30

Panzerbeobach

By Tom Cockle

31

tungswagen IV

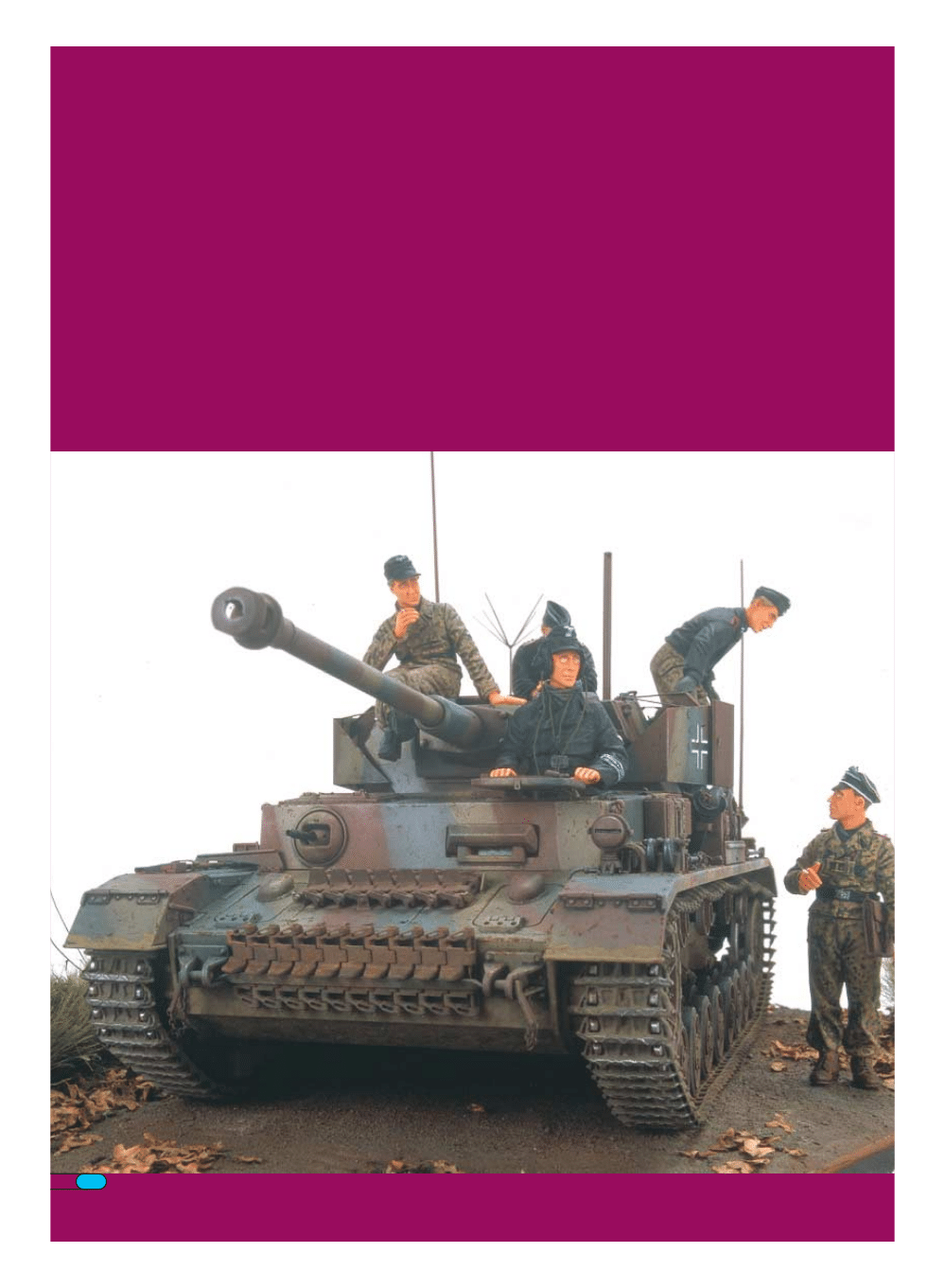

T

he first time I became aware

of this unique vehicle was

when I saw a color profile of it

in the book, ‘Pzkpfw.IV Model

Fibel’, by the Japanese

publisher Model Art in 1999. No way, I

thought. A Panzer IV with a StuG.III

commanders cupola! Where did they

dream that up? Then someone pointed out

there was a photo of one in ‘Battle of the

Bulge, Then and Now’ with a cute little

teddy bear perched on top of the gun. I

don’t know how many times I had looked at

that picture before without noticing the

cupola, but there it was in black and white.

Three more photographs of one lost on the

Eastern Front appeared in two Russian

publications, ‘German Camouflage and

Insignia 1941-1945’ in the Armada-Vertical

Series by Exprint Publishing Center and

‘Frontline Illustration Wehrmacht Panzer

Units in 1945’ Part I. Information on it was

scarce, then, just before Christmas, Osprey

released their new book

‘Panzerkampfwagen IV Ausf.G, H and J

1942-45’, by Hilary Doyle and Tom Jentz,

and most of the pieces of the puzzle

seemed to fall in place. The subject of the

color profile in the ‘Pzkpfw.IV Model Fibel’

that had first caught my eye, had a large

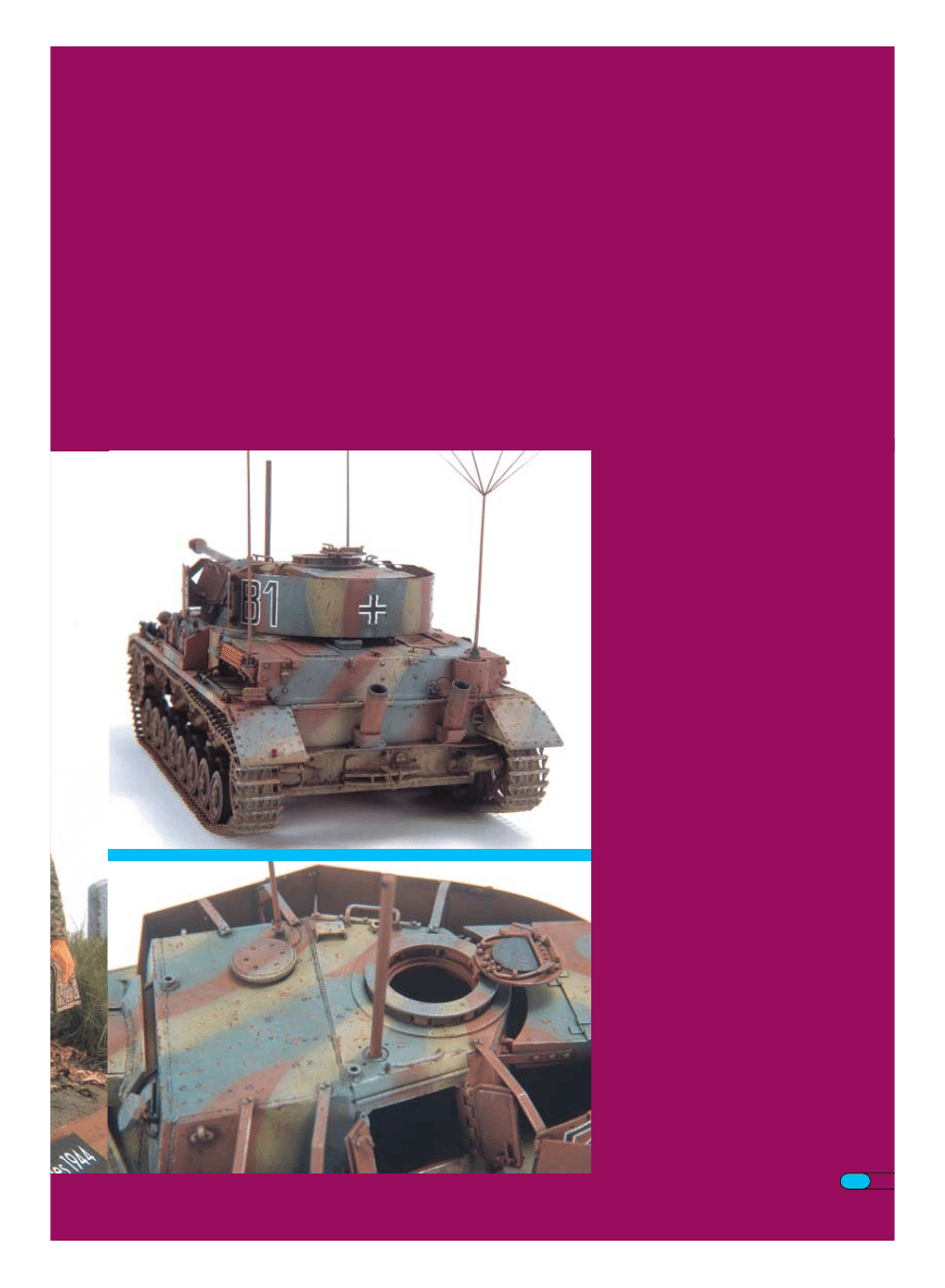

tactical number ‘B1’ painted on the rear

quarters of the turret skirts. Where had this

come from? Fortunately an inquiry posted

on the Missing-Links Panzer Talk discussion

group resulted in the answer. A scan of a

photograph taken from a Ground Power

magazine and sent to me by James

Blackwell, along with a translation of the

Japanese caption by Jeensang Jang,

32

placed it at Weisswampach in Luxembourg in early 1945. The

best information, according to Stefan De Meyer, suggests that

it probably belonged to 12.SS-Panzer-Division.

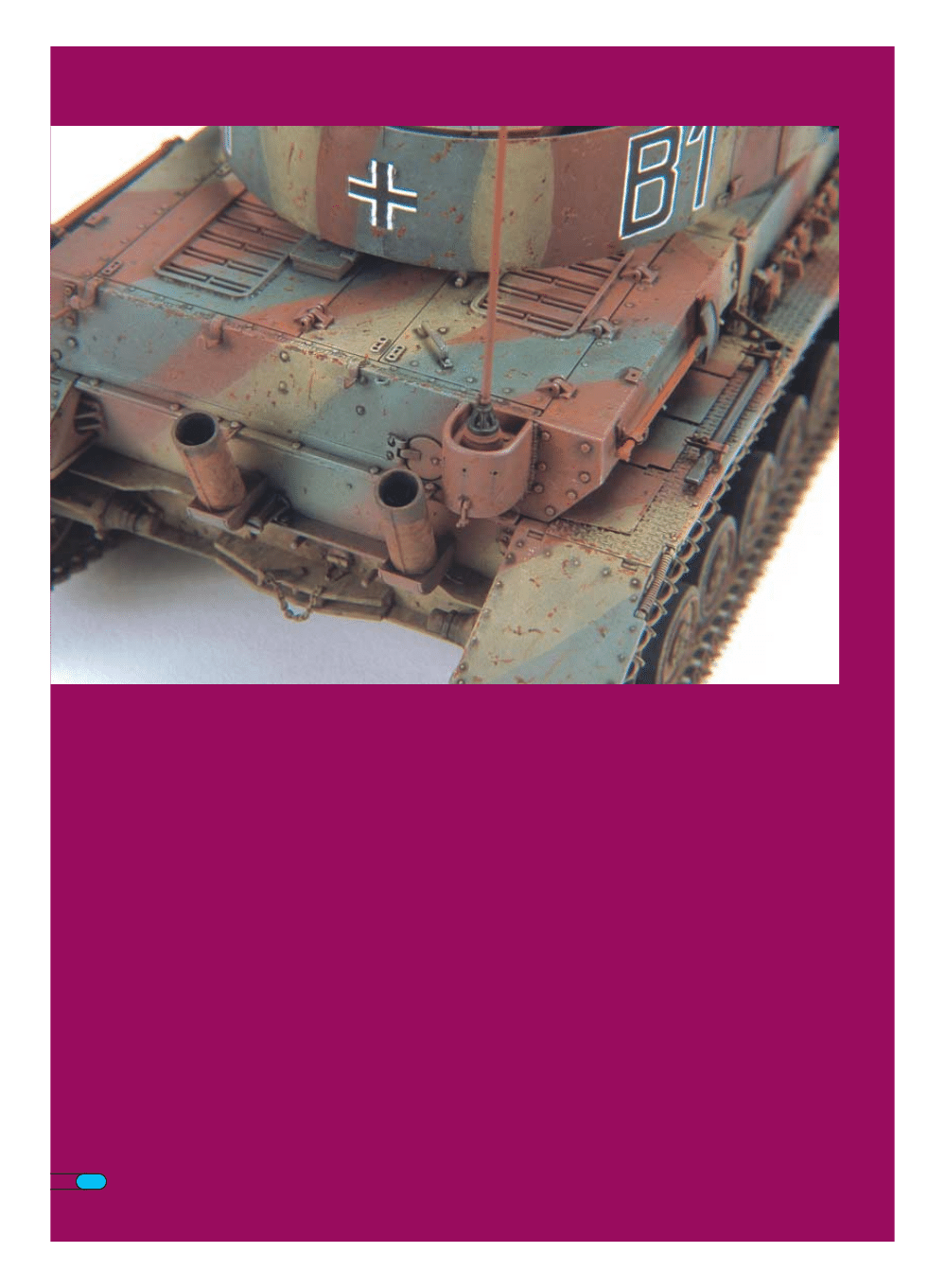

The one clearly identifiable feature of ‘B1’ is that it was fitted

with the vertical Flammentöter flame suppressing exhausts

that were first installed beginning in August 1944. I decided

that I would build mine with features that would place it in

production in late September 1944. These would include

having no Zimmerit applied but still retaining the early bolted

on tow brackets. Records show that 12.SS-Panzer-Division

received five new Pz.Beob.Wg.IV on 11 November 1944. It is

shown here as it might have looked on the opening day of the

Ardennes Offensive, 16 December 1944.

Choose Your Weapons

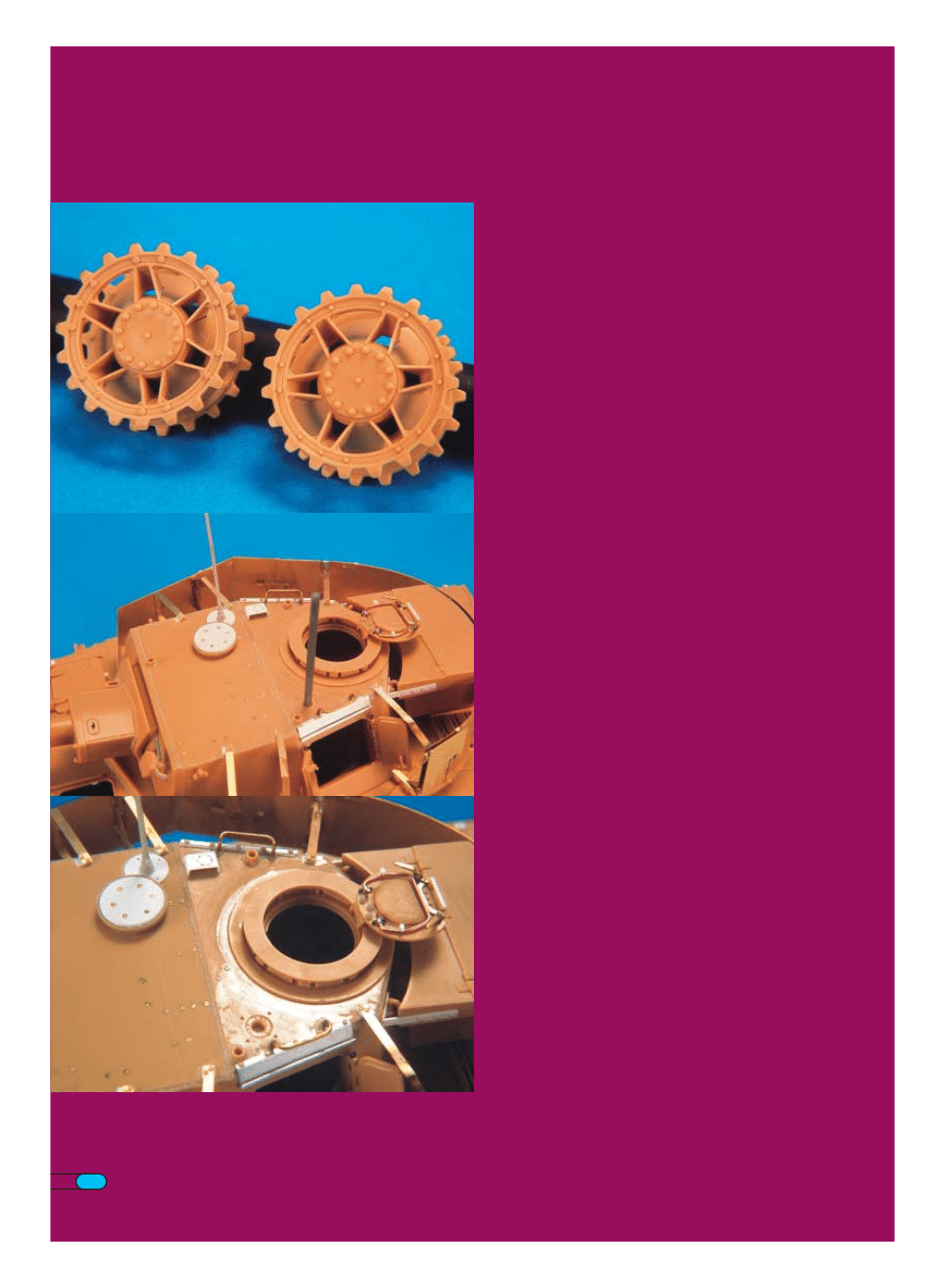

My choice for a kit was the Tamiya Panzerkampfwagen IV

Ausf.J No. 35181. As usual, I started on the lower hull and

running gear. Two bolt heads were added to the flat upper

surface of each roadwheel damper and grease nipples added

to the center of the idler wheel and each return roller. At some

point during Ausf.J production, two bolts from the top row on

the roadwheel mounts were deleted. In earlier cases, this is

evident by two empty holes and on later vehicles, the holes

were not drilled at all. I opted for a combination following the

photos of the Pz.Bef.Wg.IV at the Brussels museum. The drive

sprocket got the works though with new, more realistic looking

bolt heads around the outside of the inner and outer halves

that were taken from spare drive sprockets from the new

Tamiya Tiger II. Nuts and bolts shaved from old Tamiya Tiger II

roadwheels were added on the inner face of the inside half.

The tracks are from an older set of Model Kasten K-2 non-

workable individual links that need to be glued together but

look every bit as good as the newer workable sets when

finished.

I had noticed that the bottom intakes on the sides of the

engine deck on the Pz.Bef.Wg.IV at Brussels did not curve up

from the mudguard like the kit parts and so these were

removed and replaced with sheet plastic. After this was

complete, the upper and lower hull parts were glued together

along with some .030 plastic card to close off the opening in

the sponsons above the tracks. This was set aside to dry

completely and I turned my attention to the turret assembly.

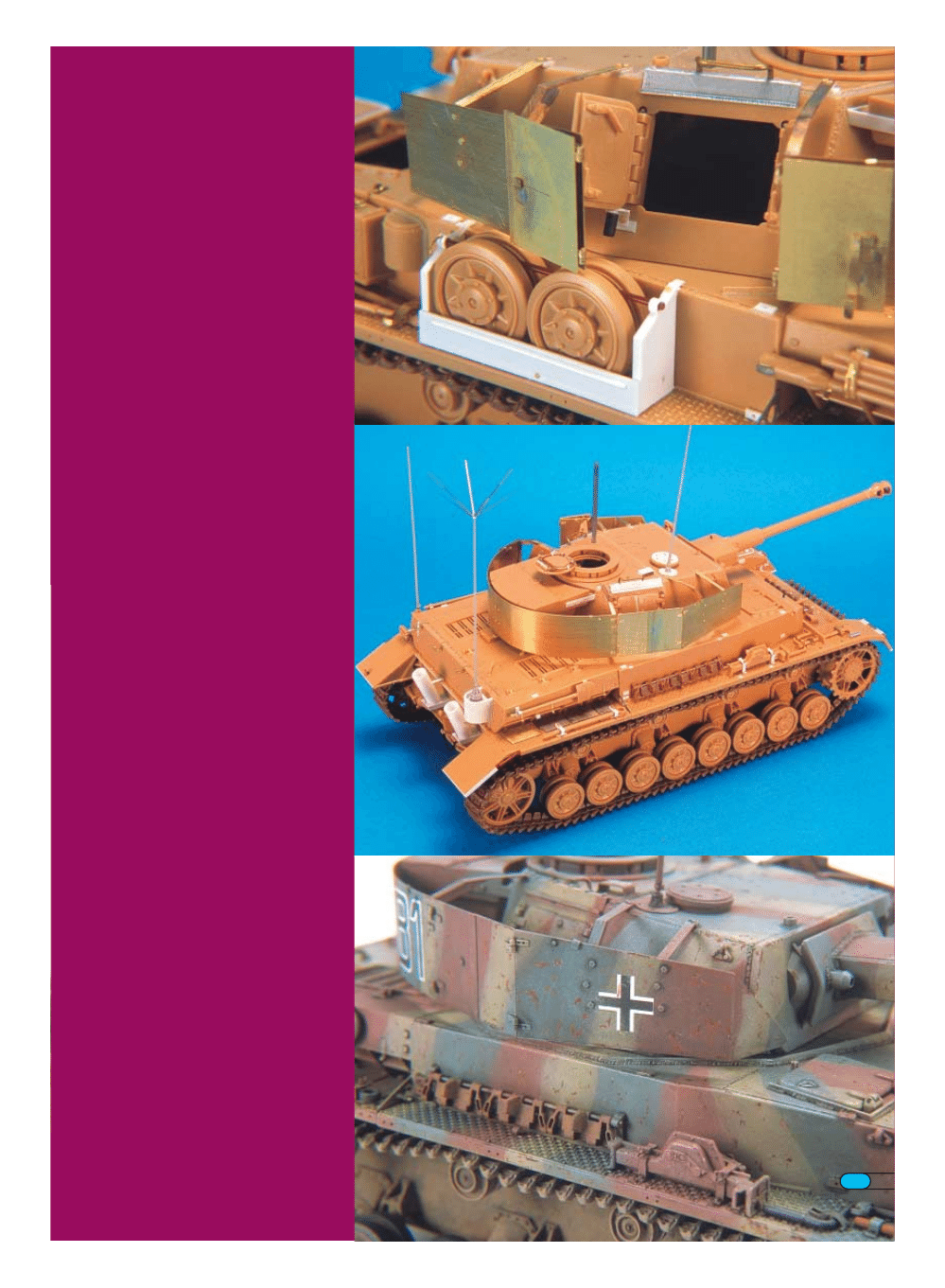

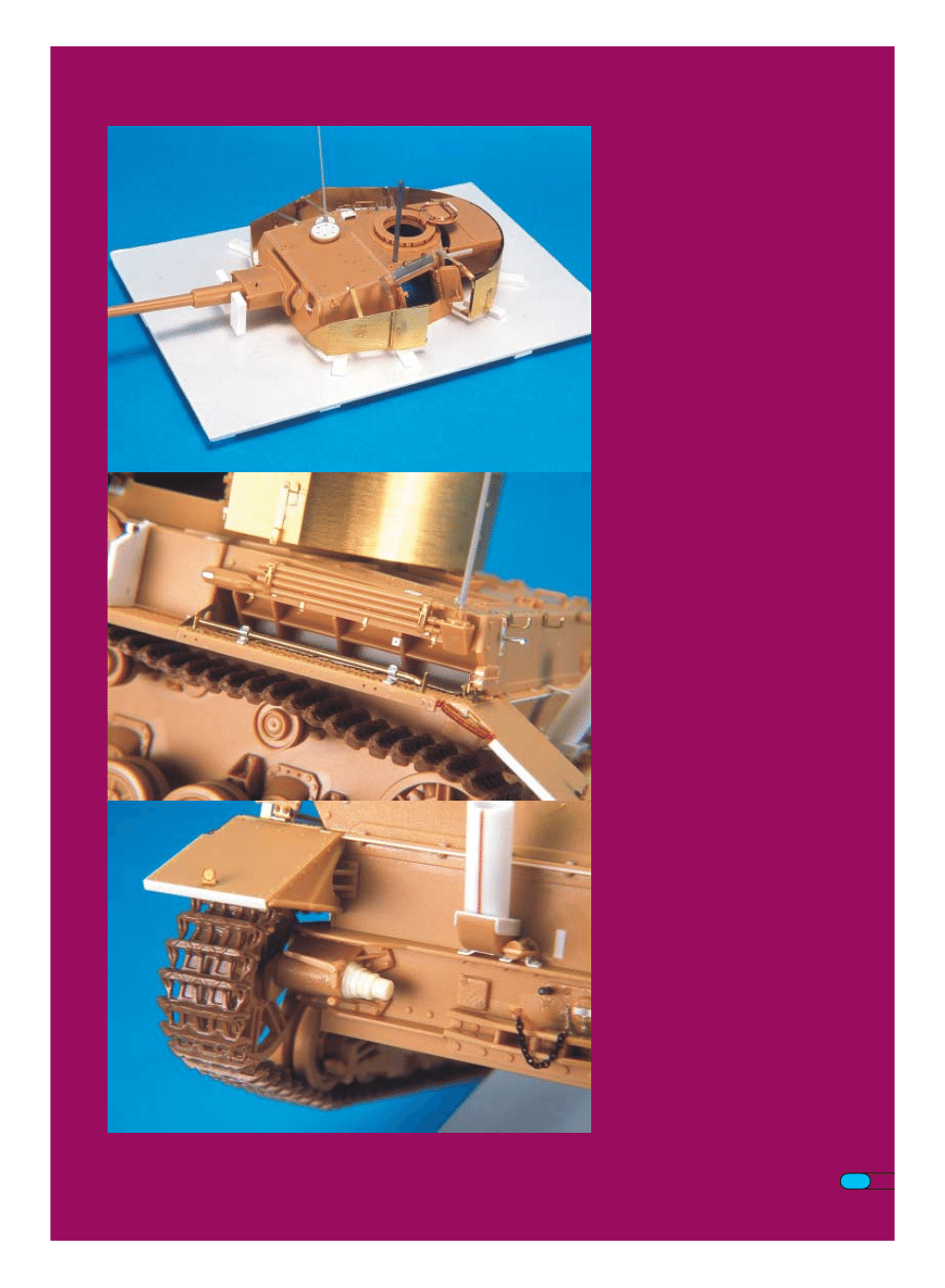

The Turret Takes Shape

The first task was to remove all traces of the cupola ring

molded onto the turret roof and to enlarge the hole to receive

a cupola taken from a Tamiya StuG.III Ausf.G kit. I elected to

just use the one from the kit that I will replace at some future

33

date by ordering a new sprue from

Japanese retailer ‘Rainbow Ten’. The

cupola hatch received some detail

attention in the form of bent brass strip

handles, a copper wire closing arm and

Grandt Line nuts and bolts. The pattern of

screw heads on the roof was traced on to

a piece of tracing paper using drawings

and transferred to the kit part using a

compass point. They were then drilled out

and photoetch brass screw heads from

Royal Models Screws and Bolts Set

No.034 were glued in place. A new larger

diameter, reinforced ventilator cover was

made from an old Tamiya Jagdtiger

ventilator and Royal Model photoetch

brass screws were added as well. This

larger ventilator cover was introduced in

July 1944, yet neither the Tamiya nor the

Dragon kits include it. Just to the right of

the ventilator, an antenna base was added

where the ‘Nahverteidigungswaffe’ would

have normally been installed. The antenna

and base came from Dragon’s German

Tank Antenna set. On the left side of the

roof, a periscope was added. At its base, a

circle was scribed in and sectioned into

three segments using photographs as

reference.

New grab handles were made from bent

brass wire and glued into holes drilled

about a millimetre farther back. When you

study the relationship of the handle to the

Pilze and the rain gutter over the turret

doors, you can see it needs to be moved.

New rain gutters were made from thin

metal printers plate bent over a steel ruler.

All the welded joints were vee’d out and

new weld beads made from Zimm-It-Rite

epoxy putty were added. Texturing was

done using a round toothpick that had a

small groove carved in the end. This

applies to all the weld beads on the rest of

the model as well.

The turret stowage bin was glued together

and allowed to dry thoroughly before filing

the joint smooth and scribing in a new line

to separate the lid from the bin. The two

mounting points were removed and the

groove in the bottom was filled with a

piece of styrene carefully cut to fit. The

bottom and side brackets are made from

styrene strip. I added Royal Model hasps

to the rear of the bin but the turret skirt

armour obscures their fine detail.

Panzerbeobachtungswagen IV

34

Since Tamiya thoughtfully provided a

separate gunners vision flap in the front of

the turret, I added two arms and glued it in

place in an open position. A lightly tinted

green clear plastic strip was glued in from

the back after painting to represent the

armoured glass. A small tin plate rain

gutter was added above the gunsight

opening in the mantlet. Pz.Bef.Wg. and

Pz.Beob.Wg.IV were not equipped with a

coaxial machine gun so I drilled out the

opening and opened up the cooling slots in

the top and bottom of the armored sleeve

on the mantlet. After gluing the halves of

the gun barrel together, I carefully sanded

it by twirling it inside a strip of sandpaper

while slowly moving it up and down the

length of the barrel. Done properly, this will

give you a seamless barrel. Three small

rivet heads and three small screw heads

were added to the armored sleeve in front

of the recuperator housing and a small

plastic ring on the top left side.

The locking handles on the turret side

access doors were separated from the

hatch face and the bottom two were

further drilled out and slotted. New hatch

hold open brackets were made from sheet

styrene and rod.

Now comes the fun part. I bought a set of

Aber photoetch brass turret skirts (35A06)

thinking this would save me all kinds of

time over scratchbuilding. I soldered

together the brackets first, bending them

to shape and laying them flat on a ceramic

tile. They were held in place with small

blobs of Blu-Tac. To properly align the

skirts to the turret, I made a jig from sheet

styrene with a hole the same size as the

one in Tamiya’s upper hull and glued short

pieces of .156 styrene strip around to

support the bottom edge of the skirt. Two

upright pieces were glued on either side of

the gun barrel to keep the turret from

moving. Aber gives you small pieces of

brass with holes in them to glue to the

turret but I decided to use styrene strip

instead. I superglued these to the brackets

which then could be glued to the turret

using liquid poly allowing for some

adjustment in the final position. Here I ran

into my first major problem. Aber’s skirts

are about a millimeter higher than both the

Tamiya skirts and Hilary Doyle’s drawings

and therefore, the top of the two rear

brackets was that much higher than the

top of the turret. To correct this, I simply

melted off the gusset, adjusted the angle

and soldered in a new gusset cut from the

photoetch runner. The top of the bracket

looks a little flat, but is not noticeable Aber

gives you some photoetch bolt heads but

for some strange reason, they don’t give

enough. I was fortunate to have some left

over from their Panther set I was able to

Panzerbeobachtungswagen IV

35

use. The nuts and bolts used to detail the

inside came from Grandt Line.

Back to the Hull

Moving back to the hull, the first thing I did

was tackle the armored housing welded to

the back of the hull that was unique to the

Pz.Bef.Wg.IV and Pz.Beob.Wg.IV. I took a

piece of .030 styrene strip and immersed it

for a few seconds in boiling water. It was

then quickly formed around a small X-acto

knife handle and then run under cold water

so it would retain its shape. The ends were

cut to the angle of the rear plate and it was

glued in place. The mount for the star

antenna is recessed down from the top

and a small piece of styrene was cut to

shape and glued in. Three small drain

holes were drilled into the housing just

above this. The antenna mount itself came

from the Dragon German Antenna set

which, I believe, is no longer available. I’m

glad I bought a few of them while I could

as the antennas are perfect, especially the

star antenna which is provided as a

stainless steel photoetch piece. There was

a special porcelain insulator on the base of

this antenna, also provided by Dragon. The

bottom of the housing is open and the

heavy cable from the antenna passes

through a rectangular hole in the rear

plate. After reproducing all this detail, I

came to realize that there was a sheet

metal cover plate underneath that was

supported by an angle welded to the rear

plate and held in place by a pivoting wing

nut on the outside of the housing. It would

have been far simpler to just close off the

bottom but, for my model, this plate is just

missing in action.

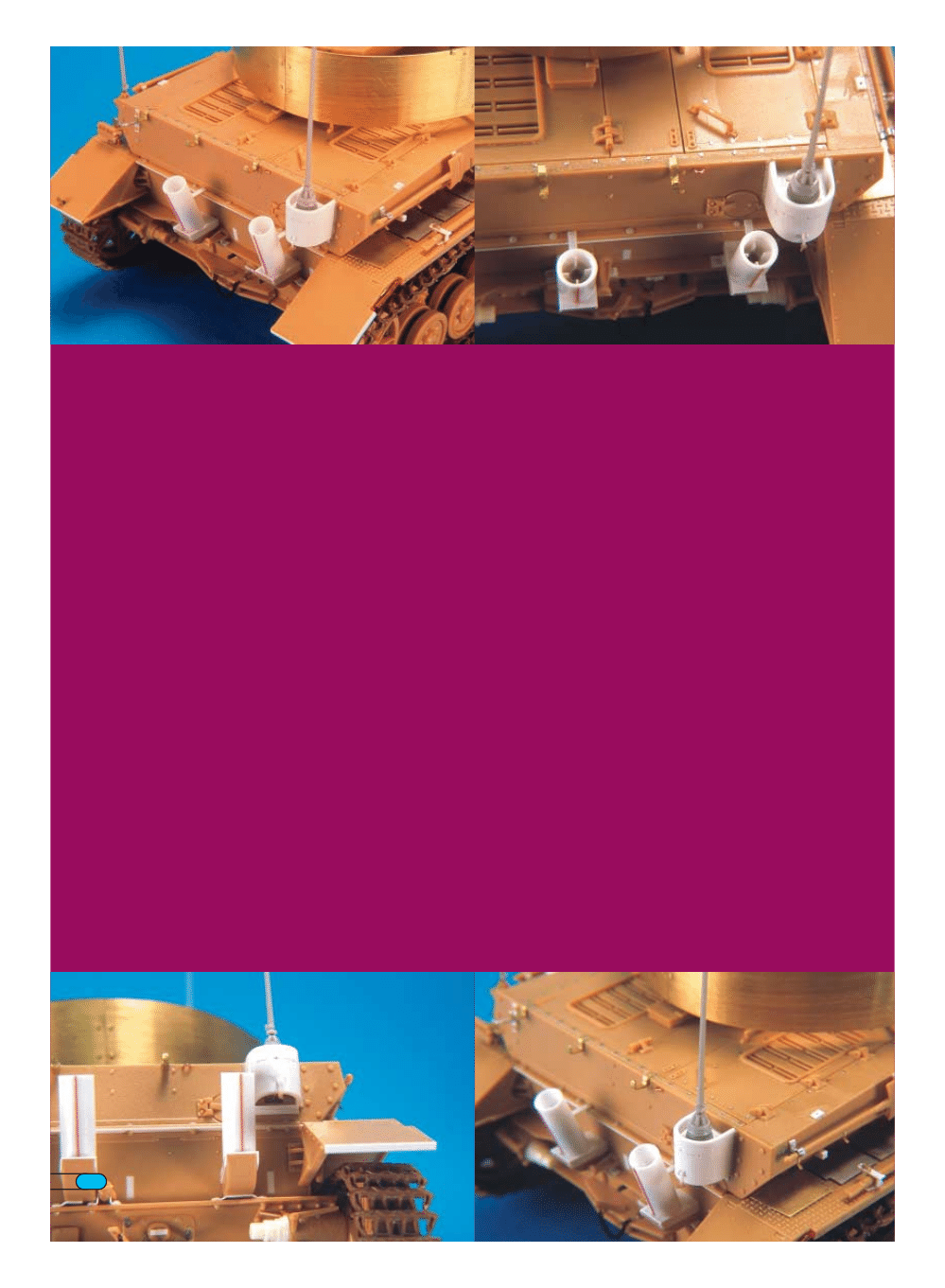

New Flammentöter exhaust pipes replaced

the kit exhaust and were made from

styrene tube. I made the inner pipe from

another piece of styrene tube and attached

it to the outer tube with four small styrene

strip vanes.

The double angle flange connecting the

upper and lower hull was detailed with an

additional styrene strip and numerous bolt

heads and nuts. At the bottom of the rear

plate, the idler mounts were actually

fastened on with nuts while the kit is

molded with bolt heads. This was a simple

36

thing to correct by simply gluing on small

stubs shaved from the bottom of a Dragon

Pz.Kpfw.IV hull. Coincidentally, about the

time I was doing this, there was a posting

on Missing-Links that pointed out that the

large hex nuts on part D34 used to tension

the idlers should really be octagonal. So I

made a pair of octagonal nuts from .125 x

.125 styrene strip and, using part D34 from

another kit, made a master which I then

molded and cast new ones in resin.

The rear mudguards had a styrene strip

added to the back and outside edges.

Small rivet heads were added to the inside

faces, parts B4 and B5, lining up with the

ones on the large flat face. To make the

springs, I wrapped a thin wire around a

small drill bit chucked backwards in to my

pin vise. Remember to count the wraps so

both sides are the same.

When it comes to adding the tools and

other details, I usually start at one point

and work my way around the vehicle

instead of jumping around all over. The first

thing to do is fill all the locating holes. After

all this time, you would think the

manufacturers would realize how much we

detest these molded in imperfections.

I started with the Notek light on the left

rear mudguard. It is the Tamiya kit part

with the base removed and a new one

added from bent brass strip along with a

very thin wire lead running down through a

hole in the mudguard.

The cover plates lying flat on the

mudguard for the engine air intake louvers

are stainless steel photoetch ones from

Tamiya. The one at the back below the

standard antenna mount needs to have a

small recess filed into it to clear the

antenna base which actually projects

down. I got the two sides mixed up and as

a result, had to make a new one for the

right side from brass sheet. The little

spring clips that hold them up were made

from narrow brass runners from another

photoetch brass sheet. I made a little jig

with a piece of triangular plastic glued to it

to form them over so they would all be a

uniform size.

The gun cleaning rods are from the kit and

were detailed with brass strip mounts on

the back to space them away from the hull

and Royal Models photoetch brass hasps

were added. The pry bar was made from a

piece of brass rod. I flattened and bent

one end with a pair of pliers and then filed

it to shape. The brackets are my own

design made from brass runners and

another jig made using a piece of half-

round styrene. Each one is two parts that

are then glued to a piece of .010 styrene

strip so they can be attached to the kit

with styrene cement.

The spare roadwheel box was made from

.010 sheet and strip styrene using the kit

parts as a guide as they are actually thin

sheet metal. The raised rib on the side

panel is a piece of half-round styrene.

37

I detailed the jack block with a wire spring

and a photoetch brass chain. The clamp for

the wire cutters is from an Aber workable

set as are all the others used on this

model. The short pry bar and brackets

were made the same way as the one on

the back except the bar is styrene.

In the Osprey New Vanguard book by Doyle

and Jentz, they state that S-hooks replaced

the C-hooks on Pz.Kpfw.IV starting in June

1944 but I could not find even one

photograph to substantiate this. I did,

however, find several photographs of late

Pz.Kpfw.IV fitted with mesh skirts

(September 1944) and the rotating cupola

hatch (October 1944) that still had the C-

hook bracket. Not having a photoetch

brass detail set with one handy, I made one

from styrene sheet. The C-hooks are from

the kit and were thinned down a bit to fit in

the new bracket.

The fire extinguisher is one from the new

Royal Models German Fire Extinguisher Set

No.247, I modified the headlight mount by

cutting out a slot in the base on the

outboard side and adding a copper wire

electrical lead down to the glacis. The

headlight itself is one I had left over from

an old Gunze Sangyo High-Tech Panther

which I used simply because I had it and it

is nicely detailed.

You will notice that the two large wrenches

stowed behind the fire extinguisher are not

there as they were deleted at some point in

Ausf.J production. At least they are not on

Hilary Doyle’s drawings of the Pz.Bef.Wg.IV

and Pz.Beob.Wg.IV in the ‘Begleitwagen

Panzerkampfwagen IV’ book. This

presented a bit of a challenge as the

brackets for them are molded on the

mudguard. I carefully ground them off with

a flat Dremel bit and repaired the

treadplate pattern by removing the small

pieces from another kits mudguard, under

the area where the engine intake flaps lie,

and gluing them carefully in place. A couple

of days after I finished the model, I picked

up a new book published in Russia on Lake

Balaton in which there is a photo of a

Bergepanzer IV with the two wrenches

mounted in brackets on the front and rear

of the spare roadwheel bin. These two

brackets were also on the Pz.Bef.Wg.IV in

Brussels but I didn’t know what they were

for at the time, so I had left them off.

38

Armed with this new information, I added

them along with the two wrenches.

Moving to the front, the spare track links and

brackets come from the Model Kasten SK-19

Late Model Spare Track set. The pins in the

tow brackets are from the kit detailed with

fine chain. The square transmission access

plate on the glacis had the hex bolt heads

removed and replaced with square heads

made from styrene strip. In addition, the

simulated screw heads surrounding it were

gently cleaned out with a flat Dremel bit

twirled in my fingers to remove the raised

‘slot’ and Royal Models screws were glued in.

The hinged part of the front mudguards were

detailed with a piece of styrene rod on the

bottom edge and new hinges and pins made

from a piece of telephone wire that had most

of the insulation removed. The remaining

insulation forms part of the hinge. The inside

face of the mudguards had some small

details added from styrene strip, rivets and

bolt heads and wire springs made the same

way as the ones on the rear.

On the engine deck, I added several rows of

raised blank bolt heads made by punching

out a piece of lead foil on an eraser with a

.020 drill bit chucked backwards into my pin

vise. It’s odd that Tamiya did not reproduce

these as they did on their earlier Panzer IV

kits because they are quite noticeable.

Incidentally, the rear hinge on the right side

hatch should be moved forward a bit, which I

did not do as I discovered it too late. Check

out the drawings in ‘Panzer Tracts No.4’ or

the ‘Begleitwagen’ book.

The drivers and radio operators hatches in

the kit are the earlier welded edge type

which were replaced with thicker ones with

rounded edges beginning in July 1944,

although existing stocks were installed until

they were used up. I rounded off the edge

with a file and detailed the inside of the

driver’s hatch with a new locking handle and

bar. The raised edge was made by adding

strip styrene around the hatch and trimming

off the excess after the glue was dry. Just

behind the hatches, there was a weld joint

that is missing on the kit. I scribed in a deep

groove and filled it with Zimm-It-Rite epoxy

putty weld.

This completed the construction phase of the

model.

Time to Paint

In September 1944, German tanks began to

leave the factory with a coat of RAL 8012 Rot

primer with a camouflage pattern of RAL

7028 Dunkelgelb and RAL 6003 Olivgrün

sparingly applied in stripes and patches with

hard edges. The lower hull sides and wheels

were not camouflage painted. I like to use

Testors Model Master Acryl paints, but there

is not a suitable color to represent the primer

and I used an old Humbrol color HG15

(RLM61). This matches very closely a paint

sample I have adhered to the back of a piece

of Zimmerit coating from a Panther. After

this, I sprayed on the camouflage using

Model Master Acryl 2095 Panzer Dunkelgelb

1943 and 2097 Panzer Olivgrün 1943, mixed

50/50 with their acrylic thinner. When this had

dried, the hard edges were touched up with

a brush using the leftover thinned paints,

which worked surprisingly well. As the vehicle

would have been camouflaged in the factory

with the Schürzen brackets still mounted, I

touched up all the mounting lugs with primer

color.

The rubber tyres were painted with Vallejo

acrylic that brushed on extremely well right

from the bottle.

I tried a new wash technique demonstrated

by Chris Mrosko in his book ‘Panzer’s

Tactics’. He uses a thinned black oil wash

applied directly over the base paint which

eliminates the need for the clear acrylic

sealer coat and the messy, time consuming

39

effort required to wipe off the thick oil wash

that I previously used.

The black oil wash is thinned with paint

thinner, not turpentine, to produce a flat

finish. A small amount of paint is placed on

a palette to which small amounts of thinner

are added to obtain the right consistency.

This is brushed liberally over the whole

model. Next, after drying for a day, a ‘pin

wash’, made from burnt sienna and

Vandyke Brown oil paint, is applied around

raised details to make them stand out. The

area around the details is first wetted with

pure thinner with a large brush and the ‘pin

wash’ is applied with a smaller no. 1 or 2

brush. Wetting the area ensures the wash

will only go where you want it and not all

over the place. I eliminated a second ‘pin

wash’ of Indian Red and Mars Black as I

was satisfied with the results of the first

wash. Although I am not a proponent of

heavily rusted and paint chipped vehicles, I

did apply some sparingly with burnt

sienna, burnt umber and black designer’s

gouache watercolor paints. The advantage

of using this medium is that it can easily

be changed if you don’t like the results the

first time.

The colors for drybrushing were obtained

by tinting the Model Master enamel

equivalents of the acrylic colors and the

Humbrol HG15 with white artist’s oil paint.

I painted the tracks with a base coat of

Humbrol 29 Matt Dark Earth enamel and

weathered them with Rembrandt pastel

chalks using Makoto Takaishi’s technique

from the Japanese publication ‘Armour

Modelling’. You will need 409-3, 409-7,

411-3 and 411-7 blended with 235-3 for

the rust coloured inside face and 408-3,

408-7 and 234-3 for the dust coloured

outside face. I have ground a small

amount of each chalk using fine sandpaper

into an egg carton with each number

marked inside the lid for easy identification.

The pastels are applied by dipping an old

no. 5 brush into Tamiya acrylic paint

thinner and then into the chalk powder and

dabbing onto the surface of the tracks in a

random pattern. Repeat the process using

different colours as you progress. Drybrush

the wearing surfaces lightly with silver

Rub’n Buff. It is important to use an

enamel for the base coat so there is no

reaction with the Tamiya acrylic thinner.

Both tracks can be easily completed in an

hour.

The lower hull and running gear was also

treated to a heavy coating of the three

dust colored pastels to represent a dirty

mud buildup. A thin wash of burnt umber

artists oil paint was applied liberally to the

area around the fuel filler caps on the left

side to represent spilled fuel mixed with

the dirt and also around the grease nipples

on the road wheels and drive sprockets.

The crosses on both sides and the rear of

the turret skirt armor came from a Third

Group decal set for a Pz.Kpfw.III, mainly

because they were the correct size, about

7mm high. Before dipping in water, the

white outline was lightly scored with a

hobby knife to thin it down by half. Solvaset

helped snug them down to the model

without the benefit of a gloss coat. The

tactical number ‘B1’ was airbrushed on

with Tamiya XF2 Flat White using a home

made stencil cut out from a Post-It Note.

The inside was hand brushed using Vallejo

black acrylic paint.

40

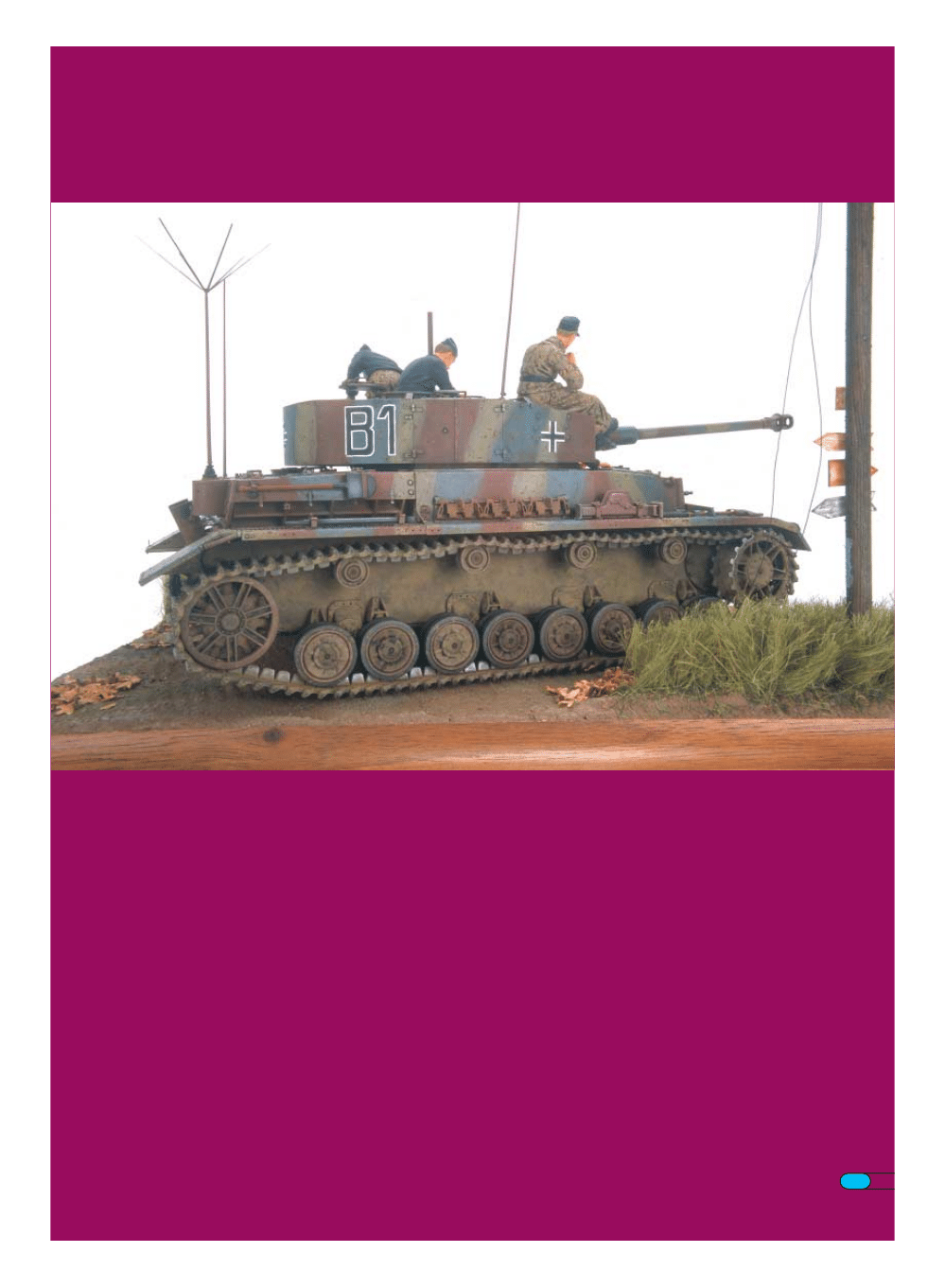

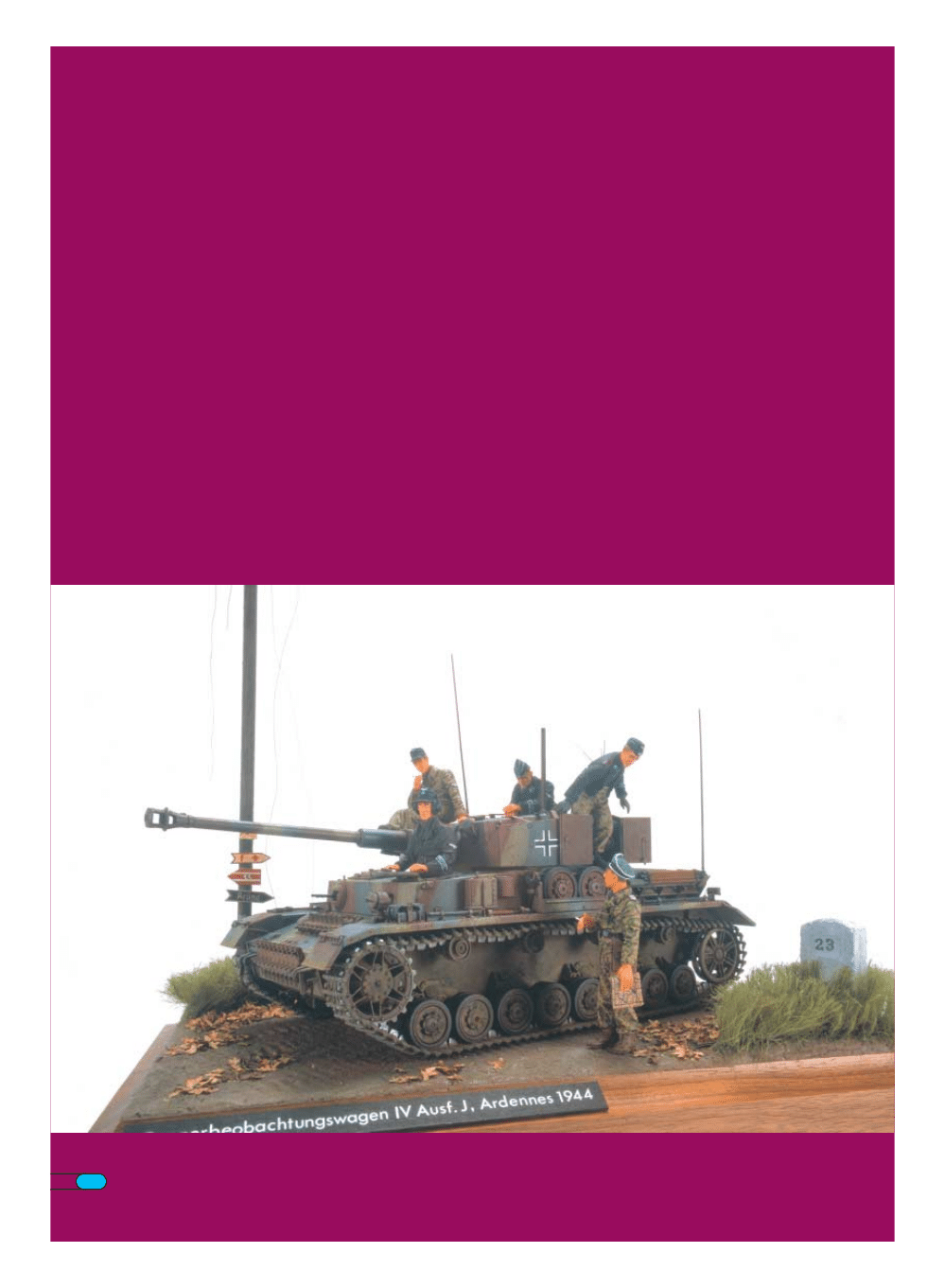

The Vignette

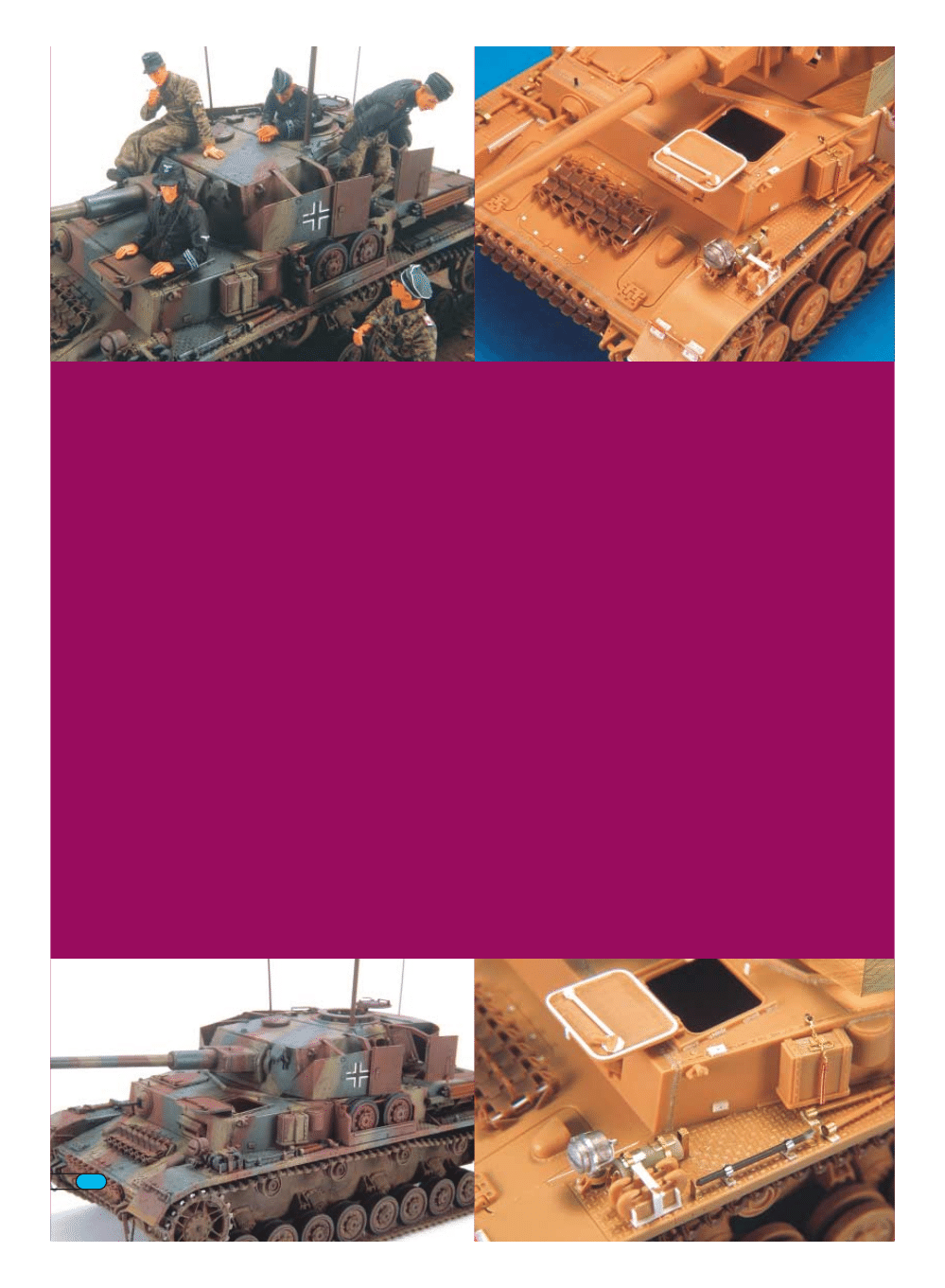

The figures are all Warriors resin products. The vehicle

commander and the driver are from the Waffen SS Panzer Crew

#1 (35030) set but with their positions reversed. I used a resin

head from Verlinden (I think) on the commander and a different

Warriors head on the driver. The gunner and radio operator are

from their Waffen SS Panzer Crew #2 (35031) set. I modified the

trousers on the radio operator sitting on the turret roof as they

were sculpted to represent some sort of coveralls. Standing on

the ground is the Waffen SS Tanker With Map (35038) built right

from the box without modification except for two seams in the

back of his jacket that were added.

I primed them with Tamiya XF2 Flat White and sprayed the faces

and hands with XF15 Flat Flesh. The flesh areas were further

treated by applying a coat of burnt sienna tinted with a bit of

white which was then wiped off with a small gun cleaning cloth,

which is as close to lint free as you will find. Uniforms were all

painted with various Humbrol enamels and oils. A light ‘pin wash’

of burnt umber oil paint was applied and the figures drybrushed

to highlight the raised details. Faced for the first time with having

to actually paint a map, I was forced to ask myself what they

really did look like? It turns out they don’t much look like the

printed maps you get from Verlinden and others. Fortunately,

Ron Volstad has an authentic 1943 German map which is printed

on a sepia tone paper with black lines for the roads and

contours, blue lines for the rivers and streams and green outlines

for woods and forested areas.

The base is an old 6” x 9” walnut wall plaque award that I

salvaged from work. I started off by masking off the lower edges

with masking tape before applying the groundwork. The

groundwork was made with hydrostone plaster compound mixed

with some sand and model railroad ballast along with a

generous dollop of burnt umber acrylic paint for color. The

verges were slightly built up by adding more of the mixture in

these areas. An old toy motorcycle wheel was used to provide

the track impressions in the road surface.

After this was completely dry, the surface was brush painted with

a coat of Tamiya XF52 Flat Earth acrylic paint and then

drybrushed with Humbrol SW4 (no longer available) mixed with a

bit of white artists oil paint. The grass is green garden twine cut

into short pieces and glued with white glue to the base. After the

glue had dried, the pieces were teased out with a pair of

tweezers and all loose strands removed to produce a fairly

realistic looking tall grass.

The wooden power pole is an Elefant product and the road

monument is from a Plus Model set I picked up at a small hobby

shop in Lucerne, Switzerland. The military signs on the pole are

from the Verlinden Normandy set. Hudson and Allen Forest Litter

was sprinkled around the sides of the road to impart an ‘autumn’

look to the base. The final touch was to add a title plate made

from black art board with Letraset lettering.

All in all, I was quite satisfied with the end result. The information

contained in the Osprey New Vanguard book allowed me to try a

unique camouflage scheme seldom seen on models of the

Pz.Kpfw.IV.

Wyszukiwarka

Podobne podstrony:

OD33 Panzer IV vs Char B1 Bis France 1940

Achtung Panzer 012 112 124 (PzKpfw IV)

Achtung Panzer 013 125 132 (Jagdpanzer IV)

Achtung Panzer 007 61 76 (StuG III IV)

wyklad IV

Mała chirurgia II Sem IV MOD

Temat IV 2 2

Pr UE Zródła prawa (IV 2013)

IV lek leczenie wspomagające w onkologii Żywienie

IV NIPiP Zmiany w podsystemie

IV 1 2 Atrybuty Osobow

BIOMATERIALY IV 2010

Zarządzanie skrzynką pocztową IV

Prezentacja wykłady I IV

1 Budownictwo ogólne sem IV

Wykład IV Model Portera

więcej podobnych podstron