, P= 1.2MPa, c= .3mm, Pext= 0MPa

GESTOSC WLASCIWA PLYNU ROBOCZEGO....................:SG 0.00

SLUP CIECZY.........................................:LH 605.00 mm

DANE PLASZCZA (S1.1)

Rodzaj plaszcza: Plaszcz walcowy

SREDNICA ZEWNETRZNA PLASZCZA........................:De 1600.00 mm

RZECZYWISTA GRUBOSC SCIANKI (w stanie nie skorodowanym) :en 10.00 mm

UJEMNA TOLERANCJA WYKONANIA.........................:th 0.3000 mm

EN 10028-2:2003, 1.0425 P265GH plate and strip, HT:N THK<=16mm 120'C

Rm=410 Rp=265 Rpt=233.8 fs=155.87 f20=170.83 ftest=252.38 E=204605(N/mm2) ro=7.85

DANE MATERIALU KRÓCCA

Delivery Form: Blacha korpusu

WSPÓLCZYNNIK ZLACZA SPAWANEGO: Grupa badan 3 (z=0.85)

EN 10028-2:2003, 1.0425 P265GH plate and strip, HT:N THK<=16mm 120'C

Rm=410 Rp=265 Rpt=233.8 fb=155.87 f20=170.83 ftest=252.38 E=204605(N/mm2) ro=7.85

DANE WYMIAROWE KRÓCCA

Mocowanie: Króciec wpuszczany

Srednica krócca: Obliczanie w oparciu o Dz krócca

Ksztalt krócca/otworu: Okragly

Application:

9.4.6.3 NOT a critical fatigue area, and calc.temp.is outside creep range.

SREDNICA ZEWNETRZNA KRÓCCA..........................:deb 508.00 mm

RZECZYWISTA GRUBOSC KRÓCCA (w stanie nie skorodowanym):enb 4.77 mm

Wielkosc krócca i kolnierza: ND500

Komentarz (opcjonalnie): .SCH 5S

TOLERANCJA UJEMNA/NADDATEK NA PRZECIENIENIE.........: 0.00 mm

WYSOKOSC KRÓCCA MIERZONA OD SREDNICY ZEWNETRZNEJ ZBIORNIKA:ho 150.00 mm

21 N.2 Króciec,Blacha korpu krociec met II

Umax= 95.7%

Strona: 18

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-01 Operator :RR Rev.:A

EN13445:Issue26 - 9.5 OTWORY POJEDYNCZE W PLASZCZACH

N.2 krociec met II 17 Nov. 2008 19:44 ConnID:S1.1

POLOZENIE KRÓCCÓW / ORIENTACJA

Króciec przechodzacy przez spoine: Króciec nie przechodzi przez spoine plaszcza

KAT PhiC (UKOSNA W PRZEKROJU POPRZECZNYM SEKCJI) Rys. 9.5-2:PhiC 0.00 Degr.

KAT PhiL ( UKOSNA W PRZEKROJU PODLUZNYM SEKCJI) Rys. 9.5-1 :PhiL 0.00 Degr.

DANE DOTYCZACE SPAWANIA

Nozzle/Pad to Shell Welding Area:

Wylaczyc powierzchnie spoiny laczacej króciec z plaszczem

DANE NAKLADKI WZMACNIAJACEJ

Rodzaj nakladki: Nakladka pojedyncza

GRUBOSC NAKLADKI WZMACNIAJACEJ......................:eap 10.00 mm

SZEROKOSC NAKLADKI WZMACNIAJACEJ ...................:Ip 125.00 mm

EN 10028-2:2003, 1.0425 P265GH plate and strip, HT:N THK<=16mm 120'C

Rm=410 Rp=265 Rpt=233.8 fp=155.87 f20=170.83 ftest=252.38 E=204605(N/mm2) ro=7.85

GRANICE WZMOCNIENIA

Zmniejszenie granicy wzmocnienia: Zmniejszenie granicy nie jest wymagane

WYNIKI OBLICZEN

OBLICZENIA PODSTAWOWE

Obliczeniowa grubosc plaszcza eas

eas = en - c - th =10-0.3-0.3= 9.40 mm

Obliczeniowa grubosc krócca eab

eab = enb - c - NegDev =4.77-0.3-0= 4.47 mm

Obliczeniowa grubosc nakladki wzmacniajacej ep

ep = MIN( eap, eas) (9.5-20) =MIN(10,9.4)= 9.40 mm

Zmniejszenie wytrzymalosci materialu krócca z uwagi na spoine wzdluzna krócca

fb = fb * z =155.87*0.85= 132.49 N/mm2

Wewnetrzny promien krzywizny

ris = De / 2 - eas (9.5-3) =1600/2-9.4= 790.60 mm

dib = deb - 2 * eab =508-2*4.47= 499.06 mm

Min. grubosc krócca wynikajaca z cisnienia wewnetrznego ebp

ebp = P * deb / (2 * fb * z + P)

=1.2*508/(2*155.87*0.85+1.2)= 2.29 mm

Naprezenia dopuszczalne

fob = Min( fs, fb) (9.5-8) =Min(155.87,132.49)= 132.49 N/mm2

fop = Min( fs, fp) (9.5-9) =Min(155.87,155.87)= 155.87 N/mm2

OGRANICZENIA GEOMETRYCZNE

»Sprawdz maksymalna grubosc nakladki eap=10 <= 1.5*eas=14.1[mm] «» OK«

»Sprawdenie maksymalnej srednicy krócca dib/(2*ris)=0.3156 <= .5[mm] «» OK«

»Minimalna grubosc krócca ebp=2.29 <= eab=4.47[mm] « » (U= 51.2%) OK«

9.5.2.4.4 Nozzles normal to the shell, with or without reiforcement pads.

Obliczenie efektywnej powierzchni obciazonej naprezeniem jako wzmocnienie

Area of Shell Afs

Granica wzmocnienia wzdluz plaszcza

Iso = Sqr(( 2 * ris + eas) * eas)

=Sqr((2*790.6+9.4)*9.4)= 122.28 mm

Króciec wpuszczany

Afs = eas * Is (9.5-78) =9.4*122.28= 1149.40 mm2

21 N.2 Króciec,Blacha korpu krociec met II

Umax= 95.7%

Strona: 19

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-01 Operator :RR Rev.:A

EN13445:Issue26 - 9.5 OTWORY POJEDYNCZE W PLASZCZACH

N.2 krociec met II 17 Nov. 2008 19:44 ConnID:S1.1

Area of Reinforcement Pad Afp

Granica wzmocnienia wzdluz nakladki

Ip = Min( Ip, Is ) (9.5-86) =Min(125,122.28)= 122.28 mm

ep = Min( ep, eas) (9.5-87) =Min(9.4,9.4)= 9.40 mm

Afp = ep * Ip (9.5-85) =9.4*122.28= 1149.40 mm2

Area of Nozzle Afb

Granice wzmocnienia wzdluz krócca (na zewnatrz plaszcza)

Ibo = MIN( Sqr(( deb - eb) * eb), ho) (9.5-75)

=MIN(Sqr((508-4.47)*4.47,)150)= 47.44 mm

Króciec wpuszczany

Afb = eb * (Ibo + Ibi + eas) (9.5-77) =4.47*(47.44+0+9.4)= 254.09 mm2

Obliczenie powierzchni obciazonej cisnieniem

In the Nozzle Apb

Apb = 0.5 * dib * (Ibo + eas) (9.5-83) =0.5*499.06*(47.44+9.4)= 14183.88 mm2

Element walcowy w przekroju podluznym Aps

ApsL = ris * (Is + a) (9.5-93) =790.6*(122.28+254)= 2,9748E05 mm2

Element walcowy w przekroju poprzecznym Aps

ApsT = 0.5 * ris ^ 2 * (Is + a ) / (0.5 * eas + ris) (9.5-104)

=0.5*790.6^2*(122.28+258.53)/(0.5*9.4+790.6)= 1,4964E05 mm2

Aps = MAX( ApsL ApsT) =MAX(2.9748E05,1.4964E05)= 2,9748E05 mm2

9.5.2 Zasady wzmocnienia

Wymagane pole powierzchni z uwagi na cisnienie pA(req).

pAReqL = P * (ApsL + Apb) (9.5-7) =1.2*(2.9748E05+14183.88)= 374.00 kN

pAReqT = P * (ApsT + Apb + 0.5 * Apphi) (9.5-7)

=1.2*(1.4964E05+14183.88+0.5*0)= 196.59 kN

pAReq = MAX( pAReqL, pAReqT) =MAX(374.,196.59)= 374.00 kN

Dopuszczalne pole powierzchni z uwagi na cisnienie pA(aval).

pAAval = (Afs+Afw)*(fs-0.5*P)+Afp*(fop-0.5*P)+Afb*(fob-0.5*P) (9.5-7)

=(1149.4+0)*(155.87-0.5*1.2)+1149.4*(155.87-0.5*1.2)+254.09*(132.49-0.5*1.2

)= = 390.45 kN

»Wzmocnienie krócca pAAval=390.45 >= pAReq=374.[kN] « » (U= 95.7%) OK«

Maksymalne dopuszczalne cisnienie Pmax

Pmax =(Afs+Afw)*fs+Afp*fop+Afb*fob/((Aps+Apb+0.5*Apphi)+0.5*(Afs+Afw+Afb+Afp))(10)

=+0)*155.87+1149.4*155.87+254.09*132.49/((2.9748E05+14183.88+0.5*0)+0.5*(11

49.4+0+254.09+1149.4))= = 1.25 MPa

Maksymalne dopuszczalne cisnienie próby Ptmax

Ptmax = == 2.10 MPa

STRESZCZENIE OBLICZEN

9.5.2.4.4 Nozzles normal to the shell, with or without reiforcement pads.

Granica wzmocnienia wzdluz plaszcza

Iso = Sqr(( 2 * ris + eas) * eas)

=Sqr((2*790.6+9.4)*9.4)= 122.28 mm

Granica wzmocnienia wzdluz nakladki

Ip = Min( Ip, Is ) (9.5-86) =Min(125,122.28)= 122.28 mm

Granice wzmocnienia wzdluz krócca (na zewnatrz plaszcza)

Ibo = MIN( Sqr(( deb - eb) * eb), ho) (9.5-75)

=MIN(Sqr((508-4.47)*4.47,)150)= 47.44 mm

21 N.2 Króciec,Blacha korpu krociec met II

Umax= 95.7%

Strona: 20

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-01 Operator :RR Rev.:A

EN13445:Issue26 - 9.5 OTWORY POJEDYNCZE W PLASZCZACH

N.2 krociec met II 17 Nov. 2008 19:44 ConnID:S1.1

Wymagane pole powierzchni z uwagi na cisnienie pA(req).

pAReqL = P * (ApsL + Apb) (9.5-7) =1.2*(2.9748E05+14183.88)= 374.00 kN

pAReqT = P * (ApsT + Apb + 0.5 * Apphi) (9.5-7)

=1.2*(1.4964E05+14183.88+0.5*0)= 196.59 kN

pAReq = MAX( pAReqL, pAReqT) =MAX(374.,196.59)= 374.00 kN

Dopuszczalne pole powierzchni z uwagi na cisnienie pA(aval).

pAAval = (Afs+Afw)*(fs-0.5*P)+Afp*(fop-0.5*P)+Afb*(fob-0.5*P) (9.5-7)

=(1149.4+0)*(155.87-0.5*1.2)+1149.4*(155.87-0.5*1.2)+254.09*(132.49-0.5*1.2

)= = 390.45 kN

»Wzmocnienie krócca pAAval=390.45 >= pAReq=374.[kN] « » (U= 95.7%) OK«

Maksymalne dopuszczalne cisnienie Pmax

Pmax =(Afs+Afw)*fs+Afp*fop+Afb*fob/((Aps+Apb+0.5*Apphi)+0.5*(Afs+Afw+Afb+Afp))(10)

=+0)*155.87+1149.4*155.87+254.09*132.49/((2.9748E05+14183.88+0.5*0)+0.5*(11

49.4+0+254.09+1149.4))= = 1.25 MPa

Objetosc:0.03 m3 Ciezar:12 kg (SG= 7.85 )

21 N.2 Króciec,Blacha korpu krociec met II

Umax= 95.7%

Strona: 21

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-01 Operator :RR Rev.:A

EN13445:Issue26 - 9.5 OTWORY POJEDYNCZE W PLASZCZACH

N.2 krociec met II 17 Nov. 2008 19:44 ConnID:S1.1

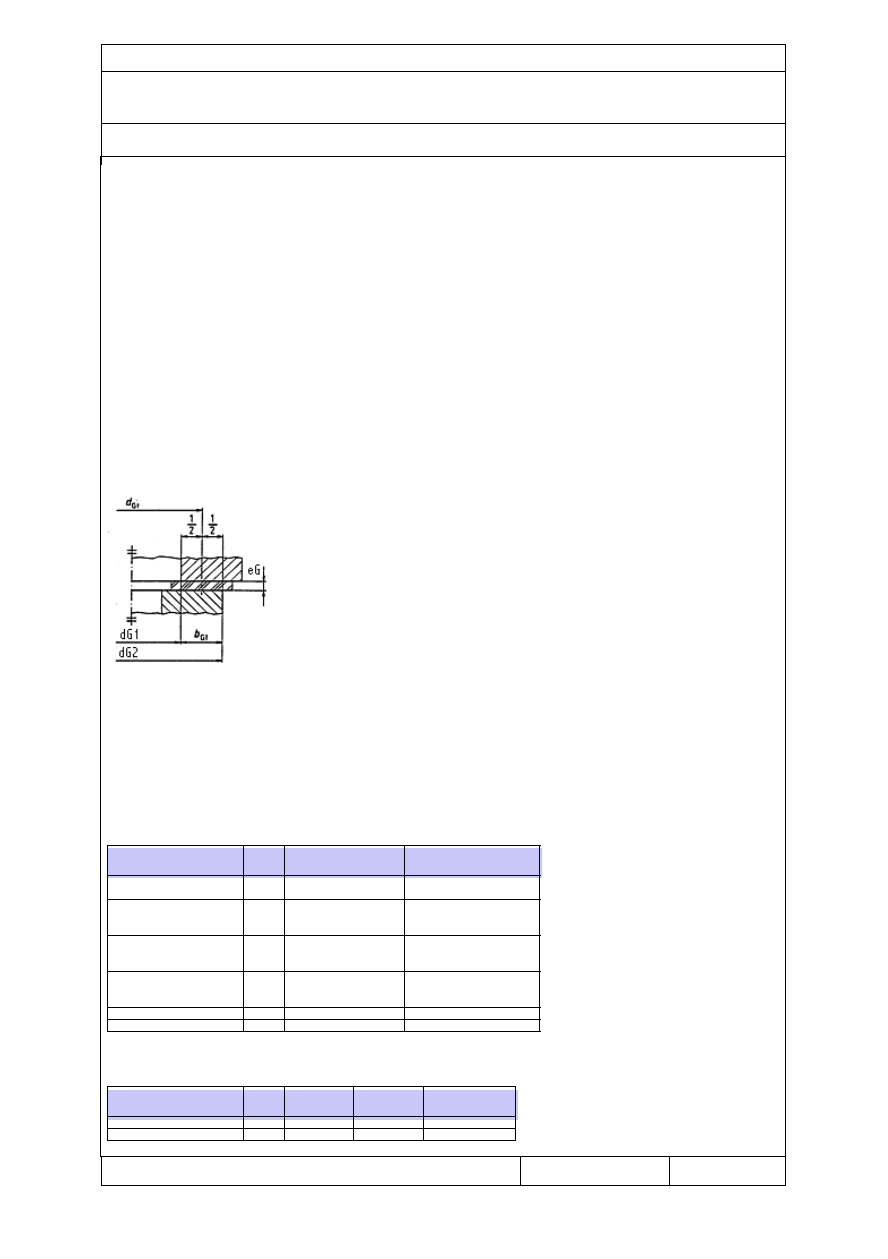

22 F.1 WN - Kolnierz Kolnierz metoda I

DANE WEJSCIOWE

ELEMENT PRZYLACZONY/POLOZENIE

Mocowanie: N.1 Króciec,Blacha korpu krociec met I S1.1

Polozenie: Wzdluz osi "z" z1= 155

Flange Design Method: Section 11 - Taylor Forge

DANE PROJEKTOWE

KARTA PROCESOWA: DANE PROJEKTOWE : Temp= 120°C, P= 1.2MPa, c= .3mm

GESTOSC WLASCIWA PLYNU ROBOCZEGO....................:SG 0.00

SLUP CIECZY.........................................:LH 605.00 mm

B: Obciazenie cisnieniem: Kolnierz podlegajacy cisnieniu wewnetrznemu

NACIAG SRUB Z DRUGIEGO KOLNIERZA(Warunki ruchowe)...:Wm1' 0.00 kN

NACIAG SRUB Z DRUGIEGO KOLNIERZA(Warunki montazowe).:Wm2' 0.00 kN

OBCIAZENIA ZEWNETRZNE KOLNIERZA: Nie

PODAJ RODZAJ PRZYLGI KOLNIERZA I USZCZELKI

A: Kolnierz znormalizowany: Kolnierze wg DIN

C: Rodzaj kolnierza: WN Szyjkowy do przyspawania

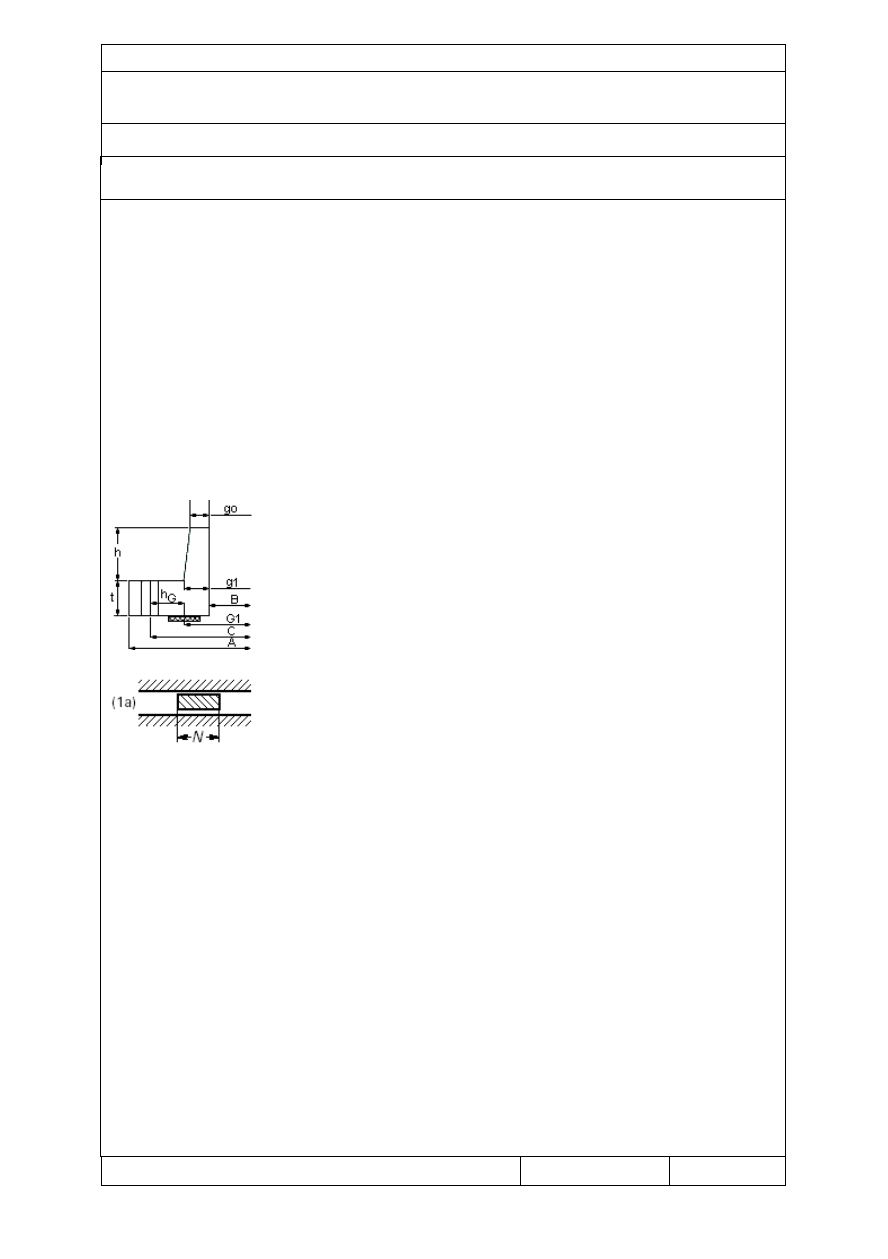

D: Przylga kolnierza (Szkic/Opis): 1a Powierzchnia uszczelniajaca plaska

DANE PlASZCZA/KRÓCCA

PLASZCZ/WYMIARY KRÓCCA I KOMENTARZ: N.1

EN 10028-2:2003, 1.0425 P265GH plate and strip, HT:N THK<=16mm 120'C

Rm=410 Rp=265 Rpt=233.8 fs=155.87 fs20=170.83 ftest=252.38 E=204605(N/mm2) ro=7.85

SREDNICA ZEWNETRZNA CZESCI WALCOWEJ SZYJKI/KRÓCCA ..:Do 508.00 mm

GRUBOSC SCIANKI KRÓCCA/PLASZCZA (w stanie nie skorodowanym):s1 4.77 mm

Kolnierze wg DIN

E: Klasa cisnienia: DIN 2633: Klasa PN 16

DANE KOLNIERZA

KOLNIERZ WEWNETRZNY: Nie (Sruby umieszczone na zewnatrz)

METODA OBLICZANIA: A) METODA OBLICZANIA KOLNIERZA INTEGRALNEGO

SREDNICA ZEWNETRZNA KOLNIERZA.......................:A 715.00 mm

GRUBOSC KRYZY KOLNIERZA (nie skorodowany)...........:e 34.00 mm

NADDATEK NA KOROZJE DLA PRZYLGI KOLNIERZA...........:cf 0.00 mm

EN 10028-6:2003, 1.8867 P355QH plate and strip, HT:QT THK<=50mm 120'C

Rm=490 Rp=355 Rpt=300 SFO=200 SFA=204.17 ftest=338.1 E=204605(N/mm2) ro=7.85

22 F.1 WN - Kolnierz Kolnierz metoda I

Umax= 93.4%

Strona: 22

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-02 Operator :RR Rev.:A

EN13445:Issue26 - 11.5 KOLNIERZE Z USZCZELKAMI WASKIMI

F.1 Kolnierz metoda I 17 Nov. 2008 20:09 ConnID:N.1

DANE SZYJKI KOLNIERZA

DLUGOSC SZYJKI .....................................:h 40.00 mm

GRUBOSC SZYJKI PRZY KRYZIE w stanie skorodowanym....:g1 27.70 mm

GRUBOSC CZESCI WALCOWEJ SZYJKI W CIENSZYM KONCU w stanie skorodowanym:go 7.70

mm

EN 10028-6:2003, 1.8867 P355QH plate and strip, HT:QT THK<=50mm 120'C

Rm=490 Rp=355 Rpt=300 SHO=200 SHA=204.17 ftest=338.1 E=204605(N/mm2) ro=7.85

DANE SRUB

OBLICZENIE MOMENTU NACIAGU SRUB: Tak

NOMINALNY WYMIAR SRUB I KOMENTARZ: M30x3 ;

EFEKTYWNE POLE PRZEKROJU SRUBY......................:Ae 544.00 mm2

ZALECANY MINIMALNY ODSTEP SRODKOW SRUB OD KRAWEDZI..:Bce 30.00 mm

ZALECANY MINIMALNY PROMIENIOWY ODSTEP SRODKOW SRUB..:Bcr 44.00 mm

SREDNICA OTWORÓW POD SRUBY..........................:d 33.00 mm

LICZBA SRUB ........................................:n 20.00

SREDNICA PODZIALOWA OTWORÓW POD SRUBY ..............:C 650.00 mm

EN 10269:1999, 1.1181 C35E bar, bolt, HT:QT THK<=60mm 120'C

Rm=500 Rp=300 Rpt=262.4 Sb=87.47 Sa=100 ftest=150 E=191484(N/mm2) ro=7.93

METODA NACIAGU SRUB:

Skrecanie, (pomiar momentu i obrotu nakretki, blisko wytrzymalosci srub) eps

=-0.07 do +0.07

WSPÓLCZYNNIK TARCIA: Normalne/przecietne warunki µ=0.20

DANE USZCZELKI

Tablica H-1 Wspólczynniki m & y Przylga:

Wspólczynniki uszczelki podane przez projektanta

WSPÓLCZYNNIK USZCZELKI..............................:m 5.00

NAPREZENIE SCISKAJACE POWIERZCHNI USZCZELNIAJACEJ LUB USZCZELKI :y 15.00 N/mm2

TYP USZCZELKI (uwaga) (Opcjonalnie): PTFE KLINERtop-chem-2000

SREDNICA ZEWNETRZNA USZCZELKI.......................:Go 582.00 mm

WIEKSZA WARTOSC SREDNICY WEWNETRZNEJ USZCZELKI LUB PLASZCZYZNY PRZYLGNI

KOLNIERZA:A1 530.00 mm

TEMA RGP-RCB-11.7 Include Additional Loads from Pass Partition Plate Gasket: Nie

WYNIKI OBLICZEN

Wspólczynnik korekcyjny naprezen dla duzych srednic K

k (D < 1000 mm) = 1 =1= 1.00

SZCZEGÓLY USZCZELKI

b = MIN VALUE(2.52 * Sqr(bo), bo ) = == 9.09 mm

OBCIAZENIE KOLNIERZA

H = 0.785 * G ^ 2 * p (11.5-5) =0.785*563.83^2*1.2= 299.46 kN

HG = (2 * PI * b * G * m) * p (11.5-6)

=(2*3.14*9.09*563.83*5)*1.2= 193.22 kN

HD = 0.785 * B ^ 2 * p =0.785*499.06^2*1.2= 234.62 kN

HT = H - HD (11.5-11) =299.46-234.62= 64.85 kN

RAMIONA MOMENTÓW

hG = (C - G) / 2 (11.5-14) =(650-563.83)/2= 43.09 mm

hD = (C - B - g1) / 2 (11.5-12) =(650-499.06-27.7)/2= 61.62 mm

hT = (2 * C - B - G) / 4 (11.5-15) =(2*650-499.06-563.83)/4= 59.28 mm

OBCIAZENIE SRUB

Warunki ruchowe

Wop = H + HG (11.5-8) =299.46+193.22= 492.68 kN

Warunki montazowe

Wamb = PI * b * G * y (11.5-7) =3.14*9.09*563.83*15= 241.52 kN

22 F.1 WN - Kolnierz Kolnierz metoda I

Umax= 93.4%

Strona: 23

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-02 Operator :RR Rev.:A

EN13445:Issue26 - 11.5 KOLNIERZE Z USZCZELKAMI WASKIMI

F.1 Kolnierz metoda I 17 Nov. 2008 20:09 ConnID:N.1

PRZEKRÓJ SRUB

Am1 = Wop / Sb =4.9268E05/87.47= 5632.55 mm2

Am2 = Wamb / Sa =2.4152E05/100= 2415.19 mm2

Wymagany przekrój srub Am

Am (Largest value of Am1 and Am2)= Am =5632.55= 5632.55 mm2

Rzeczywisty przekrój srub Ab

Ab (num.bolts*root area) = n * Ae =20*544= 10880.00 mm2

»Sprawdzenie przekroju srub Ab=10880 >= Am=5632.55[mm2] « » (U= 51.7%) OK«

W = 0.5 * (Ab + Am) * Sa (11.5-16) =0.5*(10880+5632.55)*100= 825.63 kN

MOMENTY W KOLNIERZU

Mop = HD * hD + HT * hT + HG * hG (11.5-18)

=234.62*61.62+64.85*59.278+193.22*43.086= 26625.96 Nm

Mamb = W * hG (11.5-17) =825.63*43.086= 35572.98 Nm

ROZSTAW SRUB

Bspc = C * PI / n =650*3.14/20= 102.10 mm

Wspólczynnik korekcyjny podzialu srub

CF = MAX( Sqr( Bspc / (2 * db + 6 * e / (m + 0.5))) , 1) (11.5-20)

=MAX(Sqr(102.1/(2*30+6*34/(5+0.5))),1)= 1.03

Mo = Mop * CF / B (11.5-27) =26625.96*1.03/499.06= 54.95 Nm

Ma = Mamb * CF / B (11.5-26) =35572.98*1.03/499.06= 73.42 Nm

STALE KSZTALTU

K = A / B (11.5-21) =715/499.06= 1.43

lo = SQR( B * go) (11.5-22) =SQR(499.06*7.7)= 61.99

h/lo= 0.645 K=A/B= 1.433 g1/go= 3.597

WARTOSCI Z RYSUNKÓW 11.5 do 8

BetaT = 1.740 BetaZ = 2.900 BetaY = 5.568 BetaU = 6.119

BetaF= 0.769 BetaV = 0.106 phi = 2.963

lamda = (e*BetaF+lo)/(BetaT*lo)+e^3*BetaV/(BetaU*lo*go^2)

=(34*0.769+61.99)/(1.74*61.99)+34^3*0.1062/(6.119*61.99*7.7^2)= 1.00

Warunki ruchowe

M = Mo =54.95= 54.95 Nm

11.5.4.1 naprezenia w kolnierzu przy grubosci e= 34 mm

Naprezenia wzdluzne w kolnierzu

SigH = phi * M / (lamda * g1 ^ 2) (11.5-29)

=2.96*54.95/(1.*27.7^2)= 211.63 N/mm2

Naprezenia promieniowe w kolnierzu

Sigr = (1.333 * e * BetaF + lo) * M / (lamda * e ^ 2 * lo) (11.5-30)

=(1.333*34*0.769+61.99)*54.95/(1.*34^2*61.99)= 74.06 N/mm2

Naprezenia styczne w kolnierzu

SigTeta = BetaY*M/e^2-Sigr*(K^2+1)/(K^2-1) (11.5-31)

=5.568*54.95/34^2-74.06*(1.43^2+1)/(1.43^2-1)= 49.90 N/mm2

11.5.4.2 Naprezenia dopuszczalne

»Naprezenia w szyjce k*SigH=211.63 <= 1.5 * MIN(f;fH)=300[N/mm2] (11.5-39)«» (U= 70.5%) OK«

»Naprezenia promieniowe k*SigR=74.06 <= f=200[N/mm2] (11.5-40)«» (U= 37%) OK«

»Naprezenia styczne k*SigTeta=49.9 <= f=200[N/mm2] (11.5-41)«» (U= 24.9%) OK«

»Naprezenia promieniowe+w szyjce 0.5*k*(SigH+SigR)=142.85 <= f=200[N/mm2] (11.5-42)«» (U=

71.4%) OK«

»Naprezenia styczne+w szyjce 0.5*k*(SigH+SigTeta)=130.76 <= f=200[N/mm2] (11.5-43)«» (U=

65.3%) OK«

22 F.1 WN - Kolnierz Kolnierz metoda I

Umax= 93.4%

Strona: 24

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-02 Operator :RR Rev.:A

EN13445:Issue26 - 11.5 KOLNIERZE Z USZCZELKAMI WASKIMI

F.1 Kolnierz metoda I 17 Nov. 2008 20:09 ConnID:N.1

Warunki montazowe

M = Ma =73.42= 73.42 Nm

11.5.4.1 naprezenia w kolnierzu przy grubosci e= 34 mm

Naprezenia wzdluzne w kolnierzu

SigH = phi * M / (lamda * g1 ^ 2) (11.5-29)

=2.96*73.42/(1.*27.7^2)= 282.74 N/mm2

Naprezenia promieniowe w kolnierzu

Sigr = (1.333 * e * BetaF + lo) * M / (lamda * e ^ 2 * lo) (11.5-30)

=(1.333*34*0.769+61.99)*73.42/(1.*34^2*61.99)= 98.95 N/mm2

Naprezenia styczne w kolnierzu

SigTeta = BetaY*M/e^2-Sigr*(K^2+1)/(K^2-1) (11.5-31)

=5.568*73.42/34^2-98.95*(1.43^2+1)/(1.43^2-1)= 66.66 N/mm2

11.5.4.2 Naprezenia dopuszczalne

»Naprezenia w szyjce k*SigH=282.74 <= 1.5 * MIN(f;fH)=306.25[N/mm2] (11.5-39)«» (U= 92.3%) OK«

»Naprezenia promieniowe k*SigR=98.95 <= f=204.17[N/mm2] (11.5-40)«» (U= 48.4%) OK«

»Naprezenia styczne k*SigTeta=66.66 <= f=204.17[N/mm2] (11.5-41)«» (U= 32.6%) OK«

»Naprezenia promieniowe+w szyjce 0.5*k*(SigH+SigR)=190.85 <= f=204.17[N/mm2] (11.5-42)«» (U=

93.4%) OK«

»Naprezenia styczne+w szyjce 0.5*k*(SigH+SigTeta)=174.7 <= f=204.17[N/mm2] (11.5-43)«» (U=

85.5%) OK«

MOMENT NACIAGU SRUB - EN13445 ZALACZNIK G.8

kB = 1.2 * µ * dB0 (G.8-5) =1.2*0.2*30= 7.20 mm

epsn = eps * (1 + 3 / SQR( n)) / 4 (G.6-16)

=0.07*(1+3/SQR(20))/4= 0.0292

Wymagany minimalny naciag wstepny (Maksymalny z warunków obliczeniowego i

montazowego)

Fb0nom (Max. of Wop and Wamb) = Fb0req =492.68= 492.68 kN

Calkowity nominalny naciag wstepny

Fb0nom = Fb0req / (1 - epsn) (G.6-21) =492.68/(1-0.0292)= 507.52 kN

Calkowity nominalny naciag wstepny dla sruby

Fbnom = Fb0nom / n =507.52/20= 25.38 kN

Bolt Stress(Assembly Cond.)

SigBoltamb = Wamb / ((1 - epsn) * n * Ae)

=2.4152E05/((1-0.0292)*20*544)= 22.87 N/mm2

Bolt Stress(Operating Cond.)

SigBoltamb = Wop / ((1 - epsn) * n * Ae)

=4.9268E05/((1-0.0292)*20*544)= 46.65 N/mm2

»Naprezenie srub SigBolt=46.65 <= SB=87.47[N/mm2] « » (U= 53.3%) OK«

Nominalny moment naciagu sruby

Mtnom = kB * Fb0nom / n =7.2*507.52/20= 182.71 Nm

EN13445-5; 10.2.3.3 WYMAGANE MINIMALNE CISNIENIE PRÓBY HYDRAULICZNEJ: Ptmin

NOWY W TEMP. OTOCZENIA DLA GRUPY BADAN 1,2 i 3

Ptmin = MAX( 1.43 * Pd , 1.25 * Pd * f20 / f )

=MAX(1.43*1.2,1.25*1.2*204.17/200)= 1.72 MPa

»Cisnienie próby Ptmin=1.716 <= Ptmax=2.842[MPa] « » (U= 60.3%) OK«

PRESSURE AND TORQUE SUMMARY

Table PRESSURE AND TORQUE SUMMARY FOR F.1 :

Description

Temp(C)

P(MPa)

Limited By

Min.Req.Total Bolt Force(kN)

Design Pressure(corroded)

120

1.20

Radial+Hub Stress

492.68

Max.Allow.Pressure(corroded)

120

1.45

Radial+Hub Stress

595.16

22 F.1 WN - Kolnierz Kolnierz metoda I

Umax= 93.4%

Strona: 25

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-02 Operator :RR Rev.:A

EN13445:Issue26 - 11.5 KOLNIERZE Z USZCZELKAMI WASKIMI

F.1 Kolnierz metoda I 17 Nov. 2008 20:09 ConnID:N.1

Description

Temp(C)

P(MPa)

Limited By

Min.Req.Total Bolt Force(kN)

Max.Allow.Pressure(corroded)

Ambient

1.66

Radial+Hub Stress

681.87

Max.Allow.Test Pressure(corroded)

Ambient

2.84

Radial+Hub Stress

1166.66

Required Test Pressure

Ambient

1.72

Radial+Hub Stress

704.53

Table PRESSURE AND TORQUE SUMMARY FOR F.1 Continued

Description

Nom.Force per Bolt(kN)

Nom.Torqueper Bolt(Nm)

Design Pressure(corroded)

25.38

182.71

Max.Allow.Pressure(corroded)

30.65

220.71

Max.Allow.Pressure(corroded)

35.12

252.87

Max.Allow.Test Pressure(corroded)

60.09

432.65

Required Test Pressure

36.29

261.27

The nominal Force and Torque values are based on the following bolting up method:

Skrecanie, na wyczucie montera eps=0.3+0.5* µ

STRESZCZENIE OBLICZEN

PRZEKRÓJ SRUB

»Sprawdzenie przekroju srub Ab=10880 >= Am=5632.55[mm2] « » (U= 51.7%) OK«

Warunki ruchowe

11.5.4.1 naprezenia w kolnierzu przy grubosci e= 34 mm

Naprezenia wzdluzne w kolnierzu

SigH = phi * M / (lamda * g1 ^ 2) (11.5-29)

=2.96*54.95/(1.*27.7^2)= 211.63 N/mm2

Naprezenia promieniowe w kolnierzu

Sigr = (1.333 * e * BetaF + lo) * M / (lamda * e ^ 2 * lo) (11.5-30)

=(1.333*34*0.769+61.99)*54.95/(1.*34^2*61.99)= 74.06 N/mm2

Naprezenia styczne w kolnierzu

SigTeta = BetaY*M/e^2-Sigr*(K^2+1)/(K^2-1) (11.5-31)

=5.568*54.95/34^2-74.06*(1.43^2+1)/(1.43^2-1)= 49.90 N/mm2

11.5.4.2 Naprezenia dopuszczalne

»Naprezenia w szyjce k*SigH=211.63 <= 1.5 * MIN(f;fH)=300[N/mm2] (11.5-39)«» (U= 70.5%) OK«

»Naprezenia promieniowe k*SigR=74.06 <= f=200[N/mm2] (11.5-40)«» (U= 37%) OK«

»Naprezenia styczne k*SigTeta=49.9 <= f=200[N/mm2] (11.5-41)«» (U= 24.9%) OK«

»Naprezenia promieniowe+w szyjce 0.5*k*(SigH+SigR)=142.85 <= f=200[N/mm2] (11.5-42)«» (U=

71.4%) OK«

»Naprezenia styczne+w szyjce 0.5*k*(SigH+SigTeta)=130.76 <= f=200[N/mm2] (11.5-43)«» (U=

65.3%) OK«

Warunki montazowe

11.5.4.1 naprezenia w kolnierzu przy grubosci e= 34 mm

Naprezenia wzdluzne w kolnierzu

SigH = phi * M / (lamda * g1 ^ 2) (11.5-29)

=2.96*73.42/(1.*27.7^2)= 282.74 N/mm2

Naprezenia promieniowe w kolnierzu

Sigr = (1.333 * e * BetaF + lo) * M / (lamda * e ^ 2 * lo) (11.5-30)

=(1.333*34*0.769+61.99)*73.42/(1.*34^2*61.99)= 98.95 N/mm2

Naprezenia styczne w kolnierzu

SigTeta = BetaY*M/e^2-Sigr*(K^2+1)/(K^2-1) (11.5-31)

=5.568*73.42/34^2-98.95*(1.43^2+1)/(1.43^2-1)= 66.66 N/mm2

22 F.1 WN - Kolnierz Kolnierz metoda I

Umax= 93.4%

Strona: 26

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-02 Operator :RR Rev.:A

EN13445:Issue26 - 11.5 KOLNIERZE Z USZCZELKAMI WASKIMI

F.1 Kolnierz metoda I 17 Nov. 2008 20:09 ConnID:N.1

11.5.4.2 Naprezenia dopuszczalne

»Naprezenia w szyjce k*SigH=282.74 <= 1.5 * MIN(f;fH)=306.25[N/mm2] (11.5-39)«» (U= 92.3%) OK«

»Naprezenia promieniowe k*SigR=98.95 <= f=204.17[N/mm2] (11.5-40)«» (U= 48.4%) OK«

»Naprezenia styczne k*SigTeta=66.66 <= f=204.17[N/mm2] (11.5-41)«» (U= 32.6%) OK«

»Naprezenia promieniowe+w szyjce 0.5*k*(SigH+SigR)=190.85 <= f=204.17[N/mm2] (11.5-42)«» (U=

93.4%) OK«

»Naprezenia styczne+w szyjce 0.5*k*(SigH+SigTeta)=174.7 <= f=204.17[N/mm2] (11.5-43)«» (U=

85.5%) OK«

»Naprezenie srub SigBolt=46.65 <= SB=87.47[N/mm2] « » (U= 53.3%) OK«

EN13445-5; 10.2.3.3 WYMAGANE MINIMALNE CISNIENIE PRÓBY HYDRAULICZNEJ: Ptmin

NOWY W TEMP. OTOCZENIA DLA GRUPY BADAN 1,2 i 3

Ptmin = MAX( 1.43 * Pd , 1.25 * Pd * f20 / f )

=MAX(1.43*1.2,1.25*1.2*204.17/200)= 1.72 MPa

»Cisnienie próby Ptmin=1.716 <= Ptmax=2.842[MPa] « » (U= 60.3%) OK«

Objetosc:0.01 m3 Ciezar:59 kg (SG= 7.85 )

22 F.1 WN - Kolnierz Kolnierz metoda I

Umax= 93.4%

Strona: 27

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-02 Operator :RR Rev.:A

EN13445:Issue26 - 11.5 KOLNIERZE Z USZCZELKAMI WASKIMI

F.1 Kolnierz metoda I 17 Nov. 2008 20:09 ConnID:N.1

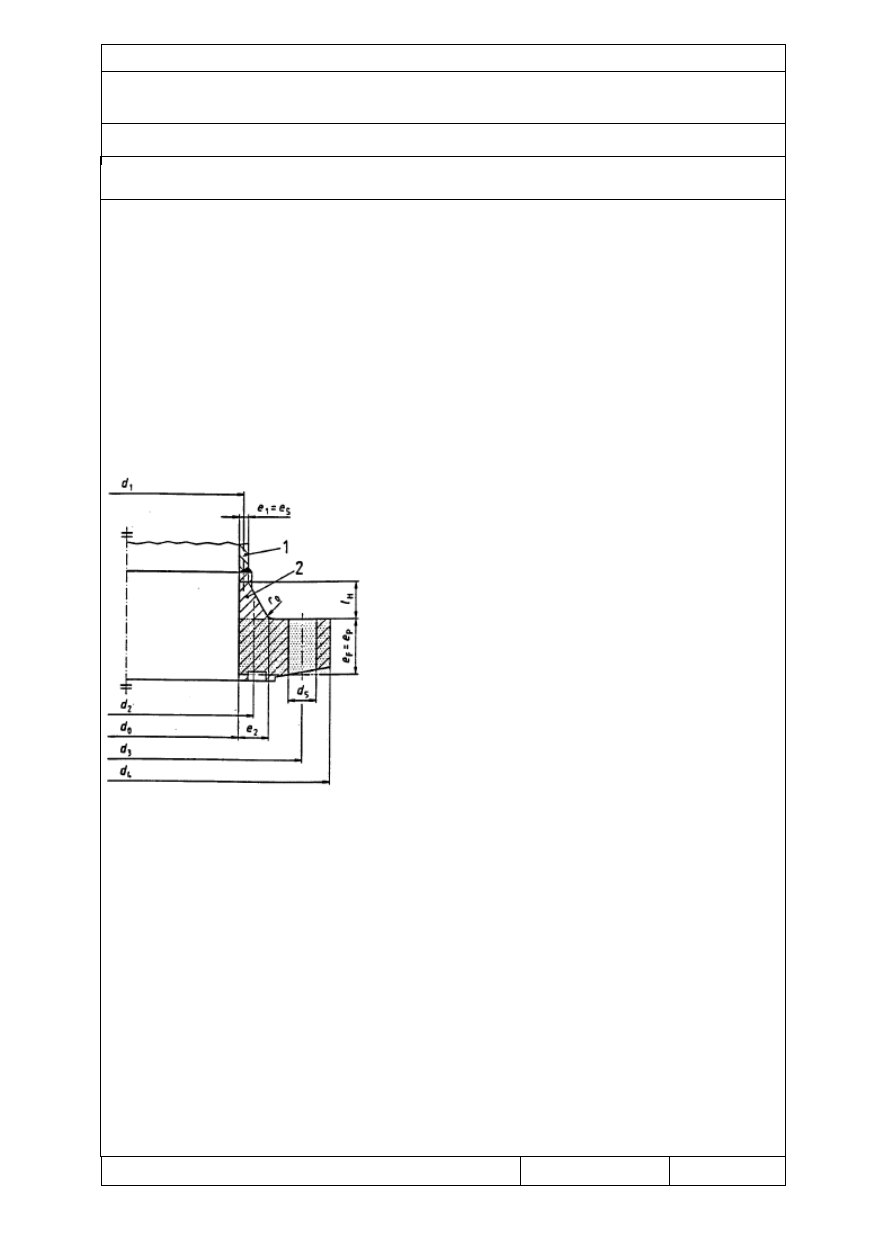

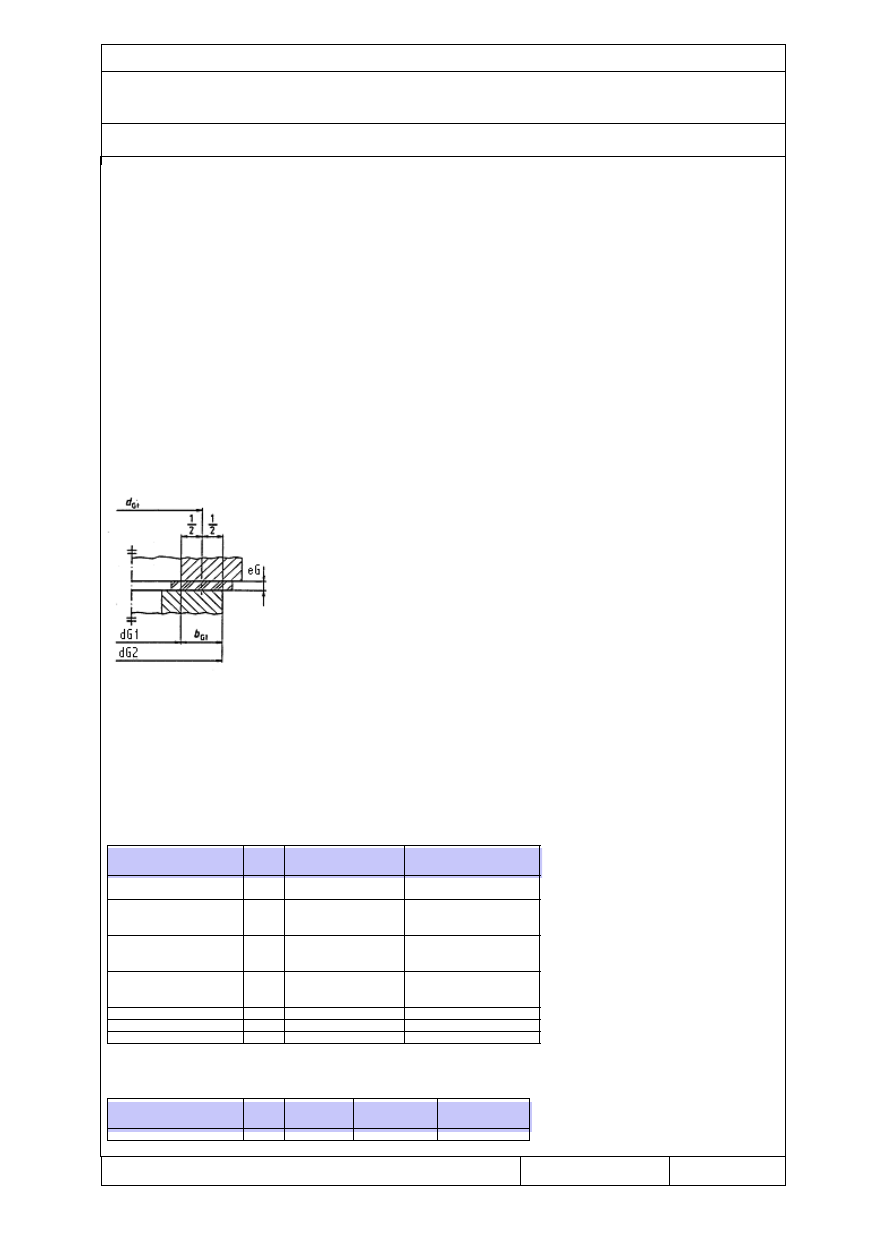

23 F.2 Integral - Flange kolnierz metoda II

DANE WEJSCIOWE

ELEMENT PRZYLACZONY/POLOZENIE

Mocowanie: N.2 Króciec,Blacha korpu krociec met II S1.1

Polozenie: Wzdluz osi "z" z1= 155

Flange Design Method:

Annex G - Alternative design rules for flanges and gasketed flange connections.

DANE PROJEKTOWE

KARTA PROCESOWA: DANE PROJEKTOWE : Temp= 120°C, P= 1.2MPa, c= .3mm

Mating Flange: Similar

INCLUDE MATING FLANGE AS PART OF DESIGN MODEL: Tak

FLANGE TYPE Side 1

Flange Type: Integral - Flange

Connecting Shell: Cylindrical or Conical Shell

Selected Sketch of Flange: Tapered hub with no thickening in the bore

FLANGE GEOMETRY Side 1

Equivalent axial thickness of flange................:eF 34.00 mm

Axial thickness radially loaded by pressure.........:eP 34.00 mm

Inside diameter of flange(corroded).................:d0 499.06 mm

Average diameter of hub, thin end...................:d1 506.76 mm

Average diameter of hub, thick end..................:d2 526.76 mm

Outside diameter of flange..........................:d4 715.00 mm

Diameter of bolt holes..............................:d5 33.00 mm

Min. wall thickness thin end of hub(corroded).......:e1 27.70 mm

Wall thickness at thick end of hub(corroded)........:e2 7.70 mm

Length of hub.......................................:lH 40.00 mm

Inclination of shell................................:PhiS 0.00 degr.

EN 10028-6:2003, 1.8867 P355QH plate and strip, HT:QT THK<=50mm 120'C

Rm=490 Rp=355 Rpt=300 fF=200 fF20=204.17 ftest=338.1 E=204605(N/mm2) ro=7.85

SHELL DATA Side 1

EN 10028-2:2003, 1.0425 P265GH plate and strip, HT:N THK<=16mm 120'C

Rm=410 Rp=265 Rpt=233.8 f=155.87 f20=170.83 ftest=252.38 E=204605(N/mm2) ro=7.85

Shell thickness(corroded)...........................:eS 0.00 mm

Average diameter of shell...........................:dS 0.00 mm

23 F.2 Integral - Flange kolnierz metoda II

Umax= 65.9%

Strona: 28

Urzad Dozoru Technicznego

Company Address

Klient :UDT T: kolnierze wg metody I i II-G i 1591

met I sec. 11-Taylor Forge lub met II Annex G - alternatywna

Visual Vessel Design by OhmTech Ver:9.9-02 Operator :RR Rev.:A

EN13445:Issue26 - ANNEX G - ALTERNATIVE DESIGN RULES FOR FLANGES

F.2 kolnierz metoda II 17 Nov. 2008 20:00 ConnID:N.2

DANE SRUB

Waisted Bolt: Nie

Specify Minimum Bolt Load for Assembly Condition, FBmin: Nie

NOMINALNY WYMIAR SRUB I KOMENTARZ: M30x3 ;

Bolt circle diameter................................:d3 650.00 mm

Number of bolts.....................................:nB 20.00

Nominal diameter....................................:dB0 30.00 mm

Effective diameter..................................:dBe 26.72 mm

Number of reassemblies during service...............:NR 10.00

Length of clamp.....................................:lB 0.00 mm

Carbon Steel Bolt Material: Tak

EN 10269:1999, 1.1181 C35E bar, bolt, HT:QT THK<=60mm 120'C

Rm=500 Rp=300 Rpt=262.4 fB=174.93 fB20=200 ftest=285.71 E=191484(N/mm2) ro=7.93

BOLTING TORQUE

METODA NACIAGU SRUB:

Skrecanie, (pomiar momentu i obrotu nakretki, blisko wytrzymalosci srub) eps

=-0.07 do +0.07

WSPÓLCZYNNIK TARCIA: Normalne/przecietne warunki µ=0.20

GASKET FORM AND GEOMETRY