Journal of Basic Microbiology 2011, 51, 385 – 396

385

© 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

Research Paper

Rhamnolipid from Pseudomonas desmolyticum NCIM-2112

and its role in the degradation of Brown 3REL

Mital Jadhav

1

, Satish Kalme

2

, Dhawal Tamboli

3

and Sanjay Govindwar

4

1

Department of Microbiology, Shivaji University, Kolhapur, India

2

National Center for Biomedical Engineering Sciences, National University of Ireland, Galway, Ireland

3

Department of Biotechnology, Shivaji University, Kolhapur, India

4

Department of Biochemistry, Shivaji University, Kolhapur, India

The biosurfactant produced by Pseudomonas desmolyticum NCIM 2112 (Pd 2112) was confirmed as

rhamnolipid based on the formation of dark blue halos around the colonies in CTAB-methylene

blue agar plates and the content of rhamnose sugar. The average yield of rhamnolipid was

0.398 g/l/day when grown on hexadecane as sole carbon source. Pd 2112 emulsification

potential associated with cell free culture broth was stable for 72 h using various hydrocarbons

and vegetable oils. Chemical structure of the biosurfactant was identified as mono-rhamnolipid

(Rha-C

6

–C

8

) using HPTLC, fourier transform infrared spectroscopy,

1

H and

13

C NMR and gas

chromatography-mass spectroscopy analysis. Pd 2112 mono-rhamnolipid (1 mg/ml) had in-

creased permeabilization of Bacillus sp VUS NCIM 5342 and increased decolorization rate of

textile dye Brown 3REL by 50%. Extracellular activities of lignin peroxidase and veratryl

alcohol oxidase, enzymes involved in dye degradation, were significantly increased in the

presence of mono-rhamnolipid by 324.52% and 100% respectively. Scanning electron micro-

scopy observations revealed that rhamnolipid did not exert any disruptive action on Bacillus

cells as compared to Tween 80. The mono-rhamnolipid of Pd 2112 has potential for its

application in biodegradation of textile dyes.

Keywords: Mono-rhamnolipid / Pseudomonas desmolyticum / Decolorization / Lignin peroxidase / Biodegradation

Received: September 13, 2010; accepted: January 11, 2011

DOI 10.1002/jobm.201000364

Introduction

*

Biosurfactants are amphiphilic compounds that consti-

tute a diverse group of surface active molecules synthe-

sized by the microorganisms which either adhere to

cell surfaces or are excreted in the growth medium [1].

The distinctive properties of biosurfactants, like lower

toxicity, biodegradable nature, similar surface-active

properties and better environmental compatibility that

are not observed in synthetic surfactants have attracted

their use in various fields as multifunctional materials

for new century [2, 3]. Increasing environmental aware-

ness and emphasis on sustainable society in harmony

Correspondence: Prof. Sanjay Govindwar, Department of

Biochemistry, Shivaji University, Kolhapur-416-004, India

E-mail: spg_biochem@unishivaji.ac.in

Phone: +91-231-2609152

Fax: +91-231-2691533

with the global environment, during the recent years,

has led to serious consideration of biosurfactants as

possible alternative to synthetic surfactants as they

cause environmental problems due to their resistance

to biodegradability and toxicity to ecosystems [4].

Textile dyes are recalcitrant molecules. Pollution by

dye-waste water is becoming increasingly alarming

with the increasing use of a wide variety of dyes. Cur-

rently various chemical, physical and biological treat-

ment methods are used to remove the color [5]. Chemi-

cal and physical methods for treating dye wastewater

have disposal problems. Microbial decolorization and

degradation is an ecofriendly alternative to the chemi-

cal decomposition process [6]. The numerous advan-

tages of biosurfactants have promoted its applications

in the environmental remediation [7]. However, there

are no reports on the effects of biosurfactant on the

microbial dye degradation.

386 M.

Jadhav

et al.

Journal of Basic Microbiology 2011, 51, 385 – 396

© 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

The biodegradation ability of bacteria is assumed to

be associated with the production of different en-

zymes. It is believed that surfactants alter the cell

membranes to facilitate enzyme release [8]. There re-

mains a dearth in availability of reports on the in-

fluence of biosurfactants on the enzymes involved

in microbial dye degradation. It can be a valuable ap-

proach to uncover the role of rhamnolipids in micro-

bial dye degradation with respect to its effects on the

microbes and the enzyme systems involved in the pro-

cess.

Recently, we have reported that Pseudomonas desmoly-

ticum NCIM 2112 (Pd 2112) could degrade diesel and

kerosene alone as well as in consortium with Nocardia

hydrocarbonoxydans [9]. Pd 2112 could reduce surface

tension of the growth medium and produce stable

emulsification during degradation of diesel and kero-

sene. In this work, we describe physical and chemical

characteristics of the rhamnolipid produced by

Pd 2112. And also the effects of Pd 2112 rhamnolipid

on dye degradation by Bacillus sp. VUS NCIM 5342 and

the enzyme systems involved in the same.

Materials and methods

Bacterial strains, growth, and media conditions

Pd 2112 was obtained from National Center for Indus-

trial Microorganisms (NCIM), Pune, India. Bacillus sp.

VUS NCIM 5342 was isolated from textile dye conta-

minated soil in our laboratory and deposited in

NCIM, Pune, India [10]. Pure cultures were maintained

on nutrient agar slants at 4 °C. Mineral salt medium

(MSM) was used for rhamnolipid synthesis with fol-

lowing composition (g/l): KH

2

PO

4

, 1.0; K

2

HPO

4

, 1.0;

MgSO

4

⋅ 7 H

2

O, 0.2; CaCl

2

⋅ 2 H

2

O, 0.2; FeCl

3

⋅ 6 H

2

O,

0.05; NH

4

NO

3

, 1.0. The final pH of the medium was

adjusted to 6.5 with 0.1 M HCl. The dry cell weight was

calculated using a predetermined correlation between

OD

660

and dry cell weight.

CTAB-methylene blue agar plate assay

Pd 2112 was initially assayed for rhamnolipid produc-

tion using mineral salt cetyltrimethylammoniumbro-

mide (CTAB)-methylene blue agar plate method (CTAB

0.2 mg/ml and methylene blue 5 μg/ml) [11]. Pd 2112

was grown for 24 h (OD

660

0.1) in MSM under appropri-

ate growth conditions. Shallow wells were cut into the

surface of the indicator plates. Ten micro liters of the

appropriate culture was placed into each well. The

plates were then incubated at 30 °C and checked peri-

odically over a 24 h to 48 h time period. The production

of rhamnolipid was confirmed by the formation of dark

blue halos around the colonies.

Cultivation conditions for rhamnolipid production

Pd 2112 was grown in the nutrient broth medium for

24 h at 30 °C. For biosurfactant production, 2% inocu-

lum of Pd 2112 was added in 100 ml MSM containing

2% (v/v) hexadecane. Cultivations were performed in

250 ml Erlenmeyer flasks and incubated at 30 °C in a

shaking incubator at 120 rpm for 168 h to obtain the

highest microbial growth and rhamnolipid concentra-

tions.

Extraction and quantification of rhamnolipid

Pd 2112 cells were separated from rhamnolipid produc-

tion medium by centrifugation at 8500 rpm at 4 °C for

20 min. The clear supernatant was further treated by

acidification to pH 2.0 using 6.0 M HCl and incubated

at 4 °C for ~12 h to precipitate biosurfactants. After

centrifugation at 10,000 rpm for 20 min, the precipitate

was dissolved in 0.1 M NaHCO

3

, followed by rham-

nolipid extraction using chloroform:methanol (2:1 v/v)

at room temperature. The organic phase was removed

using a rotary evaporator yielding a viscous honey-

colored rhamnolipid product.

The concentration of rhamnose produced was de-

termined using orcinol method [12]. In brief, 333 μl

culture supernatant was evaporated to dryness and

0.5 ml of distilled water was added to it. In 100 μl

samples 900 μl of 0.19% orcinol, prepared in 53%

H

2

SO

4

(v/v) was added. After heating at 80 °C for 30 min,

all samples were cooled at room temperature and

OD

421

was measured spectrophotometrically. Rham-

nolipid concentration was calculated using L-rhamnose

as standard and expressed as rhamnose equivalents

(RE).

Determination of surface tension

and emulsification index

Surface tension of cell-free culture broth was measured

according to the Du Nouy ring method using a surface

tensiometer (Jencon Company, India). The tensiometer

was calibrated before each measurement using distilled

water. The ring was cleaned with benzene at low heat-

ing for each measurement. Samples of the culture me-

dia were centrifuged at 8000 rpm for 20 min. The ring

was introduced in 50 ml cell-free culture broth apply-

ing an ascending force until the ring was pulled out

from the culture broth, and the surface tension was

recorded from the graduated dial.

Emulsification index (E24) was determined by the

addition of 4 ml hydrophobic substrate to equal volume

Journal of Basic Microbiology 2011, 51, 385 – 396

Rhamnolipid in dye degradation

387

© 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

of cell free culture broth, mixed with a vortex for 2 min

and left to stand for 24 h. Emulsification activity E

24

(%)

was determined using following equation:

E

24

(%) =

¥

The height of emulsion layer

100 .

The height of total solution

The hydrophobic substrates like hexadecane, kerosene,

diesel, toluene, groundnut oil, sunflower oil, and corn

oil were tested for emulsification assay.

Structural characterization of rhamnolipid

High performance thin layer chromatography (HPTLC)

was carried out using a CAMAG thin layer chromato-

graphy system composed of an automatic TLC sampler

(CAMAG Linomat 5), automatic development chamber

(CAMAG ADC2), detector (CAMAG TLC Scanner 3), and

an electronic integrator (winCATS software). An aliquot

(15 μl) of the crude rhamnolipid sample was band ap-

plied (mm) on to an HPTLC precoated silica gel 60F

254

plate (10 × 10 cm). The sample was loaded at a dosage

speed of 50 nl/s under nitrogen stream. The sample was

developed (ascending) using 10 ml of the mobile phase

of CHCl

3

/CH

3

OH/H

2

O (65:25:4, v/v/v), in plates precondi-

tioned for 3 min, to a migration distance of 85 mm. The

plate was dried, sprayed with orcinol reagent (0.19%

orcinol in 53% H

2

SO

4

), and then put in a hot-air oven at

120 °C for 15 min. The developed chromatogram was

scanned in remission type, absorbance mode at 550 nm.

The signals recovered from the scanner were integrated

into absorbance chromatograms from which peak area

was automatically calculated using the winCATS soft-

ware. Based on the R

f

value, the band of rhamnolipid

was scratched off from the other HPTLC plate after

developing and was used for further characterizations.

1

H and

13

C-Nuclear magnetic resonance (NMR) spec-

tra were obtained using an OXFORD NMR

400

spectrome-

ter. The HPTLC purified rhamnolipids were deuterium-

exchanged by repeated evaporation in methanol-D

2

O

(1:1, v/v). The NMR spectra were determined in deuter-

ated methanol at 30

o

C using tetramethylsilane (TMS) as

an internal standard.

The Fourier transform infrared spectroscopy (FTIR;

Perkin-Elmer, Spectrum one) analysis of HPTLC purified

rhamnolipid was done in the mid IR region of 400–

4000 cm

–1

with 20 scan speed. The samples were mixed

with spectroscopically pure KBr in the ratio of 5:95.

The pellets were fixed in sample holder for an analysis.

The Gas chromatography-mass spectrometry (GC-MS)

analyses were performed using Varian 4000 mass spec-

trometer equipped with an integrated chromatograph

with a DB-5 column. Helium was used as carrier gas at

a flow rate of 1 ml/min. The injector temperature was

maintained at 280 °C with oven conditions as: 80 °C

kept constant for 2 min; increased up to 200 °C with

10 °C/min;

rose up to 280 °C with 20 °C/min rate. The

negative ion mode was used throughout and scans were

initiated over the 50–1000 m/z range.

Dye degradation experiments

Decolorization of Brown 3REL by Bacillus sp.

VUS NCIM 5342 in presence of rhamnolipid

Bacillus sp. VUS strain was grown in 250 ml Erlenmeyer

flask containing 100 ml nutrient broth at static condi-

tion for 24 h at 40 °C. Before addition of dye, cells were

permeabilized with Pd 2112 produced mono-rham-

nolipid (Pd mono-rhamnolipid, 1 mg/ml) for 30 min as

described by Galabova et al. [13]. A synthetic surfactant,

Tween 80 (1 mg/ml, v/v) was used to compare its effect

with that of mono-rhamnolipid on decolorization pro-

cess. Further, Brown 3REL (procured from Manpasand

textile industry, Ichalkaranji, India) (50 mg/l) was added

in the culture medium and incubated at same condi-

tions. Three milliliter aliquot of the culture media was

withdrawn at different time intervals, centrifuged at

6000 rpm for 20 min, and decolorization was deter-

mined by measuring the change in absorbance of cul-

ture supernatants at OD

440

(Hitachi U-2800). The per-

centage of decolorization was measured as reported

previously [10].

Effect of Pd mono-rhamnolipid

and dye concentrations on decolorization

The various concentrations of Pd mono-rhamnolipid

(0.5–2 mg/ml) and Brown 3REL (50–250 mg/l) were

added in nutrient broth in order to evaluate their effect

on decolorization ability of Bacillus sp. VUS. Percent

decolorization and dry cell weight were measured at

different time intervals. The correlation between the

specific decolorization rate and dye concentration was

described by Michaelis Menten kinetics (v

dye

= v

dye,max

[Dye]/K

m

+ [Dye]); where v

dye,max

and K

m

denoted maxi-

mum decolorization rate and Michaelis Menten con-

stant respectively and [Dye] represents the concentra-

tion of Brown 3REL (mg/l).

Enzymes status during dye decolorization

Preparation of cell free extract

Bacillus sp. VUS was grown in nutrient broth for 24 h at

40 °C, harvested by centrifugation (6000 rpm, 20 min)

and suspended in 50 mM potassium phosphate buf-

fer (pH 7.4) and sonicated (30 seconds, 60 amplitude,

10 strokes) at 4 °C. This extract was used as enzyme

source without centrifugation.

388 M.

Jadhav

et al.

Journal of Basic Microbiology 2011, 51, 385 – 396

© 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

Enzyme assays

Lignin peroxidase (LiP), laccase, tyrosinase and veratryl

alcohol oxidase activities were assessed in cell free ex-

tract as well as culture free supernatant. LiP activity

was determined by monitoring the formation of pro-

panaldehyde by the method of Shanmugam et al. [14].

Laccase activity was determined in a 2 ml reaction mix-

ture containing 10% ABTS in 0.1 M acetate buffer (pH

4.9) by measuring increase in OD

420

[15]. Tyrosinase

activity was determined by the method of Zhang and

Flurkey [16]. Veratryl alcohol oxidase (VAO) was deter-

mined in a reaction mixture (2 ml) containing 4 mM

veratryl alcohol in 0.05 M citrate phosphate buffer

(pH 3) by monitoring the formation of veratraldehyde

at OD

310

[17]. All enzyme assays were carried out at

30 °C where reference blanks contained all components

except the enzyme. All enzyme assays were run in trip-

licate, average rates calculated and one unit of enzyme

activity was defined as change in absorbance unit per

min per mg of protein.

NADH-DCIP reductase activity was determined in cell

free extract using procedure reported earlier by Sa-

lokhe and Govindwar [18]. Riboflavin reductase [NAD-

(P)H:Flavin oxidoreductase] reaction rates were calcu-

lated using a molar extinction coefficient of 6.3 mM

cm

–1

by the method of Fontecave et al. [19].

Extraction and analysis of dye degradation products

After complete decolorization, medium was centrifuged

at 10,000 rpm for 20 min and supernatant was ex-

tracted with equal amount of ethyl acetate. The ex-

tracts were dried over anhydrous Na

2

SO

4

and evaporat-

ed to dryness on rotary evaporator. Metabolites ob-

tained after degradation were analyzed using HPLC and

FTIR spectroscopy. HPLC analyses were carried out

(Waters model no. 2690; Waters Corp., Milford, MA) on

C

18

column (symmetry, 4.6 × 250 mm) with methanol as

mobile phase at flow rate of 0.75 ml/min and UV detec-

tor at OD

316

. The FTIR (Perkin Elmer, Spectrum one) was

used to characterize the biodegraded products of Brown

3REL formed by mono-rhamnolipid treated cells and

compared with control dye and products formed by

mono-rhamnolipid untreated cells. The FTIR analysis

was performed as mentioned above except 16 scan

speed.

Scanning electron microscopy

of biosurfactant treated cells

Permeabilized cells and control cells were fixed in 2%

(w/v) glutaraldehyde for 2 h at 4 °C, washed with saline

solution, and dehydrated for 5 min in increasing etha-

nol concentrations (30, 50, 70, and 90% v/v) and for

15 min in absolute ethanol. The samples were air dried

then coated with gold in argon atmosphere to an ap-

proximate thickness of 50 nm with the help of sputter-

ing. The Scanning electron microscopy (SEM) observa-

tions were carried out using a scanning device JEOL

JSM-6360.

Statistical analysis

All values reported are the mean of three independent

measurements. The analyses were done using one-way

analysis of variance (ANOVA) with Tukey-Kramer mul-

tiple comparisons test.

Results

Production of mono-rhamnolipid

CTAB-methylene blue agar plate assay was used to de-

termine the rhamnolipid production by Pd 2112. A

positive reaction for rhamnolipid nature of the biosur-

factant was reported by the formation of a purple-blue

haze with a sharp defined edge around the culture well

after 24 h (data not shown). Pd 2112 produced biosur-

factant in MSM containing hexadecane as the sole car-

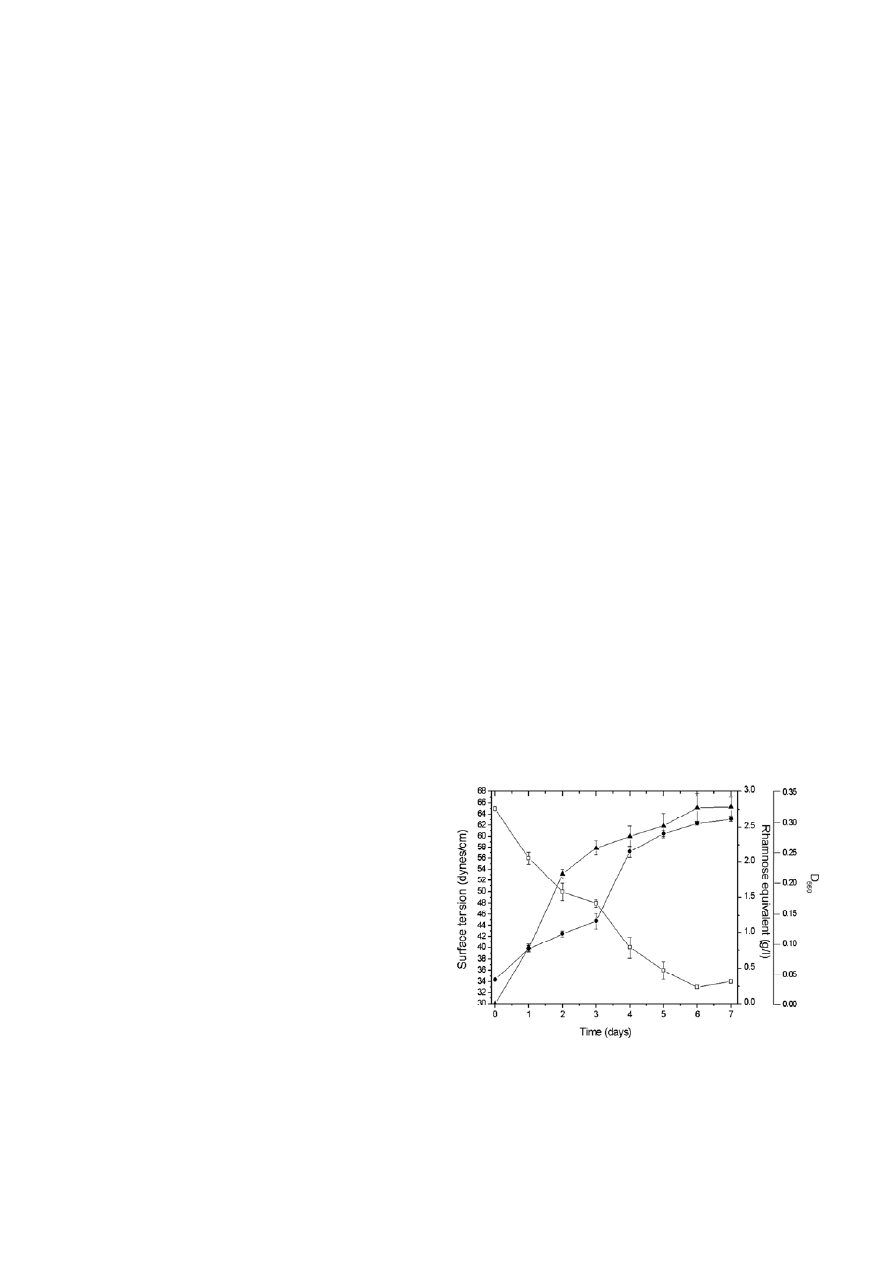

bon source. Fig. 1 depicts the growth of Pd 2112, sur-

face tension reduction of the culture broth, and

rhamnolipid production in MSM containing hexadec-

ane. Surface tension of the medium was reduced by

~51% at the end of 7 d incubation period. The rham-

nolipid production rate was 0.735 g/l d for initial 3 d,

followed by its dramatic decrease to 0.146 g/l d till 7 d

of incubation. The biosurfactant synthesis and surface

tension reduction were linearly proportional to Pd 2112

Figure 1. Time course evolution of Pd 2112 growth (

●), surface

tension reduction of the culture broth (

□), and the biosurfactant

produced in terms of rhamnose equivalent (

▲). Error bars represent

the standard deviation, calculated from at least three independent

experiments.

Journal of Basic Microbiology 2011, 51, 385 – 396

Rhamnolipid in dye degradation

389

© 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

growth. The average yield of rhamnolipid was 0.398 g/l

d. Pd 2112 emulsification potential associated with cell

free culture broth was studied using various hydrocar-

bons and vegetable oils (data not shown). Diesel associ-

ated emulsification index (E

24

, 77 ± 1%) was signifi-

cantly higher (P < 0.001) than toluene associated E

24

(49.33 ± 0.66%). Among the vegetable oils studied, corn

oil and groundnut oil showed 74.33 ± 0.66% and

56.66 ± 0.88% emulsification activity, respectively. The

order of associated E

24

was: diesel > corn oil > sunflower

oil > kerosene/hexadecane > groundnut oil > toluene.

The emulsion was stable for ~72 h at room temperature

without any significant change in the emulsification

index.

Chemical structure of mono-rhamnolipid produced

by Pd 2112

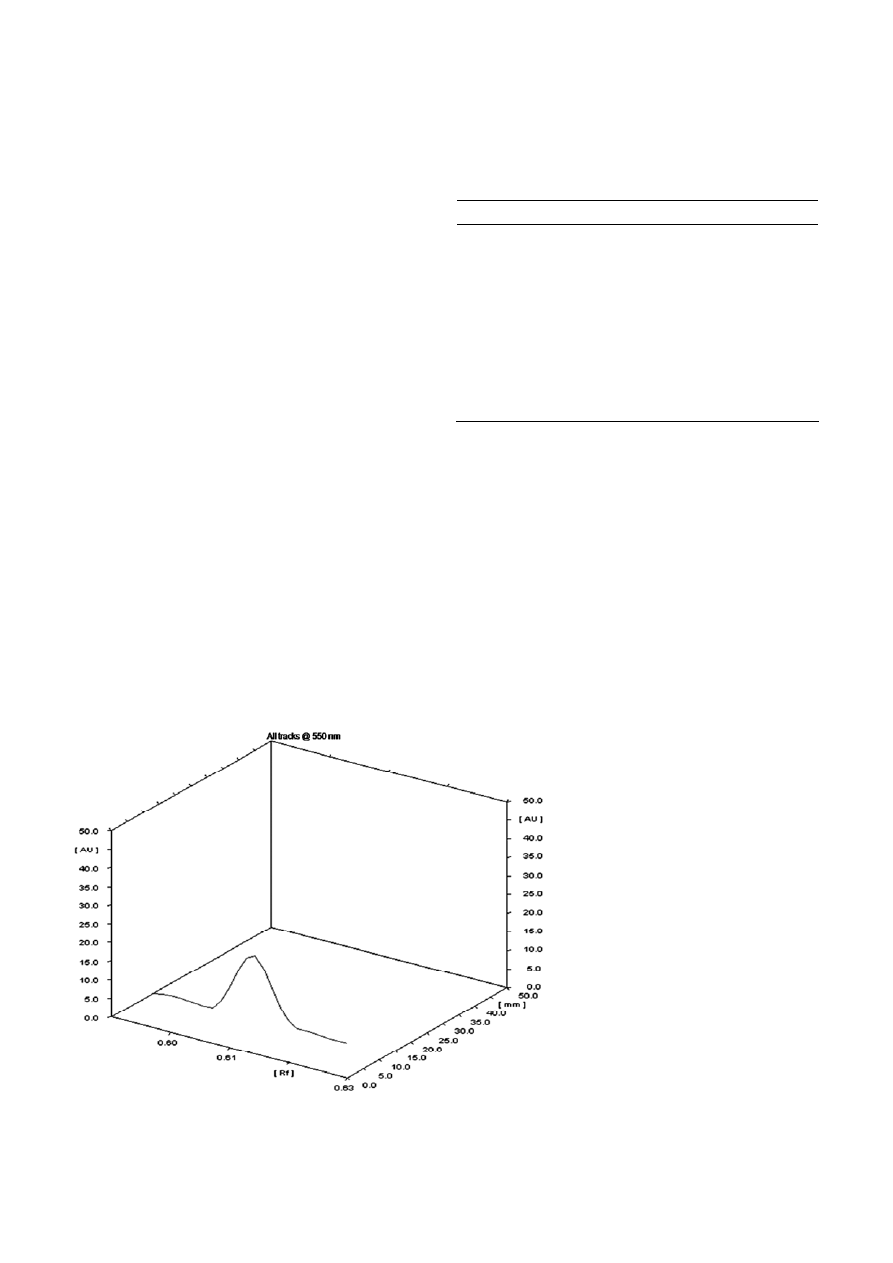

HPTLC results (Fig. 2) showed the presence of only one

peak; therefore, only one homologue was present in the

crude sample having the R

f

value of 0.61. The purified

rhamnolipid was analyzed using

1

H NMR and

13

C NMR.

As illustrated in Table 1 characteristic chemical shifts

indicate that the sample had the molecular structure of

monorhamnolipid. The long hydrocarbon chain and

rhamnose ring were indicated by the appearance of the

characteristic

1

H chemical shifts in the region of 0.96–

1.4 and 3.25–4.94 ppm, respectively.

1

H and

13

C NMR

analysis showed anomeric signal at δ 4.94/99.99, sug-

gesting L-rhamnosyl-hydroxyfatty acid linkage (1′ ↔ 1).

The rhamnosyl methyl protons are assigned to the

Table 1. Chemical shifts of purified rhamnolipid in

1

H NMR and

13

C NMR spectra.

Carbon

δ

1

H

δ

13

C

C-1′ 4.94

99.99

C-2′ 3.64

72.34

C-3′ 3.5

–

C-4′ 3.25

73.47

C-5′ 3.62

–

C-6′ 1.26

–

C-1 4.08

70.97

C-2 2.28

39.3

C-3 – –

C-4 – 70.69

C-5 2.37

40.13

–CH

2

– chain

1.4

–

CH

3

– 0.96

–

two overlapping doublets at 1.26 ppm. The chemical

shifts observed for hydrocarbon chains were 0.96 ppm

(for –CH

3

), 1.4 ppm (for –(CH

2

)– chain), 2.37 ppm (for

–CH

2

–COO–), and 3.62 ppm (for –O–CH–). The signal

at 3.64 ppm is assigned to rhamnose moiety, adjacent

to the lipid motif. The 3-hydroxyacyl lipid motifs are

evident from two proton peaks at 2.28 and 2.37 ppm.

These results are similar to those obtained by Wei et al.

[20].

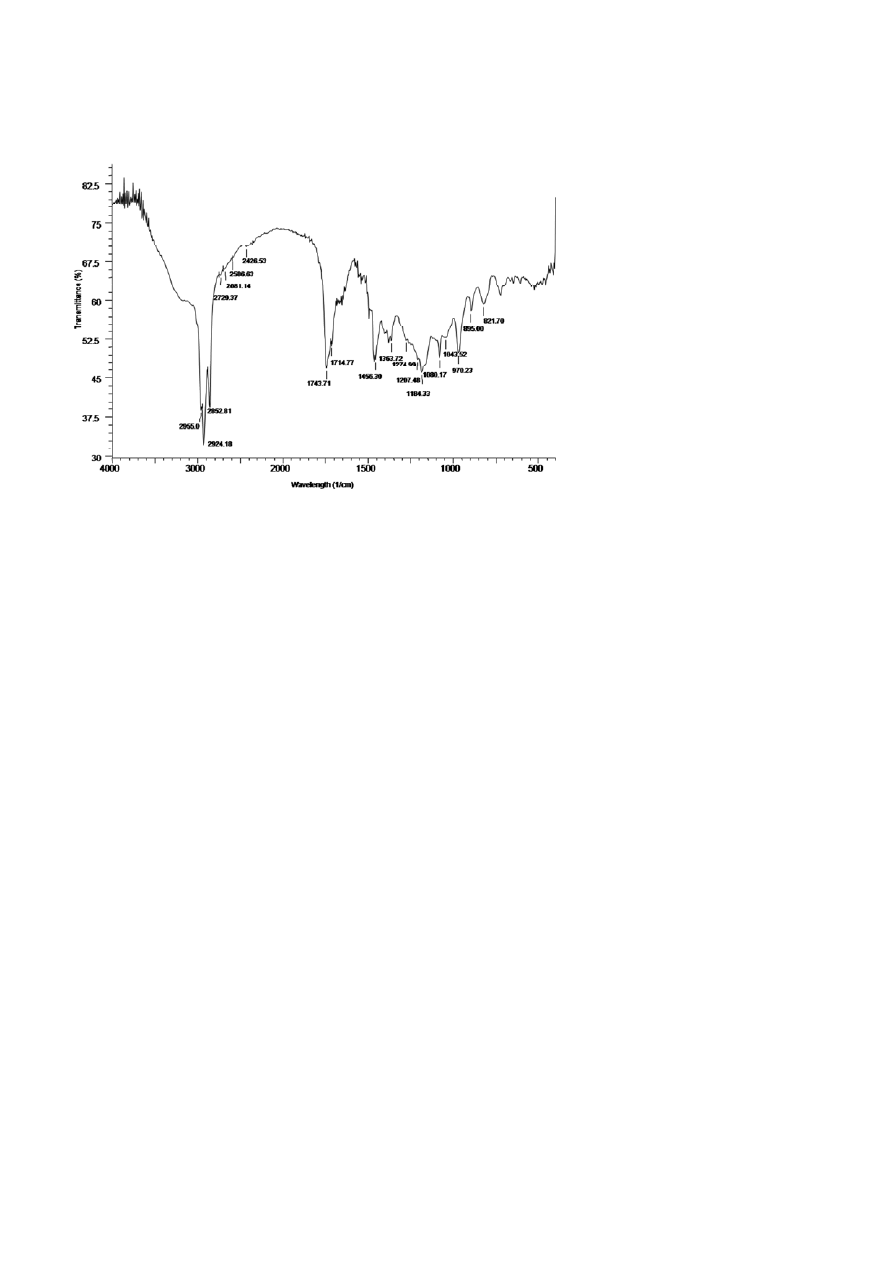

The chemical composition of the rhamnolipid was

preliminarily investigated using FTIR spectroscopy

(Fig. 3). The peaks at 2955, 2924, 2852, 1743, 1456, 1363

and 1274 cm

–1

indicate the chemical structure identical

to those of rhamnolipids which are composed of rham-

nose rings and long hydrocarbon chains. The peaks at

Figure 2. 3-D absorbance chromatogram of HPTLC of mono-rhamnolipid measured at 550 nm.

390 M.

Jadhav

et al.

Journal of Basic Microbiology 2011, 51, 385 – 396

© 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

Figure 3. FTIR spectroscopy analysis of rhamnolipid produced by Pd 2112.

2955, 2924 and 2852 cm

–1

indicate the C–H stretching

vibrations of hydrocarbon chain position. Peak at

1743 cm

–1

relates to the C=O stretching vibrations of

the carbonyl groups. The deformation vibrations at

1456 and 1363 cm

–1

represent alkyl groups while the

peak at 1274 cm

–1

showed the presence of C–O stretch-

ing in hydrocarbon chain. The peaks in the range of

1080–1043 cm

–1

corresponded to C–O–C stretching in

the rhamnose. Similar results were obtained by Porn-

sunthorntawee et al. [21] and Bondarenko et al. [22].

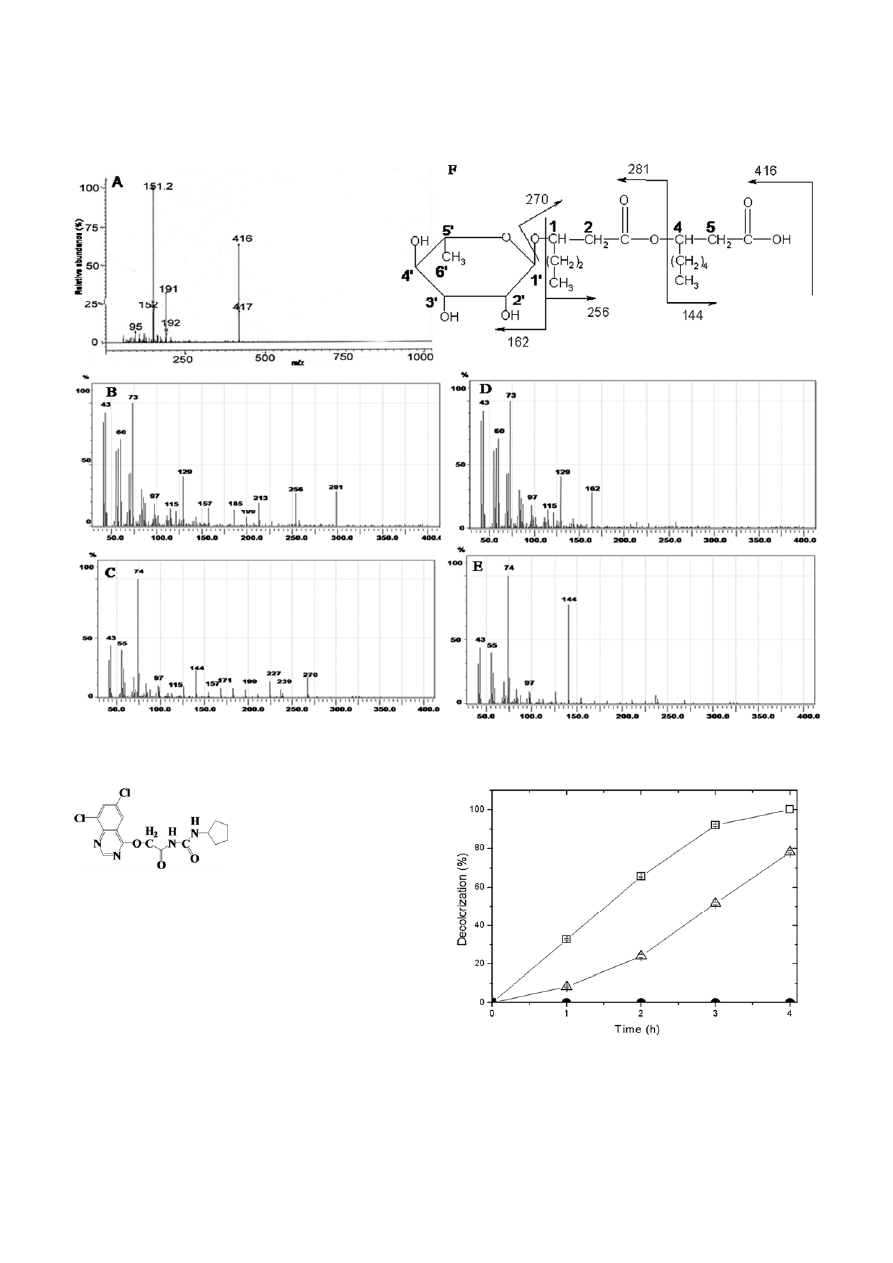

The mass spectrometric analysis of the rhamnolipid

complements the FTIR and NMR spectra results. It

showed the main pseudo-molecular ion at m/z 416

(Fig. 4A–E). The fragmentation pattern is consistent

with the mono-rhamnolipid structure (Rha-C

6

–C

8

)

(Fig. 4F). The ion fragment at m/z 162 is related to the

cleavage of the rhamnose moiety. The same cleavage

also produced m/z 270 ion which represents the fatty

acid moiety. The peak at m/z 281 represents the rup-

ture of an ester link between two alkylic chains of

mono-rhamnolipid along with peak m/z 144 for the loss

of terminal C

8

. The fatty acid moiety of the mono-

rhamnolipid consisted of two saturated hydroxy fatty

acids of 6- and 8-carbon lengths. This data constitutes

the structure of mono-rhamnolipid (Rha-C

6

–C

8

) pro-

duced by Pd 2112.

Biodegradation of Brown 3REL

Bacillus sp. VUS could decolorize textile dye Brown 3REL

(Fig. 5) in 8 h; however Pd 2112 mono-rhamnolipid

(1 mg/ml) permeabilized Bacillus sp. decolorized the

same amount of dye in 4 h (Fig. 6). The permeabilized

cells had doubled the rate of dye decolorization as

compared to the untreated cells. Tween 80 (1 mg/ml,

v/v), a synthetic surfactant, treated Bacillus sp. cells did

not show decolorization and settled in the decoloriza-

tion medium. The optimum concentration of rham-

nolipid was 1 mg/ml to achieve maximum decoloriza-

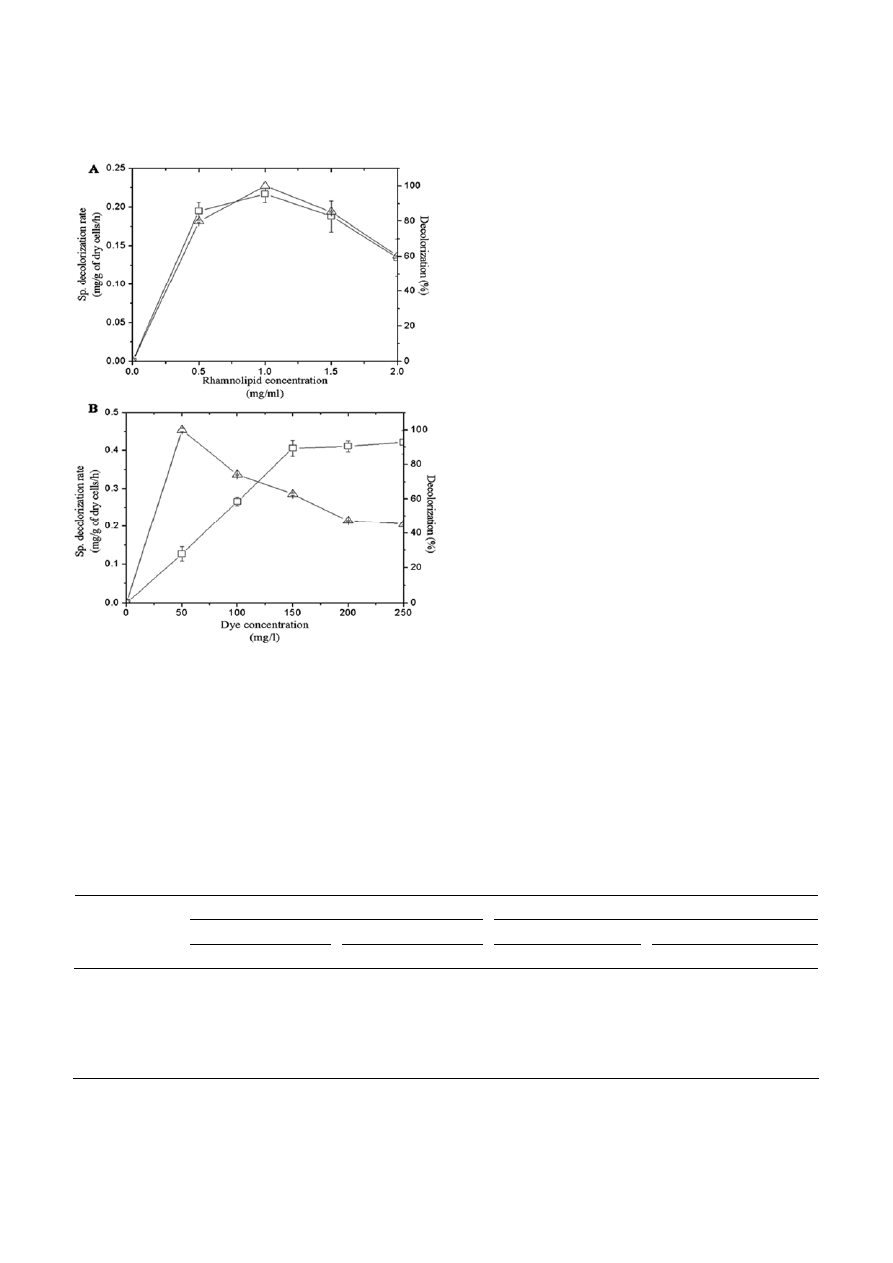

tion rate and decolorization efficiency (Fig. 7A). Rham-

nolipid treated Bacillus sp. VUS decolorized increasing

concentrations of Brown 3REL (50–250 mg/l) however,

% decolorization was decreased after 50 mg/l dye con-

centration (Fig. 7B). The kinetic constants estimated for

decolorization at different dye concentrations in the

presence of 1 mg/ml of rhamnolipid were 1.052 mg/g

cell /h for V

dye, max

and 50 mg/l for K

m

.

In order to acquire information about the effect of

mono-rhamnolipid on the enzyme systems involved in

the dye degradation, activities of various oxidative and

reductive enzymes before and after decolorization were

evaluated in the rhamnolipid treated and untreated

Bacillus sp. cells (Table 2). The activities of the evaluated

enzymes were lower at 0 h in the absence of mono-

rhamnolipid than for treated ones. The extracellular

activities of Lip and VAO were significantly increased

by 324.52% and 100% in rhamnolipid treated cells.

Induction in intracellular activities of Lip (245.56%),

laccase (100%), VAO (185.12%) and NADH-DCIP reduc-

tase (142.60%) were observed in treated cells. In rham-

nolipid treated cells, the extracellular Lip activity was

induced by 220.83% at 0 h and 276.08% at 4 h and in-

tracellular Lip activity was 205.72% higher at 4 h as

compared to untreated cells. However, extracellular

VAO activity was increased by 480% at 4 h; intracellu-

Journal of Basic Microbiology 2011, 51, 385 – 396

Rhamnolipid in dye degradation

391

© 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

Figure 4. GC-MS spectra of rhamnolipid sample and principal fragmentations of mono-rhamnolipids produced by Pd 2112 (A – E). Structure

drawn within spectra shows the molecular base fragmentation of the rhamnolipid molecules (F).

Figure 5. Structure of Brown 3REL.

lar VAO activity was 302.50% higher at 0 h and

329.41% higher at 4 h over that of untreated cells.

Biodegradation analysis

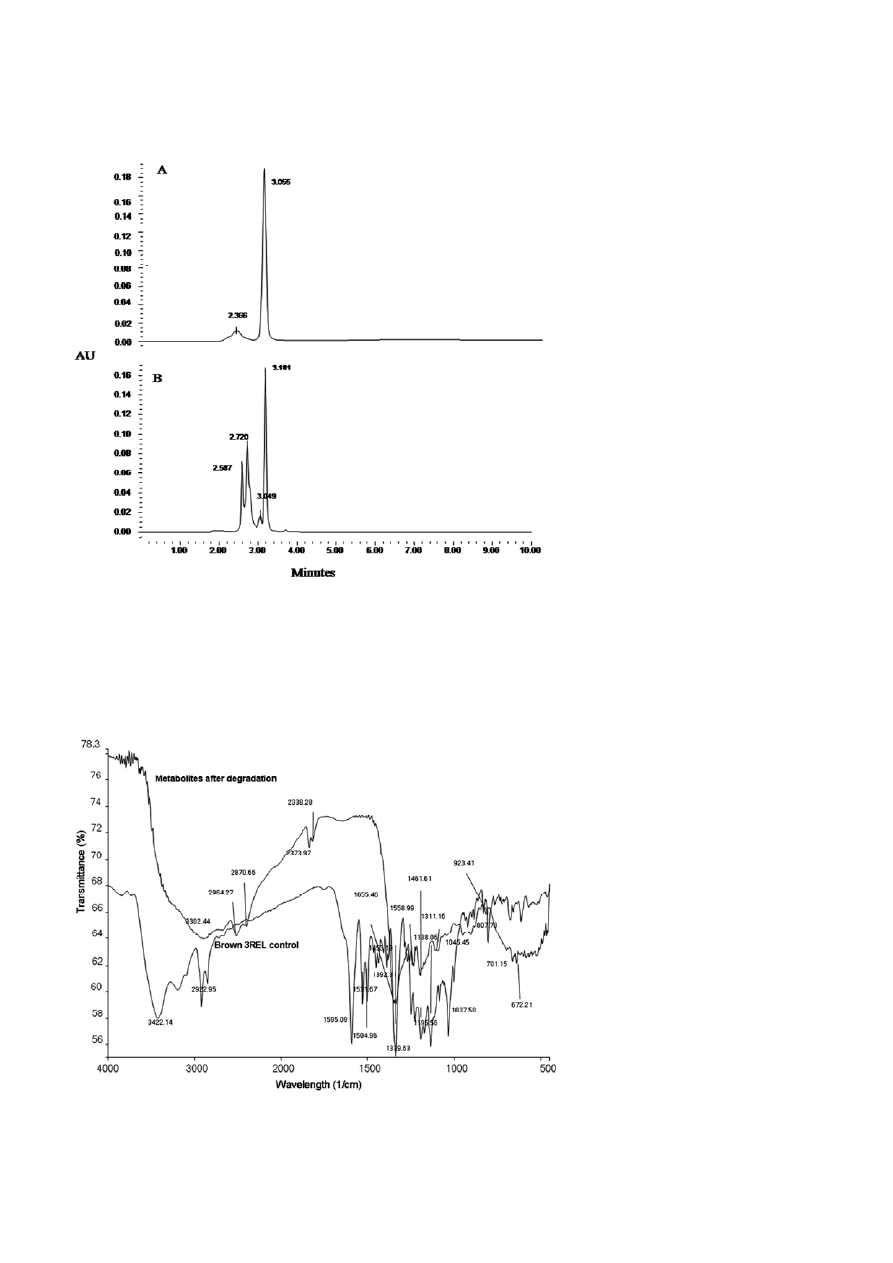

The difference in HPLC and FTIR spectrum of control

dye and extracted metabolites indicated biodegradation

of Brown 3REL. HPLC analysis of Brown 3REL dye

showed a major peak at retention time 3.05 min and

minor peak at 2.36 min (Fig. 8A) whereas the meta-

bolites extracted after degradation showed the peaks

at retention time 2.587, 2.720, 3.049, and 3.181 min

Figure 6. Percentage decolorization (Control,

∆) of Brown 3REL

(50 mg/l) by Bacillus sp. VUS in the absence and in the presence

(Test,

□) of rhamnolipid (1 mg/ml) and (▲) Tween 80 (1 mg/ml).

Error bars represent the standard deviation, calculated from at least

three independent experiments.

392 M.

Jadhav

et al.

Journal of Basic Microbiology 2011, 51, 385 – 396

© 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

Figure 7. Effect of various concentrations of rhamnolipid on speci-

fic decolorization rate (

□) and percent decolorization (∆) of Brown

3REL by Bacillus sp. VUS (A) and Effect of various concentrations

of dye on specific decolorization rate (

□) and percent decolorization

(

∆) of Brown 3REL by Bacillus sp. VUS in the presence of mono-

rhamnolipid (1

mg/ml) (B). Error bars represent the standard

deviation, calculated from at least three independent experiments.

(Fig. 8B). FTIR spectrum (Fig. 9) of control dye showed

different peaks at 3422

cm

–1

for C=O overtone,

2922 cm

–1

for C–H asymmetric stretching and 1595 cm

–1

for stretching vibrations between N–H bond. We also

observed C=C symmetric stretching (1504 cm

–1

), C–H

scissoring (1453

cm

–1

), C–N stretching (1531 and

1195 cm

–1

), O–H deformation (1392 cm

–1

), C–H de-

formation (1339 and 1138 cm

–1

), C–OH stretching

(1037 cm

–1

) and N–O stretching vibrations (807 cm

–1

).

In the extracted metabolites new peaks at 3302, 2373

and 2338, 1655, 1461, and 923 cm

–1

represents C–H

stretching, O–H stretching, C=N stretching, asymmet-

ric deformation of C–H and C–O stretching respec-

tively. Also, peaks at 2922, 1595, 1392, 1195 and

1037 cm

–1

present in the control spectra are absent in

the metabolites.

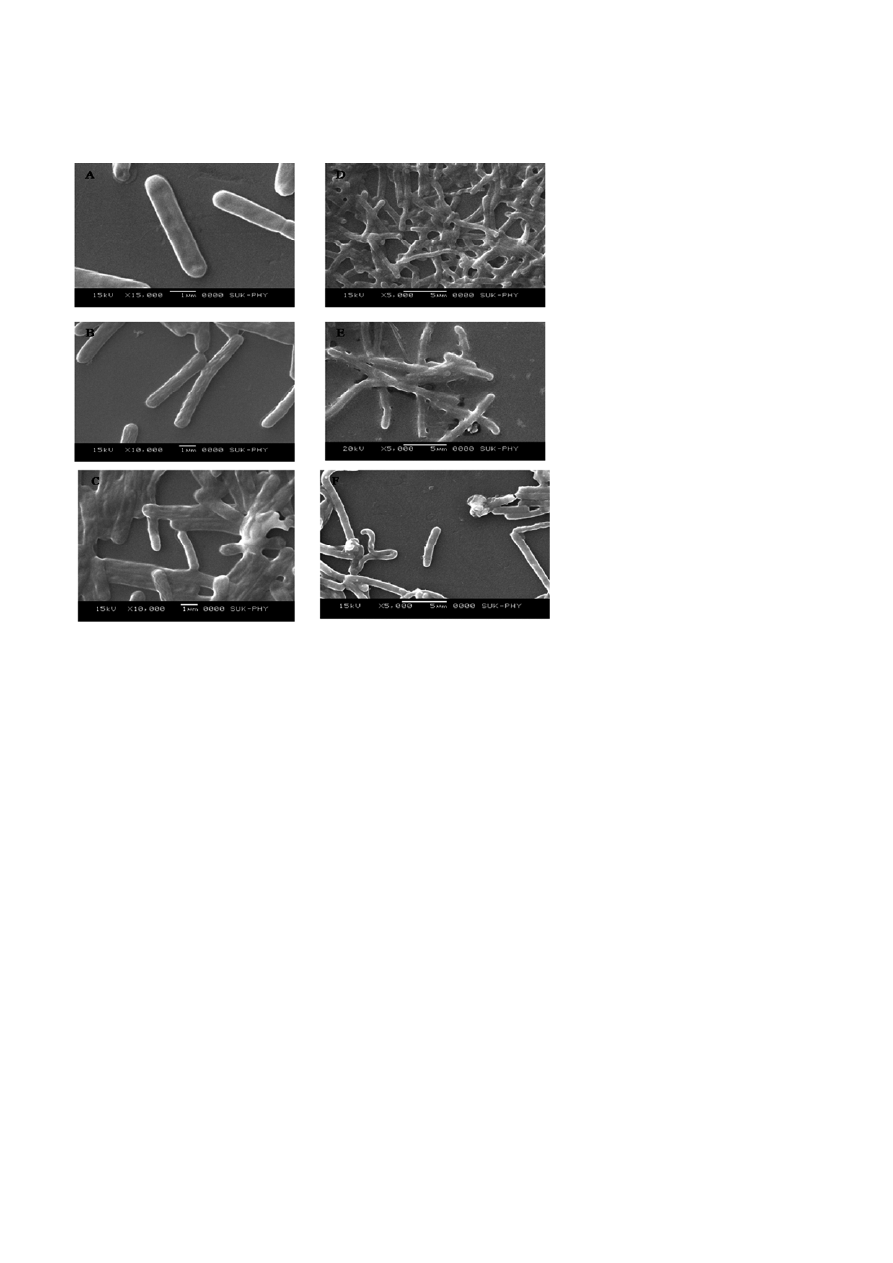

Scanning-electron microscopy

To examine morphological changes at the ultra struc-

tural level, Bacillus sp. VUS cells were permeabilized

with mono-rhamnolipid and observed using SEM. The

untreated cells (Fig. 10A) had apparent outlines and

smooth surfaces. In contrast, the cells permeabilized

with 1 mg/ml rhamnolipid (Fig. 10B) had altered cell

shapes, rough surfaces and folded cell walls. Whereas,

those cells treated with the same concentration of

Tween 80 (Fig. 10C) showed indistinct bulged cells with

different shapes and sizes and have hazy outlines. Simi-

lar results were obtained with the cells treated with

lower concentrations (0.1, 0.01 and 0.001 mg/ml) of

Tween 80 (Fig. 10D, E and F).

Discussion

Pd 2112 had been reported for biodegradation of diesel

and kerosene, and biodecolorization of sulfonated azo

dyes [9, 23, 24]. In this study, Pd 2112 formed halos

on blue agar plates which indicate the production of

extracellular anionic glycolipids. Pd 2112 produced

2.79 g/l of rhamnolipid and reduced surface tension of

Table 2. Enzyme activity status during decolorization of Brown 3REL by Bacillus sp. VUS in absence (control) and presence (test)

of rhamnolipid.

Control Test

0 h

4 h

0 h

4 h

Enzyme

E I E I E I E I

Lignin peroxidase

a

0.024 ± 0.005 0.075 ± 0.009 0.063 ± 0.016 0.095 ± 0.002 0.053 ± 0.002 0.079 ± 0.012 0.172 ± 0.020** 0.194 ± 0.020**

Laccase

a

– – – 0.023

±

0.010

–

0.014 ± 0.002 –

0.071 ± 0.004**

Tyrosinase

a

–

–

–

0.004 ± 0.001 –

0.001

–

0.014 ± 0.001

Veratryl alcohol

oxidase

a

–

0.040 ± 0.008 0.02 ± 0.005 0.068 ± 0.018 –

0.121 ± 0.012 0.096 ± 0.009** 0.224 ± 0.016**

DCIP Reductase

b

–

6.39 ± 0.870 –

9.97 ± 0.240 –

17.23 ± 0.340

–

24.57 ± 1.310*

Riboflavin reductase

c

–

1.34

–

2.215 ± 0.315 –

1.34

–

8.485 ± 2.415*

E – Extracellular; I – Intracellular;

a

activity in units mg/min;

b

mg of DCIP reduced mg/min;

c

µg of riboflavin reduced mg/min;

Significantly different than control (0 h) at *P < 0.05, **P < 0.01.

Journal of Basic Microbiology 2011, 51, 385 – 396

Rhamnolipid in dye degradation

393

© 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

Figure 8. HPLC elution profile of Brown 3REL (A) and its degradation products formed in the presence of rhamnolipid (B).

MSM-hexadecane medium to 33 dynes cm

–1

(51% of

control). Pd 2112 had reduced surface tension by 47.7%

when grown in Bushnell-Hash medium containing

diesel as the sole carbon source [9]. The stable emul-

sions formed (~72 h) with diesel and vegetable oils are

indicative of potential use of these surface active com-

pounds as emulsifying agents. Substrate-specific emul-

sification by biosurfactant has been demonstrated by

Falatko and Novak [25]. Further, Flavobacterium sp. DS5-

73 and Micrococcus sp. GS2-22 were reported to produce

Figure 9. FTIR spectra of Brown 3REL and its degradation products formed in the presence of rhamnolipid.

394 M.

Jadhav

et al.

Journal of Basic Microbiology 2011, 51, 385 – 396

© 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

Figure 10. Scanning electron micrographs of Bacillus sp. VUS. Control cells (A), Cells permeabilized 1 mg/ml of rhamnolipid (B), Cells

permeabilized with Tween 80, 1 mg/ml (C), 0.1 mg/ml (D), 0.01 mg/ml (E) and 0.001 mg/ml (F).

surfactants with the ability to emulsify various hydro-

carbons, irrespective of the substrates used as carbon

source [26]. Here, Pd 2112 produced biosurfactant using

hexadecane as the sole carbon source and it could

emulsify hexadecane as well as other hydrophobic

compounds studied. These results suggest that the

emulsification activity of Pd 2112 biosurfactant is not

substrate-specific.

HPTLC, FTIR, NMR and mass spectra data verified a

typical structure between the compounds with the

presence of rhamnose and lipidic group. The biosurfac-

tant produced by Pd 2112 was physicochemically and

structurally characterized as a mono-rhamnolipid (Rha-

C

6

–C

8

), which is in contrast with P. aeruginosa that

makes both mono-rhamnolipids and di-rhamnolipids

[27]. Pseudomonads are the best-known bacteria capable

of utilizing hydrocarbons as carbon and energy sources

and producing biosurfactants [28]. Among Pseudomo-

nads, Pseudomonas aeruginosa, P. putida, P. fluorescens, and

P. rubescans are studied for the production of mixture of

mono and di-rhamnolipid type of biosurfactants [27].

Till date, P. chlororaphis is the only organism reported

for the production of mono-rhamnolipid type of biosur-

factant while B. pseudomallei, makes only di-rhamnolipid

[29, 30]. Furthermore, GC-MS analysis have shown that

there is much variation in the composition of fatty acid

chains of rhamnolipids produced by Pd 2112 as com-

pared to rhamnolipids produced by P. aeruginosa,

P. chlororaphis, and Burkholderia pseudomallei. The lengths

of the fatty acid chains of rhamnolipids can vary sig-

nificantly, resulting in a multitude of different rham-

nolipid compositions. P. aeruginosa has been reported to

produce 28 different homologues of rhamnolipids [31].

Fatty acyl chains composed of 8, 10, 12, and 14 carbons

in length, as well as 12 or 14 carbon chains with double

bonds (12:1, 14:1), have been observed in rhamnolipids

produced by P. aeruginosa or B. pseudomallei [30, 31].

P. chlororaphis strain NRRL B-30761 produced rham-

nolipids with fatty acids containing carbon lengths of 8,

10, 12, 14, 12:1, and 14:1 [29]. This differs from our

results which indicated that Pd 2112 is capable of mak-

ing rhamnolipid with fatty acid containing chain

length of 6 and 8. The differences either in the strain

or in the culture conditions used may result in varia-

tion in the composition of fatty acid chains of rham-

nolipids.

Journal of Basic Microbiology 2011, 51, 385 – 396

Rhamnolipid in dye degradation

395

© 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

Bacillus sp. VUS which could efficiently decolorize a

range of textile dyes was selected to assess the role of

rhamnolipid in dye decolorization process with respect

to its effects on bacterial cells and the enzyme systems

involved in it. Permeabilization of Bacillus sp. VUS with

1 mg/ml rhamnolipid resulted in decreasing the time

required for degradation of Brown 3REL by half. In this

study, induction of extracellular LiP, intracellular LiP

and laccase during decolorization were responsible for

complete decolorization of Brown 3REL. Surfactants

were reported for their stimulatory effects on enzymes

like α amylase [32], cellulases and xylanases [33], phy-

tase production [34] etc. and their release in solid state

or submerged fermentation however, the mechanism

of action is still not clear [35, 36]. Most reports believe

that surfactants improve the permeability of cell mem-

brane to facilitate the enzyme release [8, 35]. Also the

unique ability of biosurfactants to enhance biodegrada-

tion has gained more and more attention and will un-

doubtedly lead to its application in pollution control

[37]. The results showed the intensified effects of

rhamnolipid on the enzymes involved in dye degrada-

tion process and the stimulatory effect on Lip and VAO

were much eminent. Liu et al. [38] reported 161.98%

increase in the activity of Lip by Phanerochaete chrysospo-

rium in the presence of dirhamnolipid. Also Liang et al.

[37] reported increase in Lip activity by 86%. Thus, the

higher activities of enzymes involved in dye degrada-

tion have favorably increased the biodegradation rate of

Brown 3REL by 50%. HPLC and FTIR analysis of ex-

tracted metabolites indicated the biodegradation of the

parent dye compound by Bacillus sp. VUS. HPLC analysis

(Fig. 9) showed that the peak at 3.055 min is shifted to

3.181 min; that means a big part of the original mate-

rial has been changed a little bit to be more hydropho-

bic (reducing enzymes seem to be responsible). Other

parts of the material have been changed a little bit to

be more hydrophilic (2.587 min, 2.720 min; oxidizing

enzymes seem to be responsible). The oxidase and re-

ductase susceptible peaks (Fig. 10, FTIR peaks at 2922,

1595, 1392, 1195 and 1037 cm

–1

) present in the control

spectra, that are absent in the metabolites, supported

enzyme induction data and HPLC analysis however

further investigation of metabolites by GC-MS is in

progress to understand degradation pattern of Brown

3REL by Bacillus sp. VUS.

In conclusion, Pd 2112 is a very efficient mono-

rhamnolipid producer and the culture conditions pro-

mote very high titers of rhamnolipid production. Also,

Bacillus sp. VUS NCIM 5342 is an efficient strain for the

treatment of dye containing waste waters. Its treatment

with rhamnolipids has increased its potential for dye

decolorization thus making it more competent and

suitable for its use in the bioremediation of textile dye

contaminated sites. Thus, the study indicates the effec-

tiveness of the rhamnolipid on micro-organisms in-

volved in dye degradation and the enzymes involved in

the process.

Acknowledgement

M. J. is thankful to Shivaji University for awarding ‘De-

partmental Research Fellowship’.

References

[1] Muthusamy, K., Gopalakrishnan, S., Ravi, T.K., Sivachi-

dambaram, P., 2008. Biosurfactants: properties, commer-

cial production and application. Curr. Sci., 94, 736–747.

[2] Kitamoto, D., Isoda, H., Nakahara, T., 2002. Functional

and potential applications of glycolipid biosurfactant

from energy saving materials to gene delivery carriers. J.

Biosci. Bioeng., 94, 187–201.

[3] Wei, Y.H., Cheng, C.L., Chien, C.C., Wan, H.M., 2008.

Enhanced di-rhamnolipid production with an indigenous

isolate Pseudomonas aeruginosa J16. Process Biochem., 43,

769–774.

[4] George, S., Jayachandran, K., 2009. Analysis of rham-

nolipid biosurfactants produced through submerged fer-

mentation using orange fruit peelings as sole carbon

source. Appl. Biochem. Biotechnol., 158, 694–705.

[5] Telke, A., Kalyani, D., Jadhav, J., Govindwar, S., 2008.

Kinetics and mechanism of reactive red 141 degradation

by a bacterial isolate Rhizobium radiobacter MTCC 8161. Ac-

ta Chim. Solv., 55, 320–329.

[6] Jadhav, S.U., Kalme, S.D., Govindwar, S.P., 2008. Biodeg-

radation of methyl red by Galactomyces geotrichum MTCC

1360. Int. Biodeter. Biodegrad., 62, 135–142.

[7] Beal, R ., Betts, W.B., 2000. Role of rhamnolipid biosurfac-

tants in the uptake and mineralization of hexadecane in

Pseudomonas aeruginosa. J. Appl. Microbiol., 89, 158168.

[8] Ahuja, S.K., Ferreira, G.M., Moreira, A.R., 2004. Produc-

tion of an endoglucanase by the shipworm bacterium

Teredinobacter turnirae. J. Ind. Microbiol. Biotechnol., 31,

41–47.

[9] Kalme, S., Parshetti, G., Gomare, S., Govindwar, S., 2008.

Diesel and kerosene degradation by Pseudomonas desmolyti-

cum NCIM 2112 and Nocardia hydrocarbonoxydans NCIM

2386. Curr. Microbiol., 56, 581–586.

[10] Dawkar, V.V., Jadhav, U.U., Jadhav, S.U., Govindwar, S.P.,

2008. Biodegradation of disperse textile dye Brown 3REL

by newly isolated Bacillus sp. VUS. J. Appl. Microbiol., 105,

14–24.

[11] Siegmund, I., Wagner, F., 1991. New method for detecting

rhamnolipids excreted by Pseudomonas species during

growth on mineral agar. Biotechnol. Tech., 5, 265–268.

[12] Chandrasekaran, E.V., Bemiller, J.N., 1980. Constituent

analyses of glycosaminoglycans. In: Methods in Carbohy-

396 M.

Jadhav

et al.

Journal of Basic Microbiology 2011, 51, 385 – 396

© 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

drate Chemistry (Whistler, R.L., ed). Academic press, New

York, pp. 89–96.

[13] Galabova, D., Tuleva, B., Spasova, D., 1996. Permeabiliza-

tion of Yarrowia lipolytica cells by triton X-100. Enzyme

Microb. Technol., 18, 18–22.

[14] Shanmugam, V., Kumari, M., Yadav, K.D., 1999. n-pro-

panol as a substrate for assaying the lignin peroxidase ac-

tivity of Phanerochaete chrysoporium. Ind. J. Biochem. Bio-

phys., 36, 39–43.

[15] Hatvani, N., Mecs, I., 2001. Production of laccase and

manganese peroxidase by Lentinus edodes on malt contain-

ing by product of the brewing process. Process Biochem.,

37, 491–496.

[16] Zang, X., Flurkey, W., 1997. Phenol oxidases in Portabella

Mushrooms. J. Food Sci., 62, 97–100.

[17] Jadhav, U.U., Dawkar, V.V., Tamboli, D.P., Govindwar,

S.P., 2009. Purification and characterization of veratryl

alcohol oxidase form Comamonas sp. UVS and its role in

dye decolorization. Biotechnol. Bioprocess. Eng., 14, 369–

376.

[18] Salokhe, M.D., Govindwar, S.P., 1999. Effect of carbon

source on the biotransformation enzymes in Serratia mar-

cescens. World J. Microbiol. Biotechnol., 15, 229–232.

[19] Fontecave, M., Eliasson, R., Reichard, P., 1987. NAD (P)H:

flavin oxidoreductase of E. coli: a ferric iron reductase par-

ticipating in the generation of the free radical of ribonu-

cleotide reductase. J. Biol. Chem., 262, 12325–12331.

[20] Wei, Y.H., Chien, L.C., Chang, J.S., 2005. Rhamnolipid

production by indigenous Pseudomonas aeruginosa J4 origi-

nating from petrochemical wastewater. Biochemical Eng.

J., 27, 146–154.

[21] Pornsunthorntawee, O., Wongpanit, P., Chavadej, S., Abe,

M., Rujiravanit, R., 2008. Structural and physicochemical

characterization of crude biosurfactant produced by Pseu-

domonas aeruginosa SP4 isolated from petroleum-conta-

minated soil. Bioresour. Technol., 99, 1589–1595.

[22] Bondarenko, O., Rahman, P.K.S.M., Rahman, T.J., Kahru,

A., Ivask, A., 2010. Effects of rhamnolipid from Pseudomo-

nas aeruginosa DS10-129 on luminescent bacteria: toxicity

and modulation of cadmium bioavailability. Microb. Ecol.,

59, 588–600.

[23] Kalme, S.D., Parshetti, G.K., Jadhav, S.U., Govindwar, S.P.,

2007. Biodegradation of benzidine based dye Direct blue 6

by Pseudomonas desmolyticum NCIM 2112. Bioresour. Tech-

nol., 98, 1405–1410.

[24] Kalme, S., Jadhav, S., Jadhav, M., Govindwar, S., 2009.

Textile dye degrading laccase from Pseudomonas desmolyti-

cum NCIM 2112. Enzyme Microb. Technol., 44, 65–71.

[25] Falatko, D.F., Novak, J.T., 1992. Effects of biologically

produced surfactants on the mobility and biodegradation

of petroleum hydrocarbons. Water Environ. Res., 64,

163–169.

[26] Rahman, K.S.M., Rahman, T.J., Kourkoutas, Y., Petsas, I.,

Marchant, R., Banat, I.M., 2003. Enhanced bioremediation

of n-alkane in petroleum sludge using bacterium consor-

tium amended with rhamnolipid and micronutrients. Bio-

resour. Technol., 90, 159–168.

[27] Kumar, M., Leon, V., Materano, A.D.S., Ilzins, O.A., Luis,

L., 2008. Biosurfactant production and hydrocarbon-de-

gradation by halotolerant and thermotolerant Pseudomo-

nas sp. World J. Microbiol. Biotechnol., 24, 1047–1057.

[28] Perfumo, A., Banat, I.M., Canganella, F., Marchant, R.,

2006. Rhamnolipid production by a novel thermophilic

hydrocarbon-degrading Pseudomonas aeruginosa APO2-1.

Appl. Microbiol. Biotechnol., 72, 132–138.

[29] Gunther, N.W., Nunez, A., Fett, W., Solaiman, D.K.Y.,

2005. Production of rhamnolipids by Pseudomonas chloro-

raphis, a nonpathogenic bacterium. Appl. Environ. Micro-

biol., l71, 2288–2293.

[30] Haussler, S., Nimtz, M., Domke, T., Wray, V., Steinmetz,

I., 1998. Purification and characterization of a cytotoxic

exolipid of Burkholderia pseudomallei. Infect Immun., 66,

1588–1593.

[31] Deziel, E., Lepine, F., Dennie, D., Boismenu, D., Mamer,

O.A., Villemur, R., 1999. Liquid chromatography/mass

spectrometry analysis of mixtures of rhamnolipids pro-

duced by Pseudomonas aeruginosa strain 57RP grown on

mannitol or naphthalene. Biochim. Biophys. Acta, 1440,

244–252.

[32] Goes, A.P., Sheppard, J.D., 1999. Effect of surfactants on

α

-amylase production in a solid substrate fermentation

process. J. Chem. Technol. Biotechnol., 74, 709–712.

[33] Liu, J., Yuan, X., Zeng, G., Shi, J., Shi, C., 2006. Effect of

biosurfactant on cellulase and xylanase production by Tri-

choderma viride in solid substrate fermentation. Process

Biochem., 41, 2347–2351.

[34] Mandviwala, T.N., Khire, J.M., 2000. Production of high

activity thermostable phytase from thermotolerant Asper-

gillus niger in solid state fermentation. J. Ind. Microbiol.

Biotechnol., 24, 237–243.

[35] Pardo, A.G., 1996. Effect of surfactants on cellulose pro-

duction by Nectria catalinensis. Curr. Microbiol., 33, 275–

278.

[36] Zeng, G.M., Shi, J.G., Yuan, X.Z., Liu, J. et al., 2006. Effects

of Tween 80 and rhamnolipid on the extracellular en-

zymes of Penicillium simplicissimum isolated from compost.

Enzyme Microb. Technol., 39, 1451–1456.

[37] Liang, Y.S., Yuan, X.Z., Zeng, G.M., Hu, C.L. et al., 2010.

Biodelignification of rice straw by Phanerochaete chrysospo-

rium in the presence of dirhamnolipid. Biodegradation

DOI 10.1007/s10532-010-9329-0.

[38] Liu, X.L., Zeng, G.M., Tang, L., Zhong, H. et al., 2008. Ef-

fects of dirhamnolipid and SDS on enzyme production by

Phanerochaete chrysosporium in submerged fermentation.

Process Biochem., 43, 1300–1303.

Wyszukiwarka

Podobne podstrony:

jobm 201000013

jobm 201000298

jobm 201000191

jobm 201000321

jobm 201000018

jobm 201000214

jobm 201000067

jobm 201000037

jobm 201000074

jobm 201000280

jobm 201000385

jobm 201000198

jobm 201000458

jobm 201000147

jobm 201000520

jobm 201000327

jobm 201000342

jobm 201000420

jobm 201000317

więcej podobnych podstron